Chevrolet Sonic Repair Manual: Clutch and Differential Housing Disassemble

Special Tools

- M-680770 Universal Sliding Mallet

- R-0007758 Holding Fixture

- R-0407008 Counter Shaft Bearing Remover

- R-0407010 Input Shaft Needle Bearing Puller and Driver

- R-0407013 Gearshift Device Bushing Puller

- R-0007761 Universal Handle for Pullers and Installers

- T-0207928 Retainer Remover

For equivalent regional tools, refer to Special Tools.

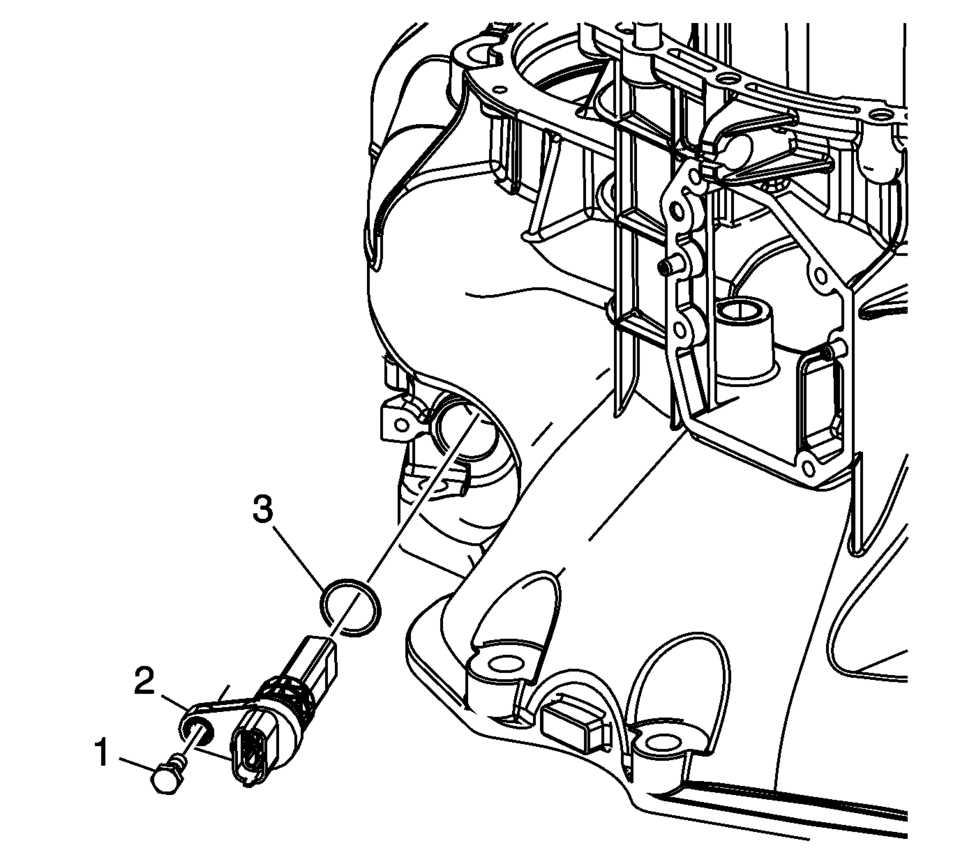

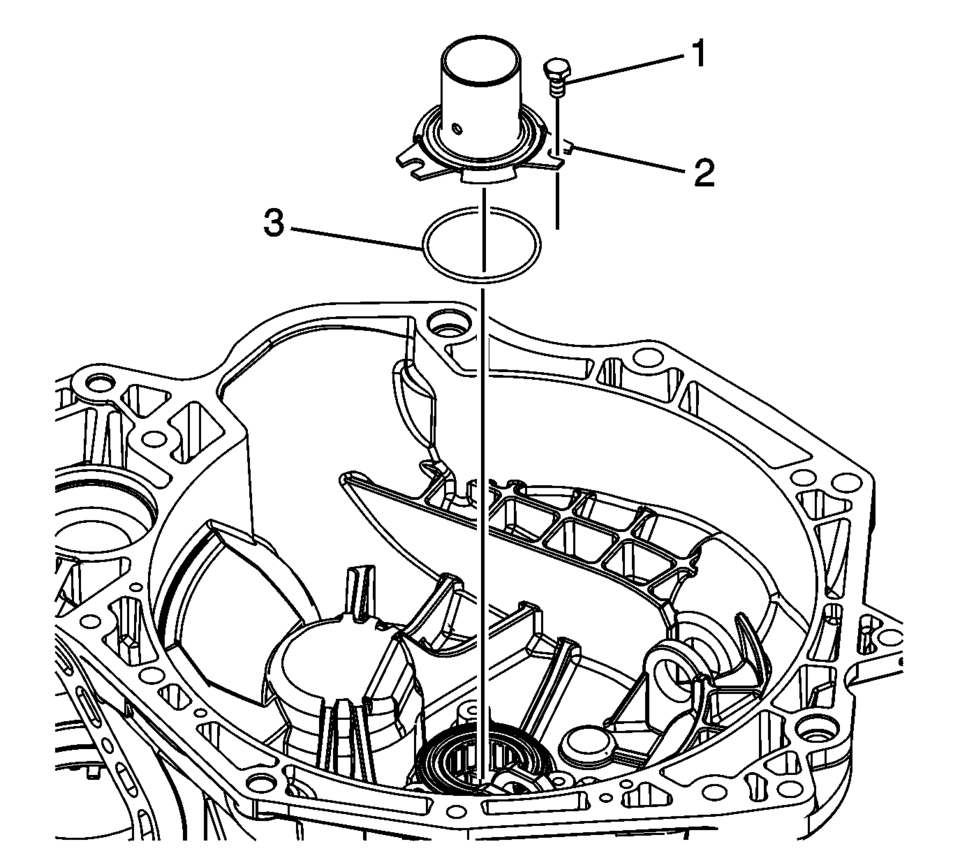

- Remove the vehicle speed sensor bolt (1) and vehicle speed sensor assembly (2).

- Remove and discard the vehicle speed sensor O-ring seal (3).

