Chevrolet Sonic Repair Manual: Piston, Connecting Rod, and Bearing Installation

Special Tools

EN-470-B Angular Torque Wrench

For equivalent regional tools, refer to Special Tools.

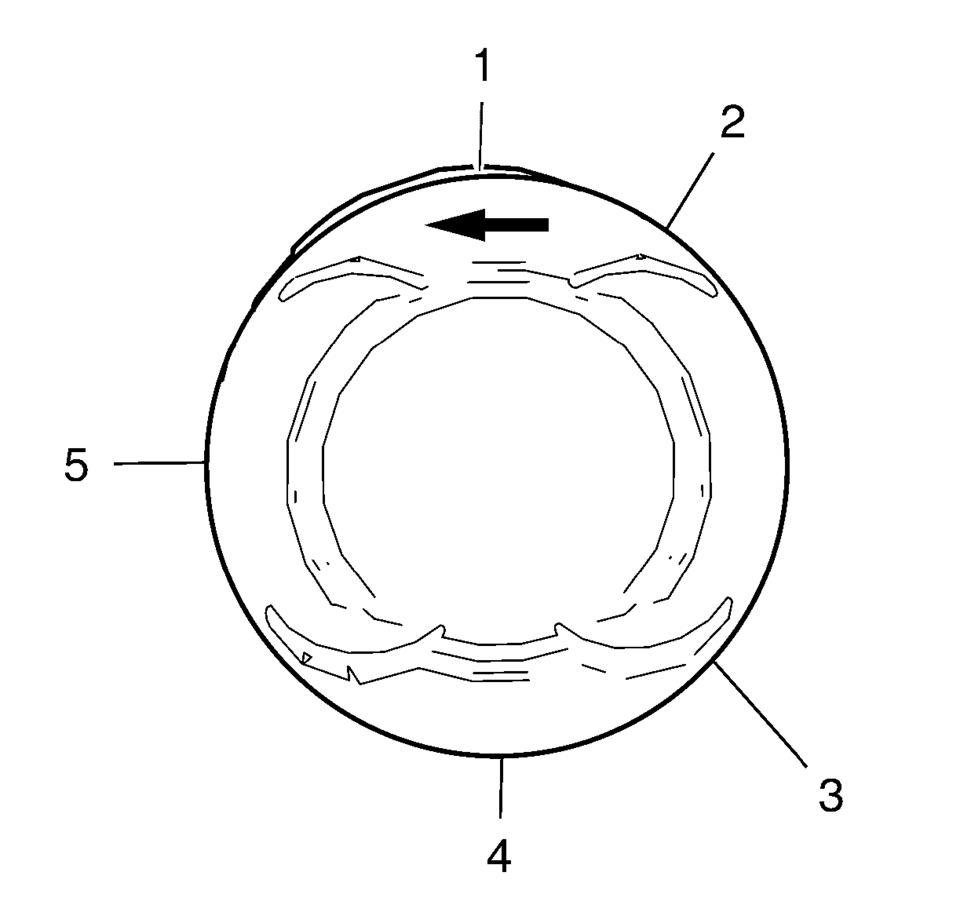

- Adjust the piston ring joints as follows:

- Upper compression ring (1).

- Lower compression ring (4).

- Oil rings (2) or (3).

- Oil ring spacer (5).

