Chevrolet Sonic Repair Manual: Front Wheel Drive Shaft Inner Joint and Boot Replacement

Special Tools

DT-35910 Drive Axle Boot Clamp Pliers

For equivalent regional tools, refer to Special Tools.

- Disassemble Procedure

-

Note:

There are types of inner joints available. If the inner joint is connected with the CV style joint, the inner joint is not serviced separately. The inner joint is serviced with the wheel drive shaft as an assembly. If the inner is a tripot type joint follow the procedure below.

- Remove the wheel drive shaft from the vehicle. Refer to Front Wheel Drive Shaft Replacement.

- Install the wheel drive shaft in a soft jawed vise.

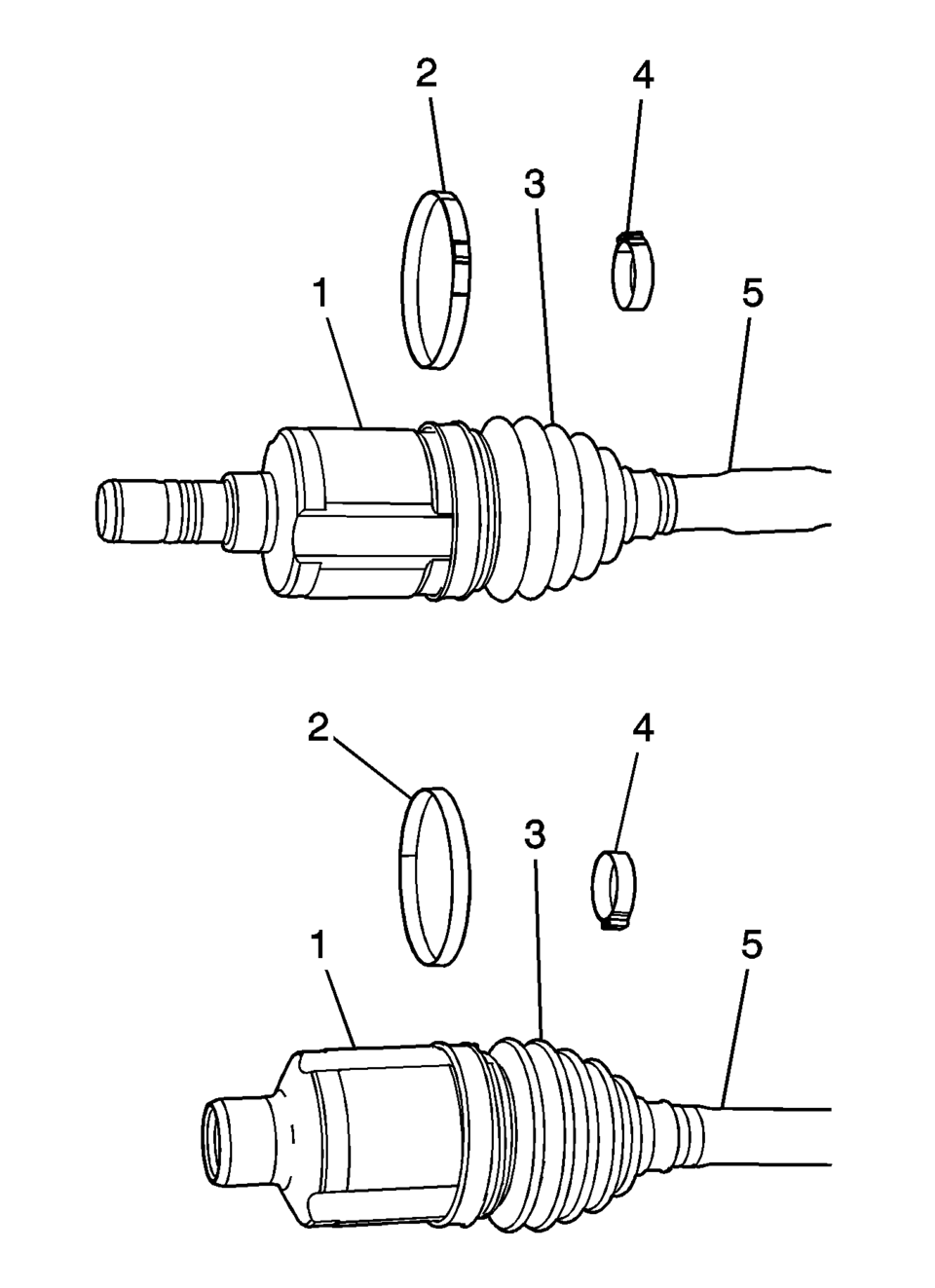

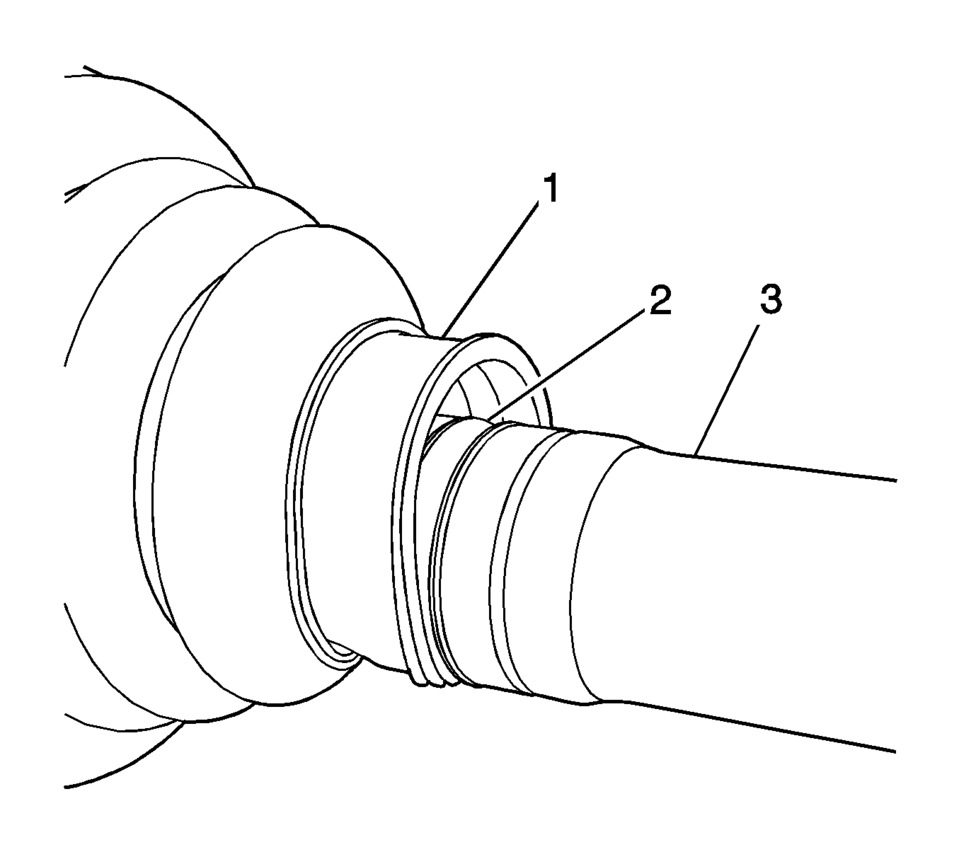

- Using a pair of side cutters, remove and discard the small boot clamp (4) from the boot (3).

- Using the appropriate tool, remove and discard the large boot clamp (2) from the boot (3).

- Remove the boot (3) from the from the tripot housing (1).

- Remove the inner tripot housing (1) from the wheel drive shaft (3).

