Chevrolet Sonic Repair Manual: Camshaft Installation

Special Tools

EN-422 Installer

For equivalent regional tools, refer to Special Tools.

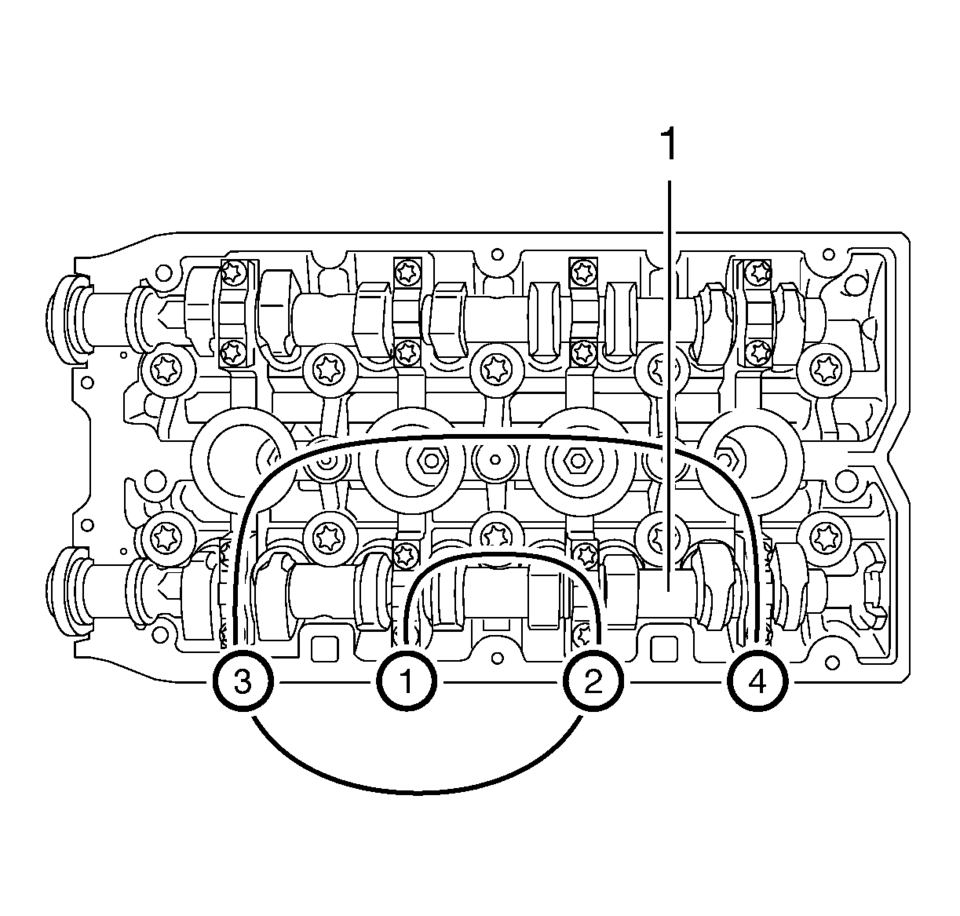

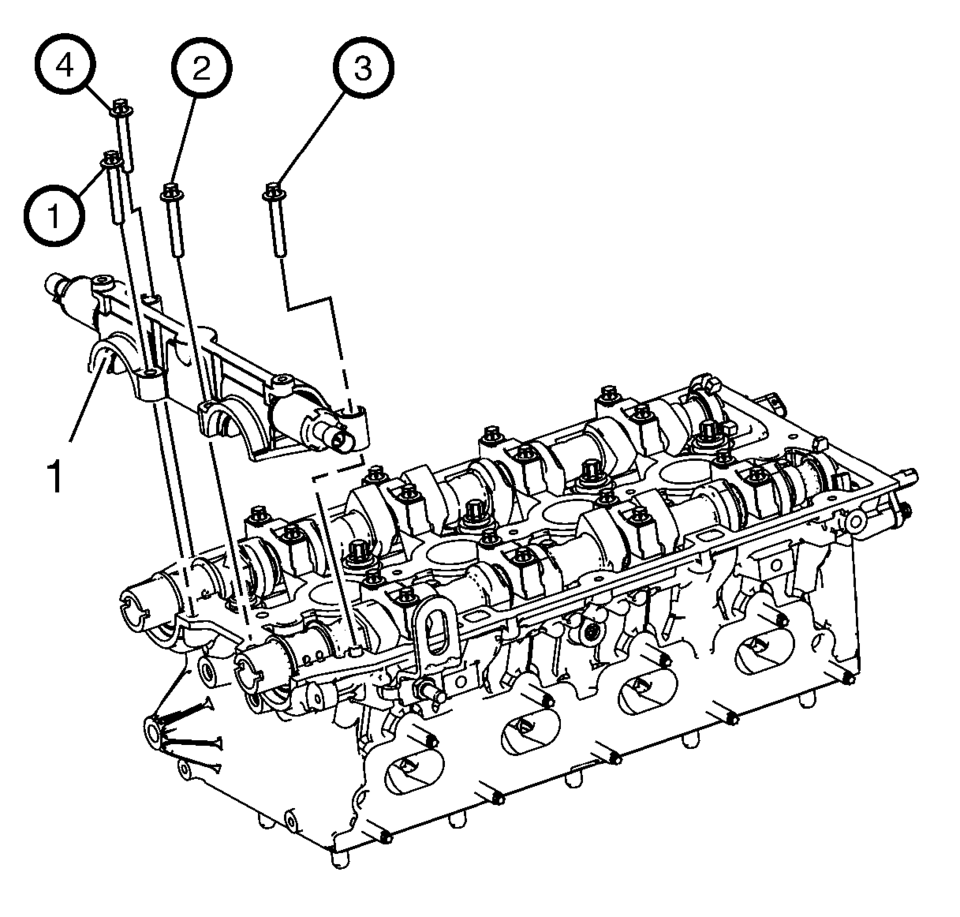

- Install the intake camshaft (1).

- Install the 4 intake camshaft bearing cover number 2-5.

- Install the 8 intake camshaft bearing cover bolts and tighten in a spiral

from the inside to the outside to 8 Y (71 lb in)

.