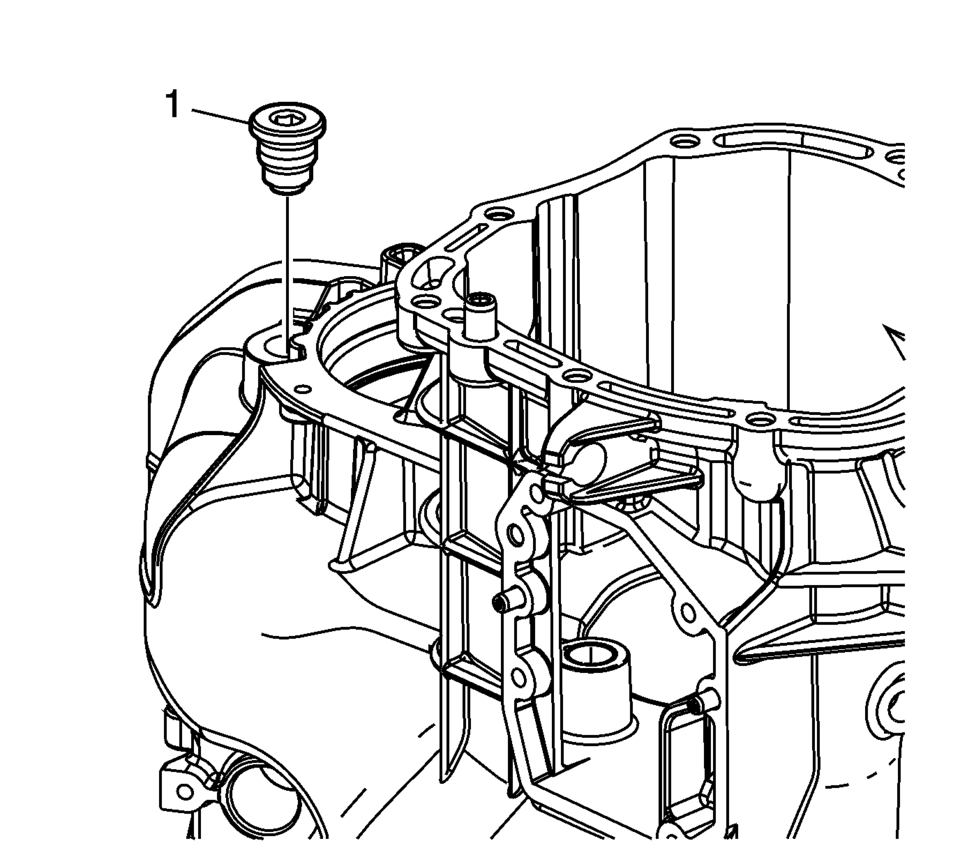

- Remove the transmission magnet (1).

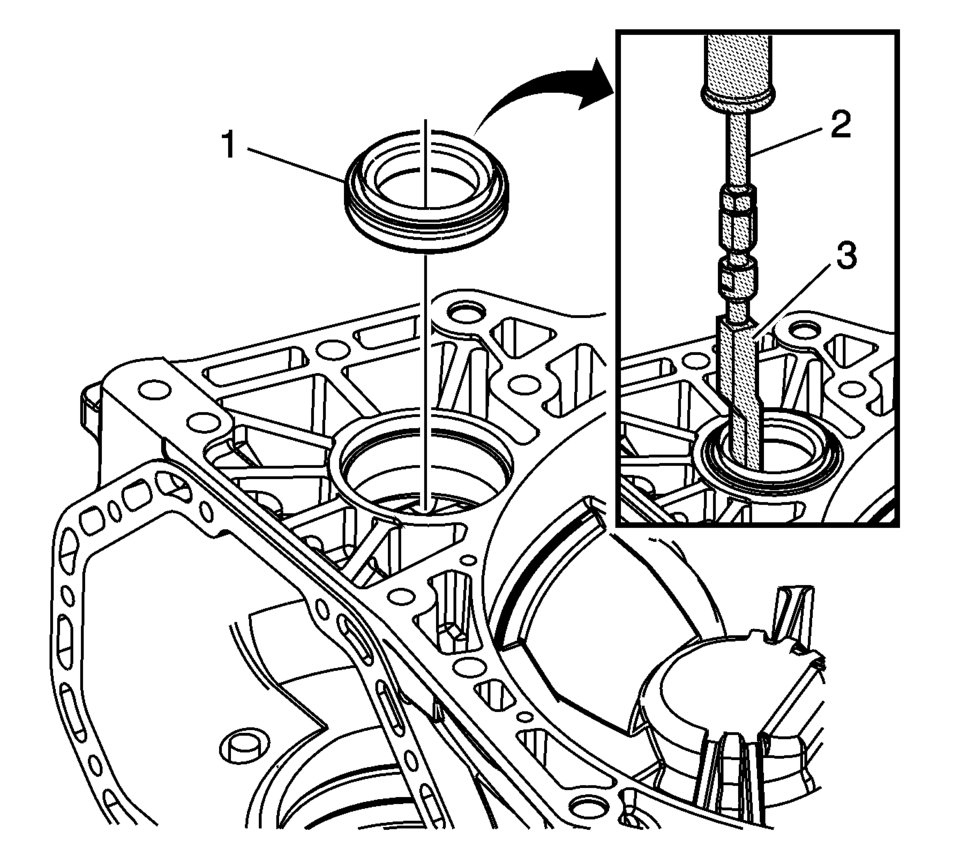

- Using the T-0207928 retainer remover (3) with the M-680770 sliding mallet (2) remove the front wheel drive shaft oil seal assembly (1).

