Chevrolet Sonic Repair Manual: Synchronizers Cleaning and Inspection

- Clean all the synchronizer parts in a suitable cleaning solvent and air dry all the parts.

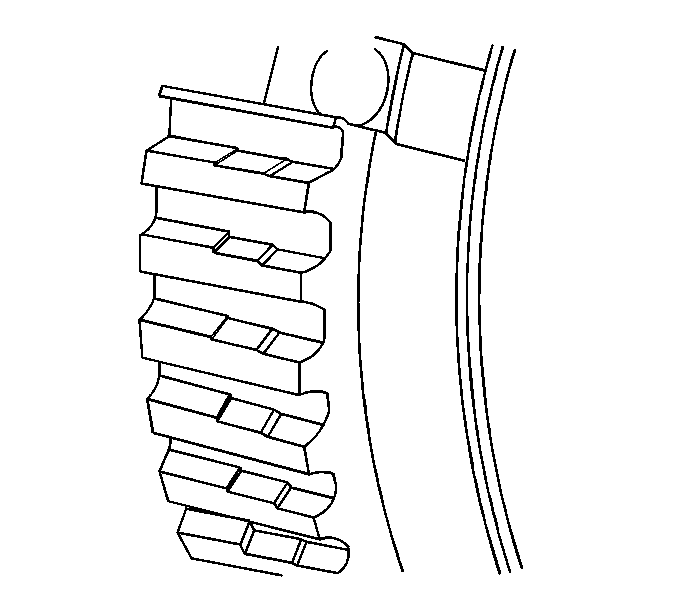

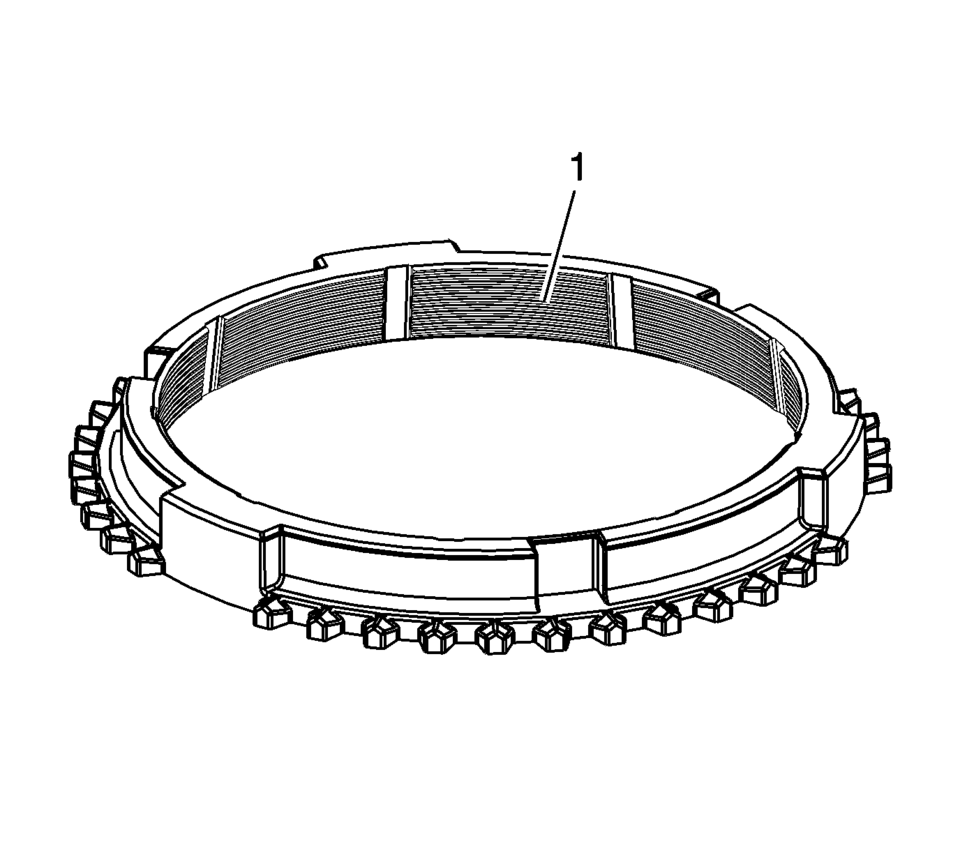

- Inspect the 1st/2nd gear, 3rd/4th gear, and 5th gear synchronizer hubs for a force fit on the main shaft.