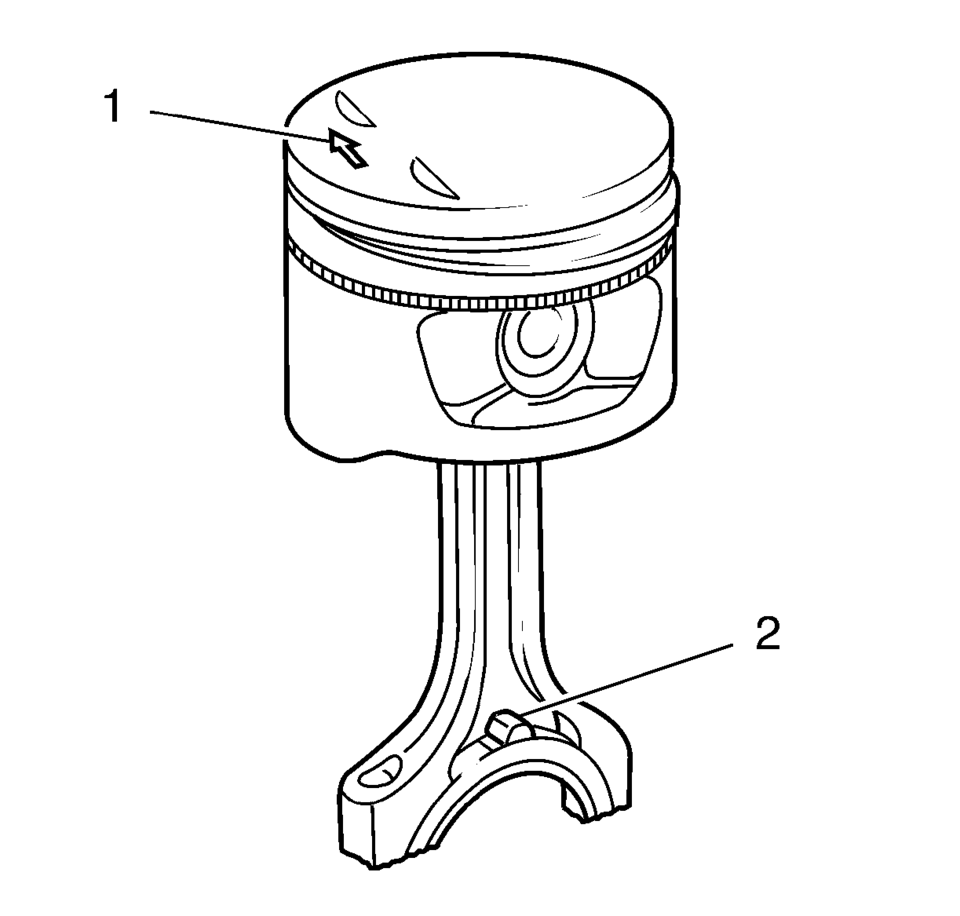

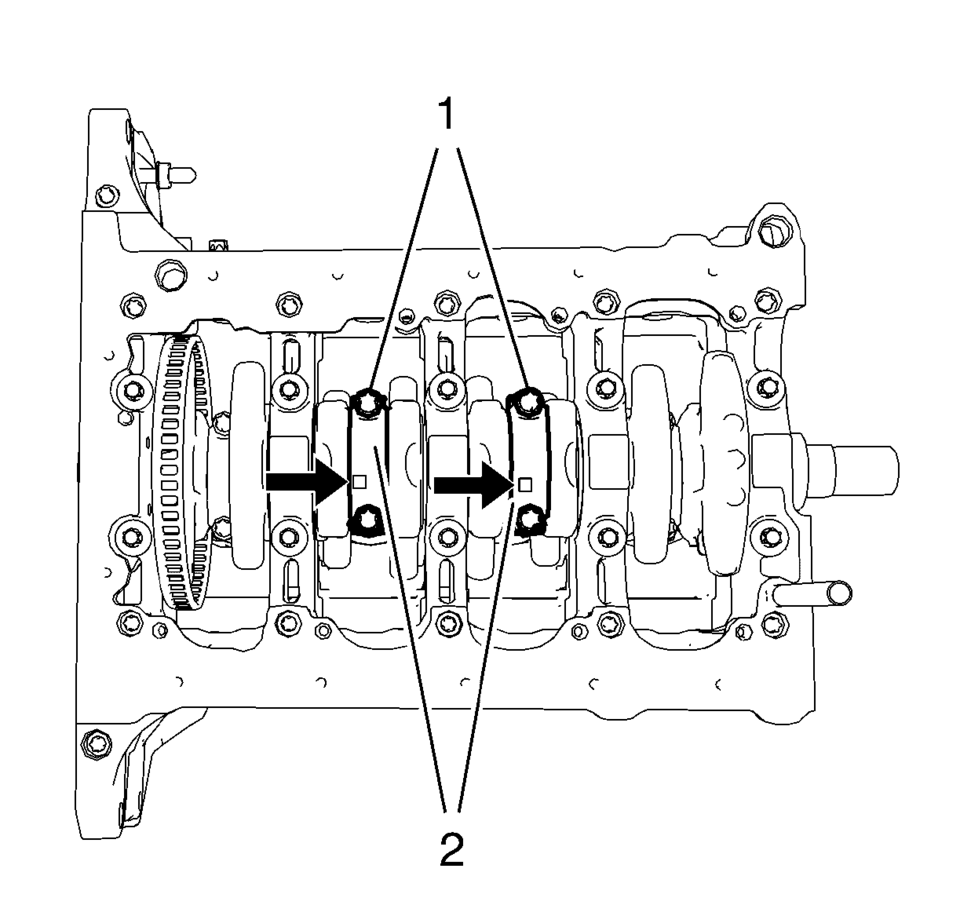

- The arrow (1) on the piston head must point to the timing side.

