Chevrolet Sonic Repair Manual: Transmission Case Assemble (Gen 1)

Special Tools

- 3-9506289 Universal Adapter

- J-840733 Driver

- R-0007758 Holding Fixture

- R-0007761 Universal Handle

- R-0007770 Holding Fixture Adapter Plates

- T-9804669 Seal Installer

- T-0307000 Extractor and Driver Fixture

For equivalent regional tools, refer to Special Tools.

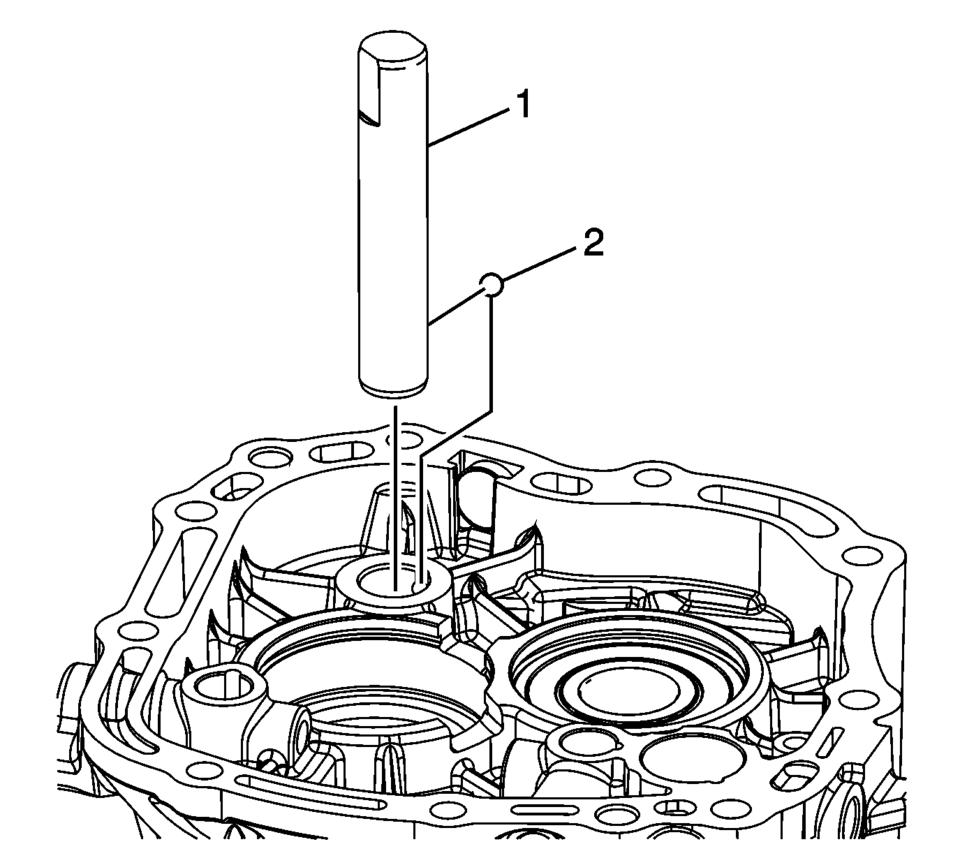

- Install the reverse idler gear shaft retaining ball (2).

- Install the reverse idler gear shaft (1).

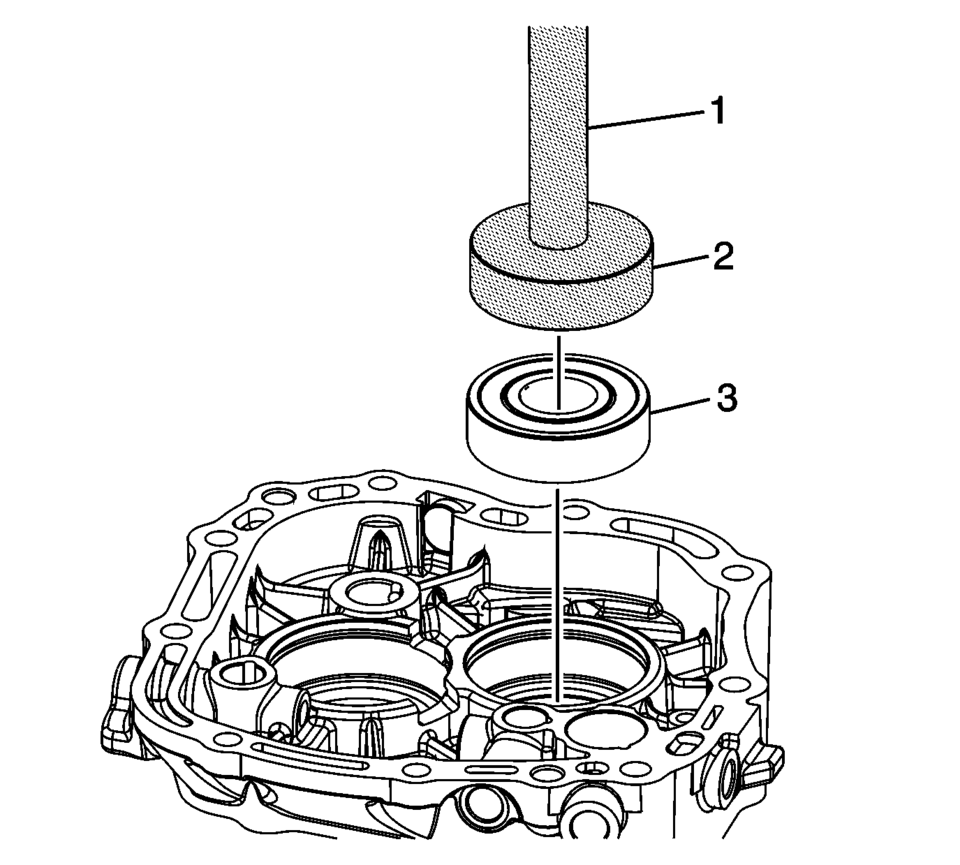

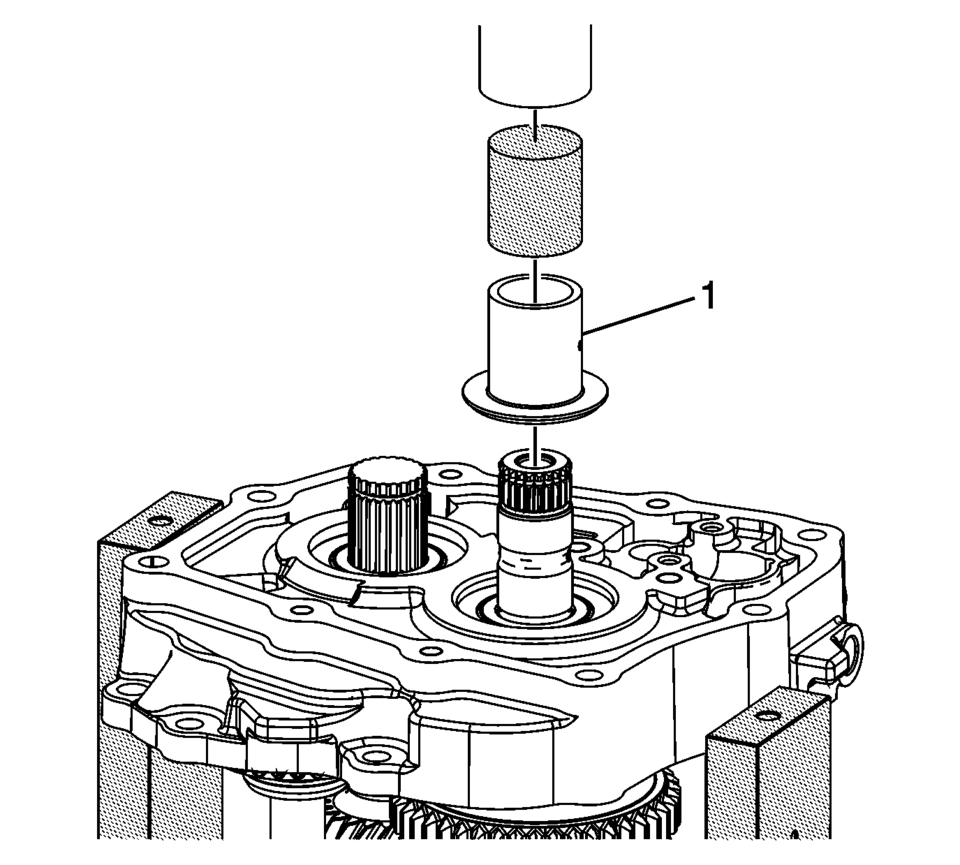

- Using T-9804669 seal installer (2) and R-0007761 handle (1), install the mainshaft bearing (3) into the case.

