Chevrolet Sonic Repair Manual: Rear End Panel Replacement

- Removal Procedure

-

- Disable the SIR System. Refer to SIR Disabling and Enabling.

- Disconnect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Remove all related panels and components.

- Visually inspect the damage. Repair as much of the damage as possible.

- Remove the sealers and anti-corrosion materials from the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Locate and mark all the necessary factory welds of the body rear end panel.

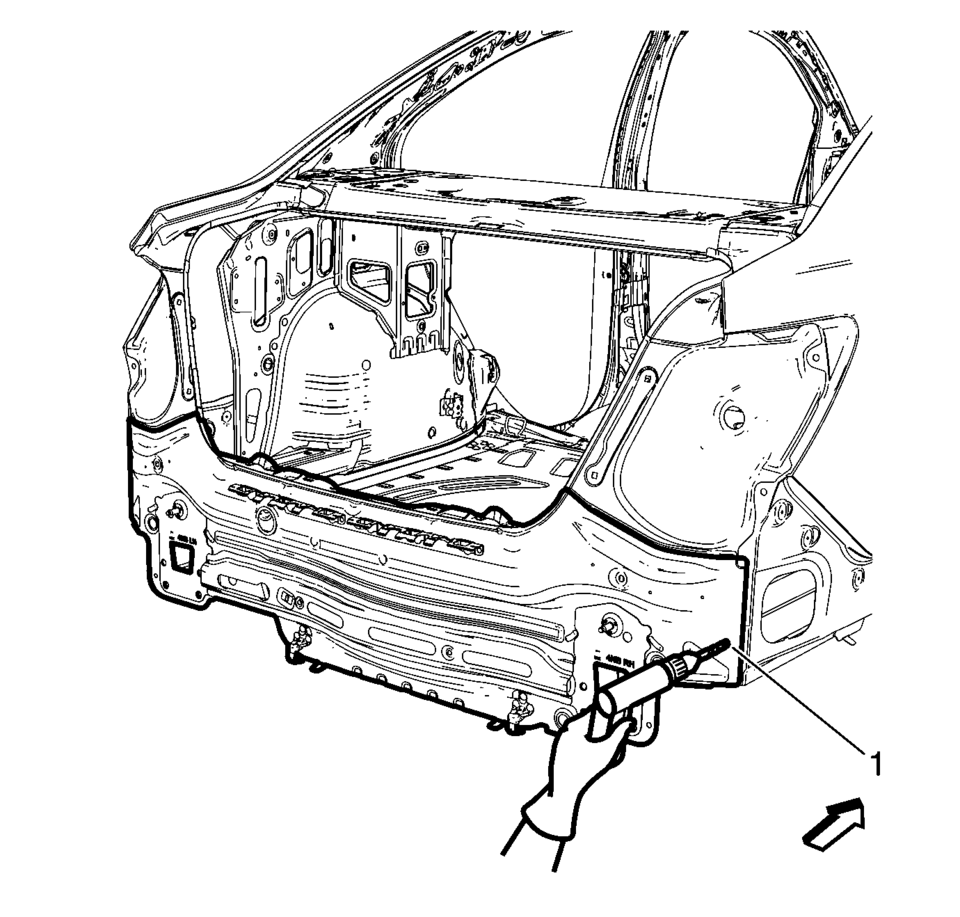

- Drill all factory welds (1).

