Chevrolet Sonic Repair Manual: Body Hinge Pillar Lower Reinforcement Replacement

- Removal Procedure

-

- Disable the SIR system. Refer to SIR Disabling and Enabling.

- Disconnect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Remove all related panels and components.

- Repair as much of the damage as possible. Refer to Dimensions - Body.

- Remove the sealers and anti-corrosion materials from the repair area. Refer to Anti-Corrosion Treatment and Repair.

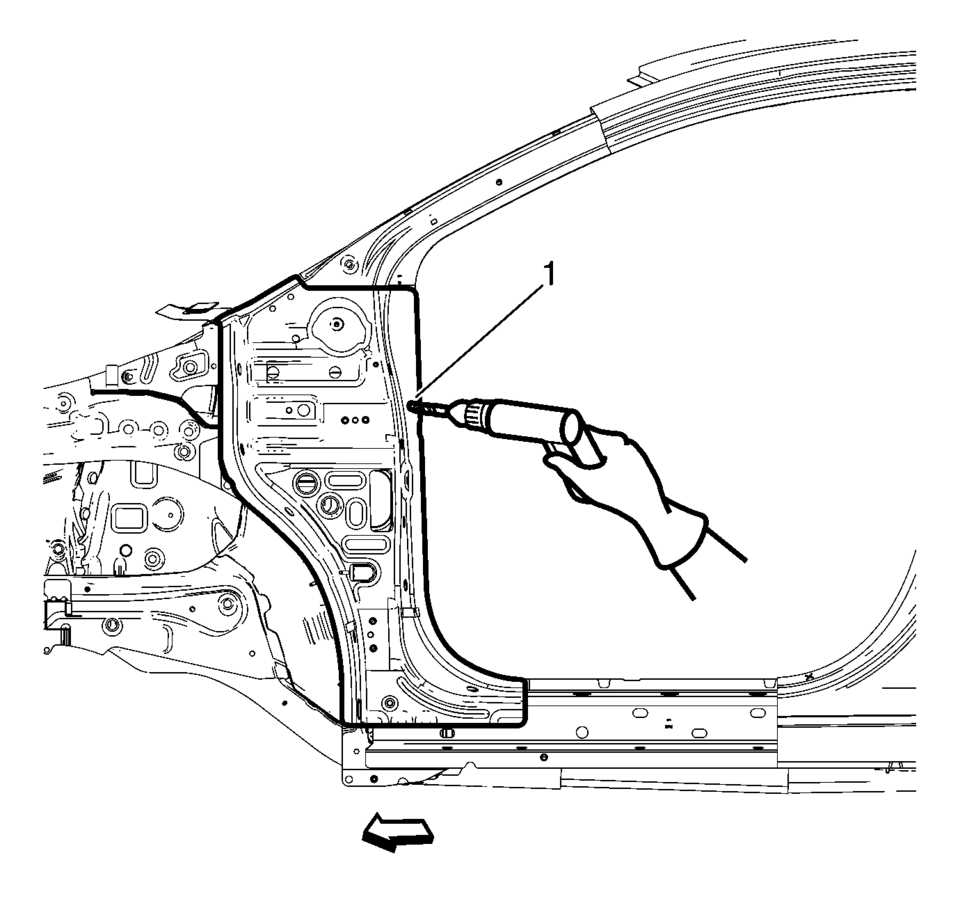

- Locate and mark all the necessary factory welds of the front hinge pillar body.