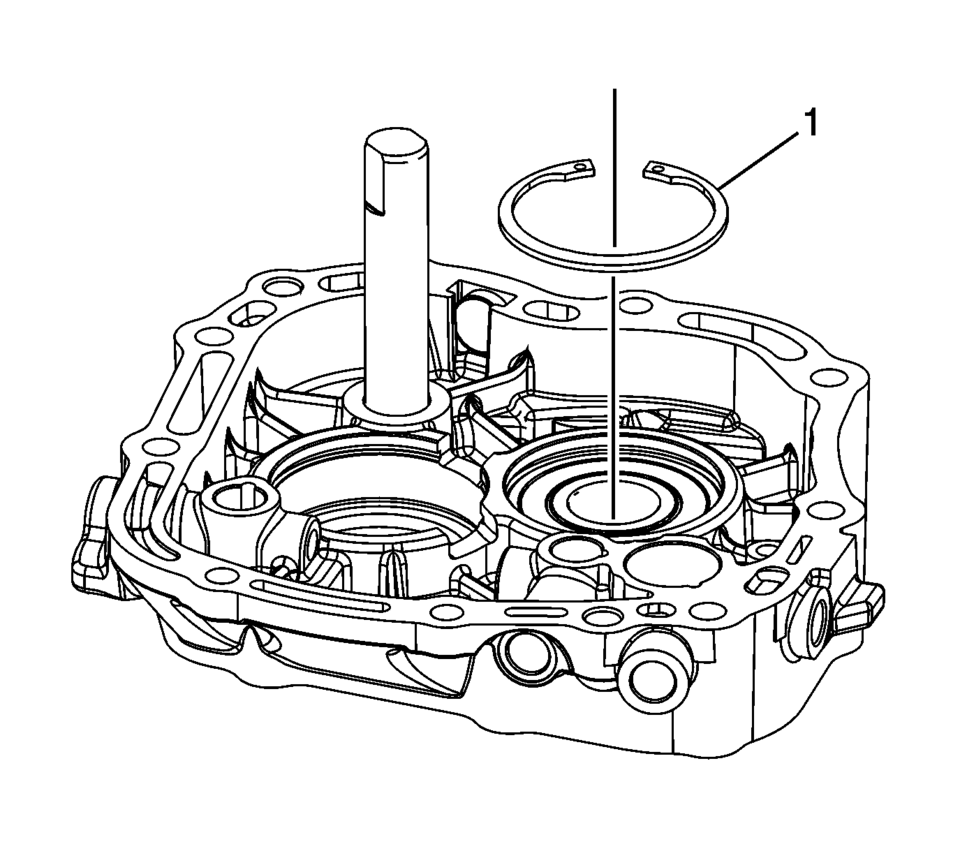

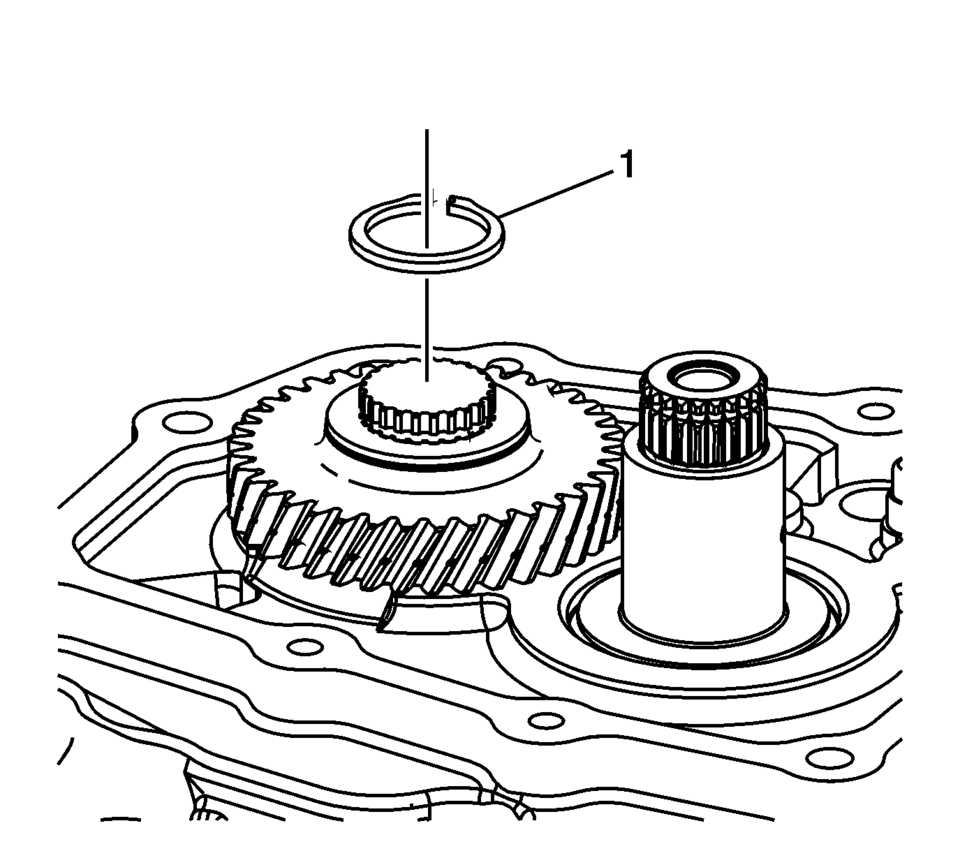

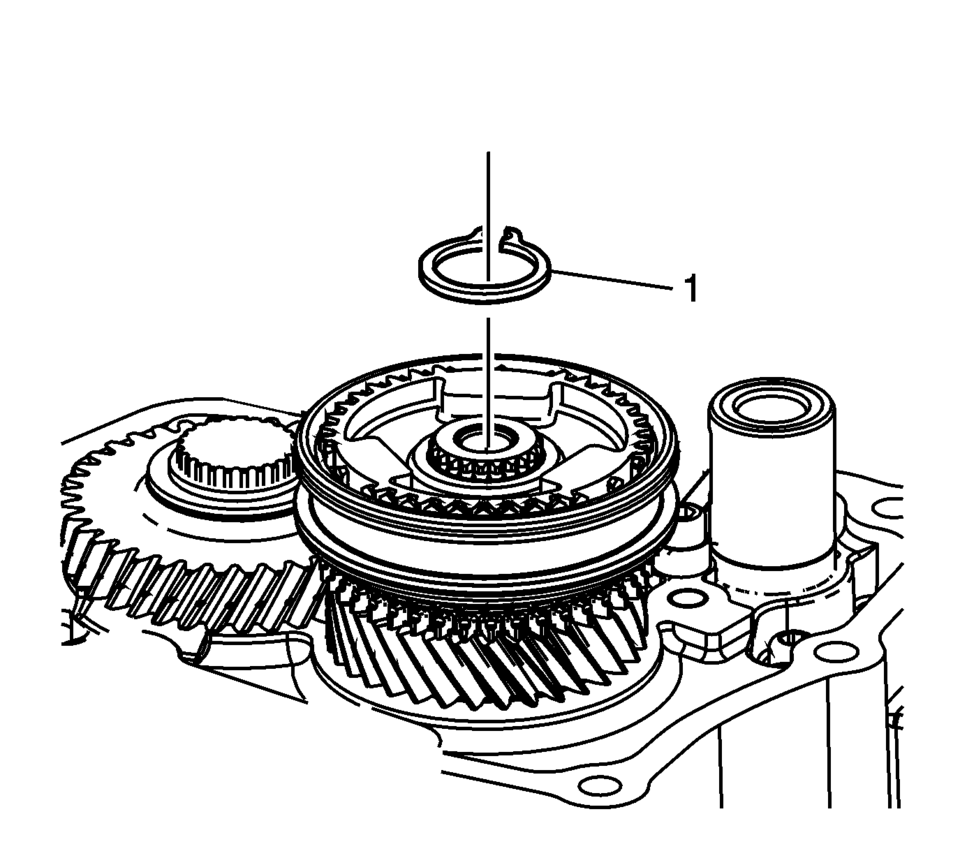

- Install the mainshaft bearing retaining ring (1).

