Chevrolet Sonic Repair Manual: Center Pillar Reinforcement Replacement

- Removal Procedure

-

- Disable the SIR system. Refer to SIR Disabling and Enabling.

- Disconnect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Remove all related panels and components.

- Visually inspect the damage. Repair as much of the damage as possible.

- Remove the sealers and anti-corrosion materials from the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Locate and mark all the necessary factory welds of the center pillar reinforcement.

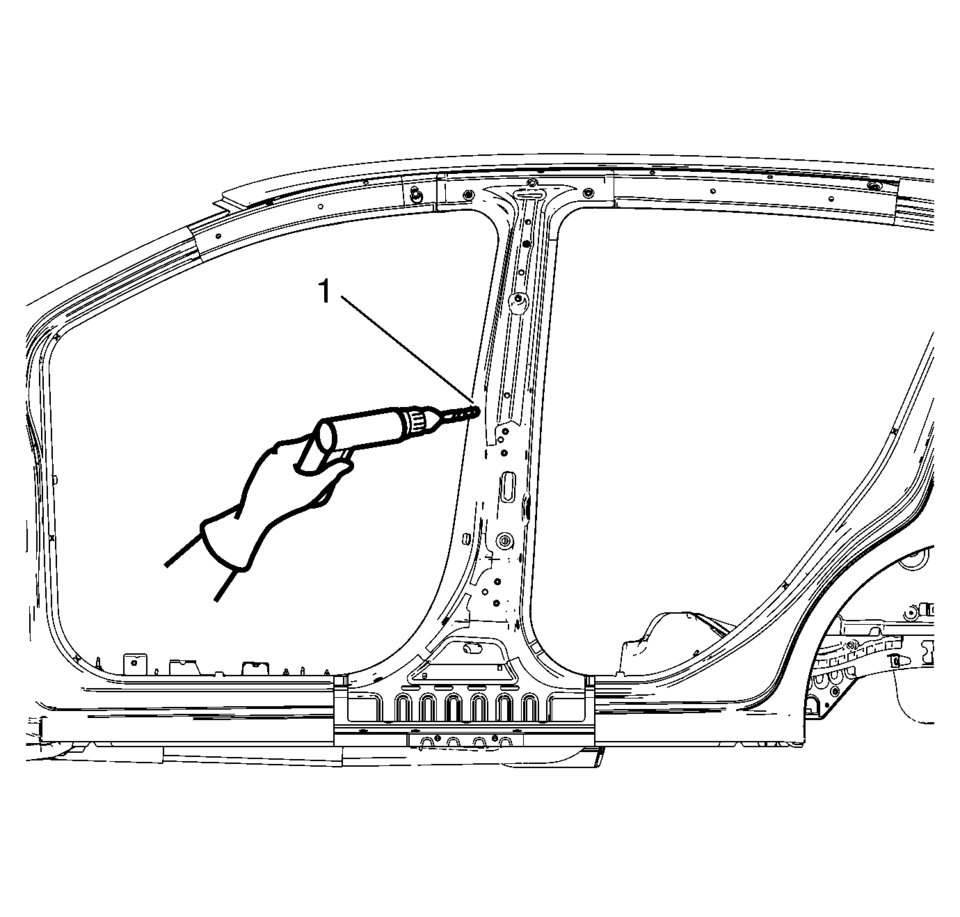

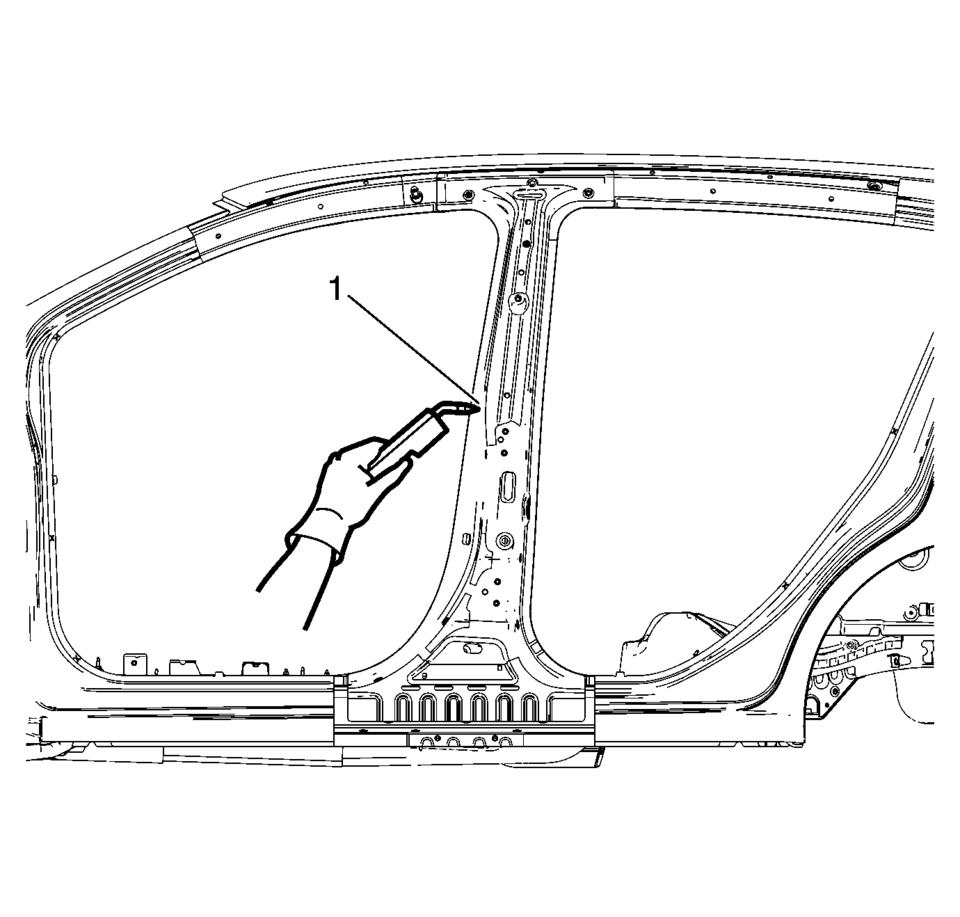

- Drill all factory welds (1). Note the number and location of welds for installation of the service assembly.

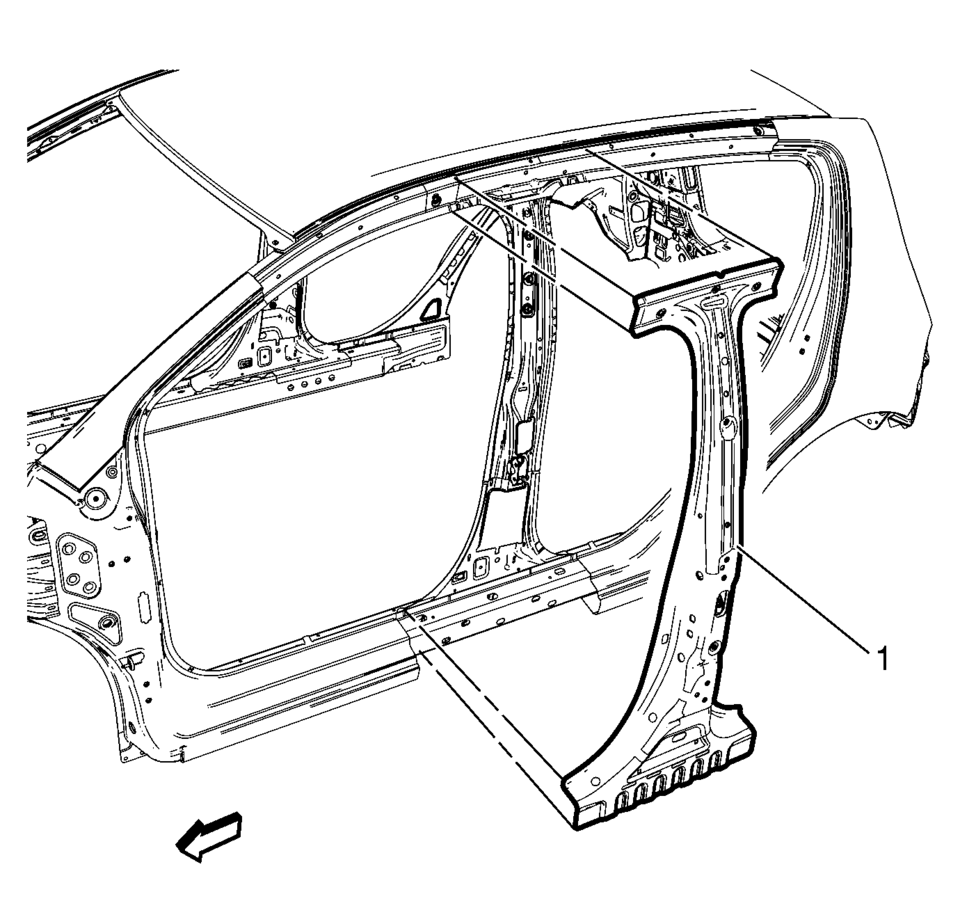

- Remove the damaged center pillar reinforcement (1).

