Chevrolet Sonic Repair Manual: Crankshaft and Bearing Installation

Special Tools

EN-45059 Torque Angle Sensor Kit

For equivalent regional tools, refer to Special Tools

- Install the crankshaft bearing clips, oil bearing clips.

- Install the crankshaft.

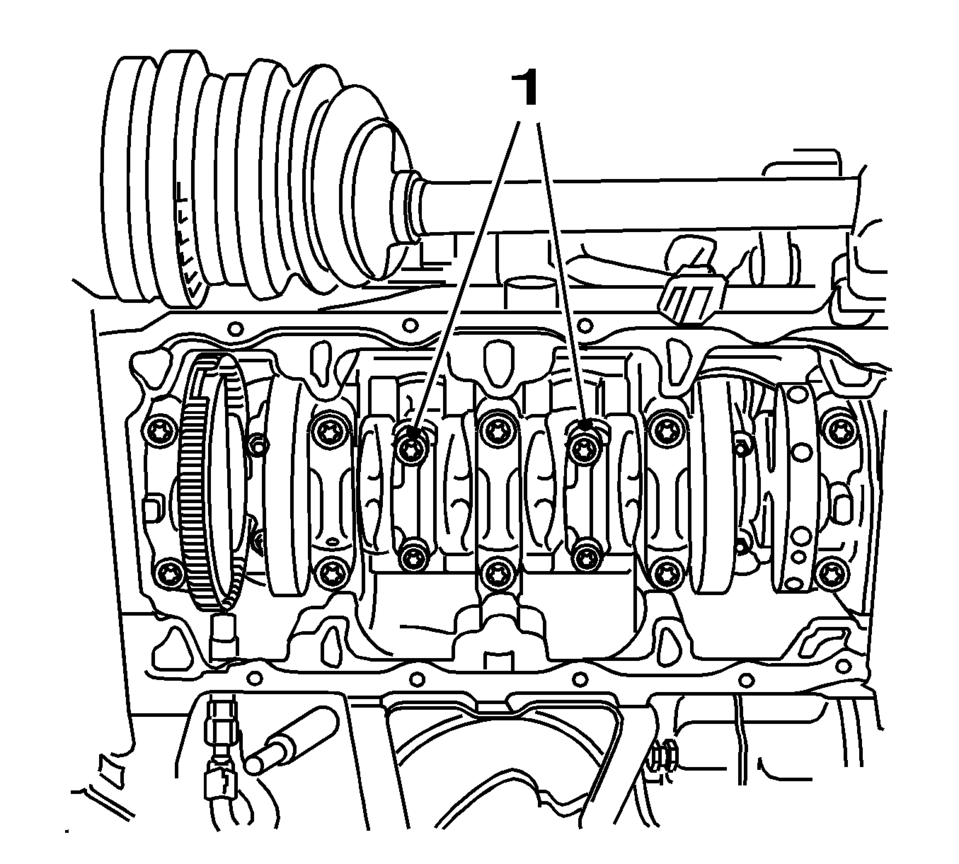

- Install the crankshaft bearing caps 1-4.

Note:

Inspect the installation position.

Note:

Inspect the installation position.

- Oil bearing clips.

- Install the 8 NEW crankshaft bearing cap bolts.

Note:

Inspect the installation position.