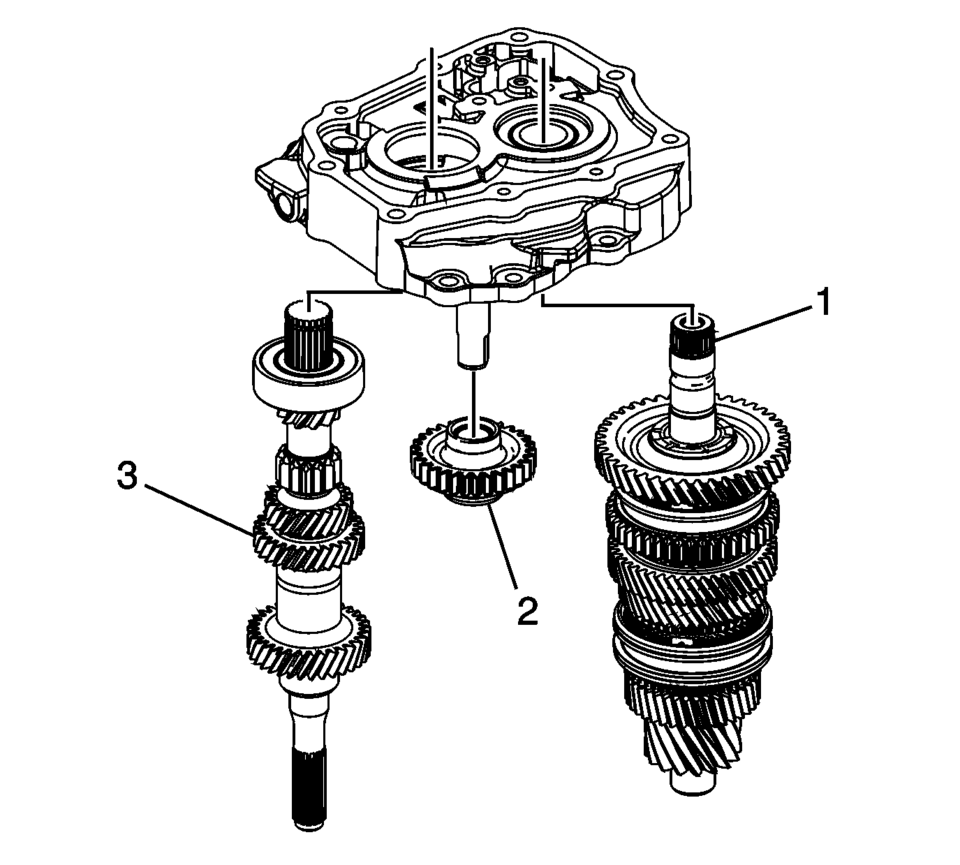

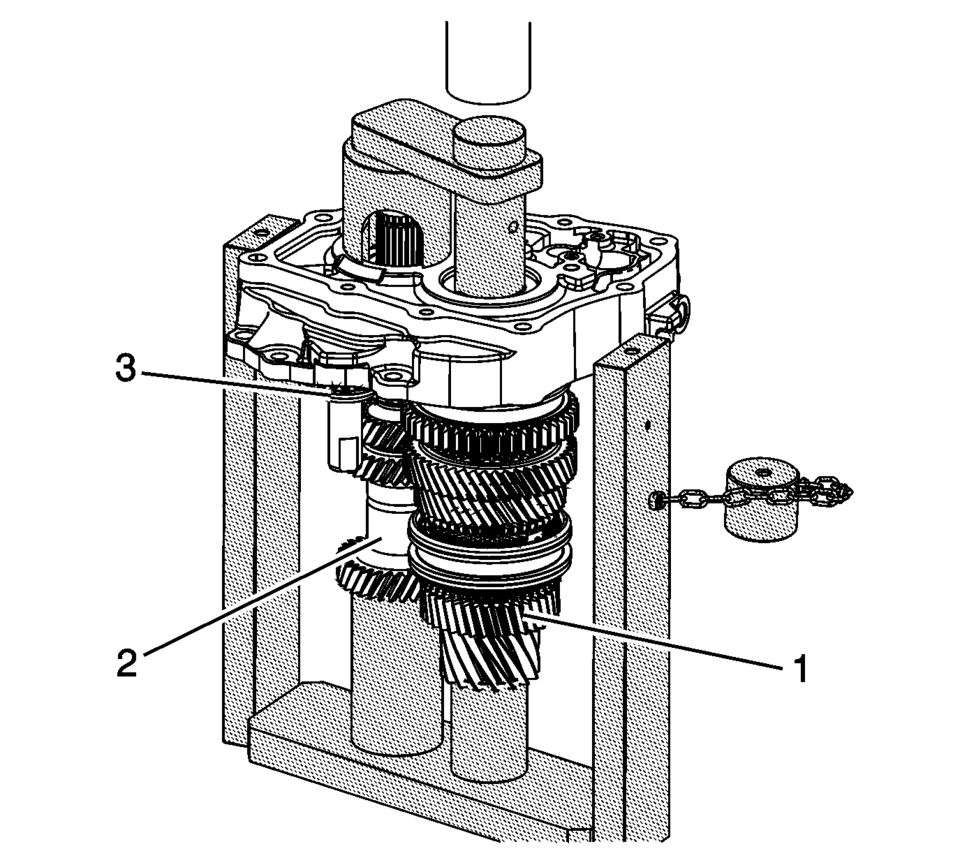

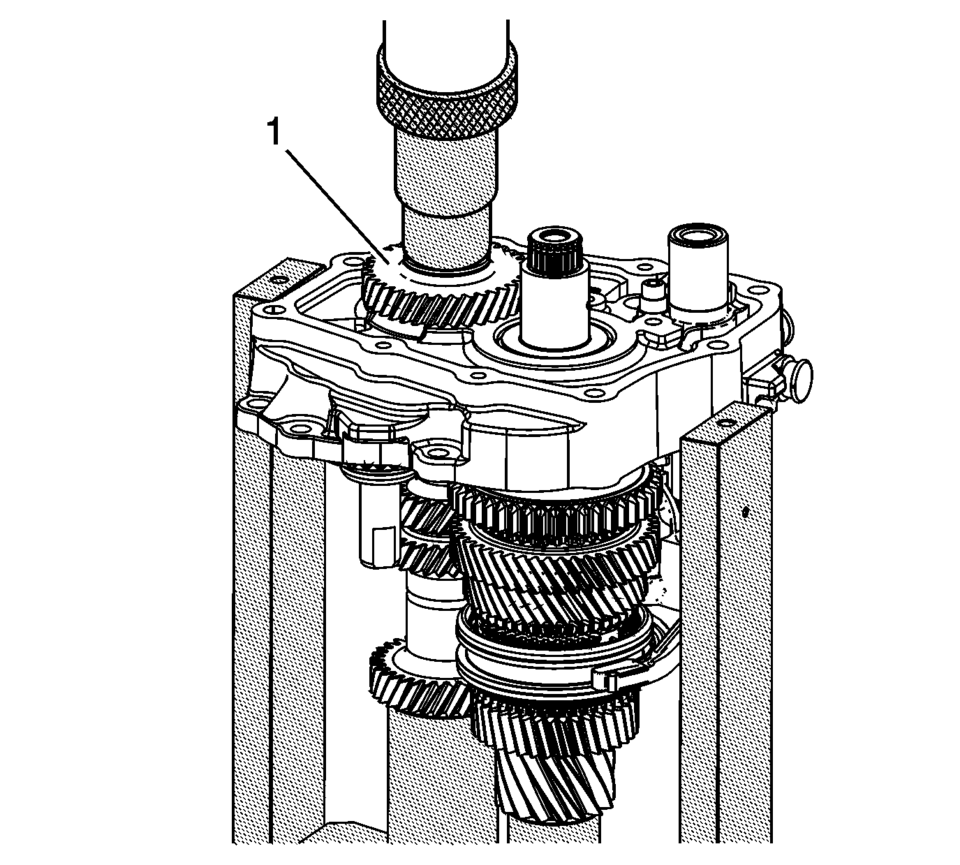

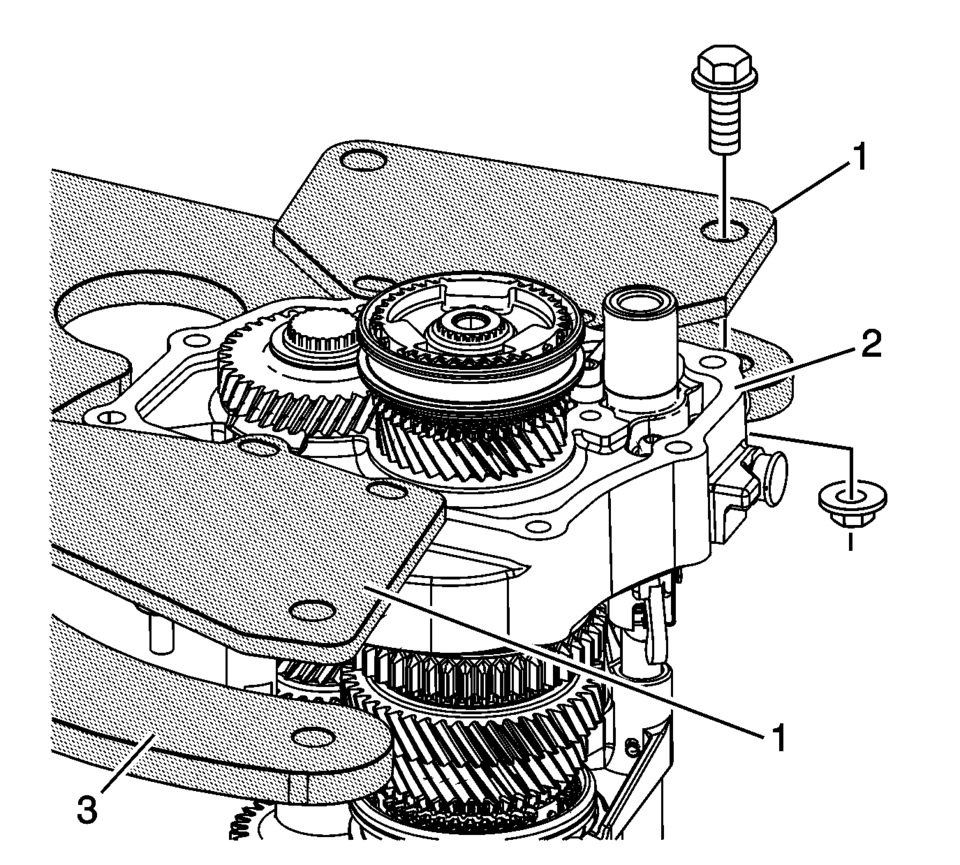

- Install the input shaft (3), reverse idler gear (2) and mainshaft (1) onto the T-0307000 driver fixture with top plate removed.

- Guide the shafts (1?) into the bores, and support the reverse idler gear (3) while pressing into the case.