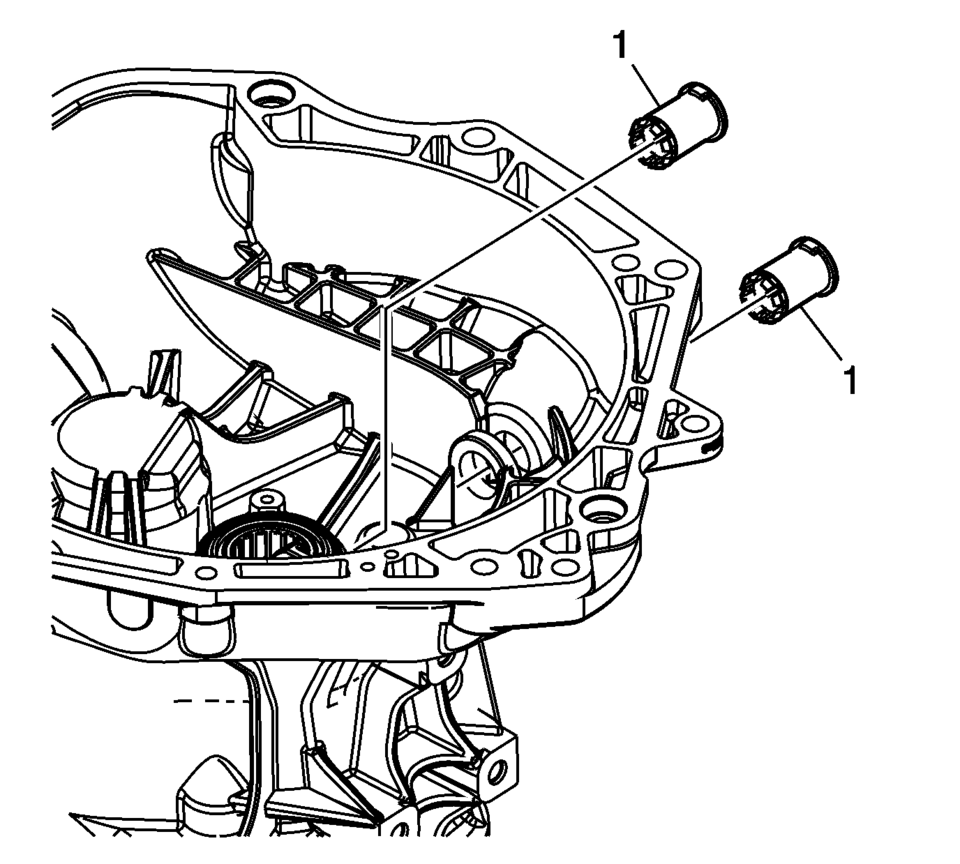

- Remove the clutch yoke shaft bushings (1).

- Remove the clutch release bearing collar bolt (1).

- Remove the clutch release bearing collar (2).

- Remove the clutch release bearing collar O-ring seal (3).

