Chevrolet Sonic Repair Manual: Drive Belt Tensioner Replacement

Special Tools

- EN-955 Locking Pin

- EN-48488 Holding Wrench

For equivalent regional tools, refer to Special Tools.

- Removal Procedure

-

- Remove the right front wheelhouse liner extension. Refer to Front Wheelhouse Liner Inner Front Extension Replacement

- Install the engine support fixture. Refer to Engine Support Fixture.

- Remove the engine mount bracket. Refer to Engine Mount Bracket Replacement - Right Side.

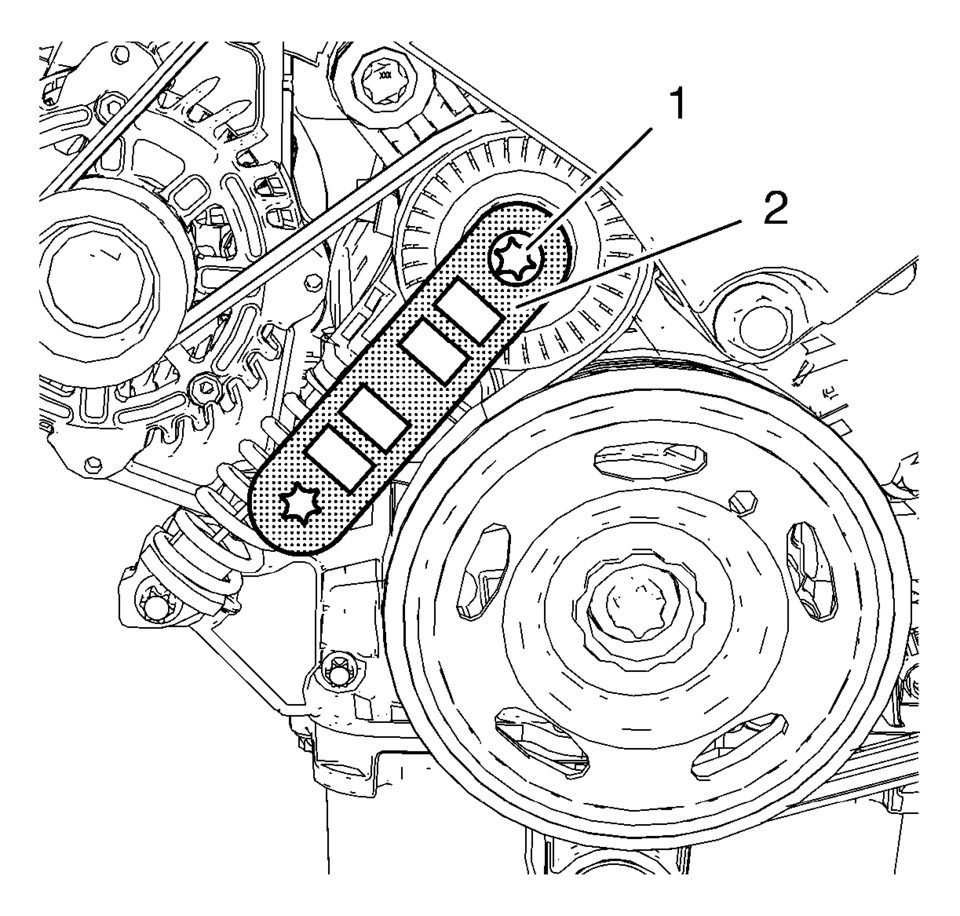

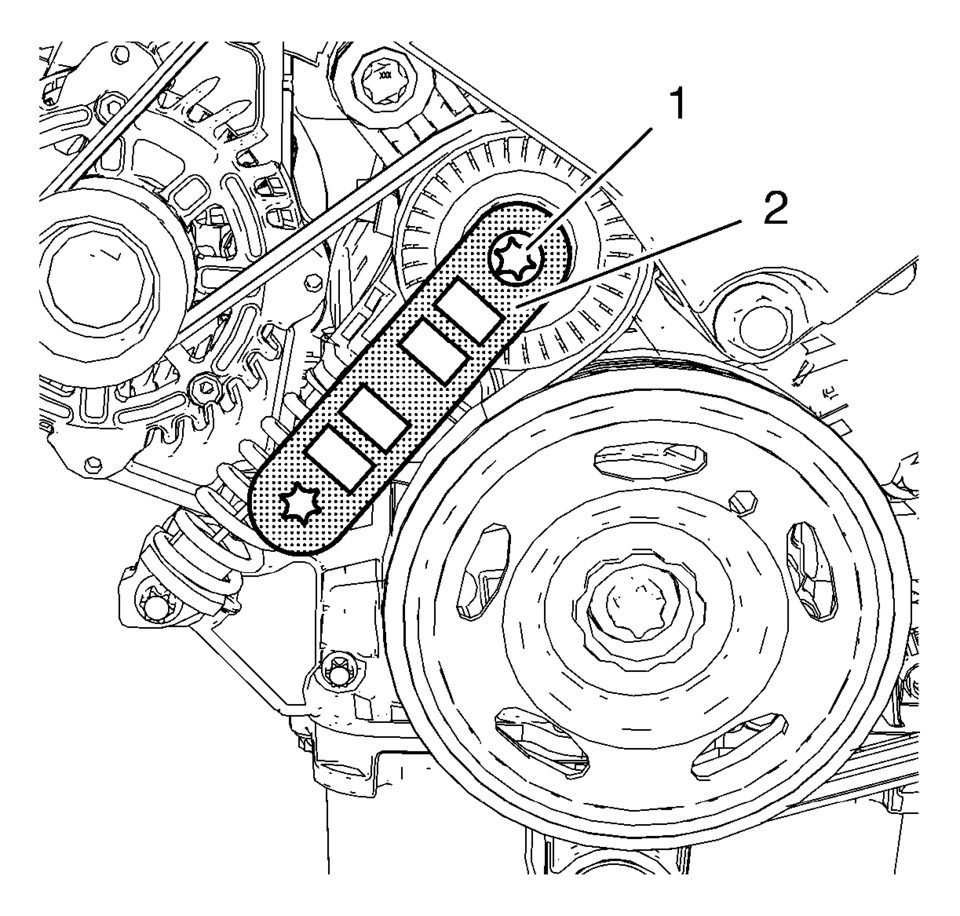

- Install the EN-48488 holding wrench (2) to the drive belt tensioner (1).