Warning:

Refer to Approved Equipment for Collision Repair Warning.

Warning:

Refer to Glass and Sheet Metal Handling Warning.

Note:

The center pillar upper stiffener is made of Dual Phase Steel and should be replaced only at factory joints. Repairing or sectioning of this part is not recommended. Refer to Dual Phase Steel.

- Installation Procedure

-

- Prepare all mating surfaces as necessary.

- Align the center pillar reinforcement.

- Drill a 8?€‰mm (5/16?€‰in)

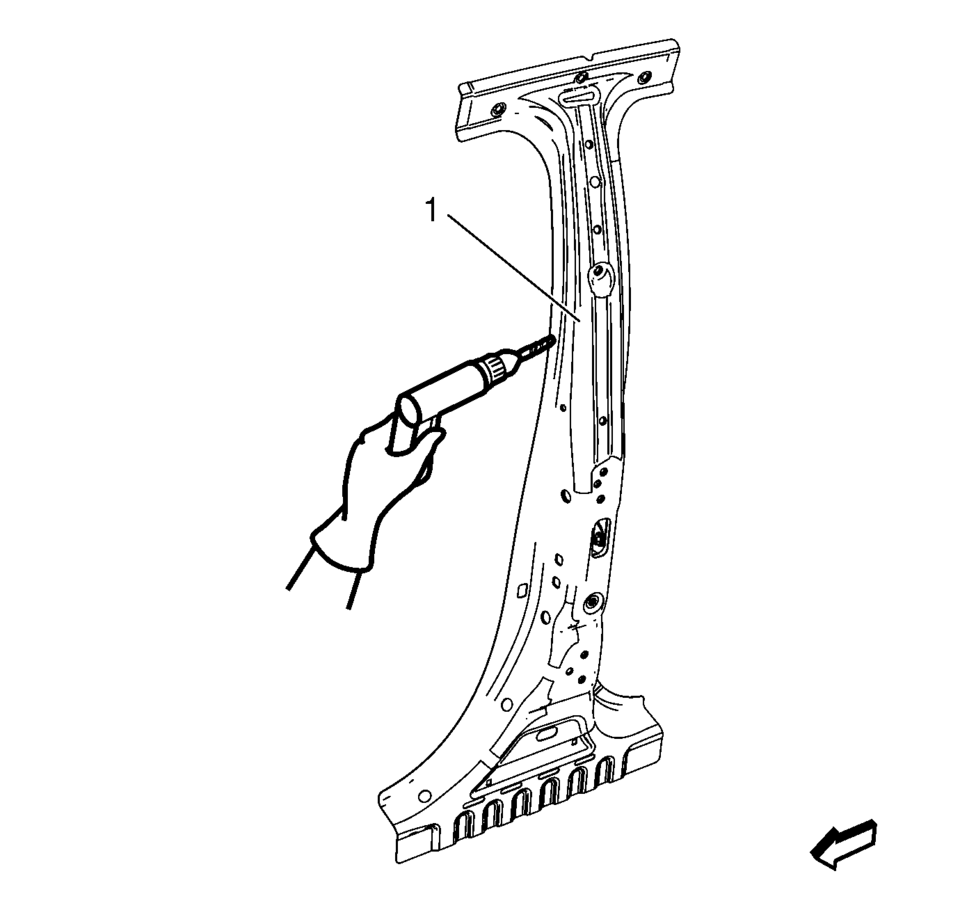

holes for plug welding along the edges of the center pillar reinforcement as noted from the original panel (1).

- Clean and prepare the attaching surfaces for welding.

