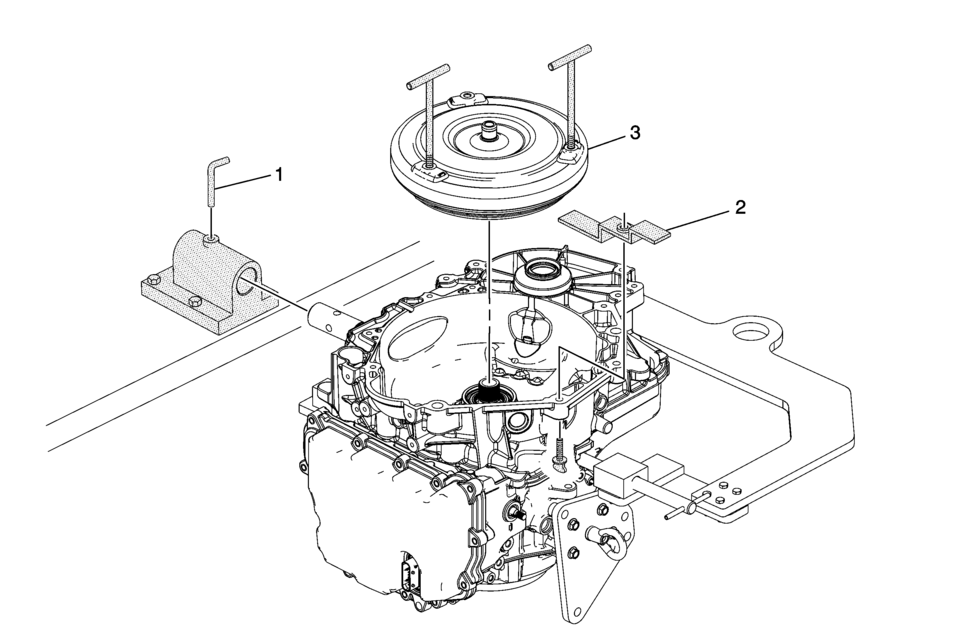

Chevrolet Sonic Repair Manual: Torque Converter Removal

|

Callout |

Component Name |

|---|---|

|

1 |

Lock Pin Warning: Lock pin must be secured into the bench fixture to hold the transmission and prevent bodily injury. Note: Ensure the DT 3289-20 holding fixture is mounted to a bench that is properly supported and will support the weight of the transmission assembly without tipping. DT-39890 holding fixture adapter and an engine stand can be used as an alternative method for supporting the transmission assembly during repairs.

For equivalent regional tools, refer to Special Tools. |

|

2 |

DT 21366 Torque Converter Holding Strap |

|

3 |

Torque Converter Assembly Caution: Only install the lift assist handles until it stops. Do not tighten. Over tightening the lift assist handles can cause damage to the torque converter. Note: Failure to raise the torque converter straight up could damage the torque converter clutch lip seal inside the torque converter clutch assembly. Special Tool

DT 46409 Torque Converter Lifting Handles For equivalent regional tools, refer to Special Tools. |

Torque Converter Installation

Torque Converter Installation

Torque Converter Installation

Callout

Component Name

1

Torque Converter Assembly

Note: Failure to lower the torq ...

Other materials:

Rear Brake Cylinder Replacement

Removal Procedure

Warning: Refer to Brake Dust Warning.

Warning: Refer to Brake Fluid Irritant Warning.

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the tire and wheel assembly. Refer to Tire and Wheel Removal

and I ...

Tire and Wheel Removal and Installation

Special Tools

CH-41013 Rotor Resurfacing Kit

CH-42450-A Wheel Hub Resurfacing Kit

For equivalent regional tools, refer to Special Tools.

Removal Procedure

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the wheel cover ...

Crankshaft Rear Oil Seal Replacement

Special Tools

EN-658 Rear Main Seal Installer

For equivalent regional tools, refer to Special Tools.

Removal Procedure

If equipped with automatic transmission, remove the flex plate. Refer

to Automatic Transmission Flex Plate Replacement.

If equipped with a manual transmis ...

0.0057