- The markings on the connecting rods (2) must point to the transmission side.

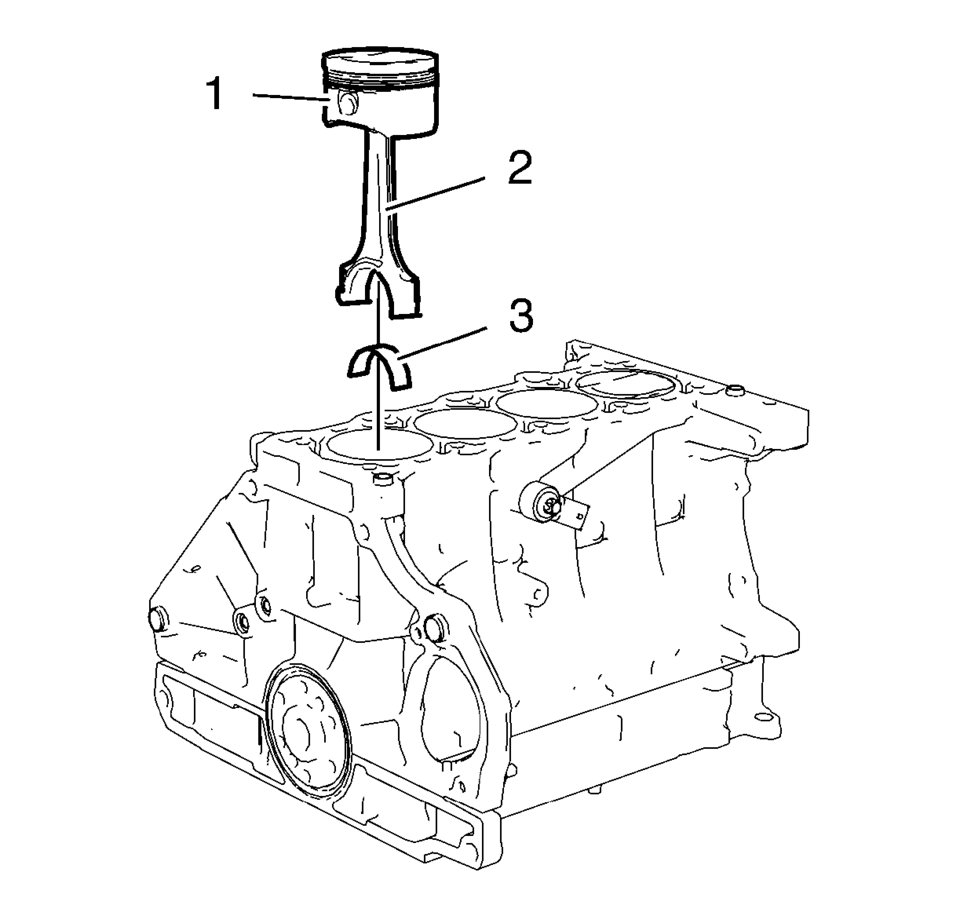

- Install a piston ring compressor to compress the piston rings.

- Install the pistons (1) in along with connecting rods (2) and upper connecting rod bearings (3) to the engine block and to the crankshaft.