- Replace synchronizer hubs that do not require a force fit.

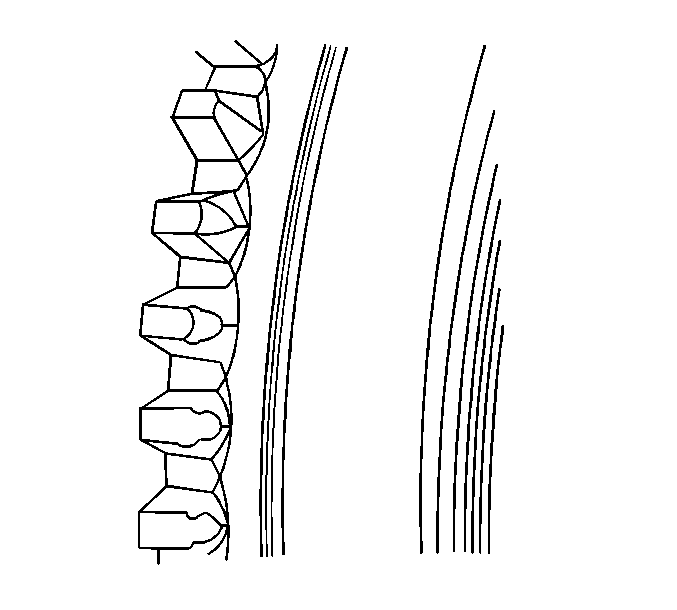

- Inspect the synchronizer hubs for wear on the external splines. A stepped effect on the teeth, due to wear, may cause shift concerns.

- Replace a worn hub.

- Correct the cause, such as, but not limited to the following conditions:

Note:

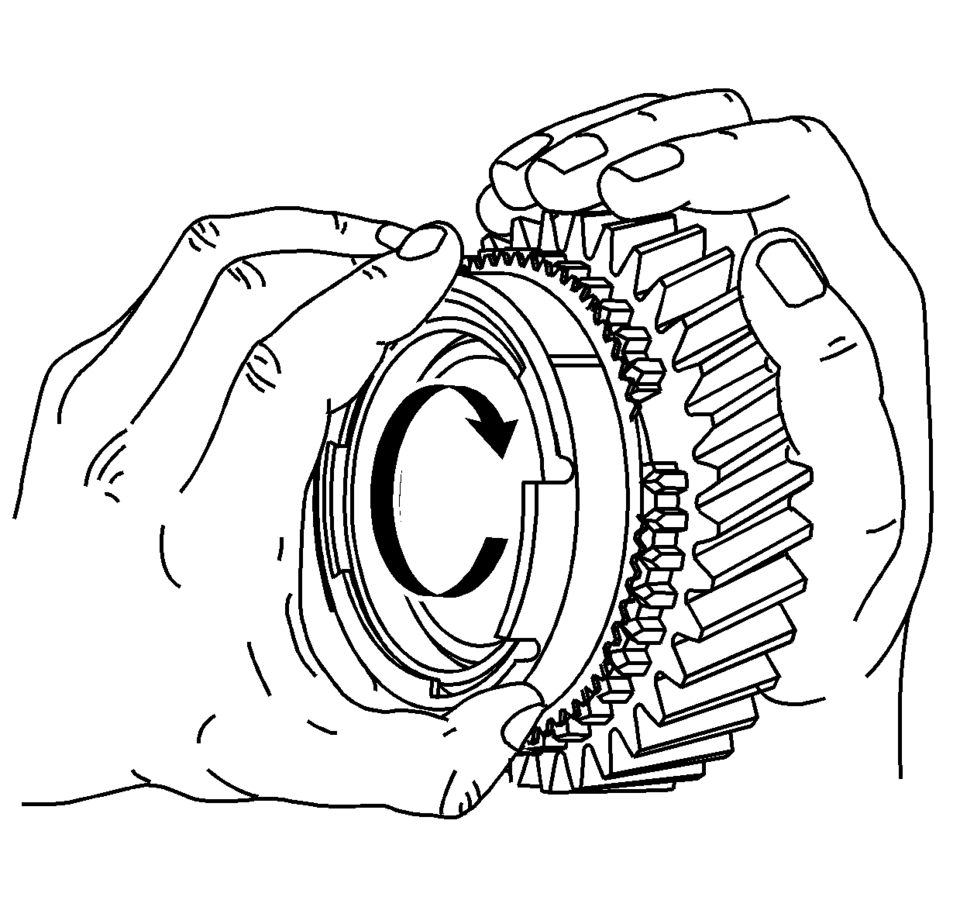

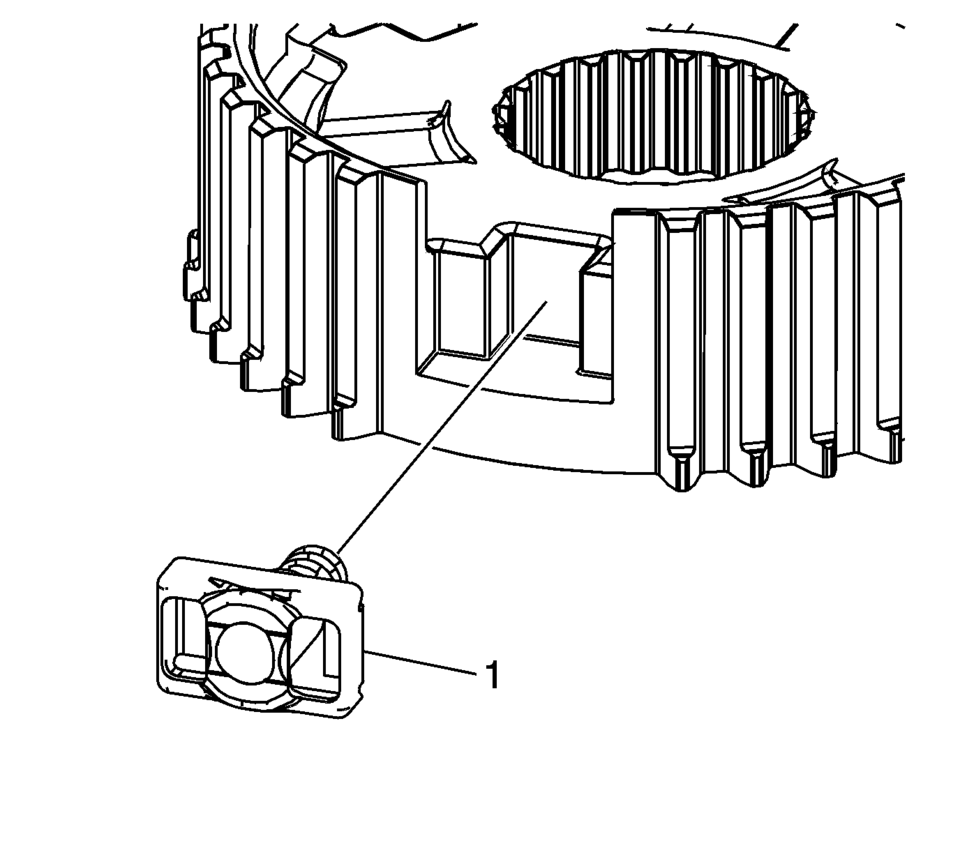

When servicing the synchronizers, retain them in the order that they are removed. Mark the parts to ensure the correct position for inspection and assembly.

