Chevrolet Sonic Repair Manual: Front Side Door Lock Cylinder Coding (Free Wheeling)

Special Tools

BO-49753 Assembly Tool

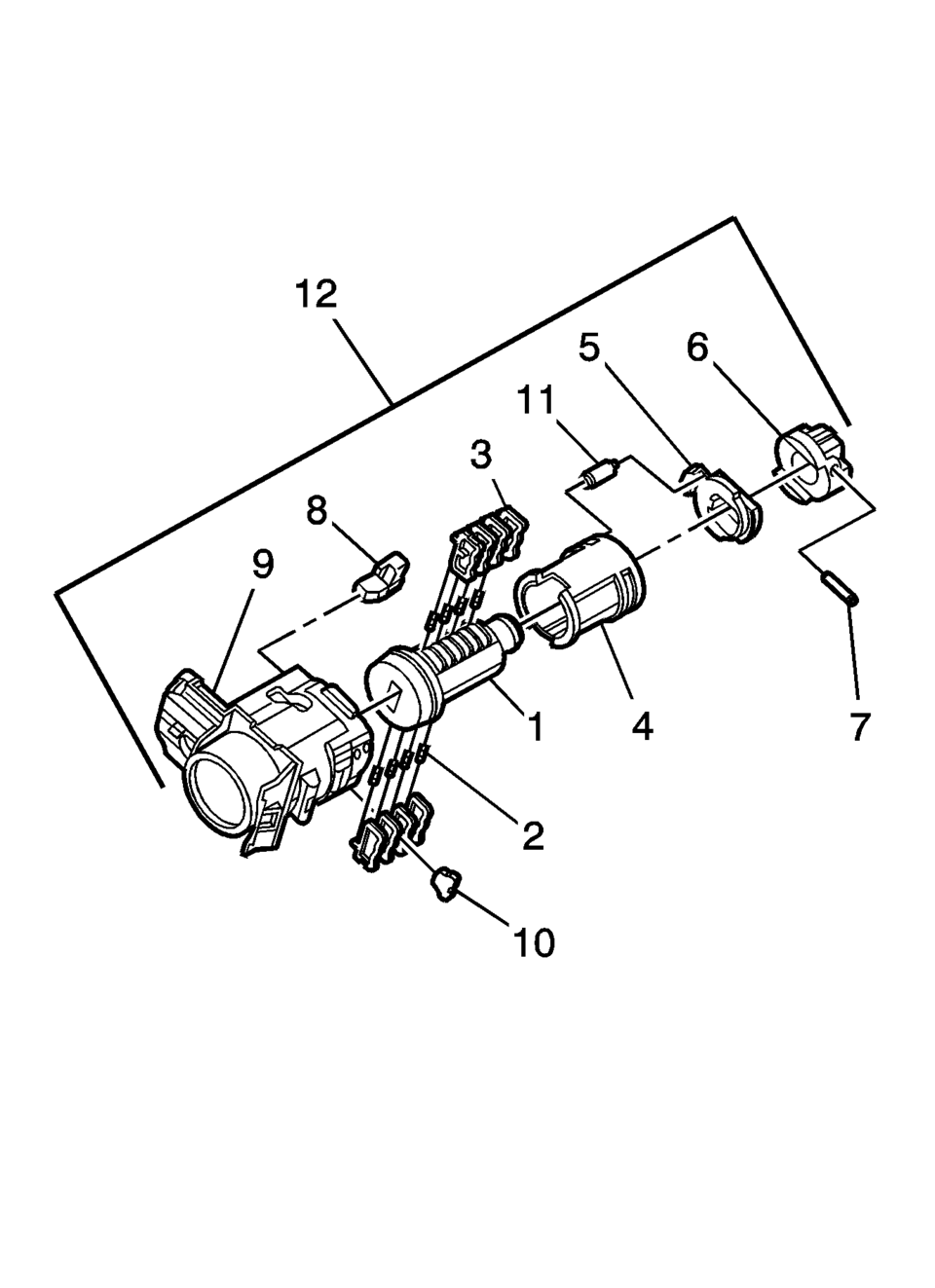

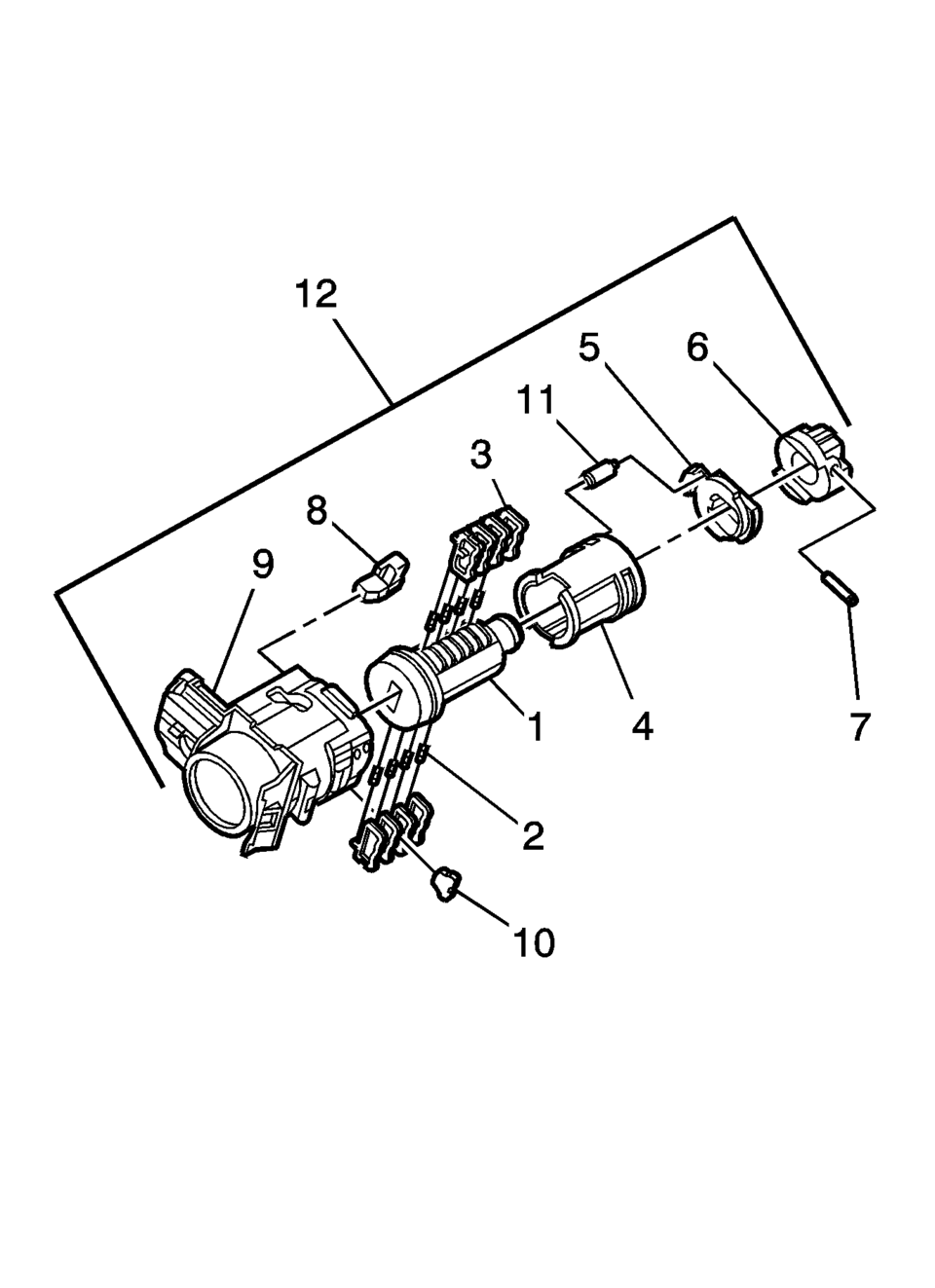

The door lock cylinder uses 8 of the 8 cut positions. The tumbler positions are staggered from side to side, 4 on one side and 4 on the other, are not self-retaining, and are not snap in.

- Hold the door lock cylinder (1) so the side with the 4 tumbler spring pockets faces up, pocket nearest to the cylinder head.

- Insert the tumbler springs (2) into the 4 spring pockets. This side uses left tumblers.

- Install the tumbler (3) for key cut position one in the slot nearest to the front of the lock cylinder. Install the remaining tumblers, key cut positions 3, 5, and 7, following the key code and same process. Press the tumblers in place until they are secure.

- Check the correct loading of the tumblers by inserting the key into the cylinder. All tumblers should be flush with the lock cylinder body.