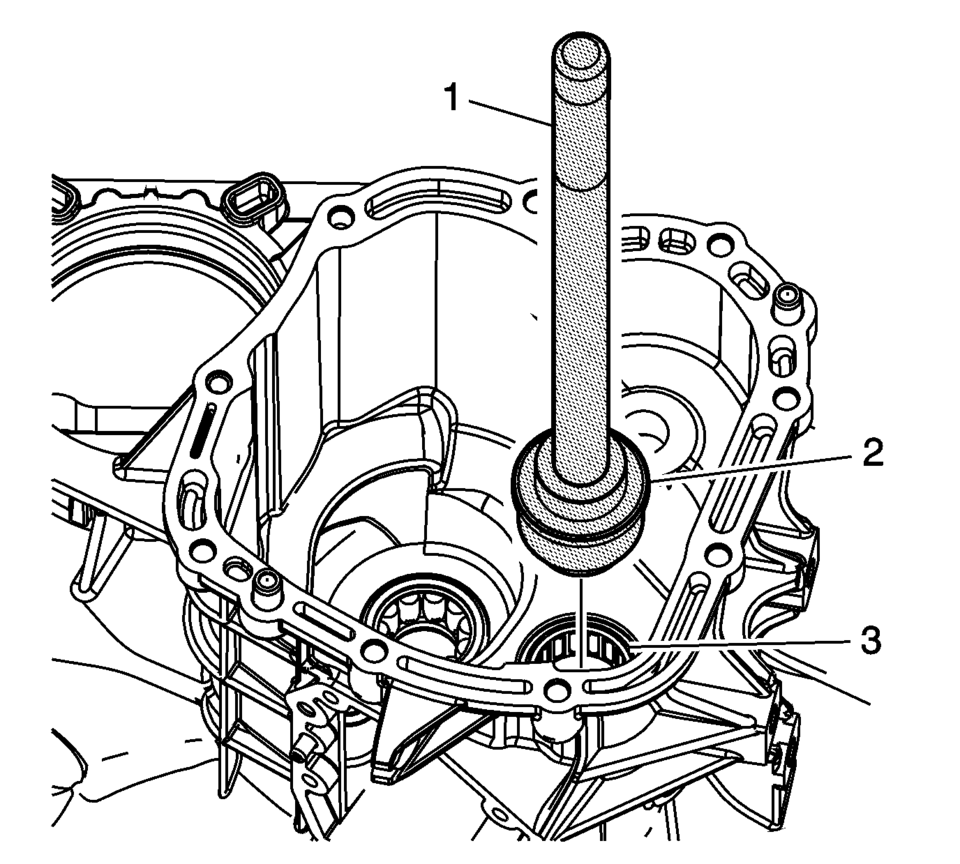

- Remove the input shaft front bearing assembly (3) using the R-0407010 driver (2) and the R-0007761 handle (1).