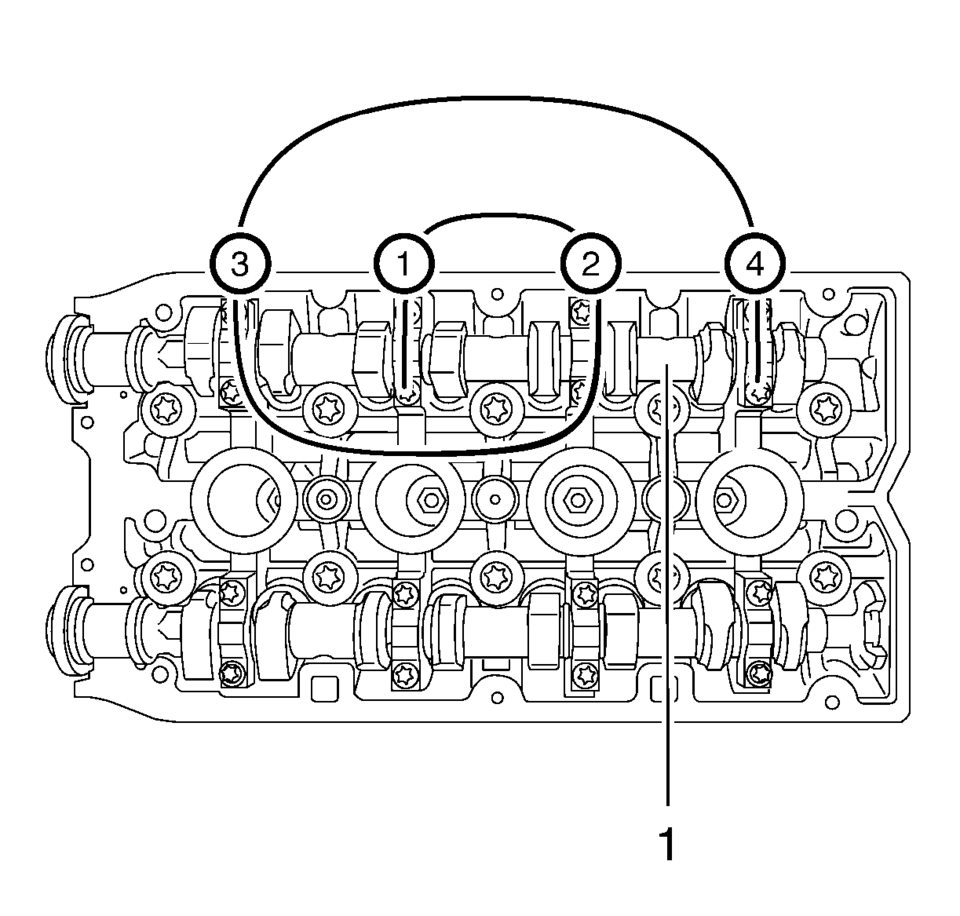

- Install the exhaust camshaft (1).

- Install the 4 exhaust camshaft bearing cover number 6-9.

- Install the 8 exhaust camshaft bearing cover bolts and tighten in a spiral

from the inside to the outside to 8 Y (71 lb in)

.

- Clean sealing surfaces of the first camshaft bearing support and the cylinder

head with a suitable tool.

Clean oil duct from any sealant residue.

Note:

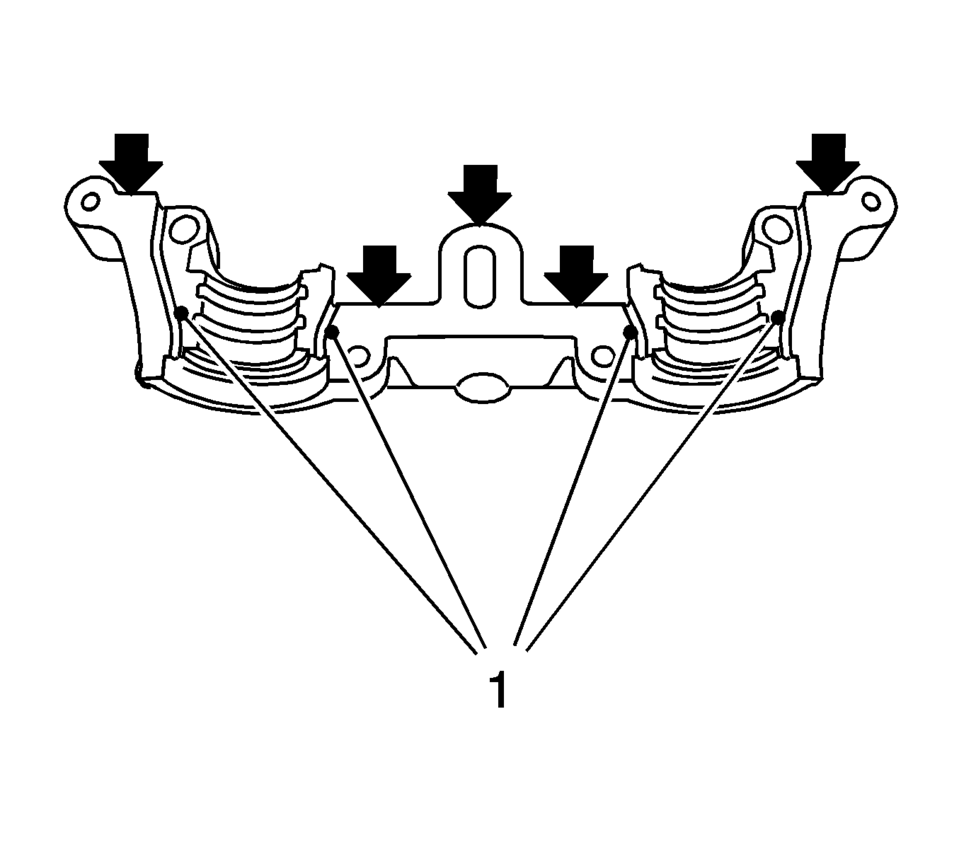

- Sealing surfaces (arrows) must be free from oil and grease.

- It is essential to ensure that no sealant is applied outside the marked sealing areas (1).