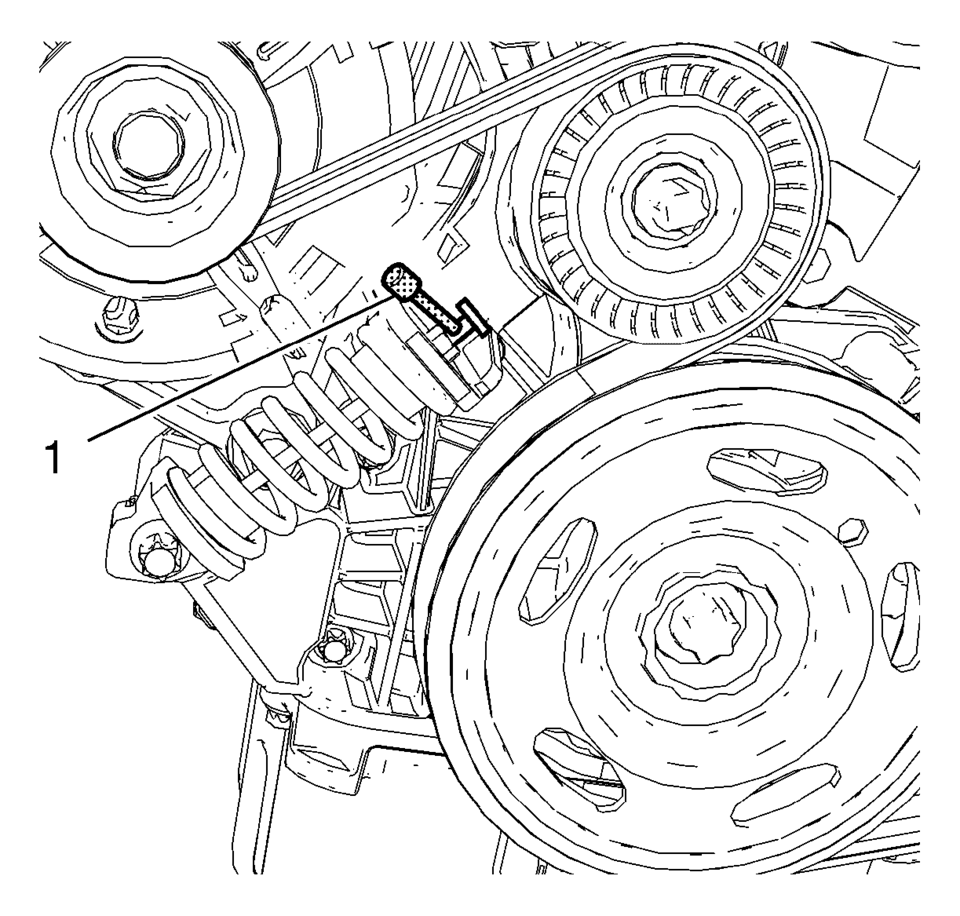

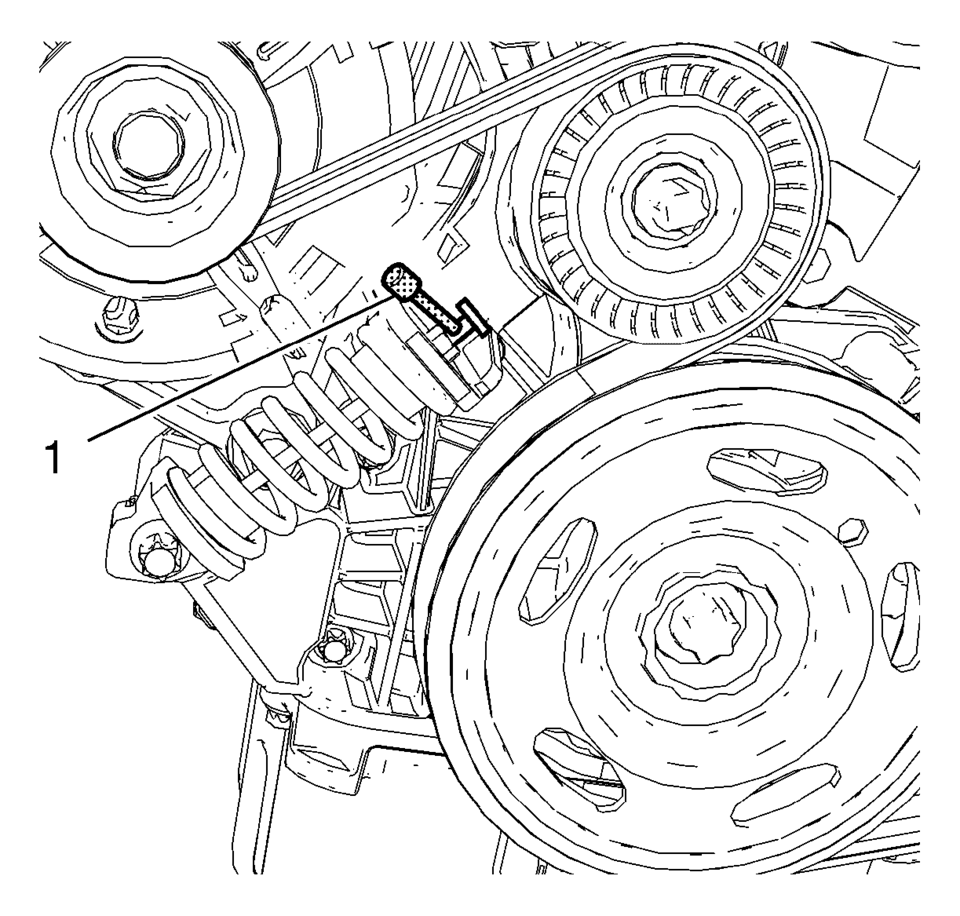

- Move the drive belt tensioner clockwise until the drive belt tensioner can be fixed with EN-955 locking pin (1).

- Remove the EN-48488 holding wrench .