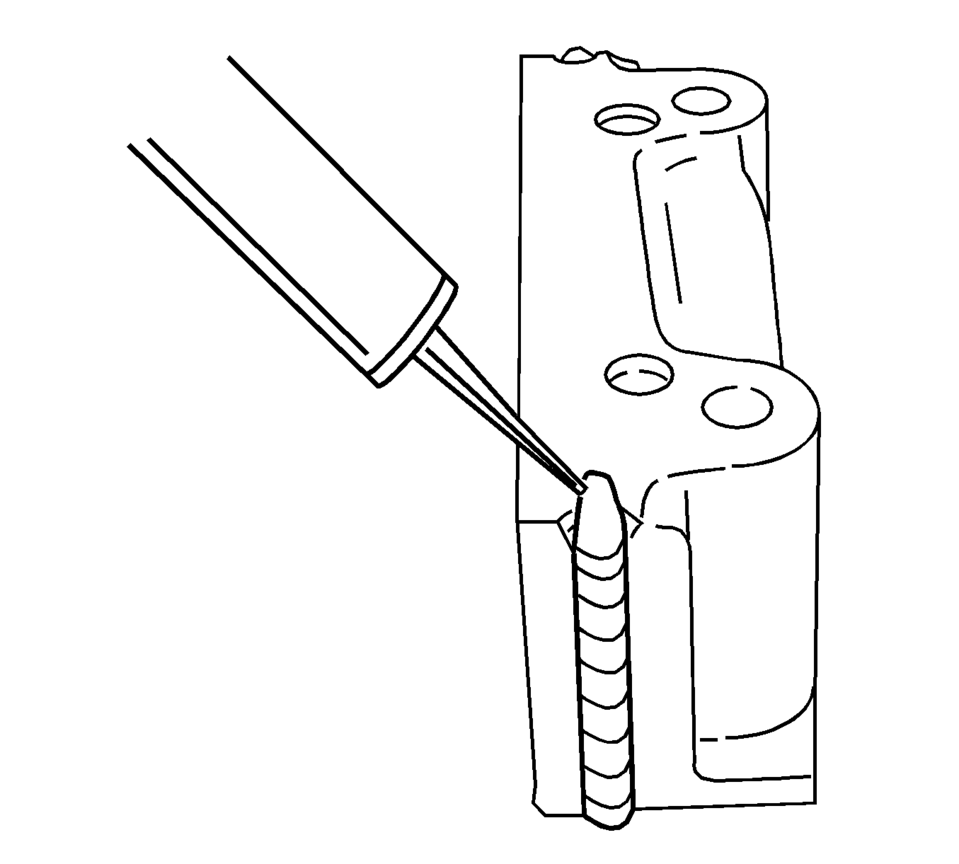

- Apply black adhesive sealing compound to the grooves of the rear crankshaft bearing cap.

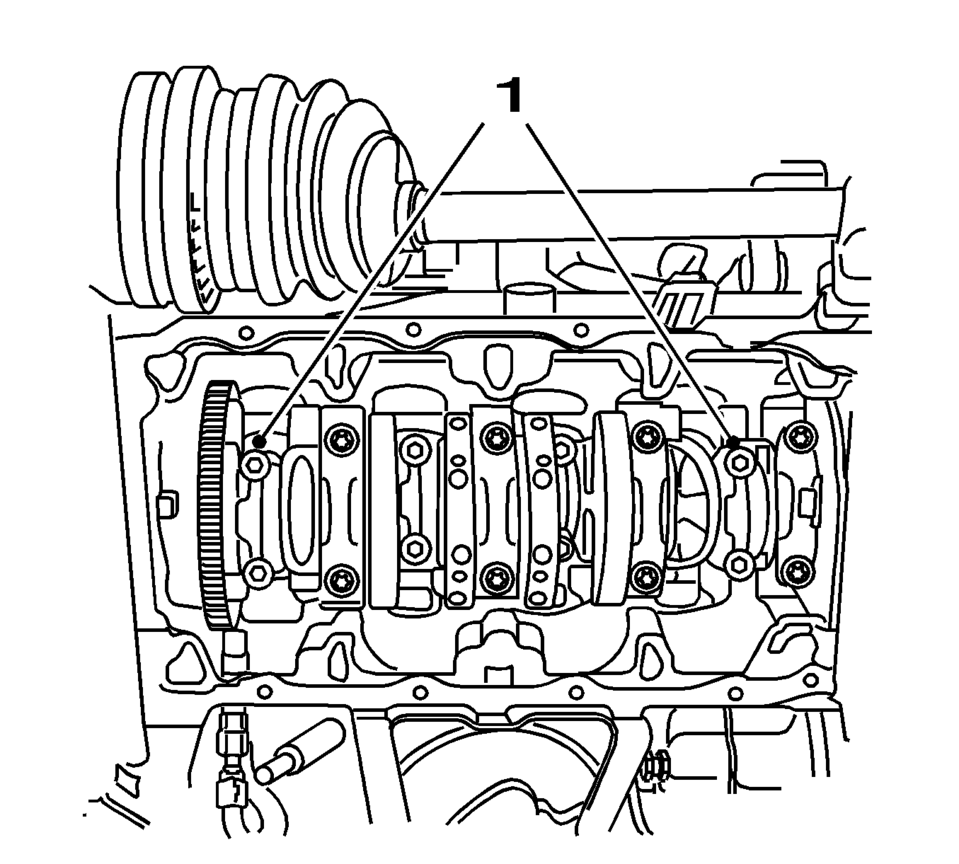

- Install the 2 NEW crankshaft bearing cap bolts.

Caution:

Refer to Fastener Caution.

Caution:

Refer to Torque-to-Yield Fastener Caution.

- First pass to 50 Y (37 lb ft)

- Second pass to 45°

- Third pass to 15°

Note:

Inspect the installation position.