- The grooves adjacent to the sealing surfaces must remain free from sealant.

- Apply surface sealant to sealing surfaces of the first camshaft bearing cap thinly and evenly.

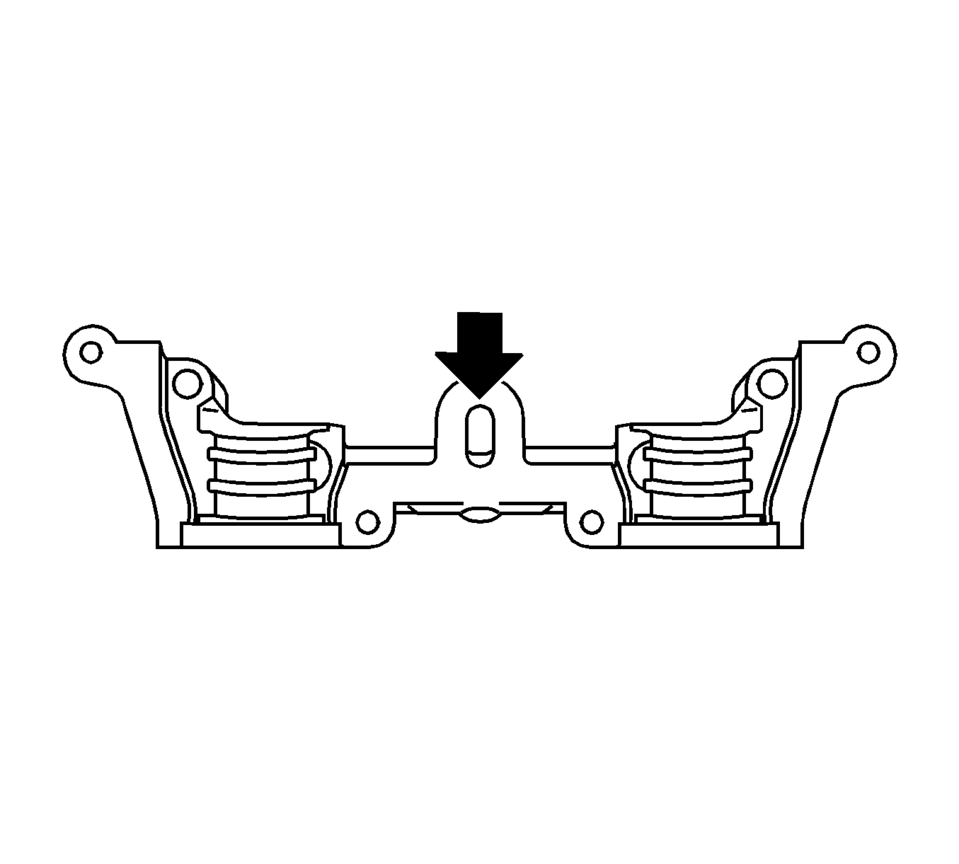

- Position the first camshaft bearing cap on the cylinder block and tighten

the bolts approximately to 2 Y (18 lb in)

.

- Install the first camshaft bearing cap.

- Install the first camshaft bearing cap (1) bolts and tighten to 8 Y (71 lb in)

.

