Chevrolet Sonic Repair Manual: Body Side Frame Rocker Reinforcement Replacement

- Removal Procedure

-

- Disable the SIR system. Refer to SIR Disabling and Enabling.

- Disconnect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Remove all related panels and components.

- Repair as much of the damage as possible to factory specifications. Refer to Dimensions - Body.

- Remove the sealers and anti-corrosion materials from the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

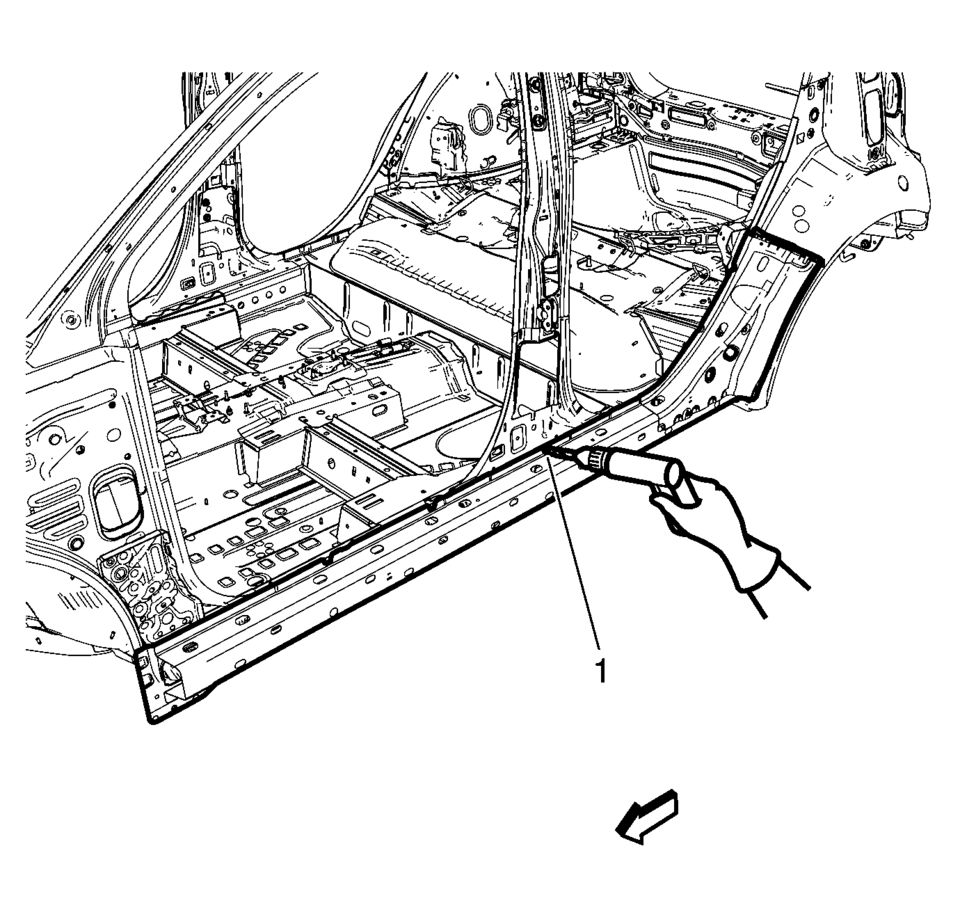

- Locate and mark all the necessary factory welds of the body side frame rocker reinforcement.

