Chevrolet Sonic Repair Manual: Generator Replacement (LUV)

- Removal Procedure

-

- Disconnect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

- Remove the drive belt. Refer to Drive Belt Replacement.

- Remove the drive belt tensioner. Refer to Drive Belt Tensioner Replacement.

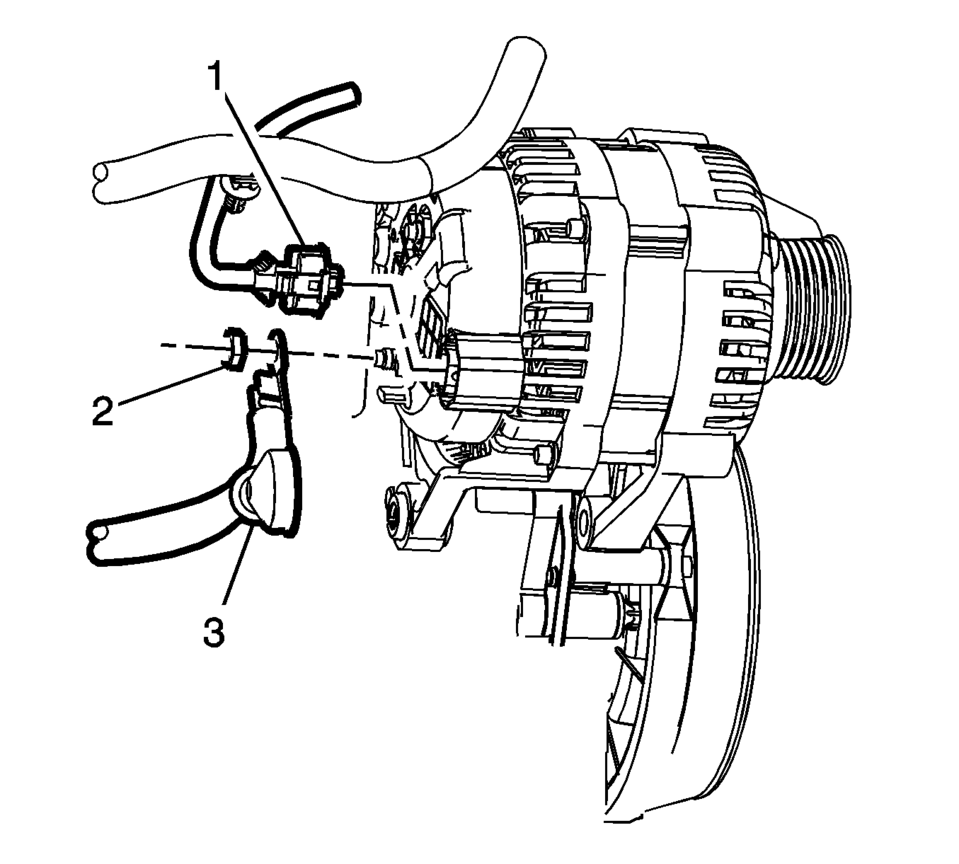

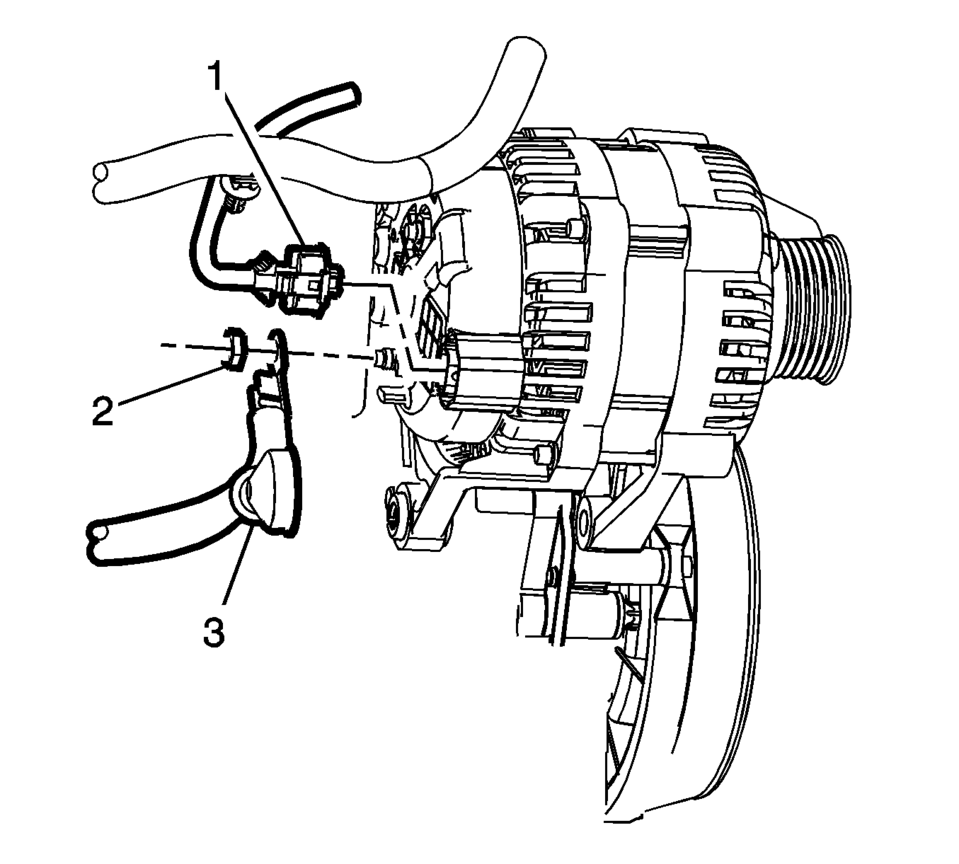

- Remove the engine harness connector (1) and the battery positive cable generator fastener (2).

- Remove the battery positive cable (3) from the back of the generator.