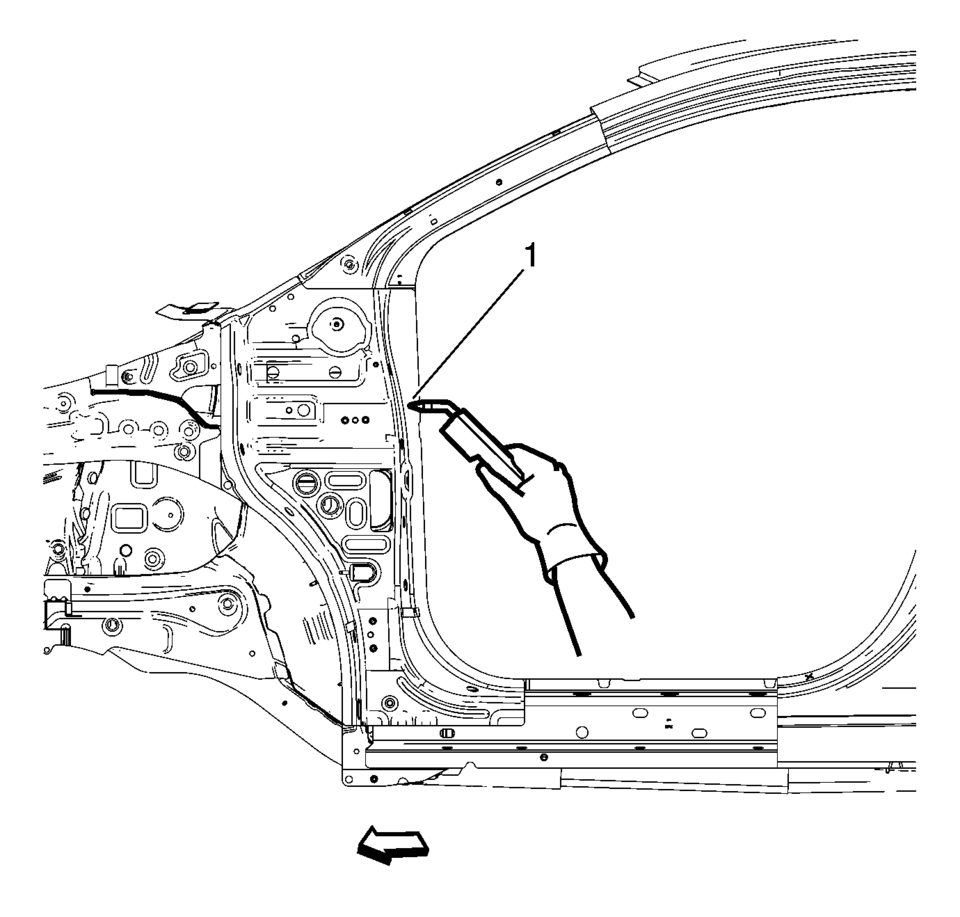

- Drill all factory welds (1). Note the number and location of welds for installation of the service assembly.