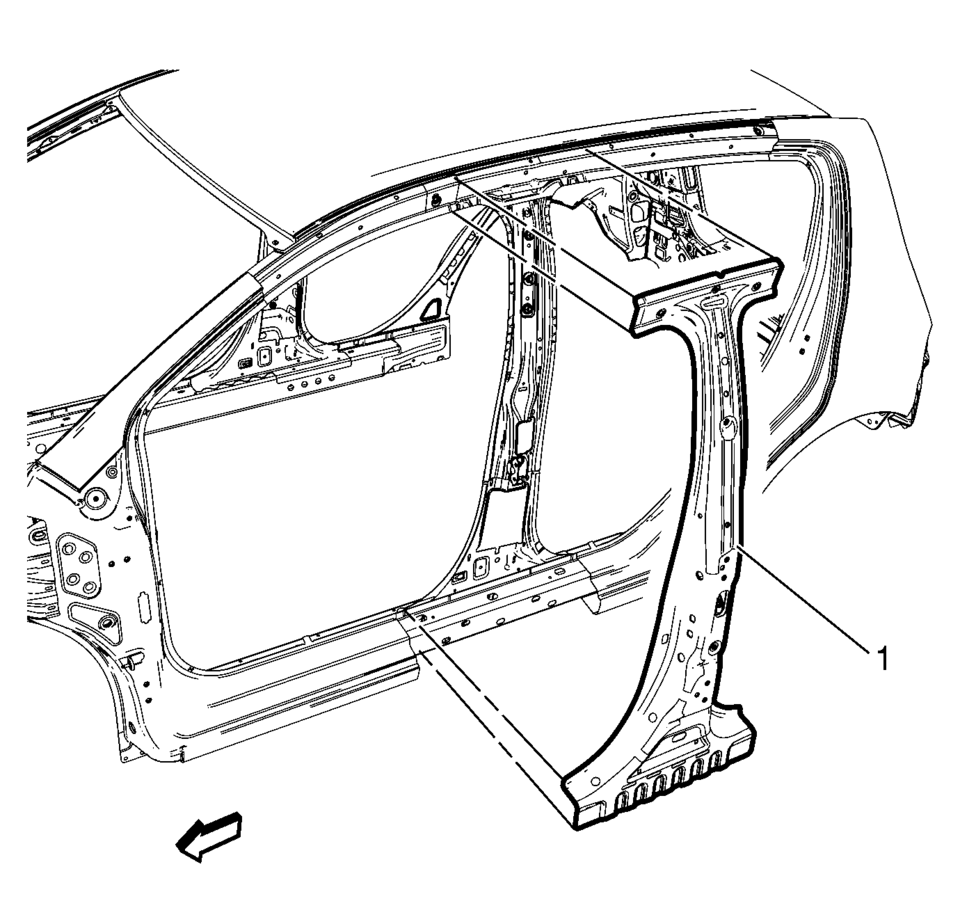

- Position the center pillar reinforcement on the vehicle (1).

- Verify the fit of the center pillar reinforcement.

- Clamp the center pillar reinforcement into position.

- Plug weld accordingly (1).

- Apply the sealers and anti-corrosion materials to the repair area, as necessary. Refer to Anti-Corrosion Treatment and Repair.

- Paint the repaired area. Refer to Basecoat/Clearcoat Paint Systems.

- Install all related panels and components.

- Connect the negative battery cable. Refer to Battery Negative Cable Disconnection and Connection.

- Enable the SIR system. Refer to SIR Disabling and Enabling.

Special Tools

Special Tools

Illustration

Tool Number/ Description

EN-45059

J-45059

Angle Meter

...

Drivetrain and Front Suspension Frame Skid Plate Replacement

Drivetrain and Front Suspension Frame Skid Plate Replacement

Removal Procedure

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the mounting bolts?€‰(1) for the front suspension frame skid

p ...

Other materials:

Headlamp Aiming

Visual Aiming Preparation Procedure

Note: Some state and local laws specify requirements for headlamp

aim. Comply with all of these laws when performing any headlamp aiming operations.

Headlamp aim should be checked:

When a new headlamp capsule is installed.

If ser ...

Sunroof Air Deflector Replacement

Sunroof Air Deflector Replacement

Callout

Component Name

Preliminary Procedure

Remove the sunroof module. Refer to Sunroof Module Assembly Replacement.

1

Sunroof Air Deflector

Tip: Cycle ...

Rear Wheelhouse Liner Replacement (Sedan - Left)

Rear Wheelhouse Liner Replacement

Callout

Component Name

Preliminary Procedure

Remove the tire and wheel assembly. Refer to Tire and Wheel Removal and

Installation.

1

Rear Wheelhouse Panel Liner ...

0.0073