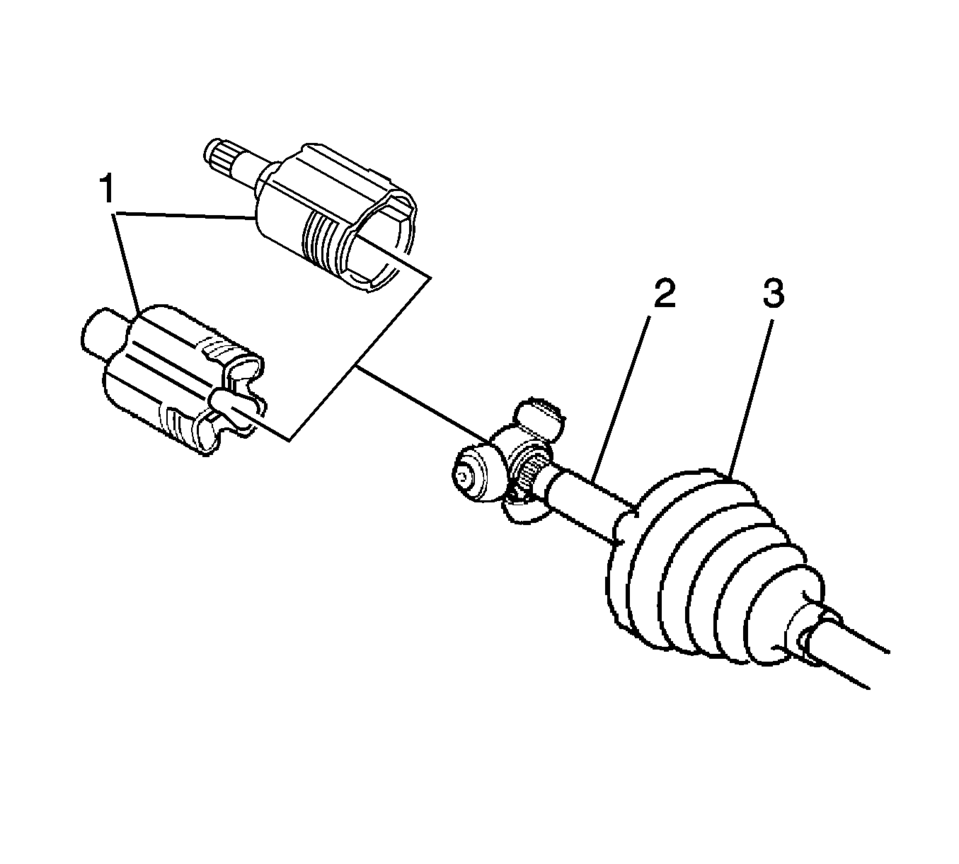

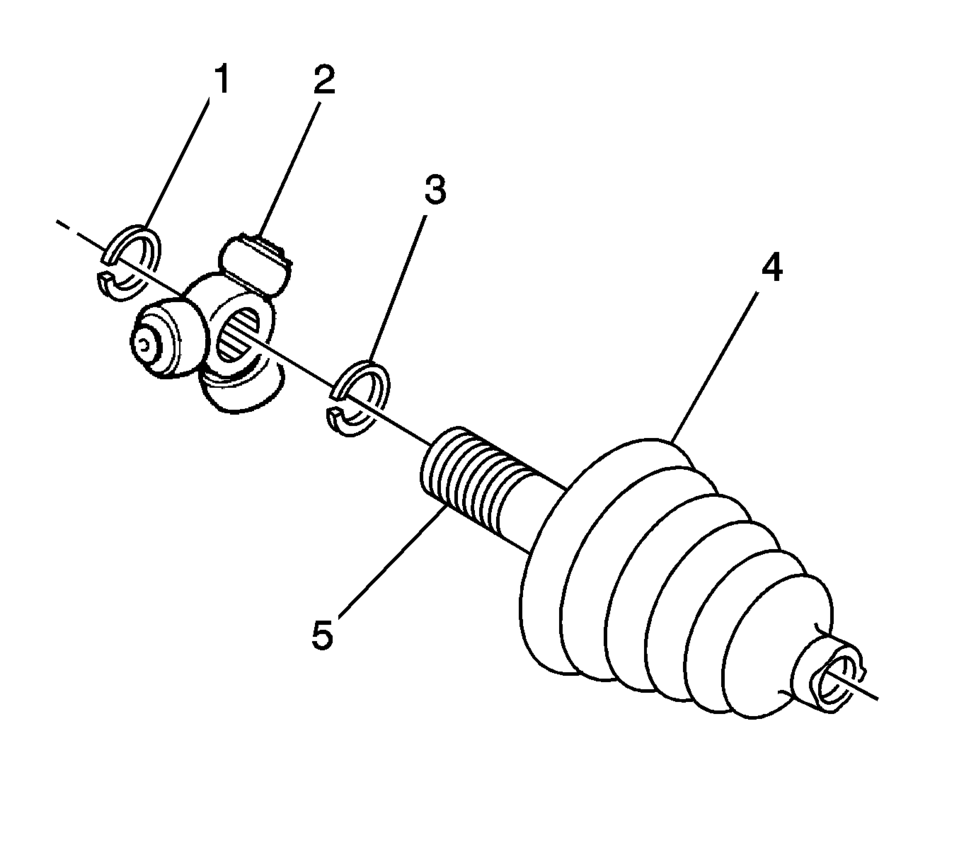

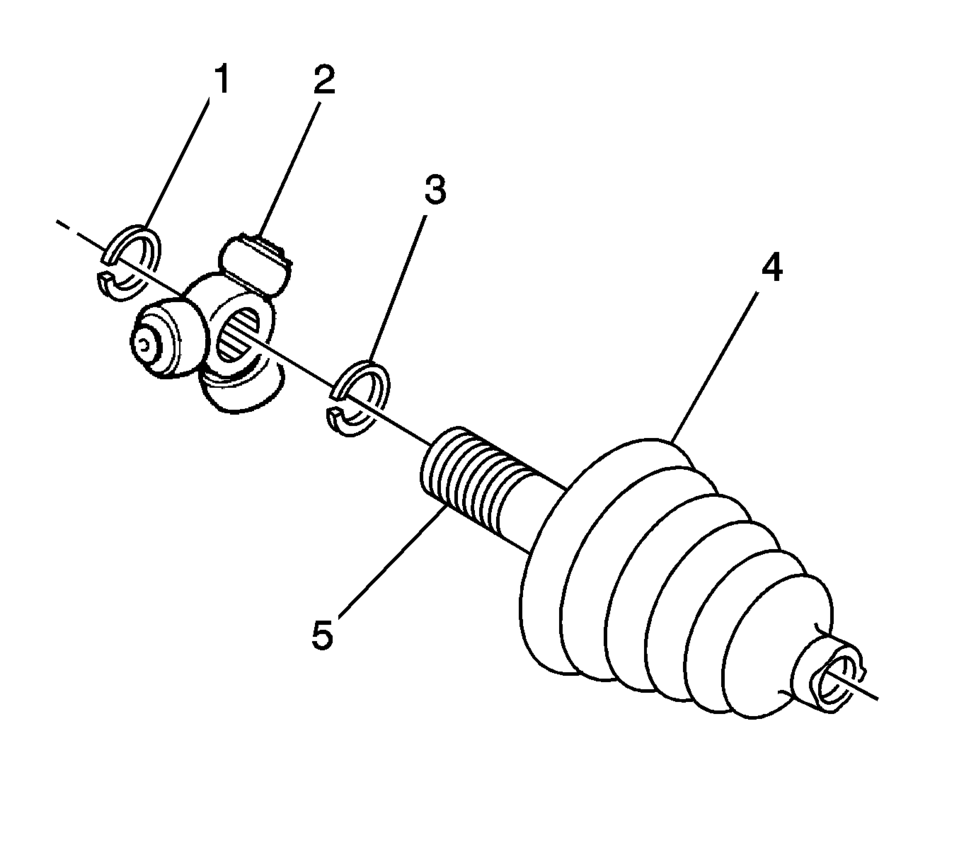

- Using the appropriate tool, remove the outer tripot spider retaining ring (1) from the wheel drive shaft (5).

- Remove the tripot spider (2) from the wheel drive shaft (5).

- Using the appropriate tool, remove the inner tripot retaining ring (3), if equipped, from the wheel drive shaft (5).

- Remove the wheel drive shaft boot (4) from the wheel drive shaft (5).

- Inspect the wheel drive shaft inner joint. Refer to Wheel Drive Shaft Inner Joint Inspection.

- Assemble Procedure

-

- Install the boot (1) on the wheel drive shaft (3).

- Ensure that the boot (1) is properly seated in the groove (2) in the wheel drive shaft.

- Using the appropriate tool, install the inner tripot retaining ring (3), if equipped.

- Install the tripot spider (2) until just touches the shoulder on the wheel drive shaft (5).

- Using the appropriate tool, install the outer tripot spider retaining ring (1).