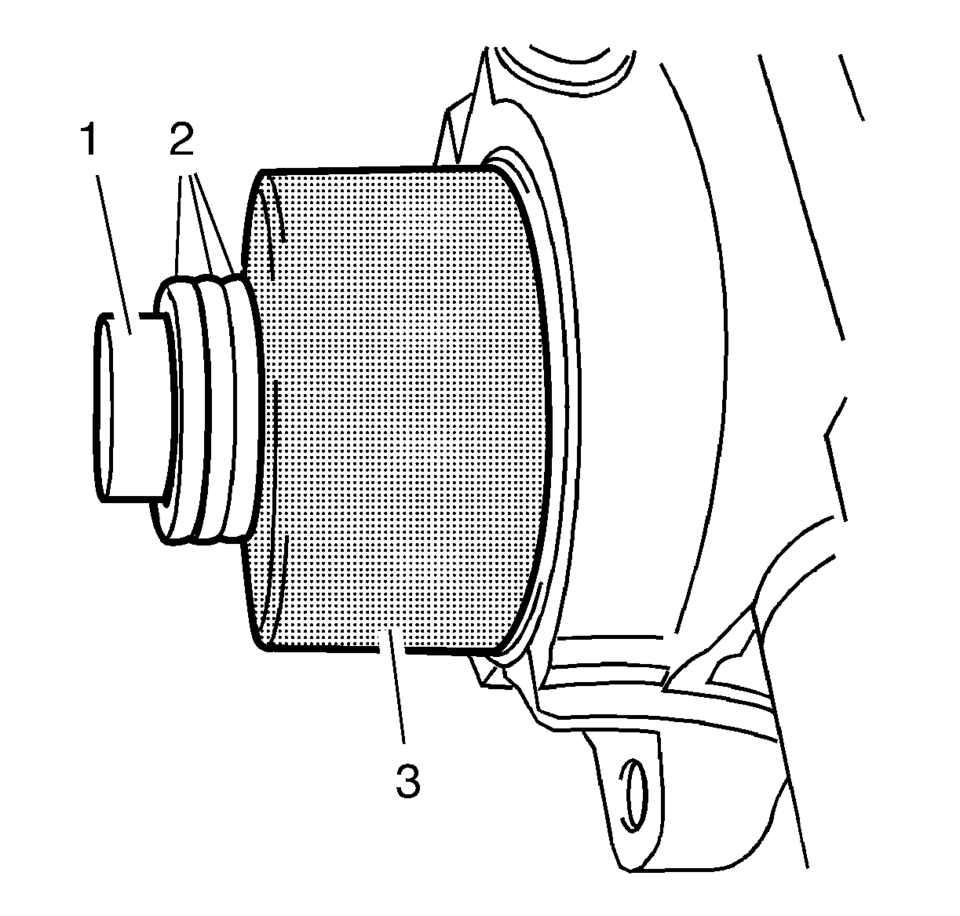

- Install 2 NEW sealing rings to the camshafts.

- Tighten the seal ring with EN-422 installer (3) on the camshaft until this is in contact with the cylinder head.

- To install, use camshaft sprocket bolt (1) in conjunction with shims (2) with a total thickness of approximately 10 mm.

- Remove the EN-422 installer (3).

Note:

Coat with MoS 2 lubricating paste. Refer to Adhesives, Fluids, Lubricants, and Sealers.

Note:

Note the identification marking on the camshaft bearing cover.

Caution:

Refer to Fastener Caution.

Note:

Coat with MoS 2 lubricating paste. Refer to Adhesives, Fluids, Lubricants, and Sealers.

Note:

Note the identification marking on the camshaft bearing cover.

Note:

Sealing surfaces must be free from oil and grease.

Note:

No sealant may reach the camshafts.

Note:

Note installation sequence 1-4.

Camshaft Cover Replacement

Camshaft Cover Replacement

Camshaft Cover Replacement

Callout

Component Name

Preliminary Procedures

Remove the ignition coil. Refer to Ignition Coil Replaceme ...

Camshaft Intake and Exhaust Sprocket Replacement

Camshaft Intake and Exhaust Sprocket Replacement

Special Tools

EN-955-A Locking Pin

For equivalent regional tools, refer to Special Tools.

Removal Procedure

Remove the air cleaner assembly. Refer to Air Cleaner Assembly Replacemen ...

Other materials:

Rear Side Door Check Link Replacement

Rear Side Door Check Link Replacement

Callout

Component Name

Preliminary Procedures

Move the window to the full up position.

Remove the rear side door trim panel. Refer to Rear Side Door Trim

Replacement

...

Basecoat/Clearcoat Paint Systems

Warning: Exposure to isocyanates during paint preparation and application

processes can cause severe breathing problems. Read and follow all of the instructions

from the manufacturers of painting materials, equipment, and protective gear.

All paint finish repairs of rigid exterior sur ...

Front Side Door Window Rear Guide Replacement

Front Side Door Window Rear Guide Replacement

Callout

Component Name

Preliminary Procedure

Remove the front side door trim panel. Refer to Front Side Door Trim

Replacement.

1

Front Side Door Win ...

0.0066