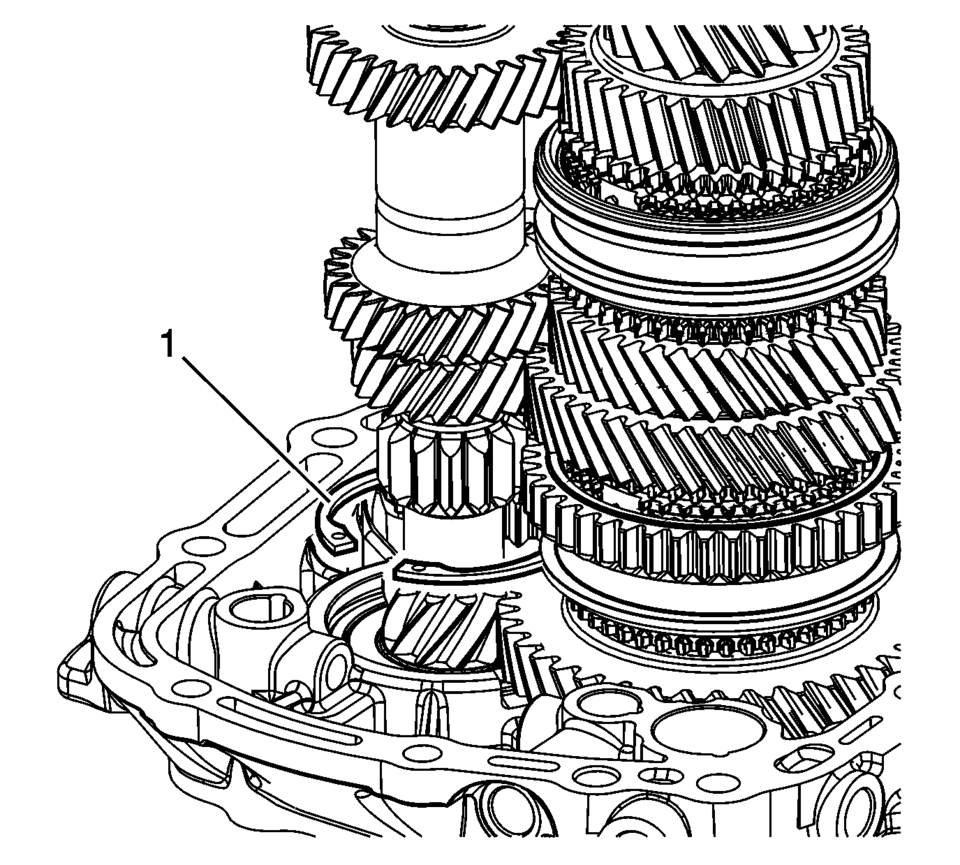

- Using the T-0307000 driver fixture , press the 5th gear bearing race (1) onto the mainshaft.

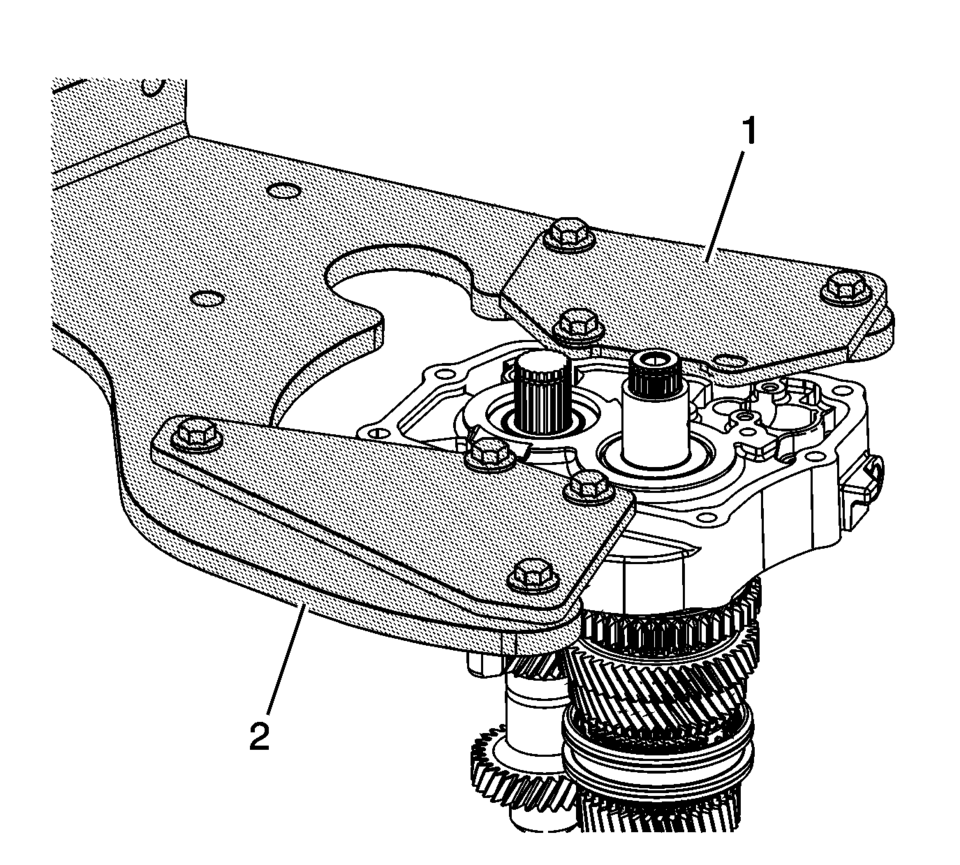

- Install the case and shafts assembly onto the R-0007770 adapter plates (1) and R-0007758 holding fixture (2).

- Install the input shaft bearing retaining ring (1).