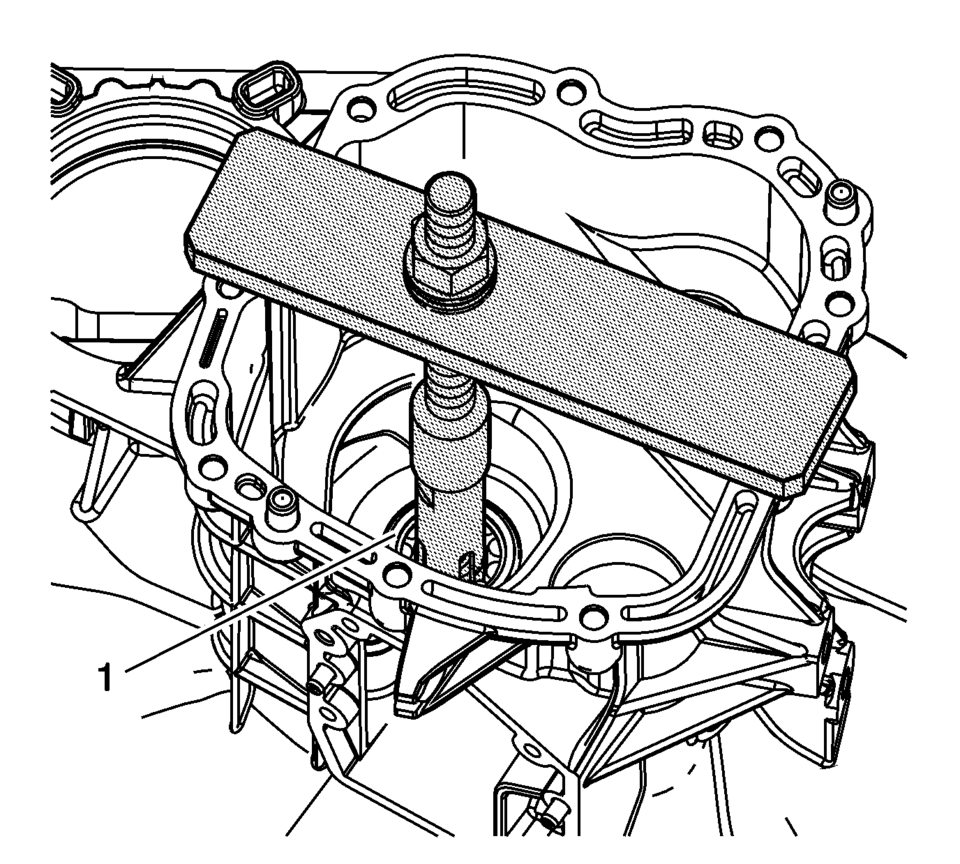

- Remove the main shaft front bearing assembly (1) using the R-0407008 remover .

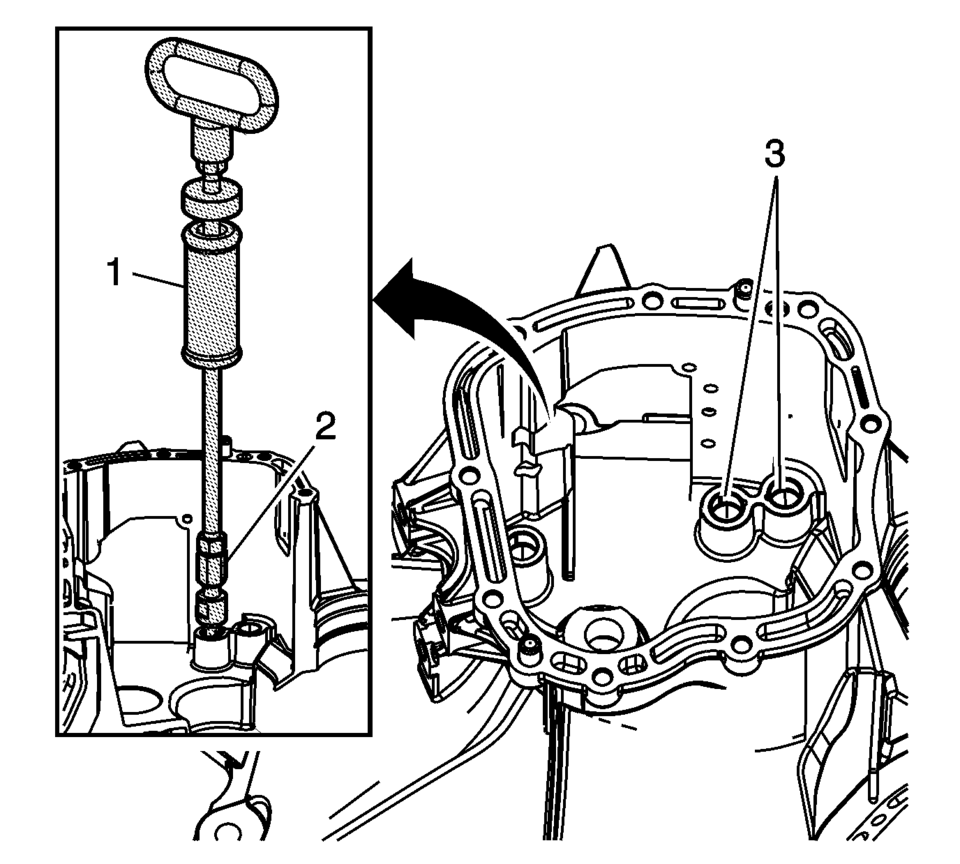

- Remove the shift shaft bushings (3) using the R-0407013 puller (2) and the M-680770 mallet (1).