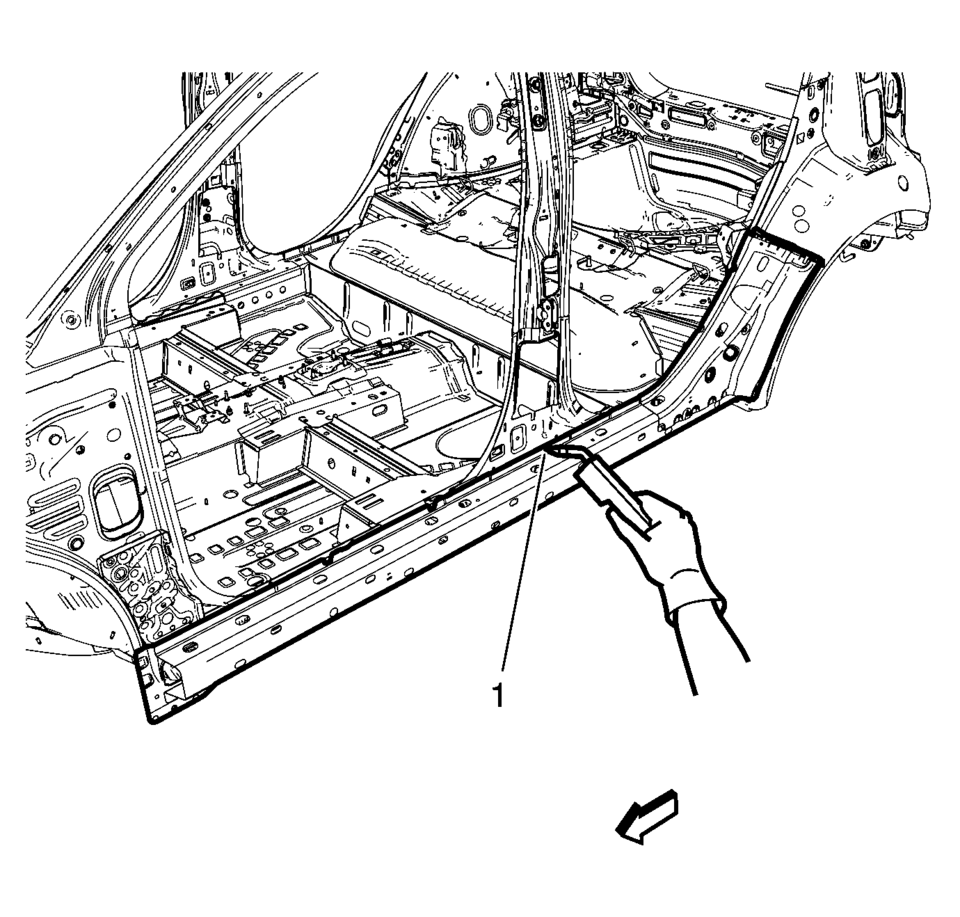

- Drill all factory welds (1). Note the number and location of welds for installation of the service assembly.

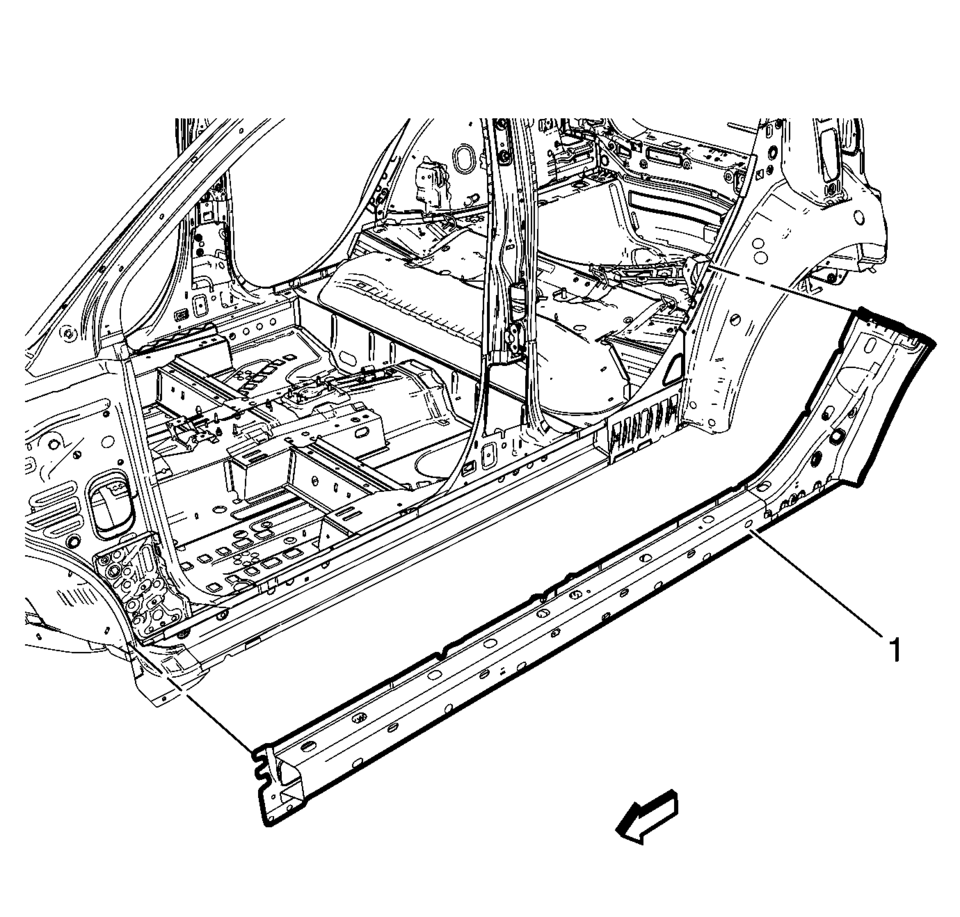

- Remove the damaged body side frame rocker reinforcement (1).