- Engine related vibrations

- Driving at a low speed in a high gear

- Defective vibration damper or crankshaft

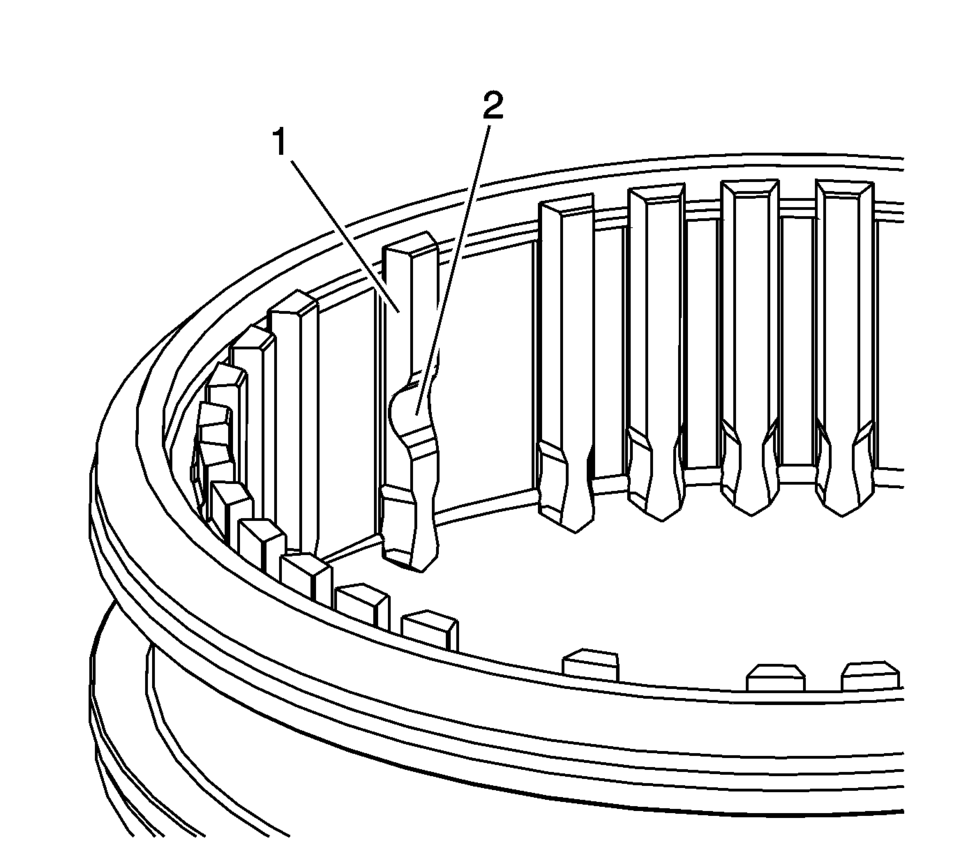

- Grated teeth

- Chipped off teeth

- Blunted teeth

Synchronizers Assemble

Synchronizers Assemble

1st/2nd Gear Synchronizer

iv

Note: When servicing the synchronizers, retain them in the

same order that they are removed. Keep the synchronizer components together

...

Synchronizers Disassemble

Synchronizers Disassemble

1st/2nd Gear Synchronizer

iv

Note: When servicing the synchronizers, retain them in the

same order that they are removed. Keep the synchronizer components together

...

Other materials:

Engine Exhaust

Warning

Engine exhaust contains carbon monoxide (CO) which cannot be seen or smelled.

Exposure to CO can cause unconsciousness and even death.

Exhaust may enter the vehicle if:

. The vehicle idles in areas with poor ventilation (parking garages,

tunnels, deep snow that may block underbody ...

Special Tools

Illustration

Tool Number/Description

BO-49385

BO-6626

KM-6626

S0201912

Wiper Arm Puller

...

Fuel Pump Flow Control Module Replacement

Fuel Pump Flow Control Module Replacement

Callout

Component Name

Preliminary Procedures

Disconnect the battery negative cable. Refer to

Battery Negative Cable Disconnection and Connection.

Remove the right rear compart ...

0.0082