Chevrolet Sonic Repair Manual: Front End Upper Tie Bar Replacement

- Removal Procedure

-

- Disable the SIR System. Refer to SIR Disabling and Enabling.

- Disconnect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Remove all related panels and components.

- Visually inspect the damage. Repair as much of the damage as possible.

- Remove the sealers and anti-corrosion materials from the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Locate and mark all the necessary factory welds of the front upper tie bar assembly.

- Drill all factory welds. Note the number and location of welds for installation of the service assembly.

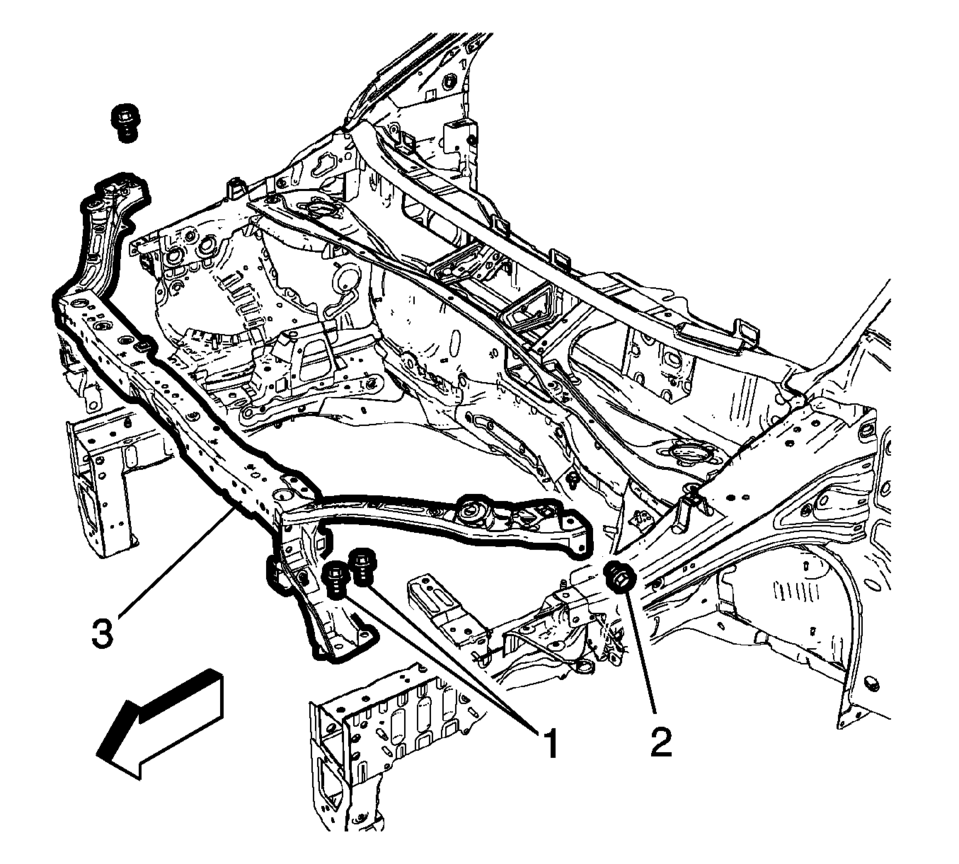

- Remove the front end upper tie bar support bolts (1) and front end upper tie bar bolts (2).

- Remove the front end upper tie bar assembly (3).

Warning:

Refer to Approved Equipment for Collision Repair Warning.

Warning:

Refer to Glass and Sheet Metal Handling Warning.