Warning:

Refer to Approved Equipment for Collision Repair Warning.

Warning:

Refer to Glass and Sheet Metal Handling Warning.

Note:

The body side frame rocker reinforcement is made of Ultra High Strength Dual Phase Steel and should be replaced only at factory joints. Repairing or sectioning of this part is not recommended. Refer to Ultra High Strength Dual Phase Steel.

..

- Installation Procedure

-

- Align the body side frame rocker reinforcement.

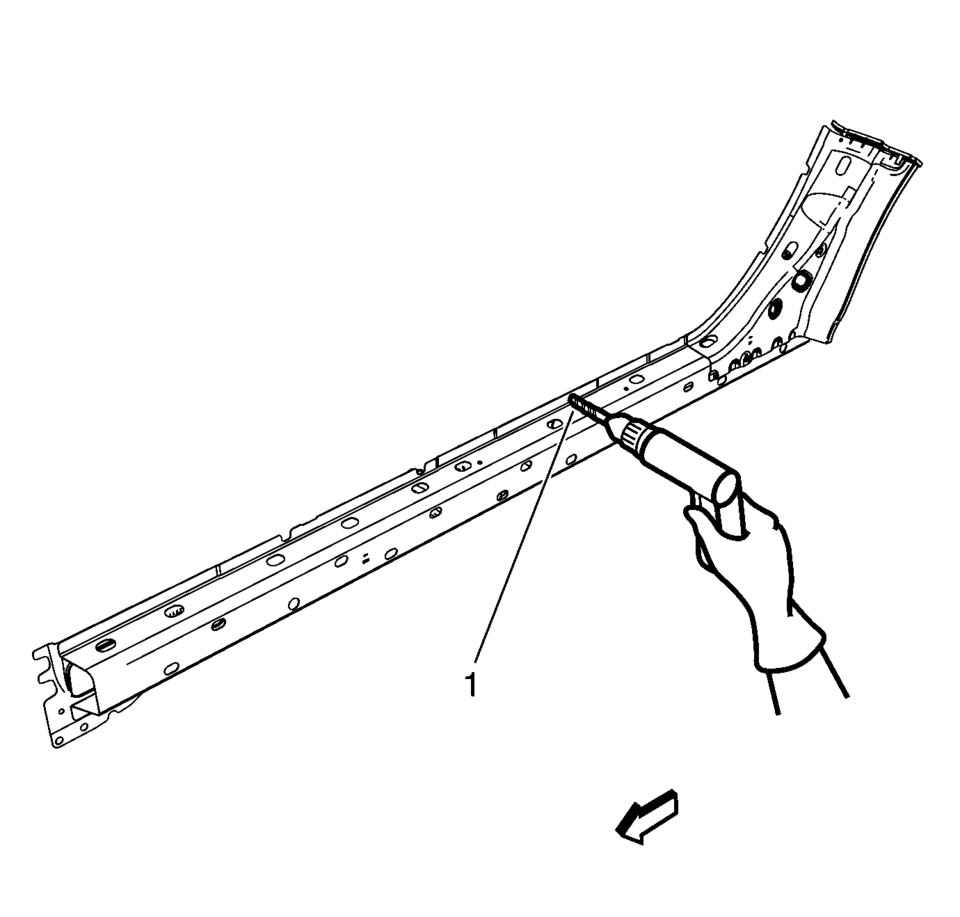

- Drill a 8?€‰mm (5/16?€‰in)

holes for plug welding along the edges of the quarter outer panel (1) as noted from the original panel.

- Clean and prepare the attaching surfaces for welding.