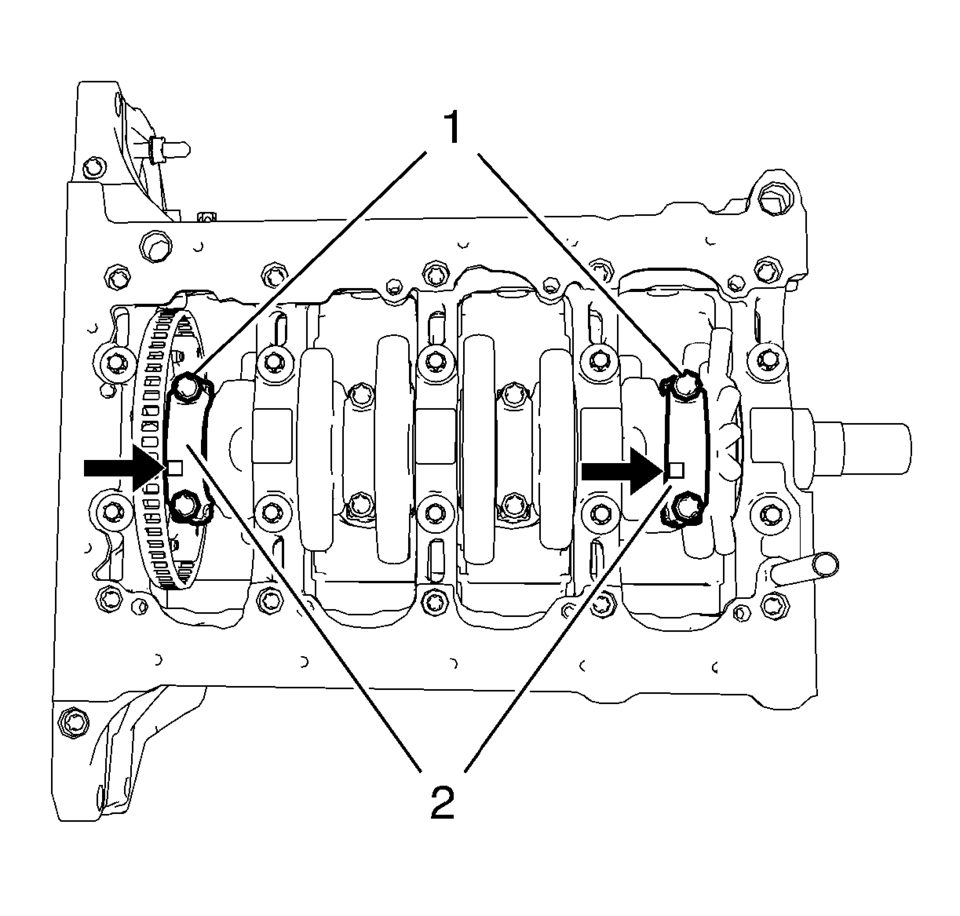

- Install the 2 connecting rod bearings and the 2 connecting rod bearing caps (2) of cylinder 1 and 4.

- Install the 4 NEW connecting rod bearing cap bolts (1) and tighten in the following sequence:

- Tighten the connecting rod bearing cap bolts to 25 Y (18 lb ft)

.

- Tighten the connecting rod bearing cap bolts an additional 45 degrees. Use EN-470 B wrench.

- Rotate the crankshaft 180 degrees.

- Install the 2 connecting rod bearings and the 2 connecting rod bearing caps (2) of cylinder 3 and 2.

- Install the 4 NEW connecting rod bearing cap bolts (1) and tighten in the following sequence:

- Tighten the connecting rod bearing cap bolts to 25 Y (18 lb ft)

.

- Tighten the connecting rod bearing cap bolts an additional 45 degrees. Use EN-470–B wrench.

Note:

The flarings (arrows) on the connecting rod bearing caps must point to the transmission side. The connecting rod bearing caps must be installed in their original position.

Caution:

Refer to Fastener Caution.

Caution:

Refer to Torque-to-Yield Fastener Caution.

Note:

Do not reuse the old bolts.

Note:

The flarings (arrows) on the connecting rod bearing caps must point to the transmission side. The connecting rod bearing caps must be installed in their original position.

Note:

Do not reuse the old bolts.

Piston, Connecting Rod, and Bearing Cleaning and Inspection

Piston, Connecting Rod, and Bearing Cleaning and Inspection

Special Tools

EN-470-B Angular Torque Wrench

For equivalent regional tools, refer to Special Tools.

Visual Inspection And Cleaning Procedure

Connecting Rod

Warning: Wear safety gla ...

Piston, Connecting Rod, and Bearing Removal

Piston, Connecting Rod, and Bearing Removal

Install the crankshaft balancer bolt.

Set the pistons 1 and 4 to TDC in direction of engine rotation.

Note: Note cylinder sequence.

Mark the connecting rod with the ...

Other materials:

How the System Works

The LDW camera sensor is on the windshield ahead of the rearview mirror.

To turn LDW on and off, press the LANE DEPART button on the steering wheel. The

control indicator will light when LDW is on.

When the vehicle is started, the LDW indicator on top of the instrument panel

to the right o ...

Door Lock and Ignition Lock Folding and Non-Folding Key Cutting

High Security keys are available from the service parts system.

Obtain the key code from the security card or from the GM Dealer World, Parts,

Key Code Look Up system.

If you have the key code and access to a Triax-E., BD Laser or other code key

cutting machine from the GM Dealer Equipment C ...

Control Valve Body Assembly Installation

Control Valve Body Assembly Installation

Callout

Component Name

1

Low and Reverse Clutch Fluid Passage Seal

2

1-2-3-4 Clutch Fluid Passage Seal

3

Control Valve Body ...

0.0047