- Installation Procedure

-

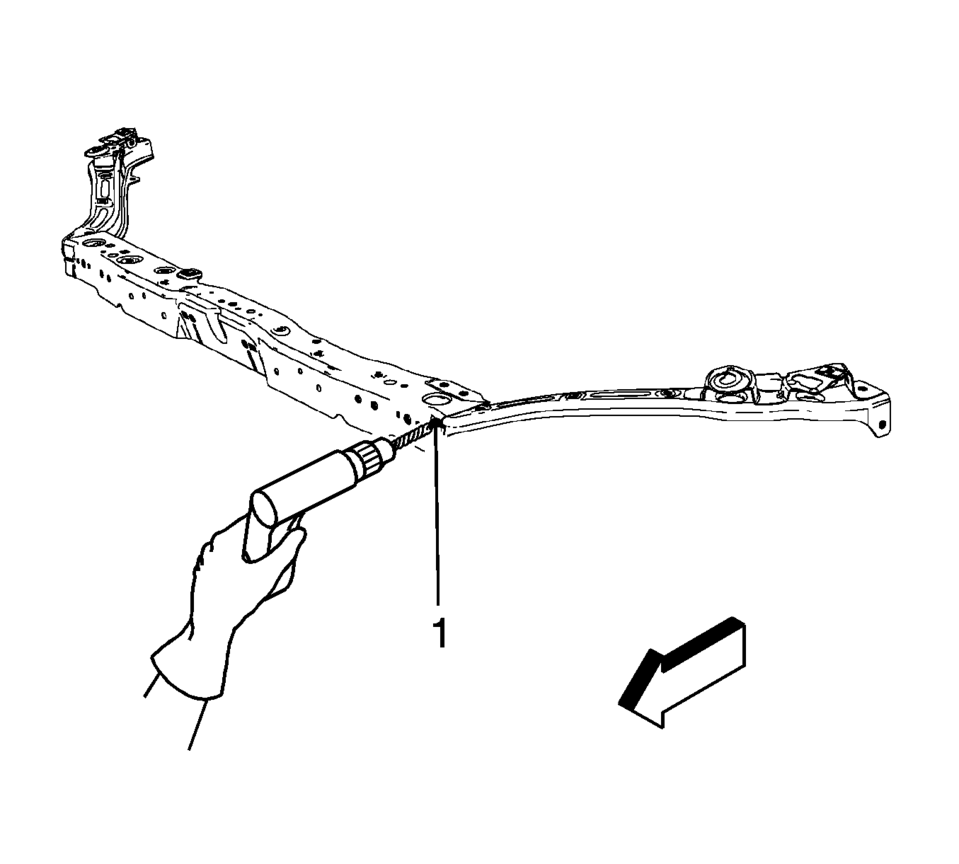

- Drill 8 mm (5/16 in) plug weld holes as necessary on service parts, in the locations noted from the original assembly (1).

- Clean and prepare the mating surface for welding, as necessary.

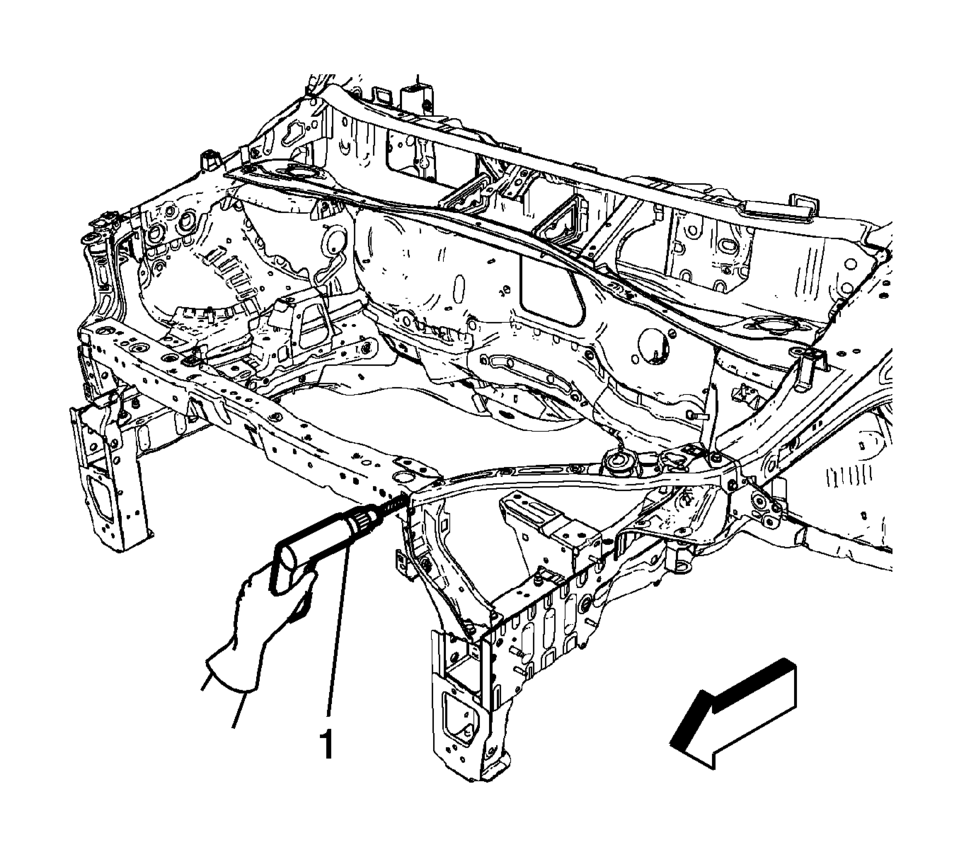

- Position the front upper tie bar support (1) and front upper tie bar (2) on the vehicle

- Verify the fit of the front end upper tie bar.

- Install the front upper tie bar support bolts (3) and tighten to

22 Y (16 lb ft)

.

- Install the front upper tie bar bolts (4) and tighten to 9 Y (80 lb in)

.

- When the service assembly is correctly positioned, plug weld accordingly (1).

- Measure frequently to ensure proper fit and alignment.

- Clean and prepare all welded surfaces.

- Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Paint the repaired area. Refer to Basecoat/Clearcoat Paint Systems.

- Install all related panels and components.

- Connect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Enable the SIR system. Refer to SIR Disabling and Enabling.

Caution:

Refer to Fastener Caution.

Front End Upper Tie Bar Replacement

Front End Upper Tie Bar Replacement

Front End Upper Tie Bar Replacement

Callout

Component Name

Preliminary Procedures

Disable the SIR system. Refer to SIR Disabling an ...

Other materials:

Rear Side Door Window Rear Guide Replacement

Rear Side Door Window Rear Guide Replacement

Callout

Component Name

Preliminary Procedure

Remove the rear side door trim panel. Refer to Rear Side Door Trim Replacement.

1

Rear Side Door Window R ...

Adhesive Installation of Rear Windows

Warning: Refer to Glass and Sheet Metal Handling Warning.

Use a urethane adhesive systems which meet GM Specification GM?€‰3651G.

Remove all mounds or loose pieces of urethane adhesive from the pinchweld

area.

If the original window is being reused, remove all but approxi ...

Exhaust Camshaft Replacement

Removal Procedure

Remove the camshaft intake and exhaust sprocket. Refer to Camshaft Intake

and Exhaust Sprocket Replacement.

Remove and DISCARD the camshaft sprocket bolts (2) and the camshaft

position exciter wheels (1).

Allow the both camshaft ...

0.006