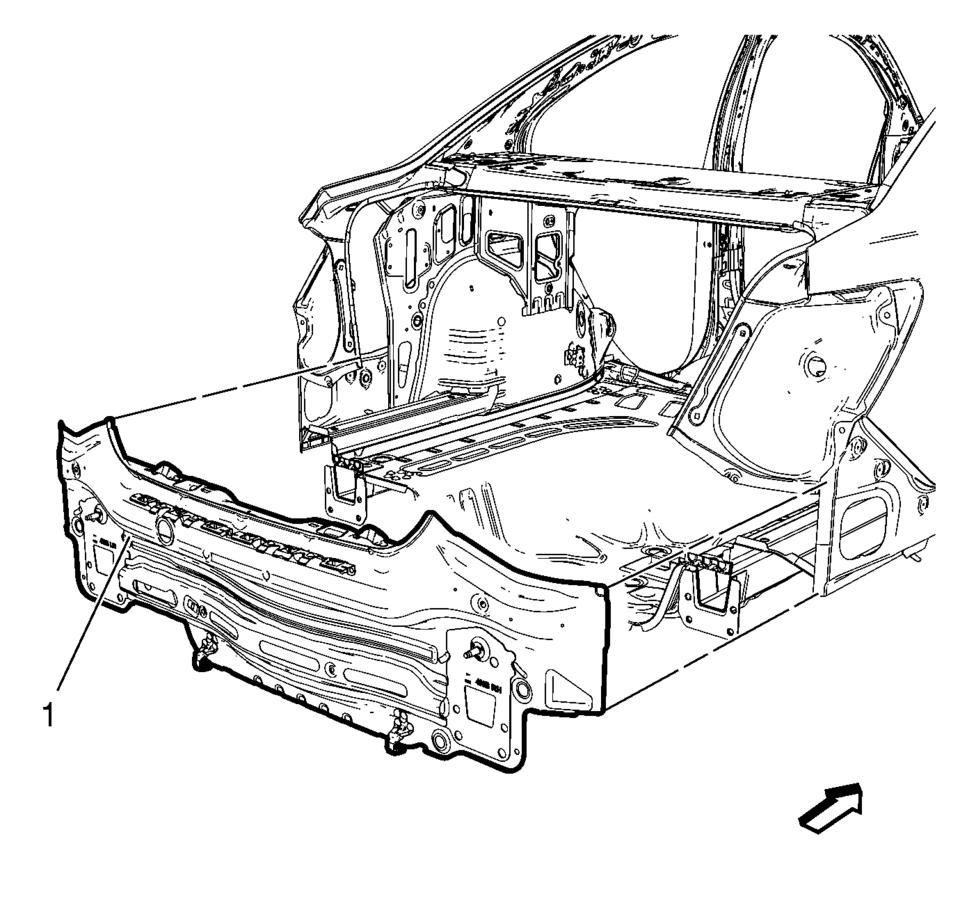

- Remove the body rear end panel (1).

Warning:

Refer to Approved Equipment for Collision Repair Warning.

Warning:

Refer to Glass and Sheet Metal Handling Warning.

Note:

The rear end lower panel reinforcement extension is made of Ultra High Strength Dual Phase Steel and should be replaced only at factory joints. Repairing or sectioning of this part is not recommended. Refer to Ultra High Strength Dual Phase Steel.

Note:

Note the number and location of welds for installation of the service assembly.

- Installation Procedure

-

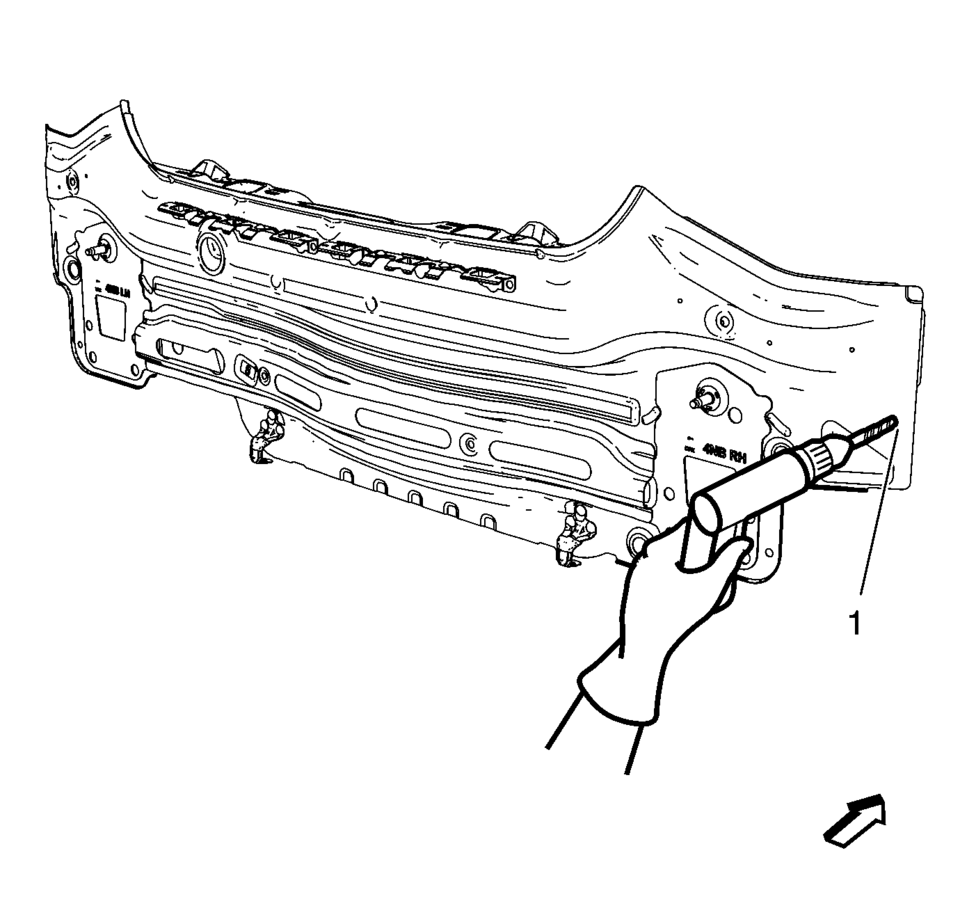

- Drill 8?€‰mm (5/16?€‰in)

holes for plug welding along the edges of the body rear end panel (1) as noted from the original panel.