- First pass to 35 Y (26 lb ft)

- Second pass to 45°

- Third pass to 15°

.

Note:

Inspect the installation position.

- First pass to 35 Y (26 lb ft)

- Second pass to 45°

- Third pass to 15°

Crankshaft and Bearing Cleaning and Inspection

Crankshaft and Bearing Cleaning and Inspection

Special Tools

EN-45059 Torque Angle Sensor Kit

GE-571-B Dial Gauge

For equivalent regional tools, refer to Special Tools.

Crankshaft End Play, Check

Note: Cranksha ...

Crankshaft and Bearing Removal

Crankshaft and Bearing Removal

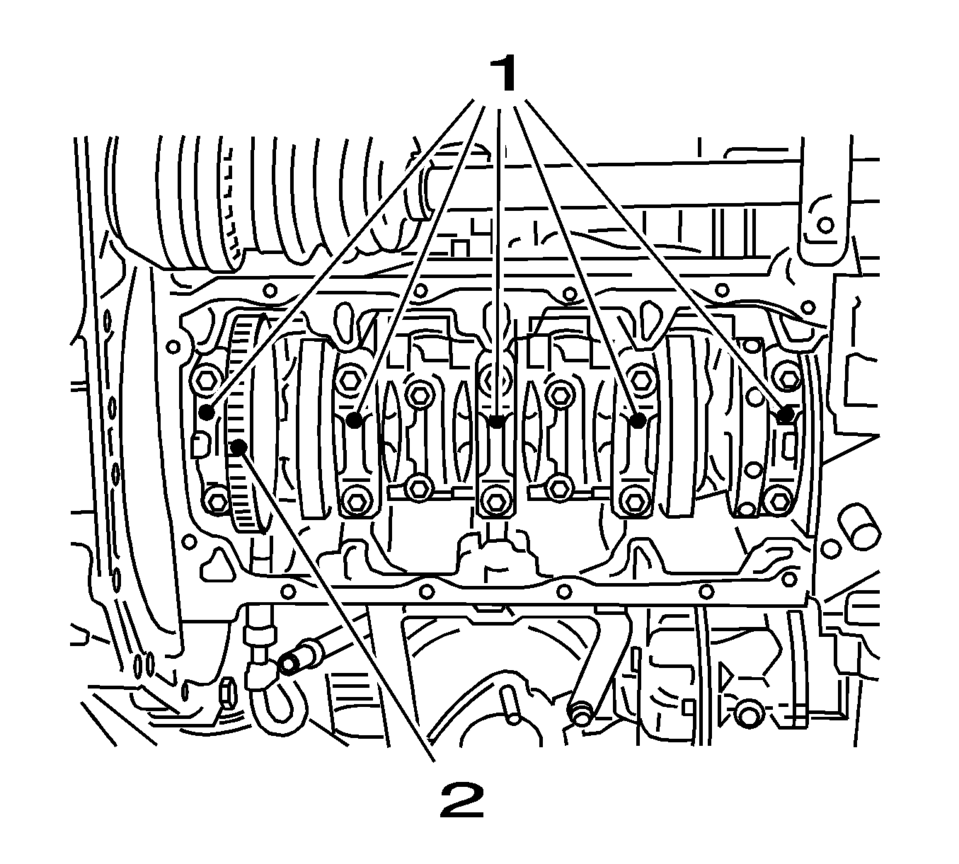

Identify all the connecting rod bearing caps (1).

Remove the 4 bolts.

Remove the connecting rod bearing caps 1 and 4 (1).

Turn the crankshaft through 180 ...

Other materials:

Seat Belt Service Precautions

Note: If the vehicle has been in a collision, refer to Repairs

and Inspections Required After a Collision for additional information.

Do not bleach or dye the seat belt webbing. Use only the following items

in order to clean the seat belt webbing:

A mild soap and water ...

Roof Rear Header Panel Replacement (5HB)

Removal Procedure

Warning: Refer to Approved Equipment for Collision Repair

Warning.

Disable the SIR system. Refer to SIR Disabling and Enabling.

Disconnect the negative battery cable. Refer to Battery Negative Cable

Disconnection and Connection.

Remove all ...

Steering Linkage Outer Tie Rod Inspection

Special Tools

GE-8001 Dial Indicator Set

For equivalent regional tools, refer to Special Tools.

Note: This inspection procedure does not supersede local government

required inspections that have more stringent requirements.

Inspect the outer tie rod seal. If the outer tie rod ...

0.0084