Chevrolet Sonic Repair Manual: Brake Rotor Thickness Variation Measurement

Warning:

Refer to Brake Dust Warning.

Note:

Any disc brake rotor that exhibits thickness variation exceeding the maximum acceptable level must be refinished or replaced. Thickness variation exceeding the maximum acceptable level can cause brake pulsation.

- If the inboard friction surface of the brake rotor is not accessible, reposition and support the caliper with the brake pads. Refer to Front Disc Brake Pads Replacement.

- Clean the friction surfaces of the brake rotor with denatured alcohol, or an equivalent approved brake cleaner.

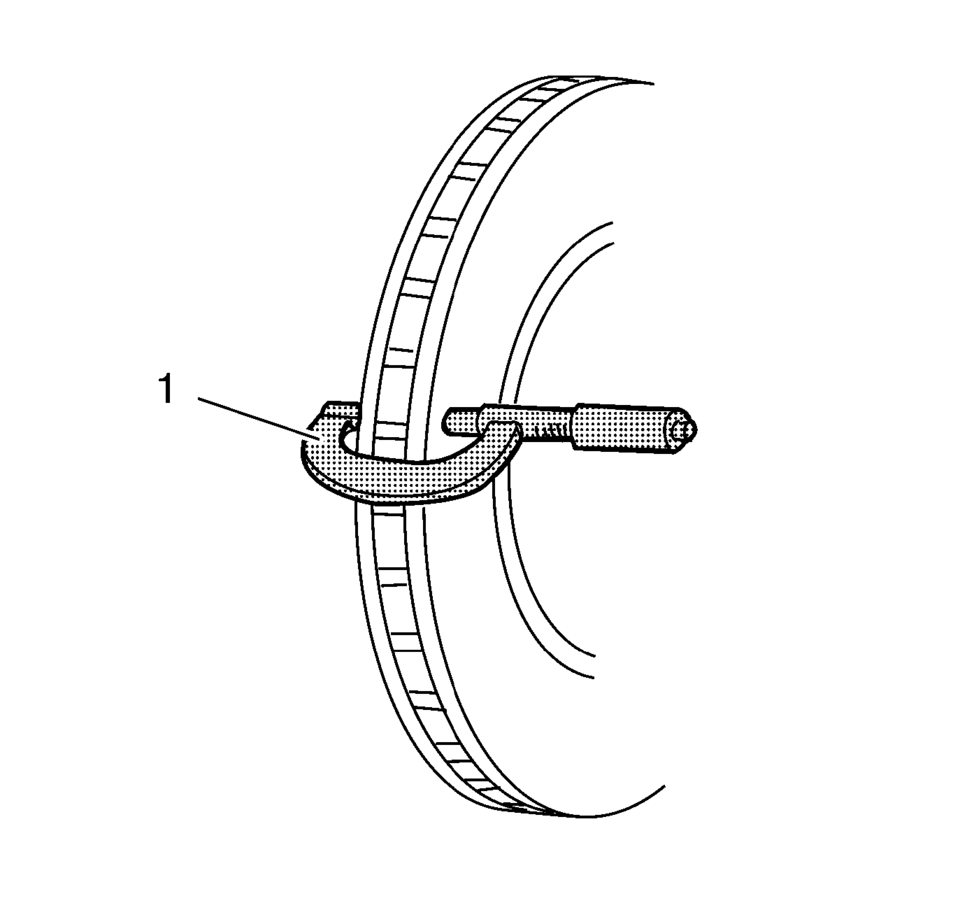

- Using a micrometer (1) calibrated in thousandths-of-a-millimeter, or ten-thousandths-of-an-inch,

measure and record the thickness of the brake rotor at 4 or more points, evenly

spaced around the brake rotor.

Make sure that the measurements are only taken within the friction surfaces and that the micrometer is positioned the same distance from the outer edge of the brake rotor, about 13 mm (1/2 in), for each measurement.

- Calculate the difference between the highest and lowest thickness measurements recorded to obtain the amount of thickness variation.

- Compare the thickness variation measurement to the following specification:

Specification

- J93, J94: 0.02 mm (0.0008 in)

- JPW, J97: 0.02 mm (0.0008 in)

- J93, J94: 0.02 mm (0.0008 in)

- If the brake rotor thickness variation measurement exceeds the specification, the brake rotor requires refinishing or replacement.

Note:

Whenever a brake rotor is refinished or replaced, the assembled lateral runout (LRO) of the brake rotor must be measured to make sure optimum performance of the disc brakes.

Brake Rotor Thickness Measurement

Brake Rotor Thickness Measurement

Warning: Refer to Brake Dust Warning.

If the inboard friction surface of the brake rotor is not accessible, reposition

and support the caliper with the brake pads. Refer to Front Disc Bra ...

Brake Rotor/Drum Balance Inspection

Brake Rotor/Drum Balance Inspection

Support the vehicle drive axle on a suitable hoist. Refer to Lifting and

Jacking the Vehicle.

Remove the tire and wheel assemblies from the drive axle. Refer to Tire

and Wheel Removal and ...

Other materials:

Liftgate Hinge Replacement

Liftgate Hinge Replacement

Callout

Component Name

Preliminary Procedures

Remove the liftgate. Refer to Liftgate Replacement.

Lower the rear of the headliner to access the inner bolts. Refer

to Headlining Trim Panel Replac ...

Instrument Panel Lower Airbag Replacement - Driver Side

Instrument Panel Lower Airbag Replacement - Driver Side

Callout

Component Name

Warning: Refer to SIR Inflator Module Handling and Storage

Warning.

Warning: Refer to SIR Warning.

Preliminary Procedure

...

Drive and Driven Sprocket, Drive Link, and Park Pawl Installation (6T40/45/50)

Drive and Driven Sprocket, Drive Link, and Park Pawl Installation

Callout

Component Name

1

Front Differential Carrier Baffle

2

Front Differential Carrier Baffle Bolt M6 x 16& ...

0.0064