Chevrolet Sonic Repair Manual: Engine Flywheel Replacement

|

Callout |

Component Name |

|---|---|

|

Preliminary Procedure

Remove the clutch pressure and driven Plate . Refer to Clutch Pressure and Driven Plate Replacement. Special Tools

For equivalent regional tools. Refer to Special Tools. |

|

|

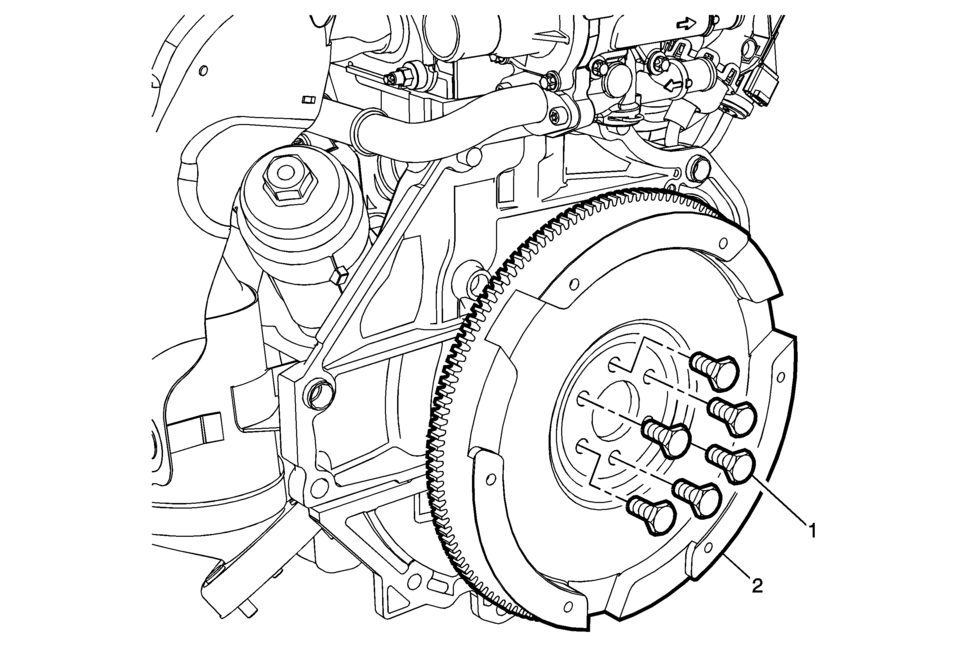

1 |

Flywheel Fastener (Qty: 6) Caution: Refer to Fastener Caution. Procedure

Discard the flywheel fastener and use a NEW fastener for installation. Tighten

|

|

2 |

Flywheel Procedure

Inspect the engine flywheel for the following:

|

Engine Flywheel Removal

Engine Flywheel Removal

Special Tools

EN-652 Flywheel Holder

For equivalent regional tools, refer to Special Tools.

Install EN-652 holder (1) to hold the engine flywheel (2).

Remove an ...

Engine Identification

Engine Identification

Engine Number

Note: The engine identification number must be stamped to the

cylinder block in case of engine replacement.

The engine number is stamped to the engine blockR ...

Other materials:

Headlamp High/Low-Beam Changer

(Headlamp High/Low-Beam Changer):

Push the turn signal lever away from you to turn the high beams on.

Push the lever again or pull the lever toward you to return to low beams.

This indicator light turns on in the instrument cluster when the high-beam headlamps

are on. ...

Radio/Audio System Description and Operation

The entertainment system on this vehicle may have several different configurations

available to it. To determine the specific configuration of the vehicle, please

see the Service Parts ID Label, and refer to RPO Code List.

Each item in the list below represents topics covered in detail below. ...

Front Side Door Lock Cylinder Coding (Non Free Wheeling)

The door lock cylinder uses 8 of the 8 cut positions. The tumbler positions are

staggered from side to side, 4 on one side and 4 on the other, are not self-retaining,

and are not snap in.

Note: All lock cylinders for side milled keys have right and left

tumblers. The locat ...

0.0058