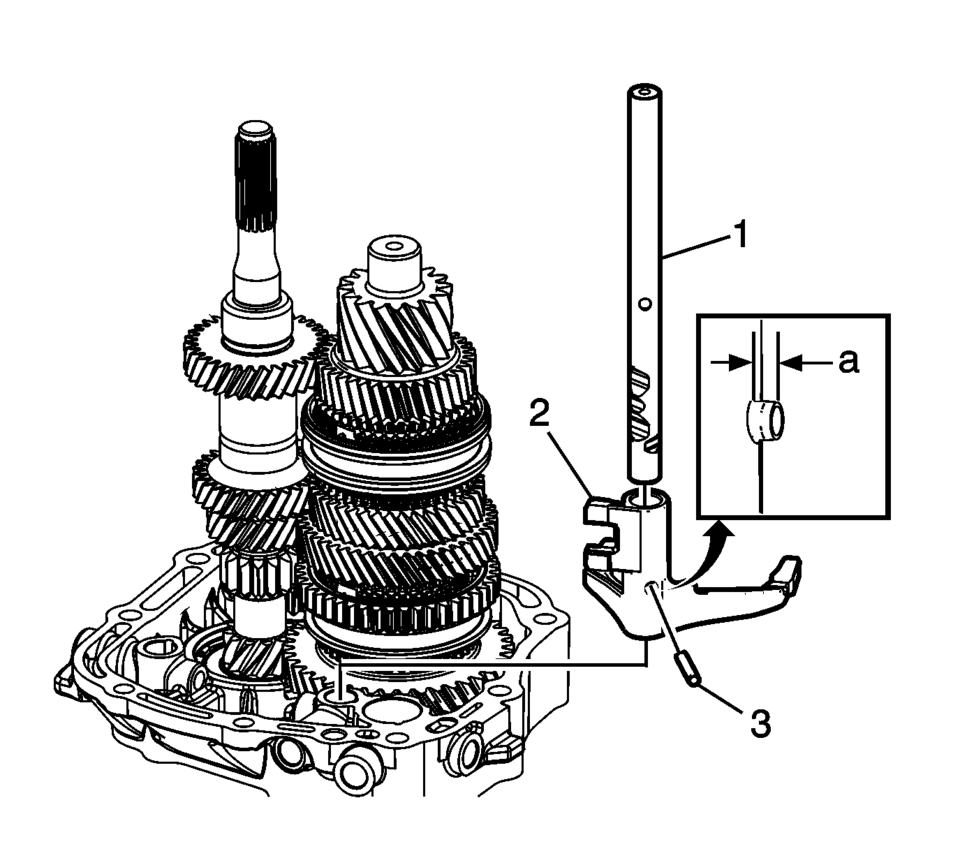

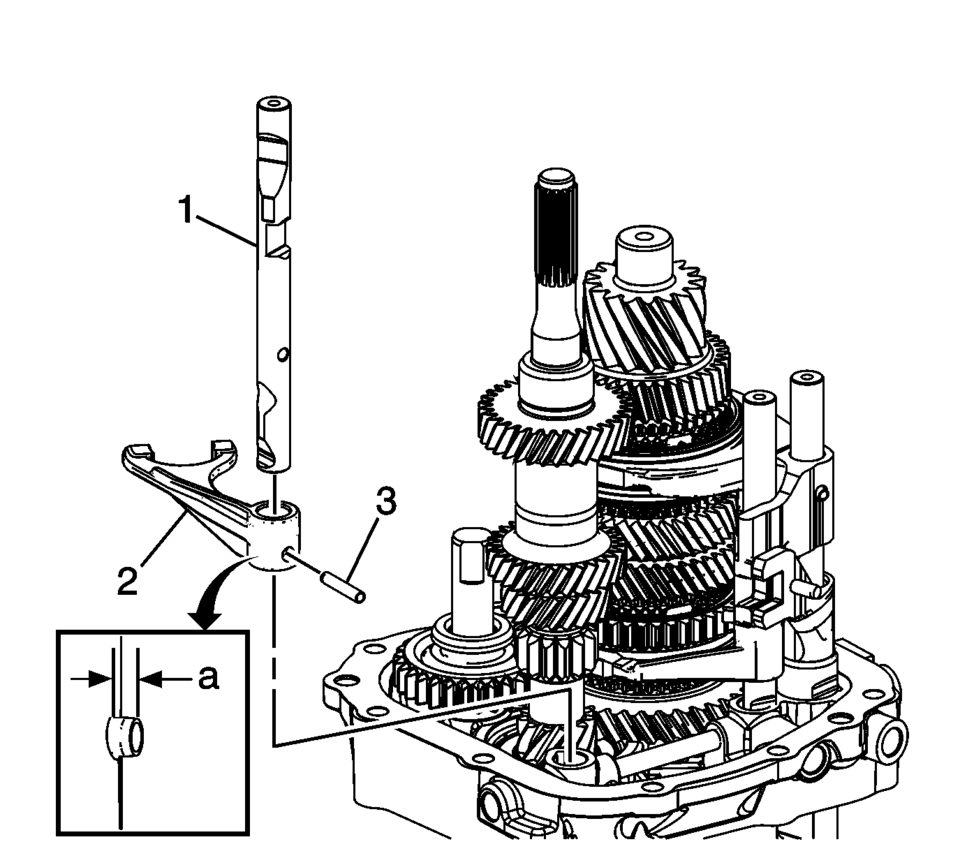

- Install the 1st and 2nd shift fork (2).

- Install the 1st and 2nd shift shaft (1).

- Install the 1st and 2nd shift fork pin (3) to the dimension ??depth of

2 mm (0.80 in)

.

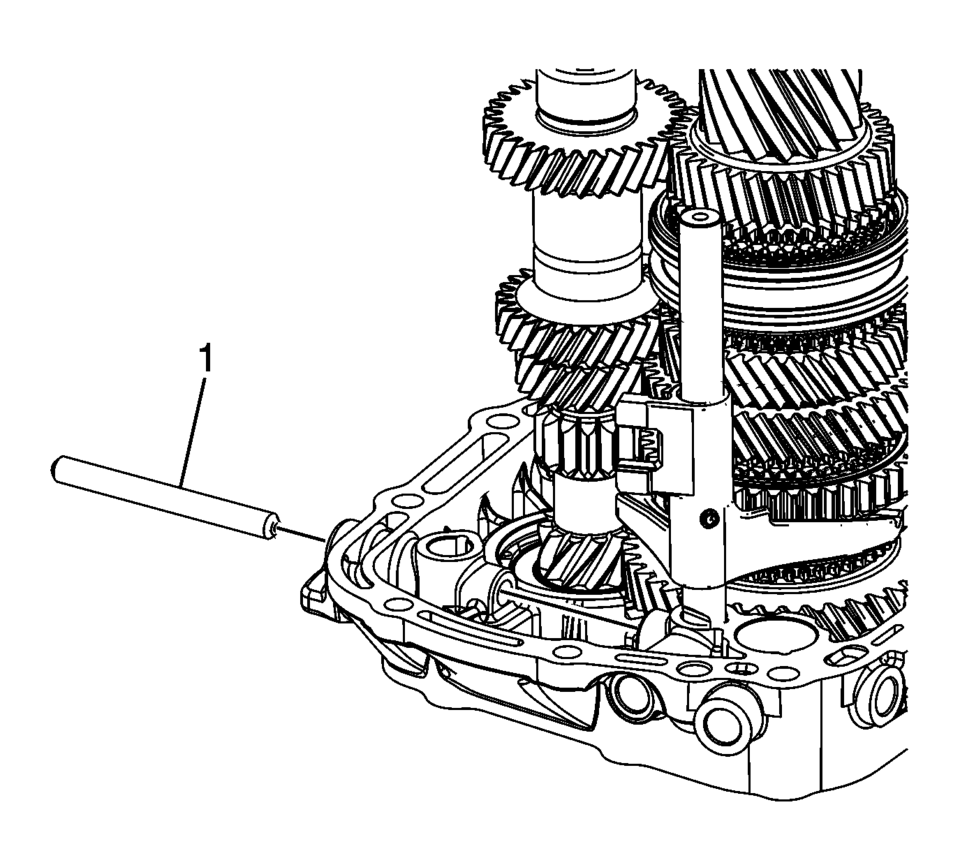

- Install the gearshift rod (1) into the transmission case.

- Install the 5th shift blocking guide (1) into the transmission case.

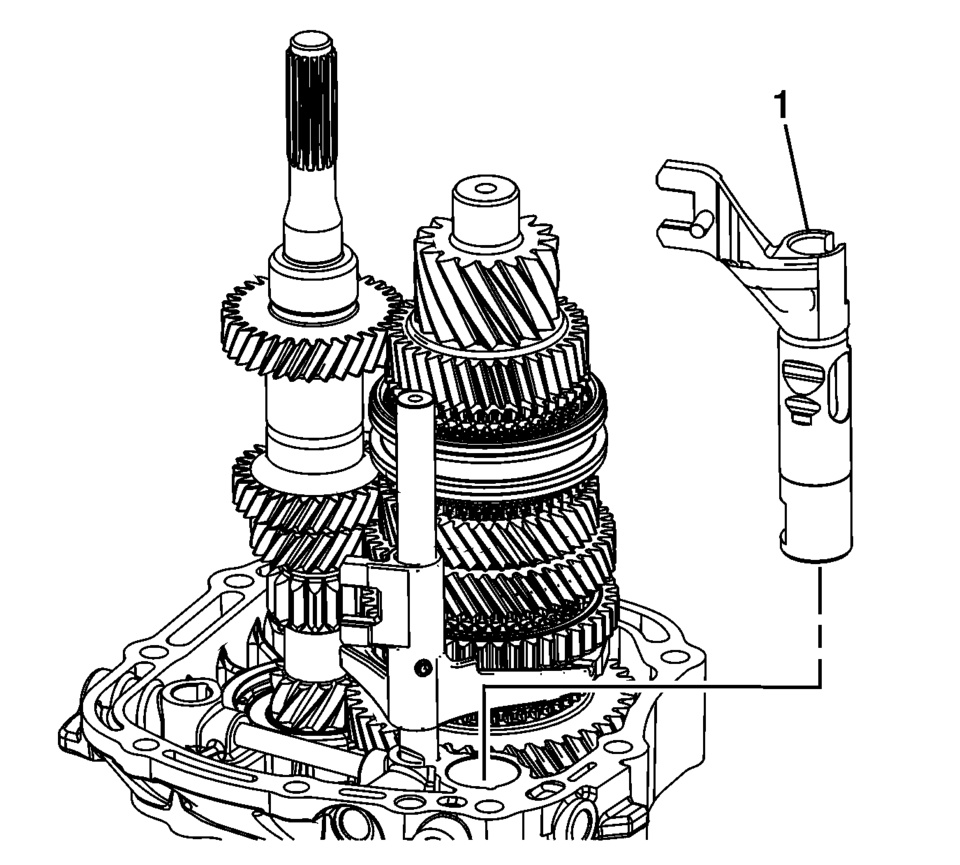

- Install the 3rd and 4th shift fork (2).