- Turn the cylinder so the side with the 4 tumbler spring wells faces up. This side uses right tumblers.

- Insert the tumbler springs into the 4 spring pockets.

- The first tumbler closest to the front of the lock cylinder to be loaded will be the second key cut position, the second number in the key code. Install the remaining tumblers for the key cut positions 4, 6, and 8. Press the tumblers in place until they are secure.

- Check the correct loading of the tumblers by inserting the key into the cylinder. All tumblers should be flush with the lock cylinder body.

- Insert the key and lightly lubricate the cylinder body diameter and tumbler surfaces and a small amount in the head of the cylinder using the supplied grease.

- Insert the sleeve (4) onto the cylinder assembly.

- Insert the clutch (5) and driver (6) onto the cylinder (1).

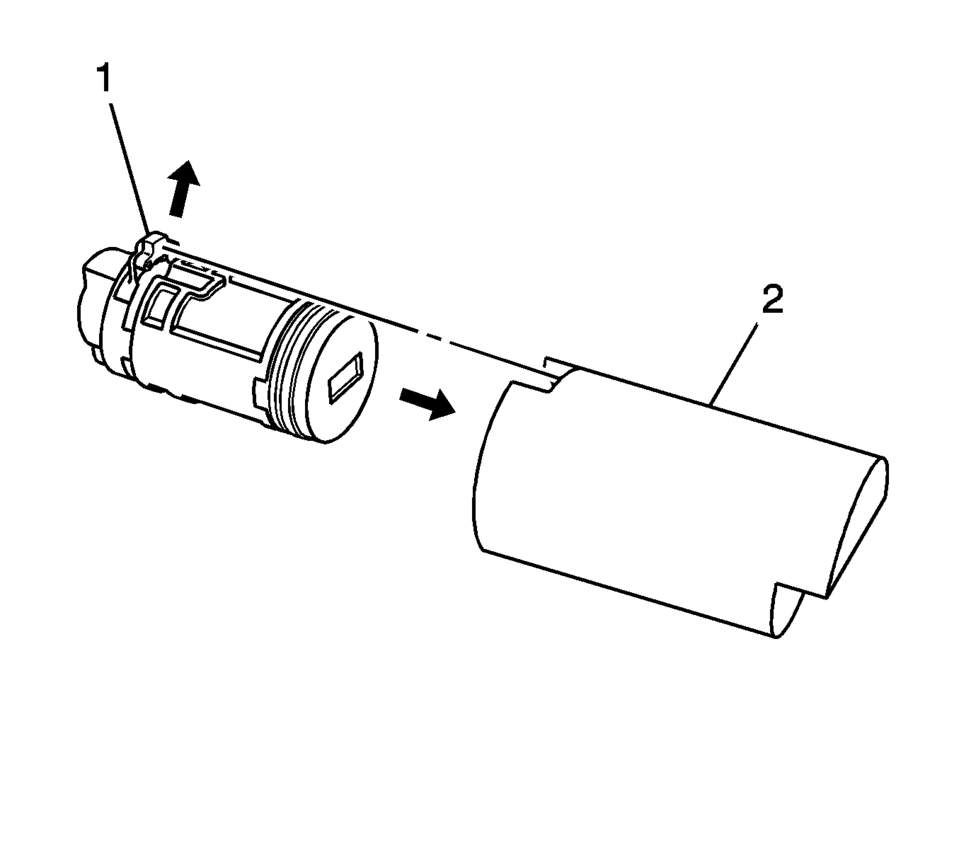

- Load the cylinder into the BO-49753 assembly tool so that the clutch (1) indexes with the notch in the opening of the tool (2).

- Load the assembly tool with the lock cylinder into a vice and tighten the vice ONLY enough to hold the tool and lock the cylinder in place.

- Insert the roll pin (7) into the driver (6) and install it using a 1/16 inch pin punch.

- Insert the buffer (8) in the case (9), verify the buffer is properly seated.

- Install the free wheel pin (11) in the sleeve (4) and clutch (5) and insert the assembly into the case (9).

- With the lock cylinder assembly installed in the case (9), install the retainer (10) and stake the retainer in place using a small punch and hammer to peen the case material onto the exposed ends of the installed retainer (10).

- Insert the key into the lock and function the lock to check for proper assembly and smooth operation.