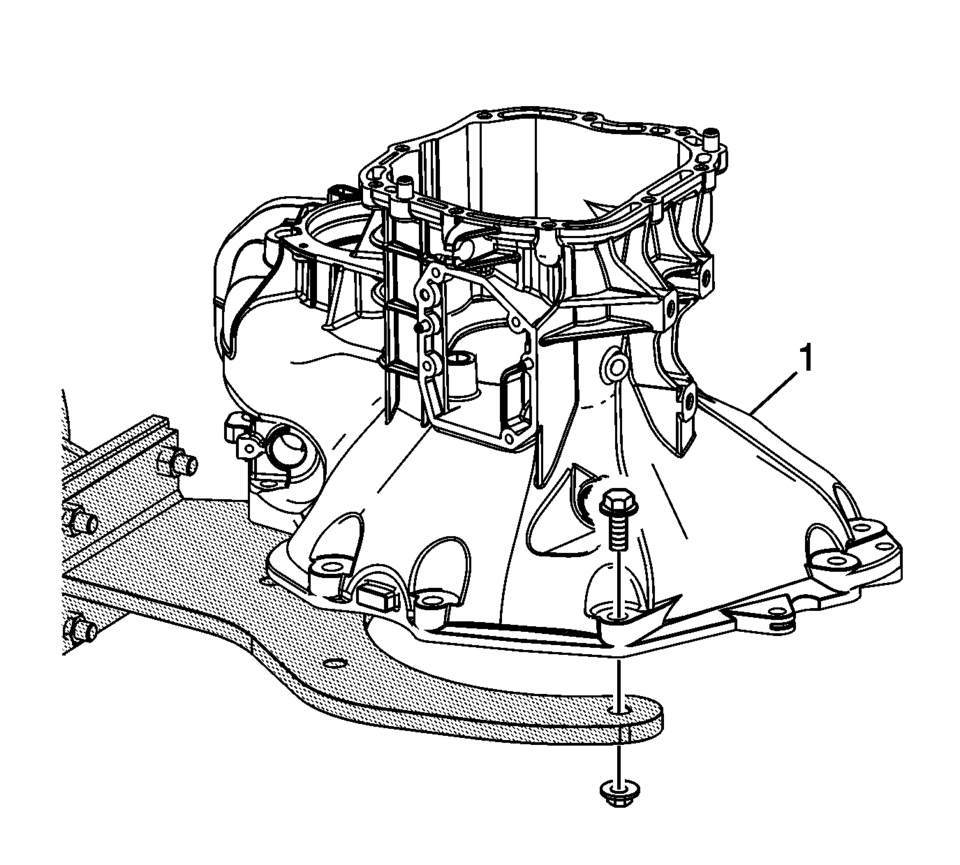

- Remove the clutch and differential housing (1) from the R-0007758 holding fixture .

Clutch and Differential Housing Cleaning and Inspection

Clutch and Differential Housing Cleaning and Inspection

Warning: Wear safety glasses to avoid injury when using compressed

air or any cleaning solvent. Bodily injury may occur if fumes are inhaled

or if skin is exposed to chemicals.

...

Differential Carrier Removal (6T30)

Differential Carrier Removal (6T30)

Differential Carrier Removal

Callout

Component Name

1

Differential Carrier Assembly

2

Final ...

Other materials:

Radio Rear Side Door Speaker Replacement

Radio Rear Side Door Speaker Replacement

Callout

Component Name

Preliminary Procedure

Remove the rear side door trim. Refer to Rear

Side Door Trim Replacement.

1

Radio Rear Side Door Speaker Bol ...

Outside Rearview Mirror Replacement (Manual)

Outside Rearview Mirror Replacement

Callout

Component Name

Preliminary Procedures

Remove the front side door upper front trim panel. Refer to Front

Side Door Upper Front Trim Panel Replacement.

Remove the outside rearview ...

Heater Inlet Hose Replacement (LUV)

Heater Inlet Hose Replacement

Callout

Component Name

Preliminary Procedures

Drain the engine coolant. Refer to Cooling System Draining and Filling.

Remove the charge air cooler outlet hose. Refer to Charge Air Cooler

...

0.0166