- Install the 3rd and 4th shift shaft (1).

- Install the 3rd and 4th shift fork pin (3) to the dimension ??depth of

2 mm (0.80 in)

.

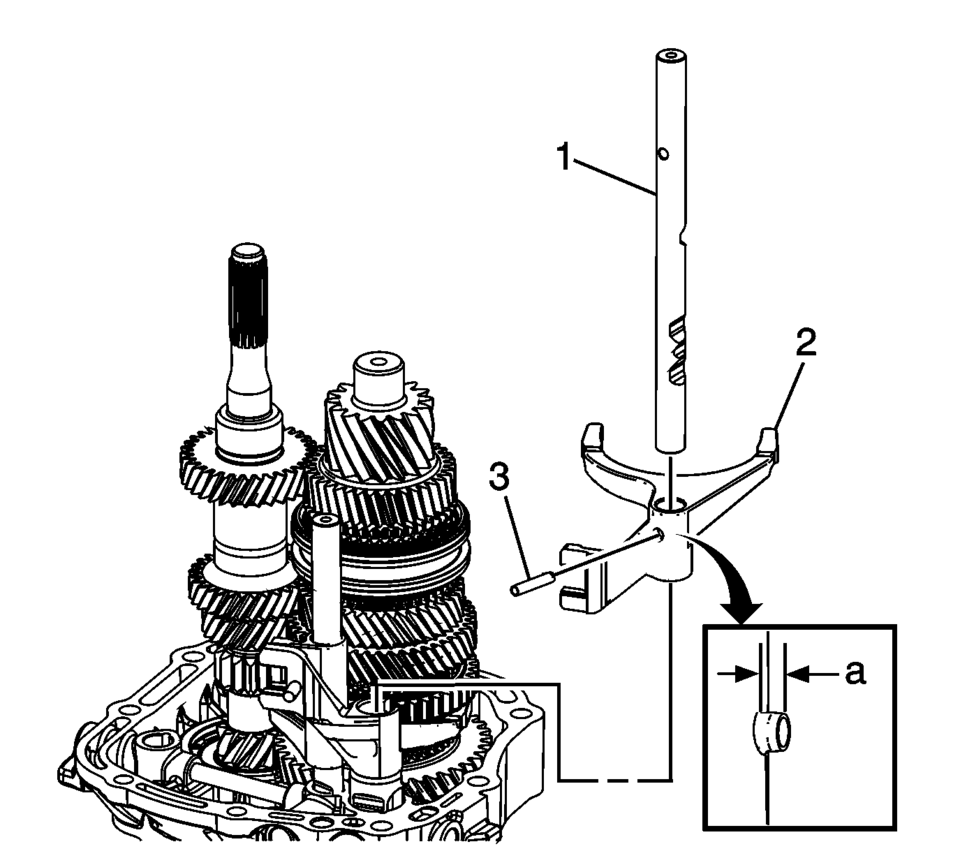

- Install the reverse shift fork (2).

- Install the reverse shift shaft (1).

- Install the reverse shift fork pin (3) to the dimension ??depth of

2 mm (0.80 in)

.

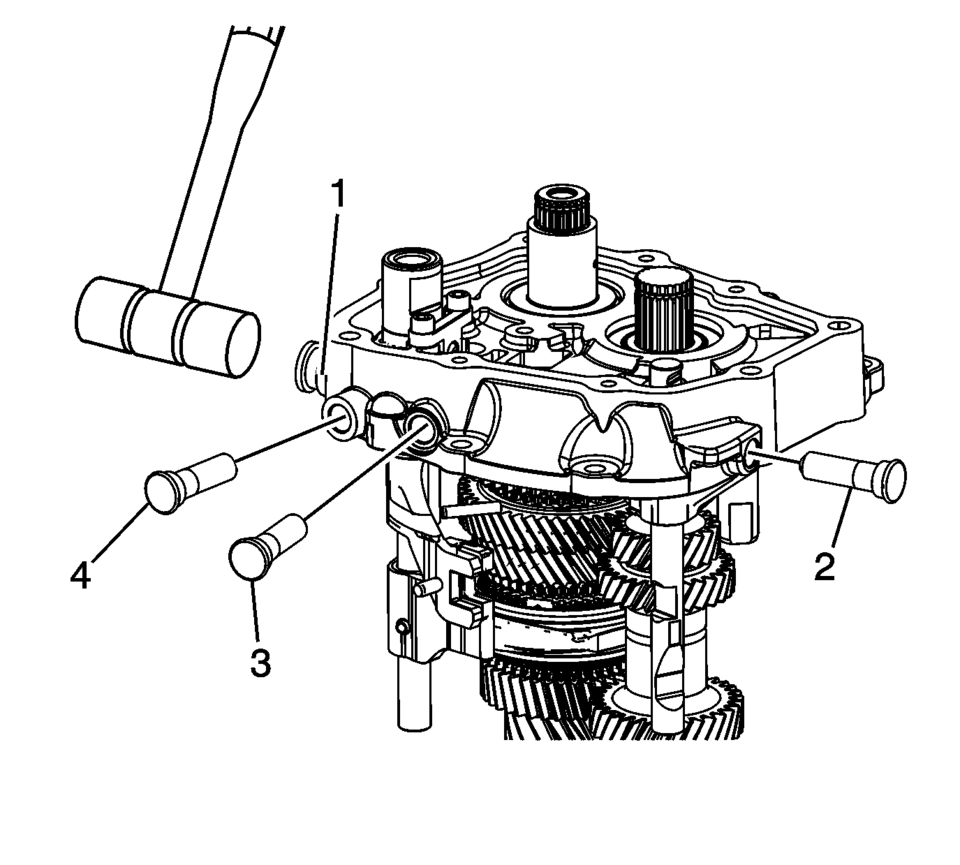

- Using a plastic hammer or equivalent install the 4 shift shaft detent sleeves (1?) into the transmission case until they stop.

- Install the shift shaft interlock pin connector (1).

- Using thread locking compound install the shift shaft interlock pin connector

bolts (2) and tighten to 7 Y (62 lb in)

.

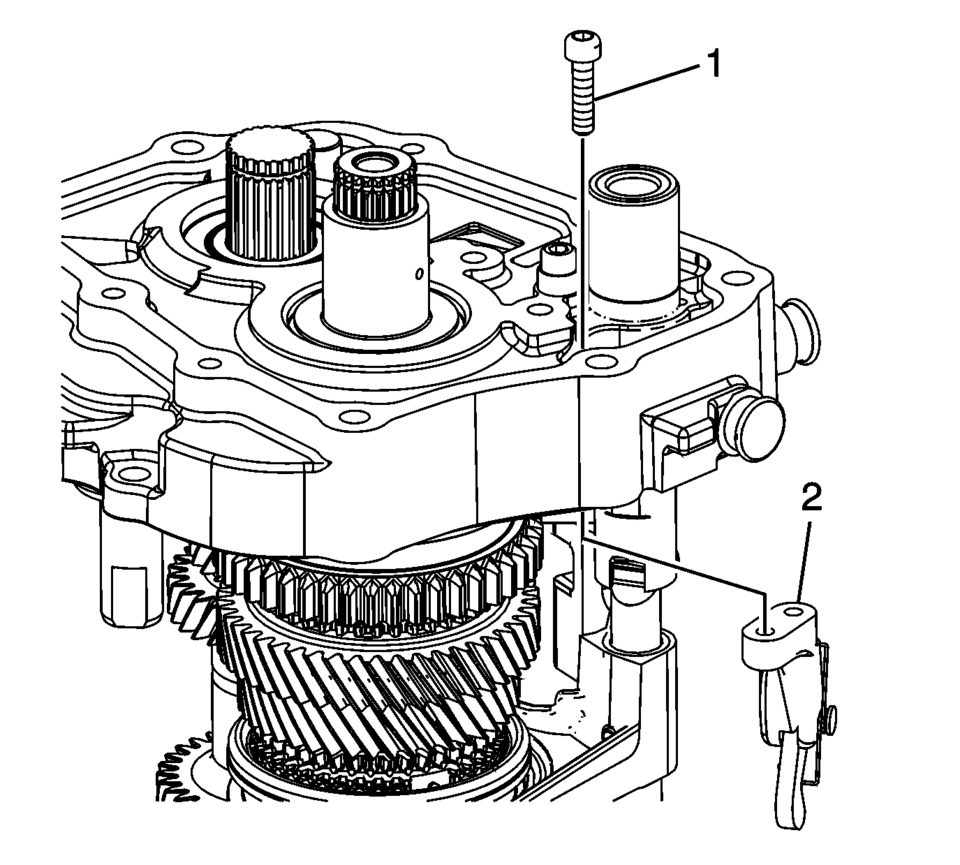

- Install the parking pawl (2).