- Remove the drive belt.

- Repeat steps 4 and 5 in order to remove the EN-955 locking pin from the drive belt tensioner.

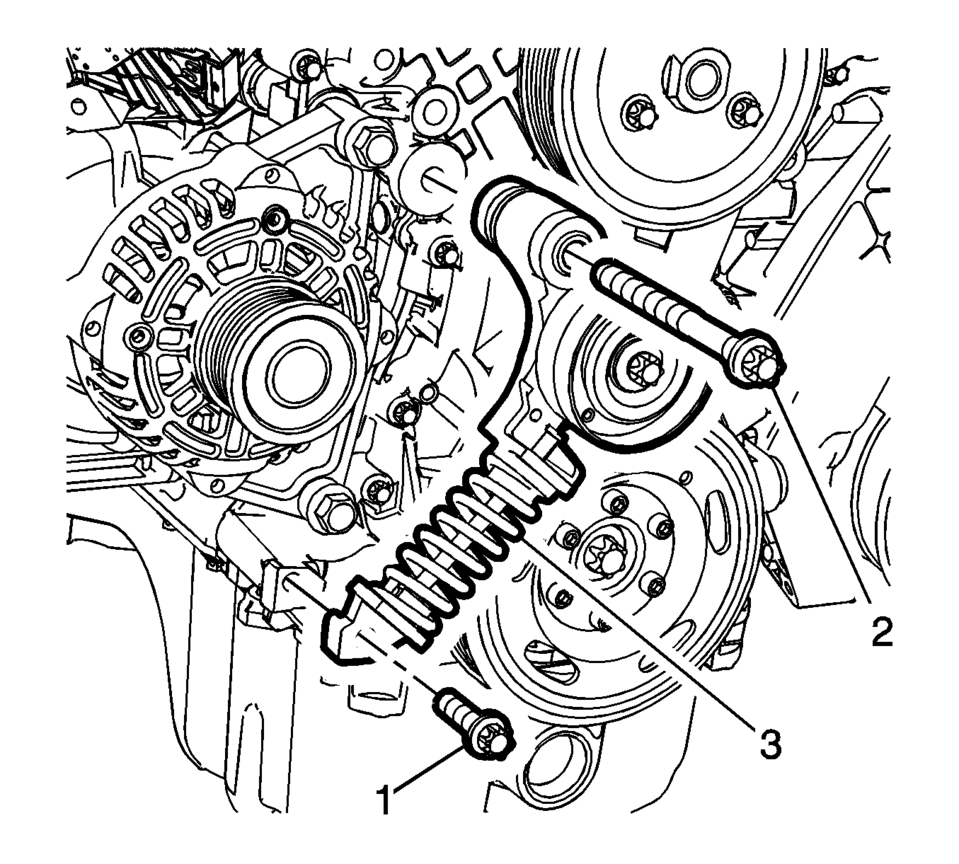

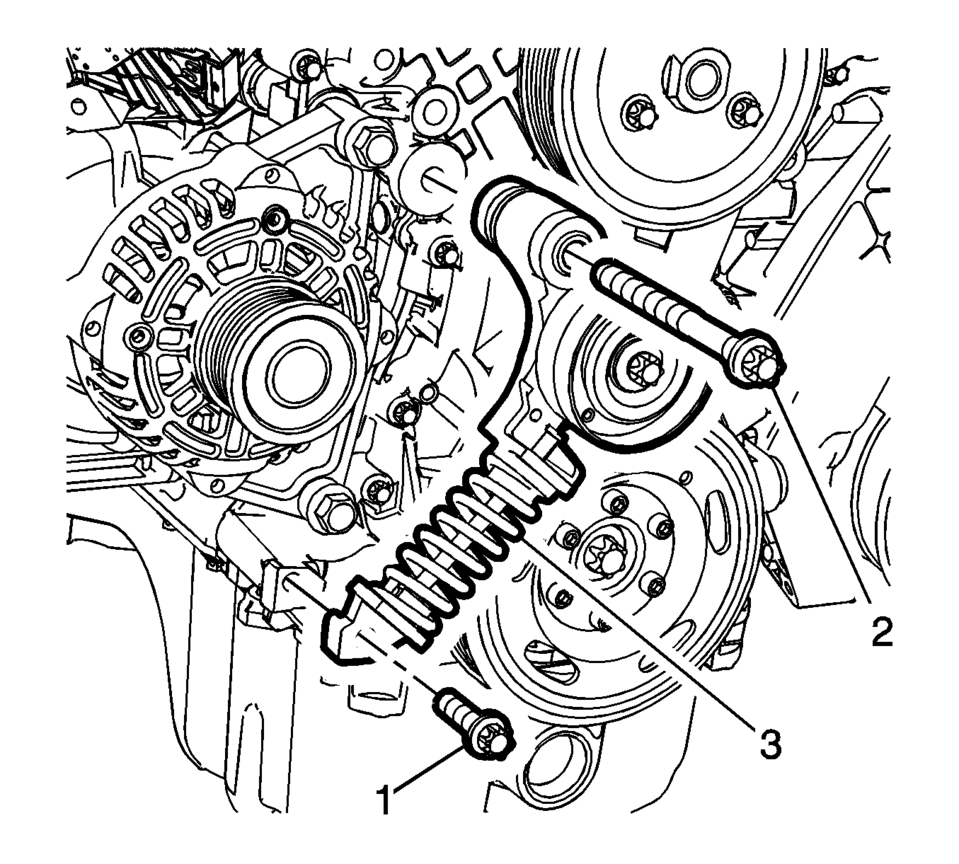

- Remove the lower drive belt tensioner bolt (1).

- Remove the upper drive belt tensioner bolt (2).

- Remove the drive belt tensioner (3).

- Installation Procedure

-

- Install the drive belt tensioner (3).

- Install the lower drive belt tensioner bolt (1).

- Install the upper drive belt tensioner bolt (2).

- Tighten the lower drive belt tensioner bolt (1) to 22 Y (16 lb ft)

.

- Tighten the upper drive belt tensioner bolt (2) to 55 Y (41 lb ft)

.

- Install the EN-48488 holding wrench (2) to drive belt tensioner (1).

- Move the drive belt tensioner clockwise until the drive belt tensioner can be fixed with EN-955 locking pin (1).

- Install the drive belt.

- Move the drive belt tensioner clockwise until EN-955 locking pin can be removed.

- Allow the tensioner to slide back slowly.

- Remove the EN-48488 holding wrench .

- Install the engine mount bracket. Refer to Engine Mount Bracket Replacement - Right Side.

- Install the right front wheelhouse liner extension. Refer to Front Wheelhouse Liner Inner Front Extension Replacement.

- Remove the engine support fixture. Refer to Engine Support Fixture.

Caution:

Refer to Fastener Caution.

