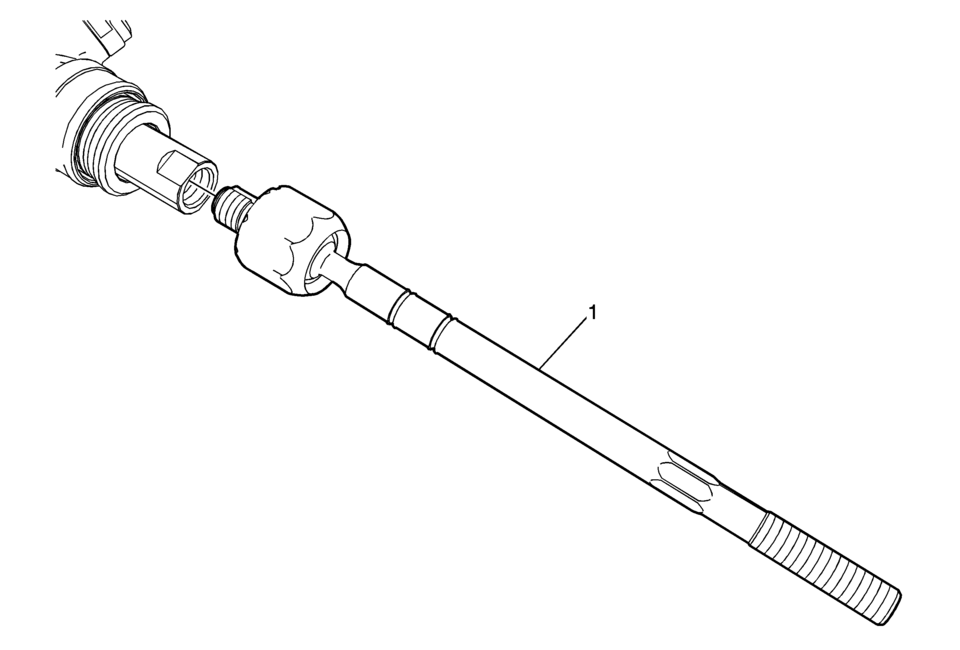

Chevrolet Sonic Repair Manual: Steering Linkage Inner Tie Rod Replacement

|

Callout |

Component Name |

|---|---|

Preliminary Procedures

|

|

|

1 |

Steering Linkage Inner Tie Rod Caution: Do not change the steering gear preload adjustment before moving the inner tie rod from the steering gear. Changing the steering gear preload adjustment before moving the inner tie rod could result in damage to the pinion and the steering gear. Caution: Refer to Fastener Caution.

100 Y (74 lb ft) |

Steering Linkage Inner Tie Rod Inspection

Steering Linkage Inner Tie Rod Inspection

Special Tools

GE-8001 Dial Indicator Set

For equivalent regional tools, refer to Special Tools.

Note: This inspection procedure does not supersede local government

required inspection ...

Steering Linkage Outer Tie Rod Inspection

Steering Linkage Outer Tie Rod Inspection

Special Tools

GE-8001 Dial Indicator Set

For equivalent regional tools, refer to Special Tools.

Note: This inspection procedure does not supersede local government

required inspection ...

Other materials:

Exhaust Manifold with Catalytic Converter Replacement (LUW)

Exhaust Manifold with Catalytic Converter Replacement

Callout

Component Name

Warning: Refer to Protective Goggles and Glove Warning.

Warning: Refer to Exhaust Service Warning.

Preliminary Procedure

...

Engine Oil Pressure Indicator Switch Replacement

Engine Oil Pressure Indicator Switch Replacement

Callout

Component Name

Preliminary Procedure

Remove the air conditioning compressor. Refer to Air Conditioning Compressor

Replacement.

1

Oil Pres ...

Gears Cleaning and Inspection (Gen 1)

Gears

Warning: Wear safety glasses to avoid injury when using compressed

air or any cleaning solvent. Bodily injury may occur if fumes are inhaled

or if skin is exposed to chemicals.

Clean the following gears in a suitable solvent and

air dry all the p ...

0.0085