- Using thread locking compound install the parking pawl retaining bolts (1)

and tighten to 7 Y (62 lb in)

.

- Remove case and shafts assembly from R-0007770 adapter plates and install onto T-0307000 driver fixture .

- Using J-840733 driver , press the 5th gear, driving (1) onto the input shaft.

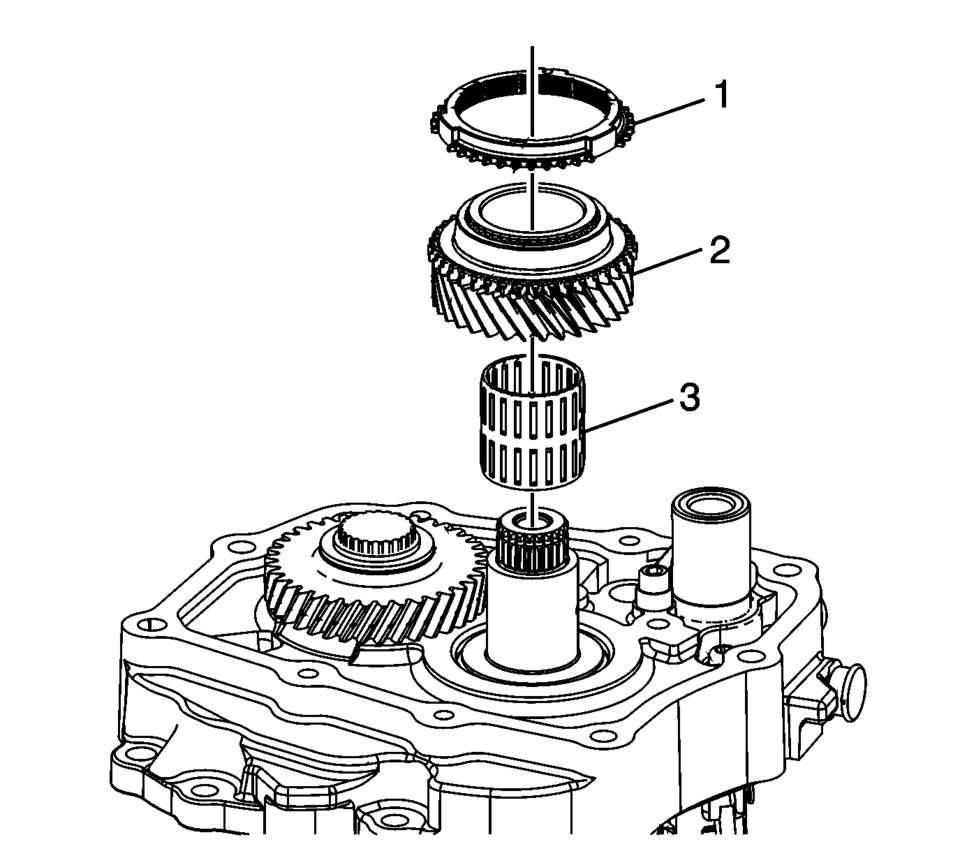

- Install a NEW 5th gear retaining ring (1).

- Install the 5th gear bearing assembly (3).

- Install the 5th gear assembly, driven (2).

- Install the 5th gear blocking ring (1).

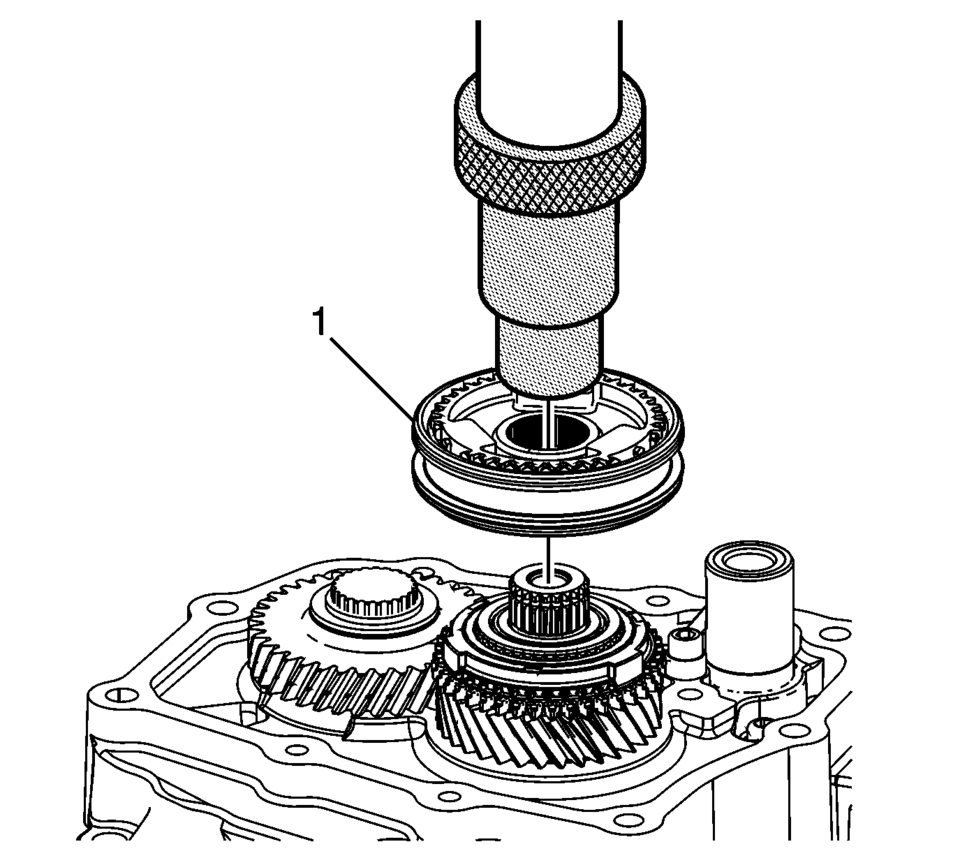

- Ensure that the synchronizer assembly (1) is functioning properly, refer to Synchronizers Cleaning and Inspection and Synchronizers Assemble.

- Using the J-840733 driver and a press, install the 5th gear synchronizer assembly (1).

- Install the 5th gear sychronizing hub retaining ring (1).

- Remove the case and shafts assembly from the T-0307000 driver fixture .

