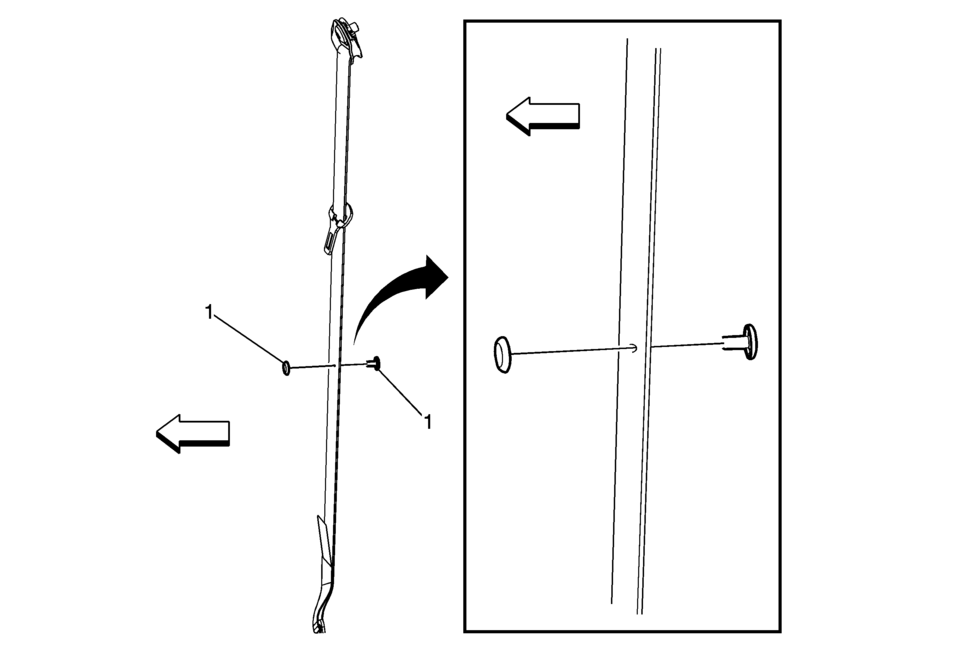

Chevrolet Sonic Repair Manual: Seat Belt Latch Stop Installation

|

Callout |

Component Name |

|---|---|

Preliminary Procedure

|

|

|

1 |

Seat Belt Stop Button Procedure

Tip: Ensure the male half of the stop button is facing forward in the vehicle in order to ensure the stop button will not snag customers clothing. |

Instrument Panel Upper Compartment Door Latch Replacement

Instrument Panel Upper Compartment Door Latch Replacement

Instrument Panel Upper Compartment Door Latch Replacement

Callout

Component Name

1

Instrument Panel Upper Compartment Do ...

Hood Assembly

Hood Assembly

...

Other materials:

Heated Seat Control Module Programming and Setup

The seat heating control module must be programmed with the proper calibration

software. The module stores and utilizes this information however if it is not properly

configured with the correct calibration software, the seat heating control module

will not control all of the vehicle features ...

Front Brake Caliper Bracket Replacement

Removal Procedure

Warning: Refer to Brake Dust Warning.

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the tire and wheel assembly. Refer to Tire and Wheel Removal

and Installation.

Note:

DO NOT use any ai ...

Fastener Tightening Specifications - Wheels

Fastener Tightening Specifications

Application

Specification

Metric

English

Clamp Fit TPM Stem Locknut

7 Y Dynamically

62 lb in

Clamp ...

0.0072