Chevrolet Sonic Repair Manual: Engine Block Cleaning and Inspection

Special Tools

EN-8087 Cylinder Gauge

For equivalent regional tools, refer to Special Tools.

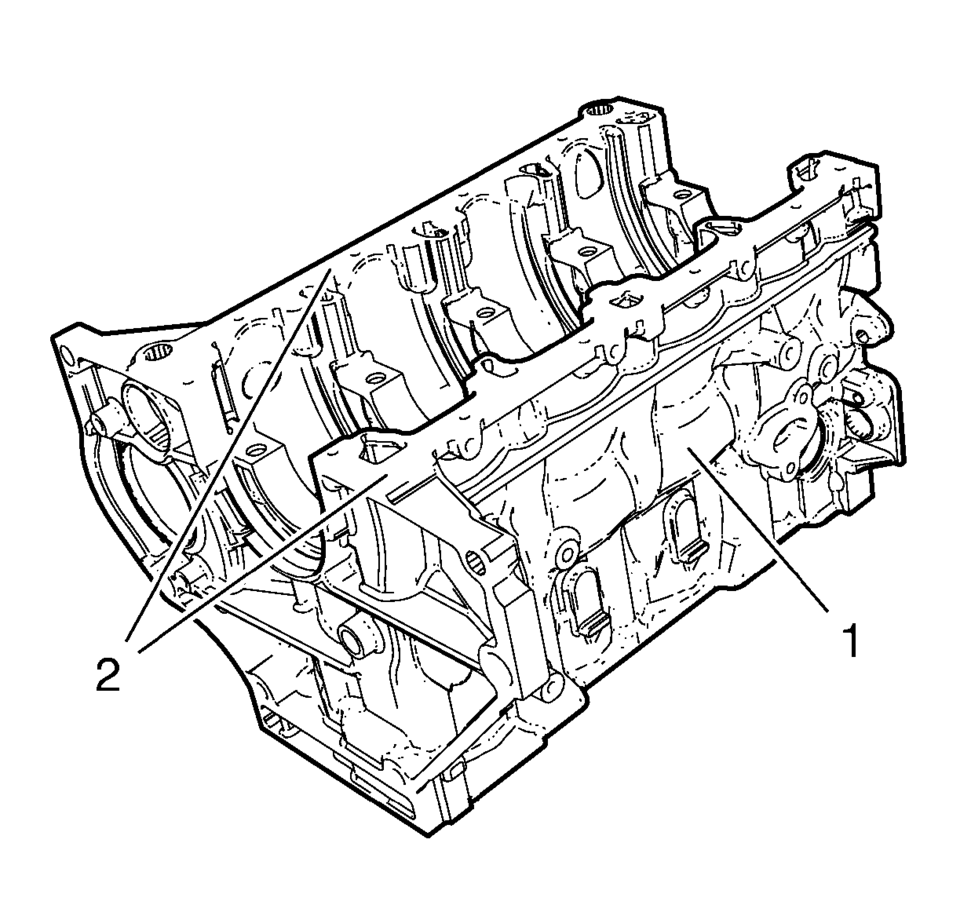

- Clean the sealing material from the gasket mating surfaces (2).

- Clean the engine block (1) and lower crankcase in a cleaning tank with solvent appropriate for aluminum. Refer to Adhesives, Fluids, Lubricants, and Sealers for the recommended solvent.

- Flush the engine block with clean water or steam.

- Clean the oil passages.

- Clean the blind holes.

- Spray the cylinder bores and the machined surfaces with engine oil.

- Inspect the threaded holes. Clean the threaded holes with a rifle brush. If necessary, drill out the holes and install thread inserts. Refer to Thread Inserts.