Note:

Engine mount bracket is removed.

Drive Belt Tensioner Removal

Drive Belt Tensioner Removal

Remove the drive belt tensioner bolt (1).

Remove the drive belt tensioner (2).

...

Drive Belt Installation

Drive Belt Installation

Special Tools

EN-955 Locking Pins

EN-48488 Holding Wrench

For equivalent regional tools, refer to Special Tools.

Note: Ensure that the drive belt tensioner is held with EN-955?E

...

Other materials:

Recreational Vehicle Towing

Recreational vehicle towing means towing the vehicle behind another vehicle,

such as a motor home. The two most common types of recreational vehicle towing are

known as dinghy towing and dolly towing. Dinghy towing is towing the vehicle with

all four wheels on the ground. Dolly towing is towin ...

Ambient Air Temperature Sensor Replacement

\/\\//\\\\(in

Ambient Air Temperature Sensor Replacement

Callout

Component Name

Preliminary Procedures

Raise and support the vehicle. Refer to Lifting and Jacking the

Vehicle.

Remove the front bumper fascia opening lower c ...

Power Steering Pump Belt Installation

Special Tools

EN-50098 Belt Installer

For equivalent regional tools, refer to Special Tools.

Install EN-50098 installer (2) and a NEW power steering pump belt (1)

to water pump pulley and power steering pump pulley.

Turn the engine slowly clockwise at the crankshaft ...

0.0064