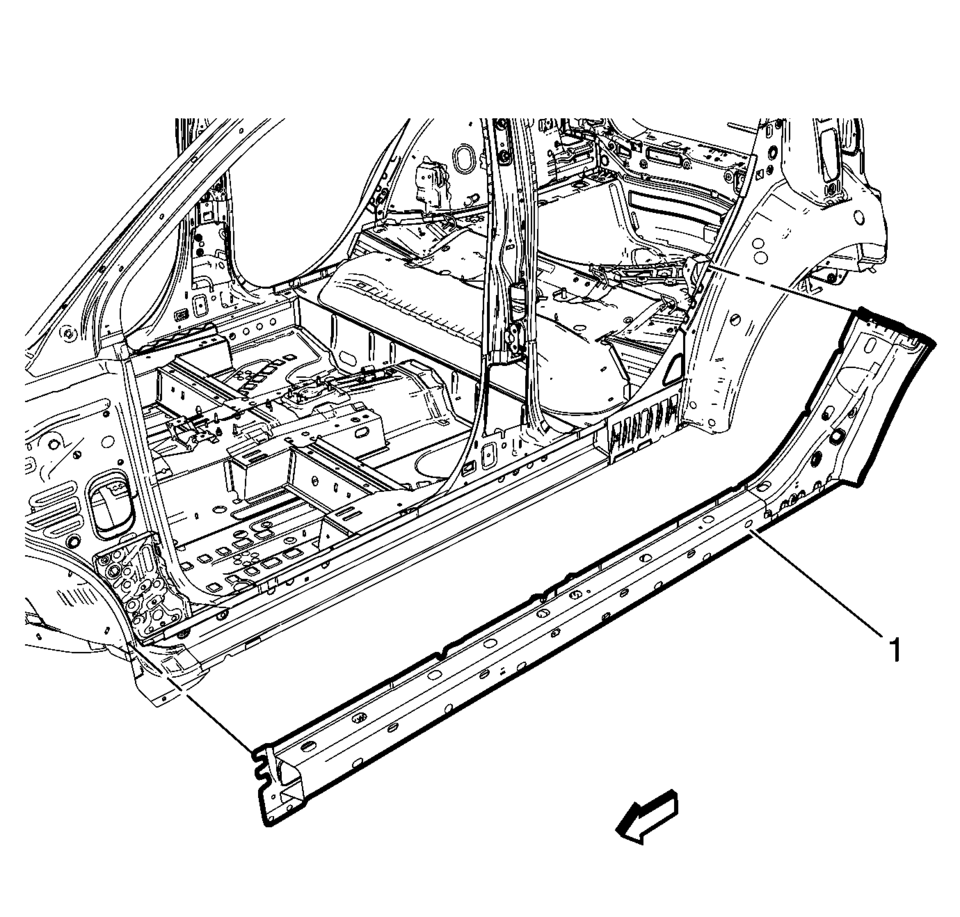

- Position the body side frame rocker reinforcement on the vehicle (1).

- Verify the fit of the body side frame rocker reinforcement.

- Clamp the body side frame rocker reinforcement into position.

- Plug the weld accordingly (1).

- Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Paint the repaired area. Refer to Basecoat/Clearcoat Paint Systems.

- Install all related panels and components.

- Connect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Enable the SIR system. Refer to SIR Disabling and Enabling.

(\ ..

Driver or Passenger Seat Back Cushion Frame Replacement

Driver or Passenger Seat Back Cushion Frame Replacement

Driver or Passenger Seat Back Cushion Frame Replacement

Callout

Component Name

Preliminary Procedures

Remove the driver or passenge ...

Other materials:

Mode Control Cable Replacement (LHD)

Mode Control Cable Replacement

Callout

Component Name

Preliminary Procedures

Remove the heater and air conditioning control.Refer to Heater and

Air Conditioning Control Replacement

Remove the instrument panel lower trim p ...

Engine Block Cleaning and Inspection

Special Tools

EN-8087 Cylinder Gauge

For equivalent regional tools, refer to Special Tools.

Clean the sealing material from the gasket mating surfaces (2).

Clean the engine block (1) and lower crankcase in a cleaning tank with solvent

appropriate for aluminum. Refer ...

Low and Reverse and 1-2-3-4 Clutch Housing, and 1-2-3-4 Clutch Plate Installation

(6T40/45/50)

Low and Reverse and 1-2-3-4 Clutch Housing, and 1-2-3-4 Clutch Plate

Installation

Callout

Component Name

1

Low and Reverse and 1??? Clutch Housing

Note: The longer legs face the bottom of the case and the

...

0.0064