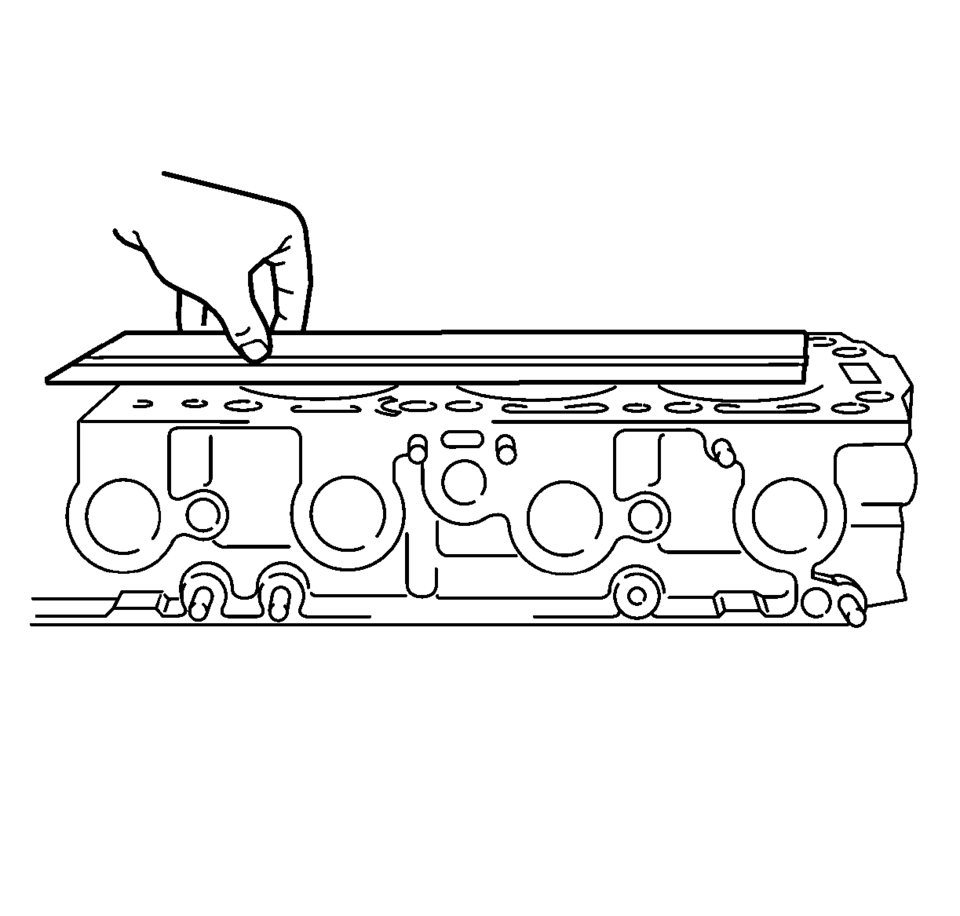

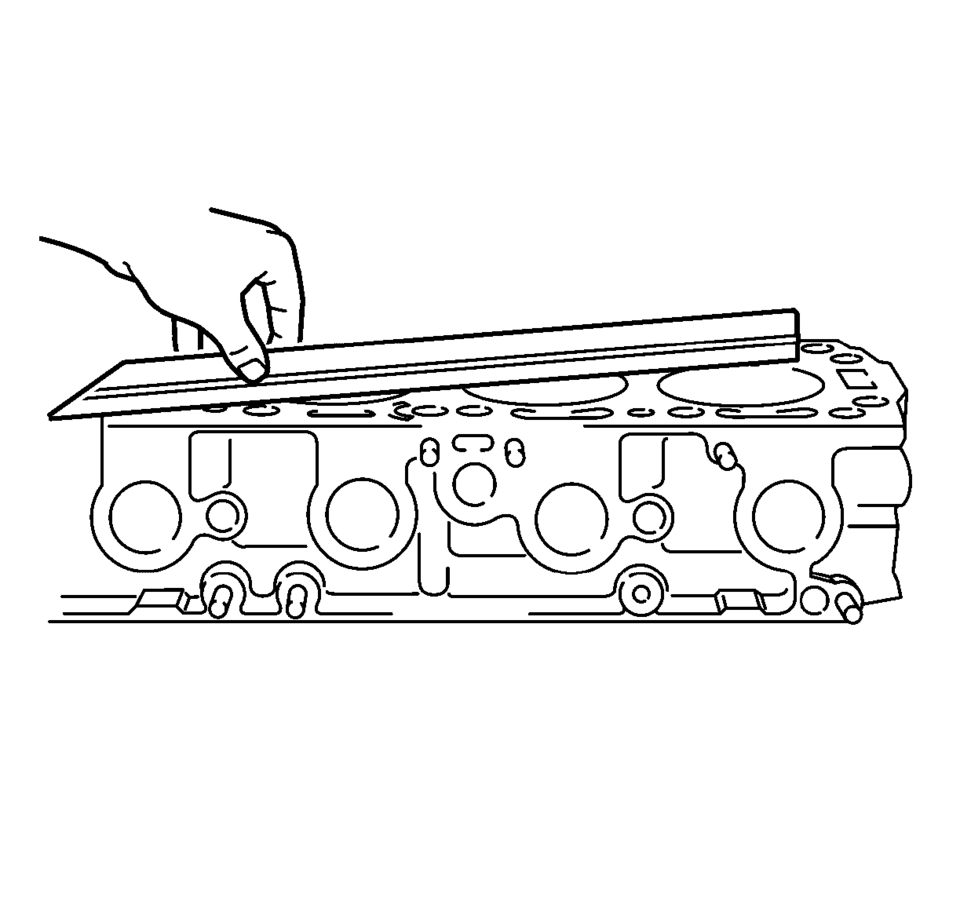

- Inspect the engine block for sag in length and width on the sealing surfaces.

- Inspect the engine block for distortion along the diagonals.