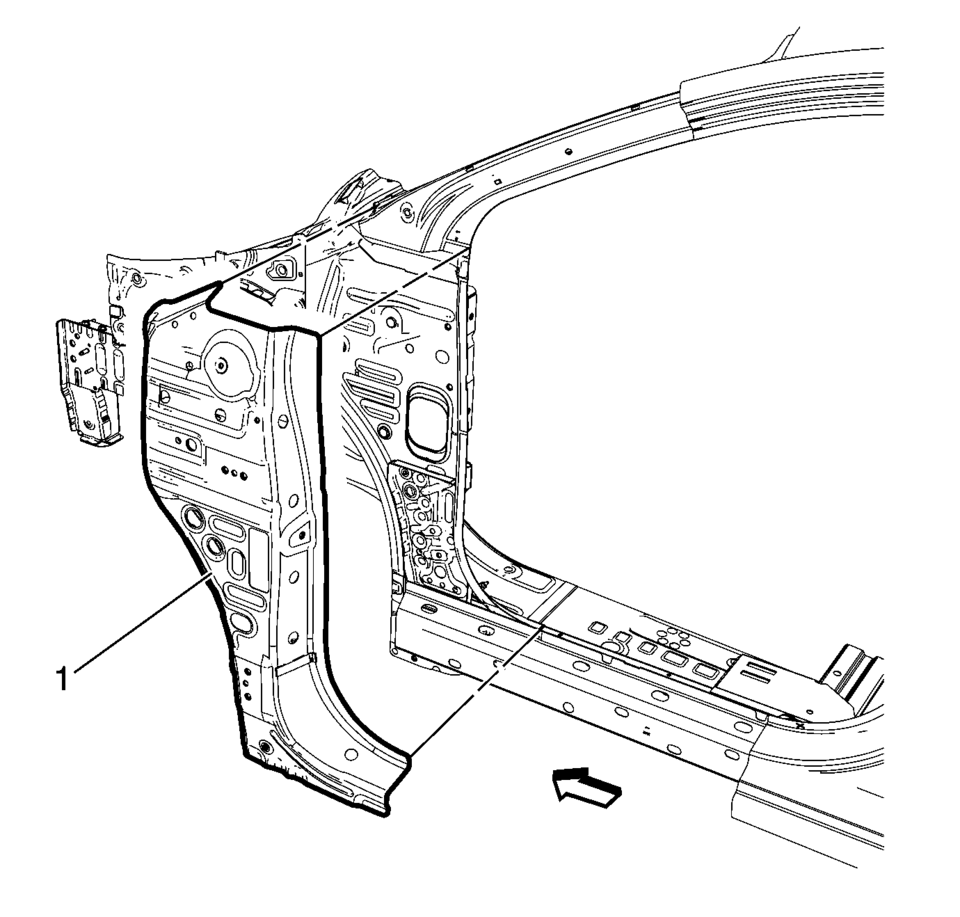

- Remove the damaged front hinge pillar body reinforcement (1).

Warning:

Refer to Approved Equipment for Collision Repair Warning.

- Installation Procedure

-

- Prepare all mating surfaces as necessary.

- Align the front hinge pillar body reinforcement.

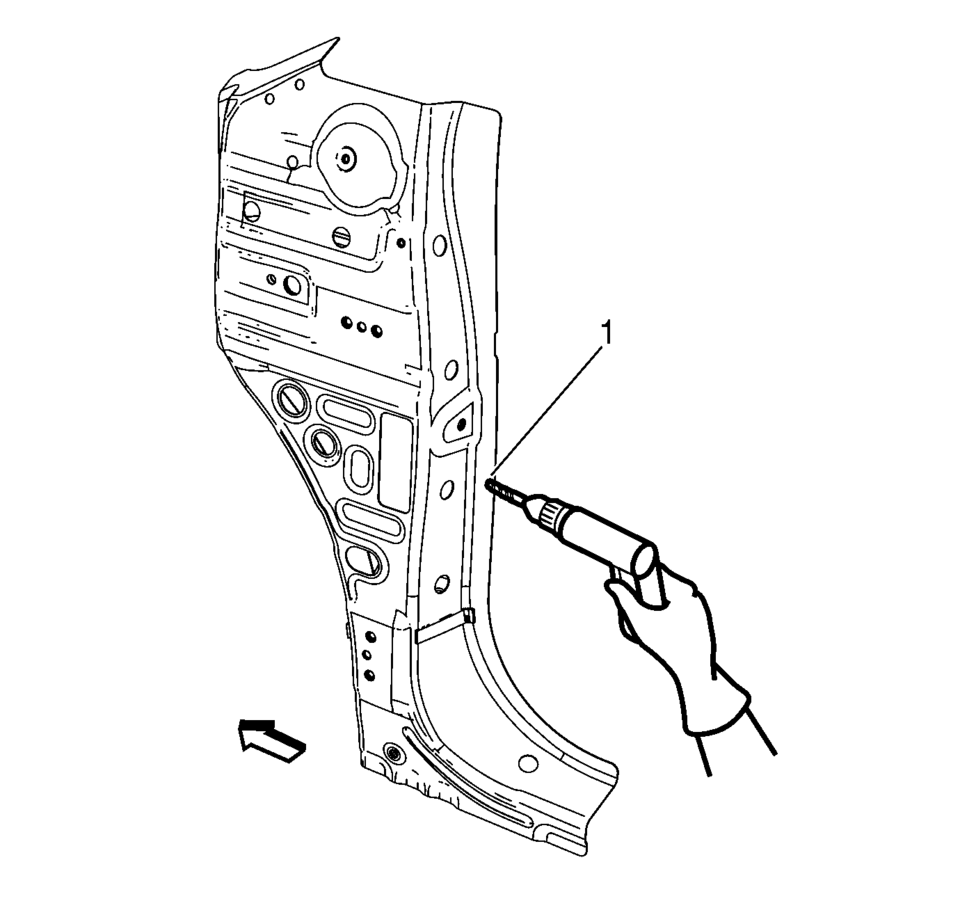

- Drill 8 mm (5/16 in)

holes for plug welding along the edges of the front hinge pillar body as noted from the original panel (1).

- Clean and prepare the attaching surfaces for welding.