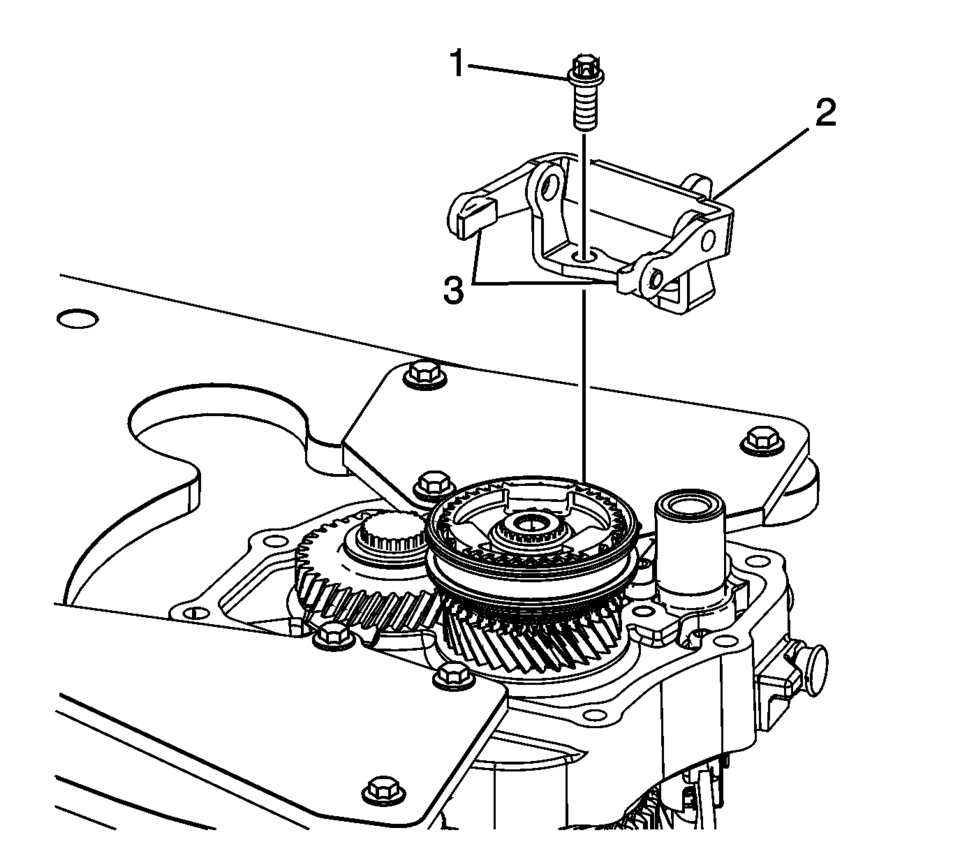

- Install R-0007770 adapter plates (1) onto case (2) and then attach to R-0007758 holding fixture (3).

- Install the 5th shift fork shoes (3).

- Install the 5th shift fork bracket assembly (2).

- Using thread locking compound install the 5th shift fork bracket bolts (1)

and tighten to 22 Y (16 lb ft)

.

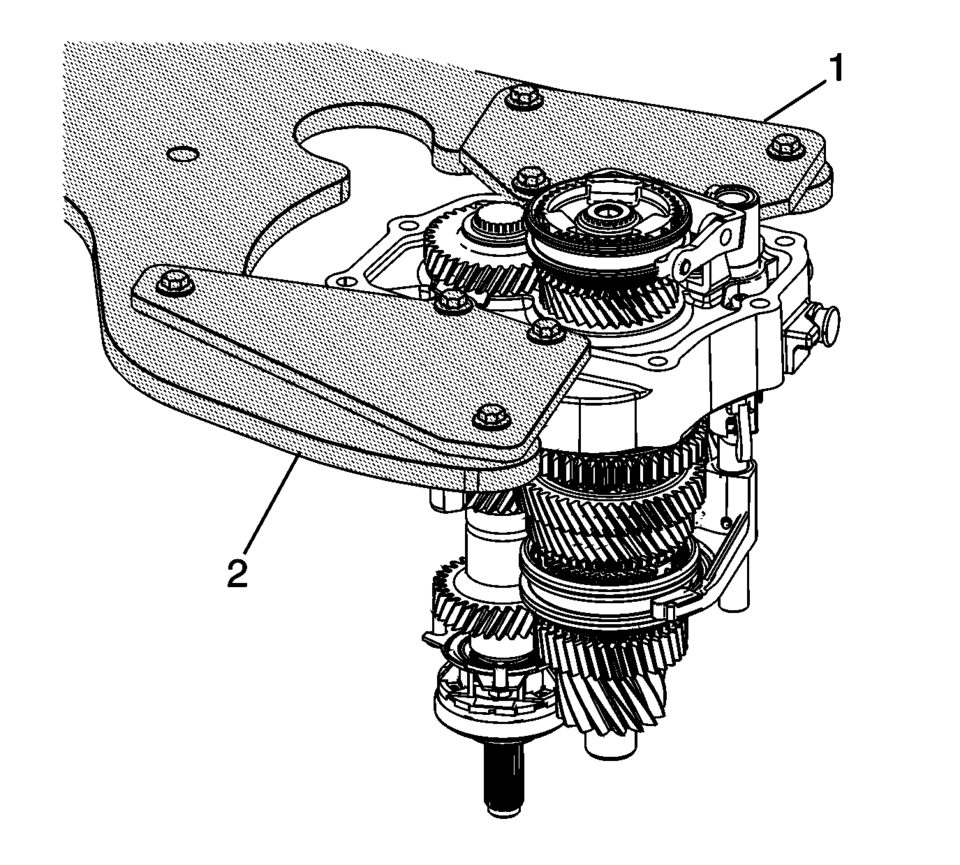

- Remove the transmission case, from the R-0007770 adapter plates (1) the R-0007758 holding fixture and 3-9506289 adapter .

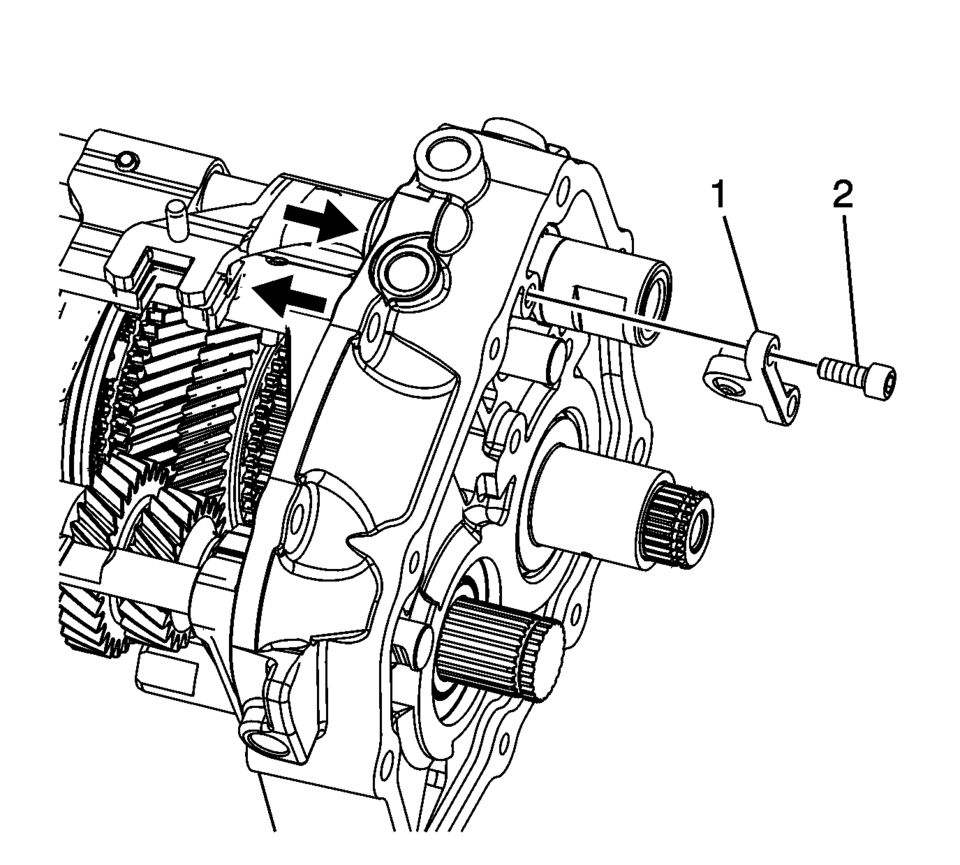

Note:

Engage the shift shafts into 3rd gear and 5th gear as indicated with arrows to install the interlock pin connector.

Note:

Move shift forks into neutral position.

Caution:

Refer to Fastener Caution.

Transmission Assemble (Gen 2)

Transmission Assemble (Gen 2)

Special Tools

3-9506289 Universal Adapter

R-0007758 Holding Fixture

S-9407197 Differential Rotating Tool

S-9407198 Differential Bearing Race Wrench

For equivalent regional tools, refer ...

Transmission Case Assemble (Gen 2)

Transmission Case Assemble (Gen 2)

Special Tools

3-9506289 Universal Adapter

J-840733 Driver

R-0007758 Holding Fixture

R-0007761 Universal Handle

R-0007770 Holding Fixture Adapter Plates

T-9804669 Seal Installer

T-0 ...

Other materials:

Recommended Fuel

Use regular unleaded gasoline with a posted octane rating of 87 or higher. If

the octane rating is less than 87, an audible knocking noise may be heard. If this

occurs, use a gasoline rated at 87 octane or higher as soon as possible. If heavy

knocking is heard when using gasoline with a higher ...

Courtesy Transportation Program

To enhance your ownership experience, we and our participating dealers are proud

to offer Courtesy Transportation, a customer support program for vehicles with the

Bumper-to-Bumper (Base Warranty Coverage period in Canada), extended powertrain,

and/or hybrid-specific warranties in both the U.S ...

Radio Antenna Replacement

Radio Antenna Replacement

Callout

Component Name

1

Radio Antenna

Procedure

Rotate the mast counterclockwise in order to release the mast from the

antenna base.

...

0.0092