If the deck surface is out of specification, replace the block. Do not machine the block.

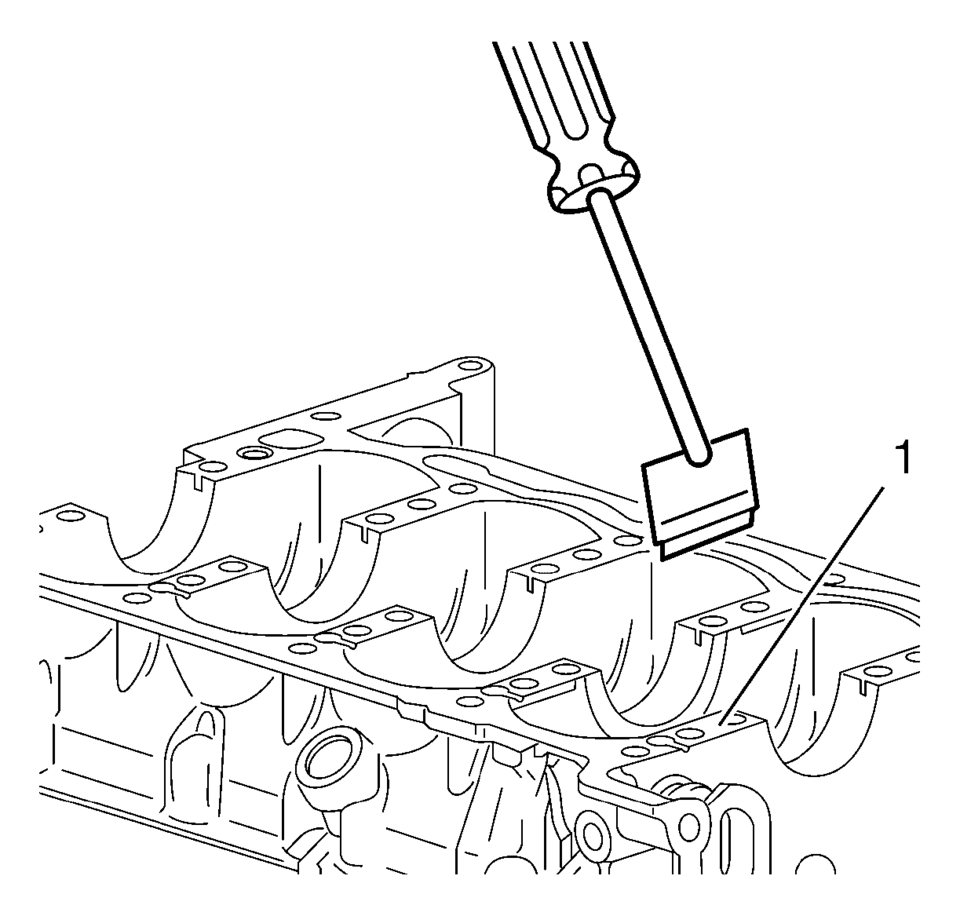

- Clean the sealing material from the gasket mating surfaces (1) on the lower crankcase oil pan side.