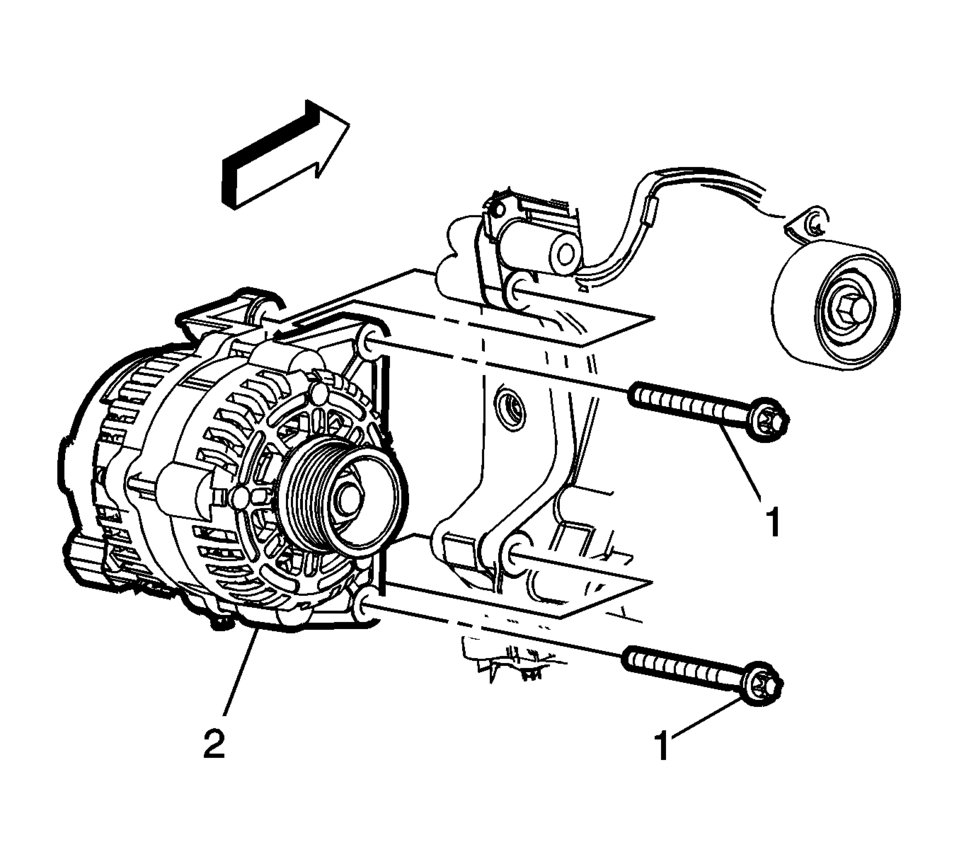

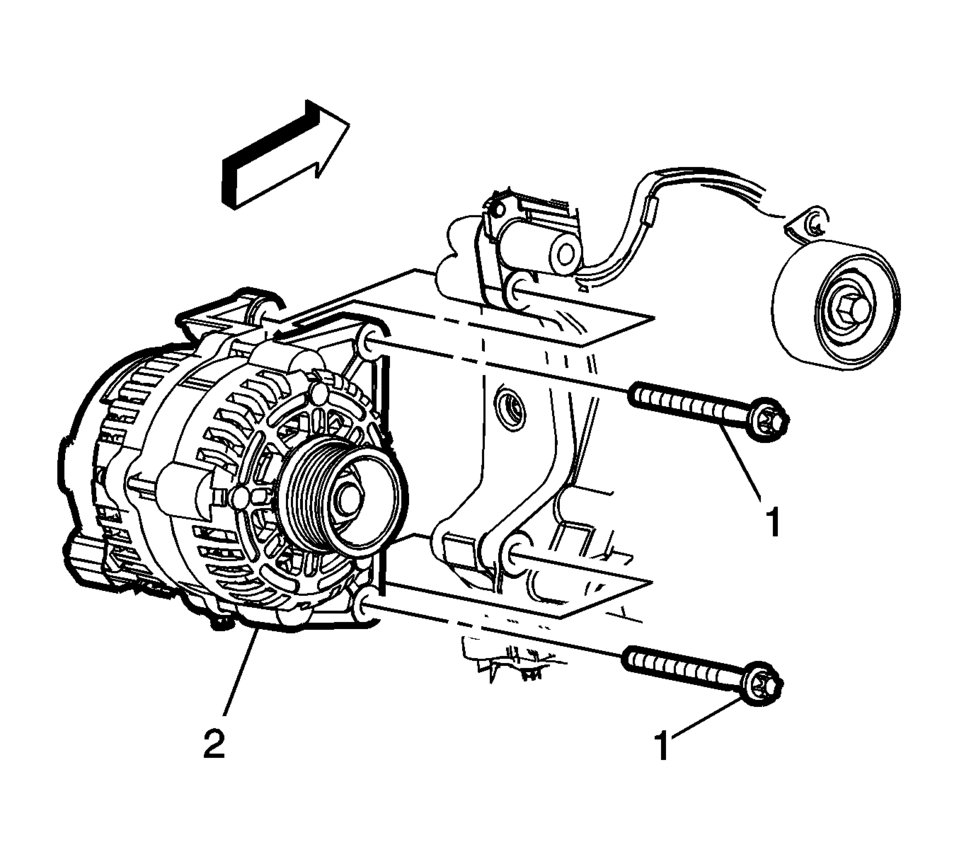

- Remove the generator mounting fasteners (1) and remove the generator (2) from the engine.

- Installation Procedure

-

- Install the generator (2) with the mounting fasteners (1) and tighten

to 35 Y (26 lb ft)

.

- Install the battery positive cable (3) and the engine harness connector (1)

to the back of the generator. Tighten fastener (2) to 9 Y (80 lb in)

.

- Install the drive belt tensioner. Refer to Drive Belt Tensioner Replacement.

- Install the drive belt. Refer to Drive Belt Replacement.

- Connect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

Caution:

Refer to Fastener Caution.

- Install the generator (2) with the mounting fasteners (1) and tighten

to 35 Y (26 lb ft)

Generator Removal

Generator Removal

Remove the 2 generator bolts (2).

Remove the generator (1).

...

Generator Replacement (LUW)

Generator Replacement (LUW)

Removal Procedure

Disconnect the negative battery cable. Refer to Battery Negative Cable

Disconnection and Connection.

Raise and support the vehicle. Refer to Lifting and Jacking ...

Other materials:

Retained Accessory Power Description and Operation

Retained Accessory Power

RAP Description and Operation Block Diagram

K9Body

Control

ModuleK73Telematics

Communication

Interface

Control ModuleA11RadioKR76Retained

Accessory

Power

Relay

Hard-W ...

Outside Rearview Mirror Glass Replacement

Removal Procedure

Warning: Approved safety glasses and gloves should be worn

when performing this procedure to reduce the chance of personal injury.

Place masking tape over the mirror glass.

Carefully push the outside rearview mirror glass upward and int ...

Rear Brake Hose Replacement (Body to Axle - Drum Brake)

Removal Procedure

Warning: Refer to Brake Dust Warning.

Warning: Refer to Brake Fluid Irritant Warning.

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the tire and wheel assembly. Refer to Tire and Wheel Removal

and Install ...

0.0599