Note:

All lock cylinders for side milled keys have right and left tumblers. The location of the tooth of the tumbler determines whether it is right of left. Illustrations in this procedure show the right tumblers on the top and the left tumblers on the bottom. All tumblers are marked 1R, 1L, 2R, or 2L. The number being cut depth and the letter meaning right or left.

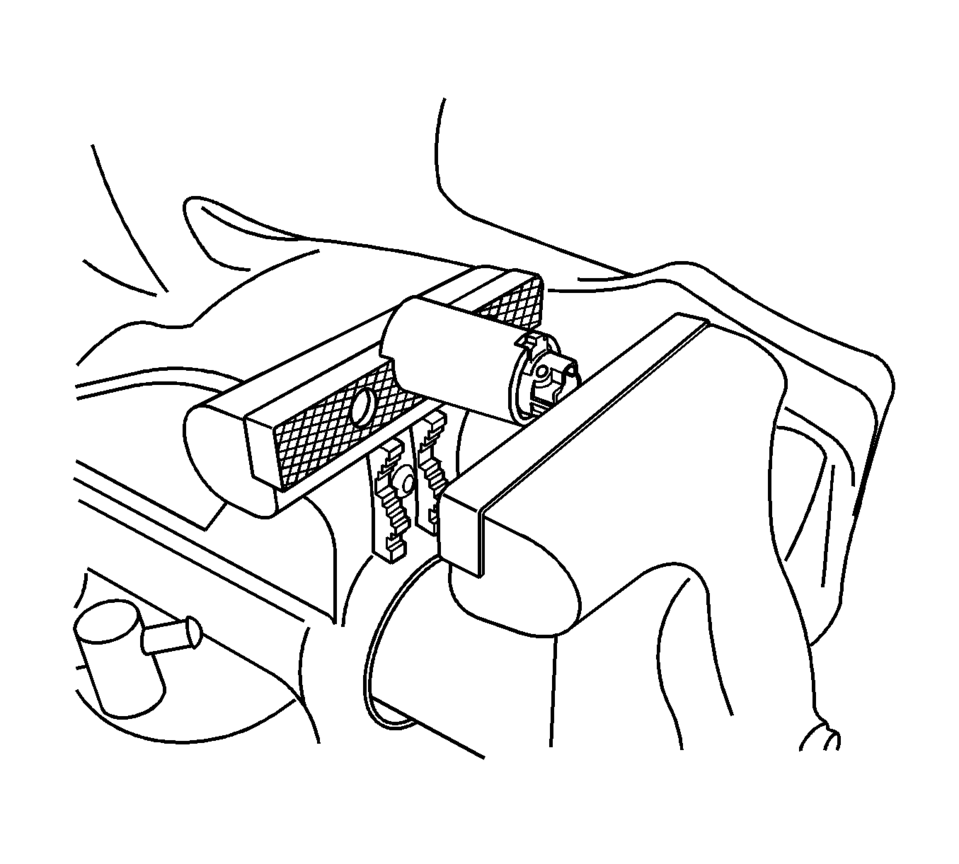

Remote Control Door Lock Receiver Replacement

Remote Control Door Lock Receiver Replacement

Remote Control Door Lock Receiver Replacement

Callout

Component Name

Preliminary Procedure

Remove the windshield outside moistu ...

Front Side Door Lock Cylinder Coding (Non Free Wheeling)

Front Side Door Lock Cylinder Coding (Non Free Wheeling)

The door lock cylinder uses 8 of the 8 cut positions. The tumbler positions are

staggered from side to side, 4 on one side and 4 on the other, are not self-retaining,

and are not snap in ...

Other materials:

Brake Fluid Level Indicator Switch Replacement

Removal Procedure

Disconnect the brake fluid level indicator switch

electrical connector.

Using a small, flat-bladed tool, lift the locking

tab on the underside of the brake fluid level indicator switch (1) and remove

the switch.

Inspect the maste ...

Rear Brake Cylinder Replacement

Removal Procedure

Warning: Refer to Brake Dust Warning.

Warning: Refer to Brake Fluid Irritant Warning.

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the tire and wheel assembly. Refer to Tire and Wheel Removal

and I ...

Engine Front Cover and Oil Pump Installation

Special Tools

EN-952 Fixing Pin

EN-953-A Fixing Tool

EN-49977-100 Transmitter Disc Fixation

EN-49977-200 Fixing Tool

For equivalent regional tools, refer to Special Tools.

Note: Mind the guide sleeves when installing engine front cover.

Install the engine front ...

0.0056