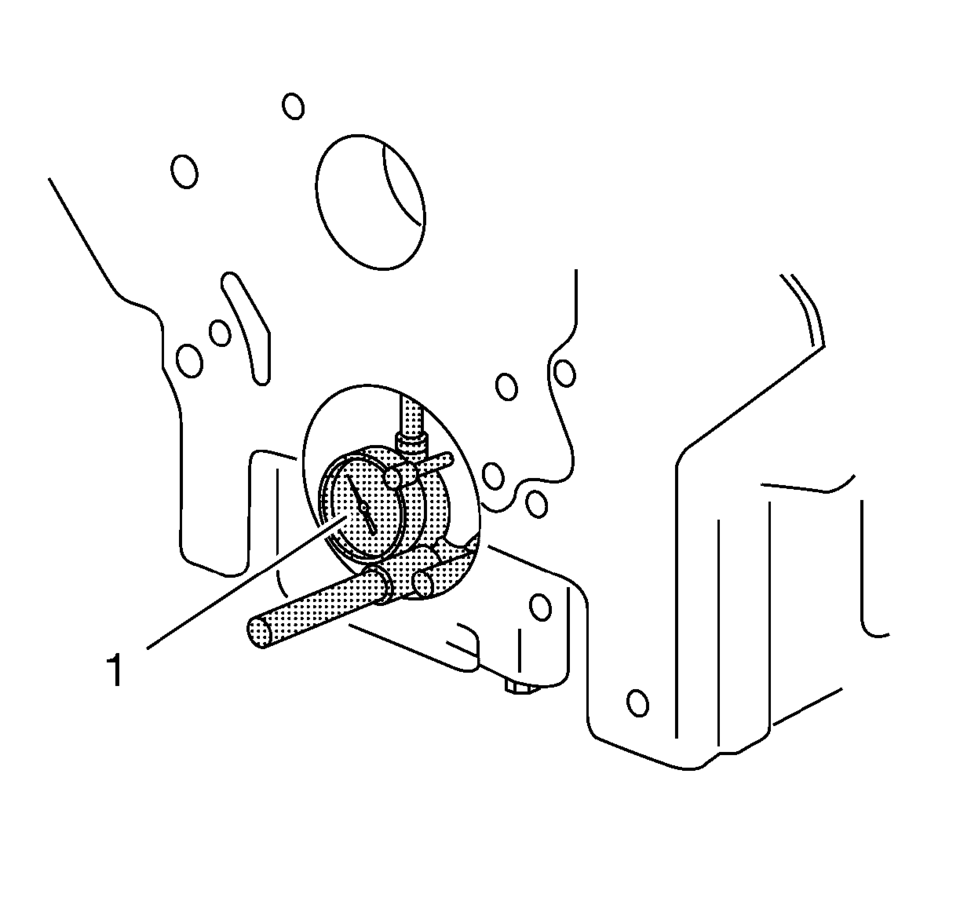

- Inspect the crankshaft main bearing bores. Use the EN-8087 gauge (1) to measure the bearing bore concentricity and alignment.

- Replace the engine block and bed plate if the crankshaft bearing bores are out of specification.