- Clean and prepare the attaching surfaces for welding.

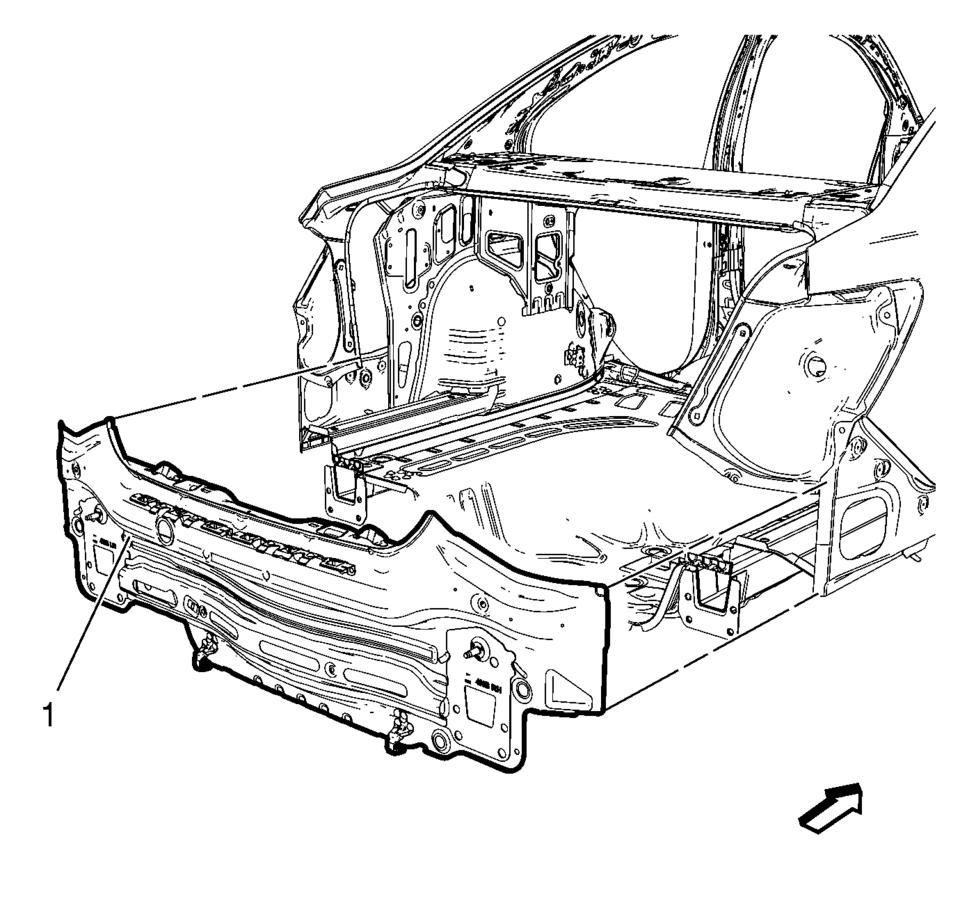

- Position the body rear end panel on the vehicle (1).

- Verify the fit of the body rear end panel.

- Clamp the body rear end panel into position.

- Plug weld accordingly.

- Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Paint the repaired area. Refer to Basecoat/Clearcoat Paint Systems.

- Install all related panels and components.

- Connect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Enable the SIR system. Refer to SIR Disabling and Enabling.

Note:

If the location of the original plug weld holes can not be determined, space the plug weld holes every 40?€‰mm (1 1/2?€‰in)

.

- Drill 8?€‰mm (5/16?€‰in)

Front Fender Replacement

Front Fender Replacement

Front Fender Replacement

Callout

Component Name

Preliminary Procedures

Remove the front bumper fascia. Refer to Front Bumper Fascia ...

Roof Panel Joint Finish Molding Replacement

Roof Panel Joint Finish Molding Replacement

Roof Panel Joint Finish Molding Replacement

Callout

Component Name

Caution: Refer to Exterior Trim Emblem Removal Caution.

...

Other materials:

Front Wheel Bearing and Hub Replacement

Special Tools

CH-50559 Wheel Hub/Bearing Remover Kit

For equivalent regional tools, refer to Special Tools.

Removal Procedure

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the steering knuckle assembly from the vehicle. Refer to Steering

...

Cooling Fan Description and Operation (LWE, LUW)

System Overview

The engine cooling fan system is composed of one cooling fan, 2 relays, the engine

control module (ECM), and the associated wiring. The cooling fan assembly includes

1 resistor mounted in the cooling fan shroud. The cooling fan resistor may be a

stand alone compon ...

Reverse (Gen 2)

When the gear selector lever is moved to the Reverse (R) position (from the Park

position) the normally-low 35R pressure control solenoid is commanded ON and the

following changes occur in the transmission? hydraulic and electrical systems:

3-5-Reverse Clutch Applies

Manual Valve

...

0.0068