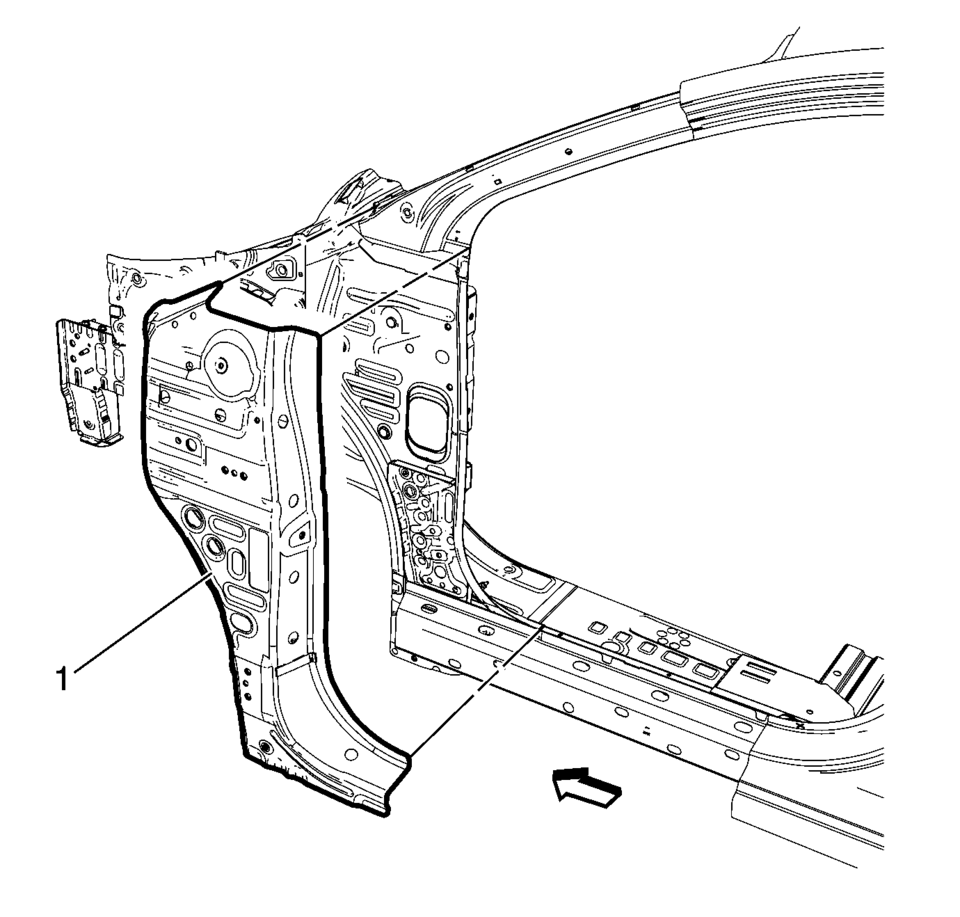

- Position the front hinge pillar body reinforcement on the vehicle (1).

- Verify the fit of the front hinge pillar body reinforcement.

- Clamp the front hinge pillar body reinforcement into position.

- Plug weld accordingly (1).

- Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Paint the repaired area. Refer to Basecoat/Clearcoat Paint Systems.

- Install all related panels and components.

- Connect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Enable the SIR system. Refer to SIR Disabling and Enabling.

General

General

...

Body Waterleak Repair

Body Waterleak Repair

Warning: If the vehicle interior is exposed to moisture and becomes

soaked up to the level of the sensing and diagnostic module (SDM), the SDM and

SDM harness connector must be replaced. ...

Other materials:

Rear Seat Center Shoulder Belt Replacement (Hatchback)

Rear Seat Center Shoulder Belt Replacement

Callout

Component Name

Preliminary Procedures

Remove the rear seat cushion. Refer to Rear Seat Cushion Removal

and Installation.

Remove the rear seat back cushion. Refer to Rear ...

Hydraulic Brake System Flushing

Warning: Refer to Brake Fluid Irritant Warning.

Caution: Refer to Brake Fluid Effects on Paint and Electrical Components

Caution.

Inspect the brake fluid for the following conditions, indicating brake fluid

contamination:

Fluid separation, indicating 2 types of fl ...

Engine Oil Cooler Housing Removal

Remove the 2 engine oil cooler pipe bolts (1).

Remove the oil cooler pipe (2).

h.\.\,.\\..,v:..//

Remove the 5 engine oil cooler housing bolts (2).

Remove the engine oil cooler housing (1).

Remove the engine oil cooler inlet pi ...

0.0043