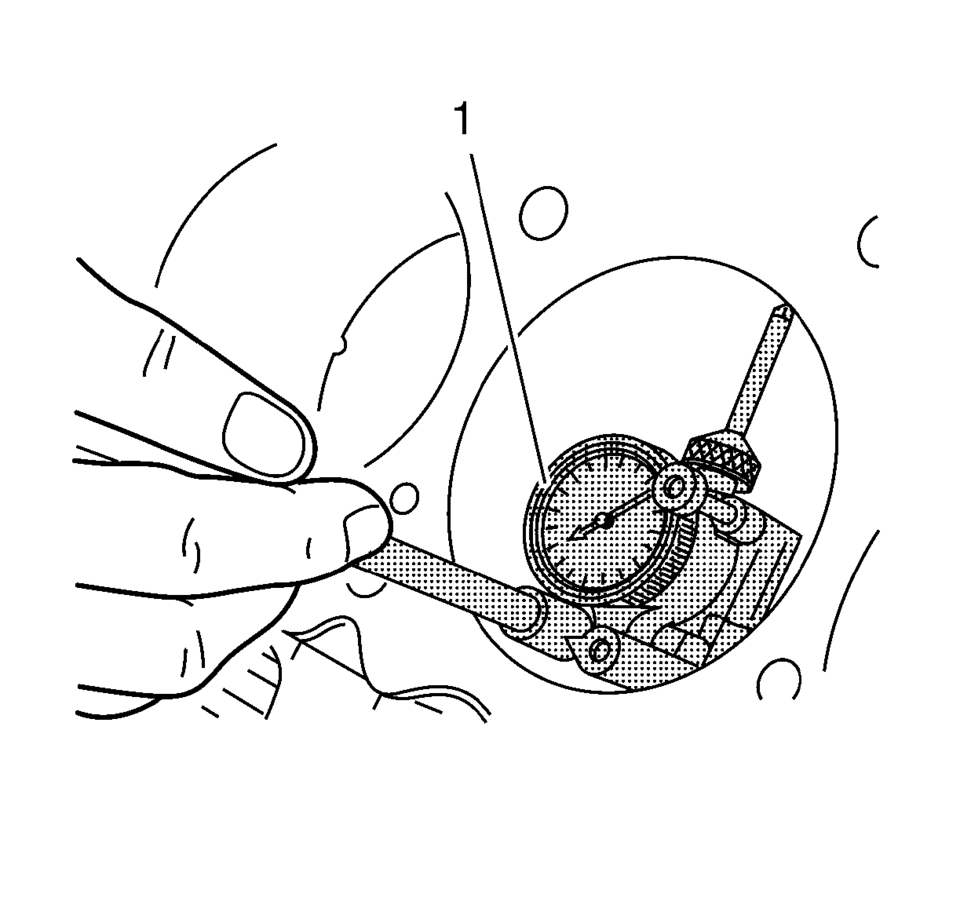

- Inspect the cylinder bores using the EN-8087 gauge (1). Inspect for the following items:

Note:

Do not attempt to machine the lower crankcase to engine block surfaces.

- Wear

- Taper

- Runout

- Ridging

Engine Block Disassemble

Engine Block Disassemble

Remove the cylinder head locating (1, 2).

Remove the oil pressure switch (1).

Remove the knock sensor bolt (2) and the knock sensor (1).

Clea ...

Cylinder Block

Cylinder Block

...

Other materials:

Automatic Transmission

Move the shift lever to P (Park) or N (Neutral). The engine will not start in

any other position. To restart the engine when the vehicle is already moving, use

N (Neutral) only.

Caution

Do not try to shift to P (Park) if the vehicle is moving. If you do, you could

damage the transmission. Sh ...

Engine Coolant Thermostat Housing Removal

Caution: Refer to Engine Coolant Thermostat Housing Caution.

Remove the engine coolant thermostat housing retainer nut (4).

Remove the engine coolant thermostat housing retainer (1).

Remove the 4 engine coolant thermostat housing bolts (3).

Remo ...

Engine Oil Cooler Housing Installation

Clean the engine oil cooler housing to thermostat housing sealing surfaces.

Install 2 NEW gaskets.

h.\.\,.\\..,v:..//

Install the engine oil cooler inlet pipe (3).

Install the engine oil cooler housing (1) and the 5 engine oil cooler bolts (2)

and t ...

0.0051