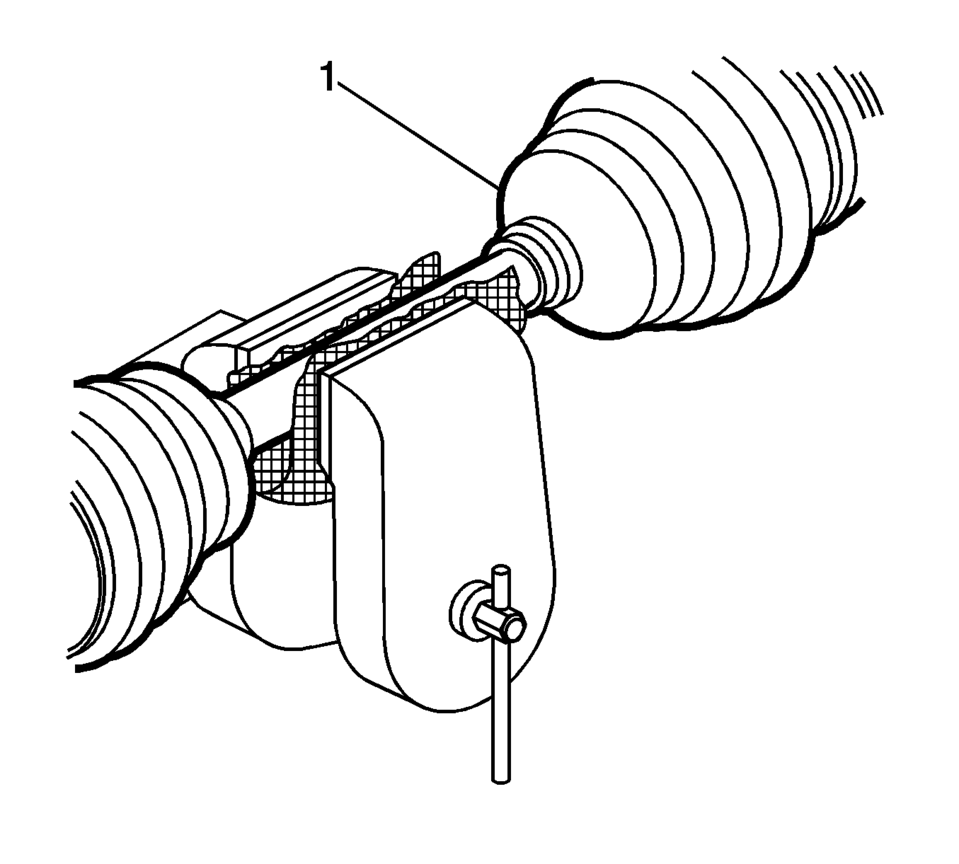

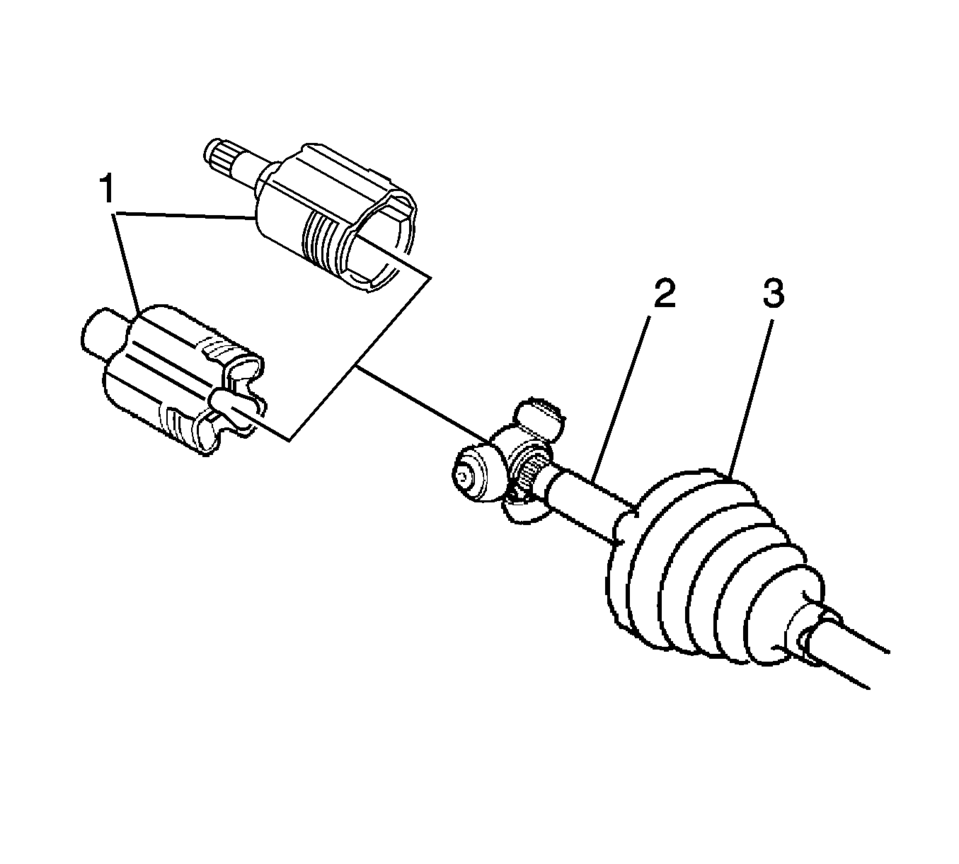

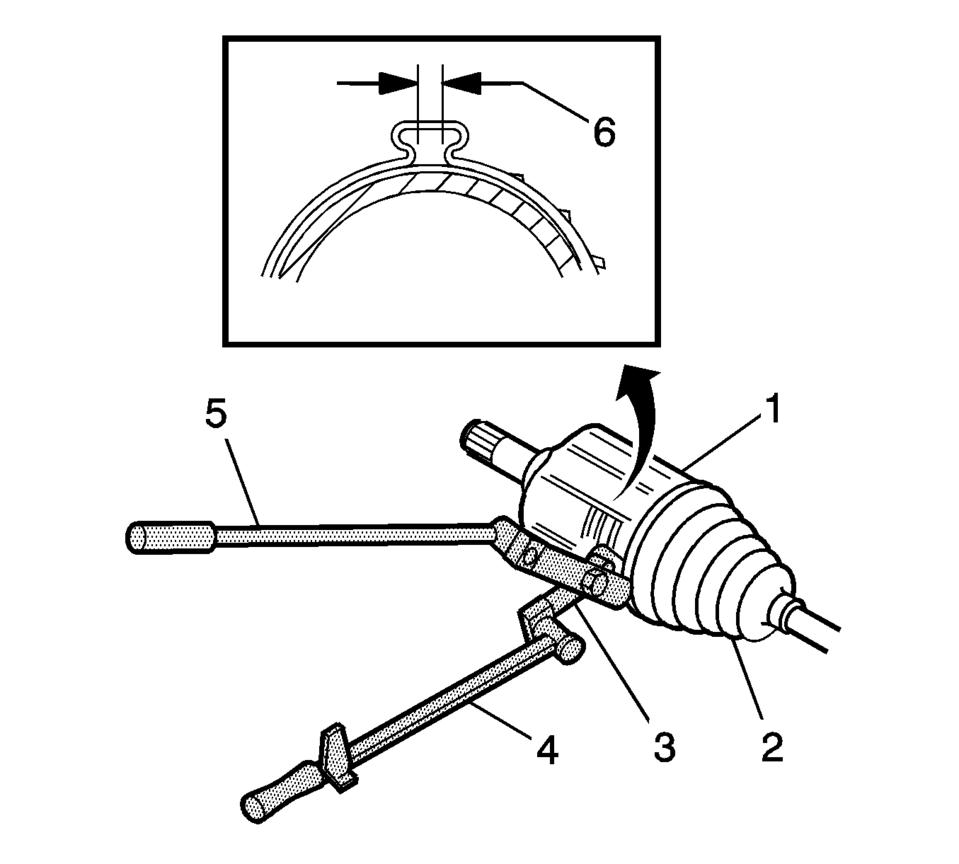

- Using the DT-35910 drive axle boot clamp pliers with a ratchet

wrench and a breaker bar (1), close the boot clamp (2) until the gap (3) measures

1.8 mm (0.07 in)

.

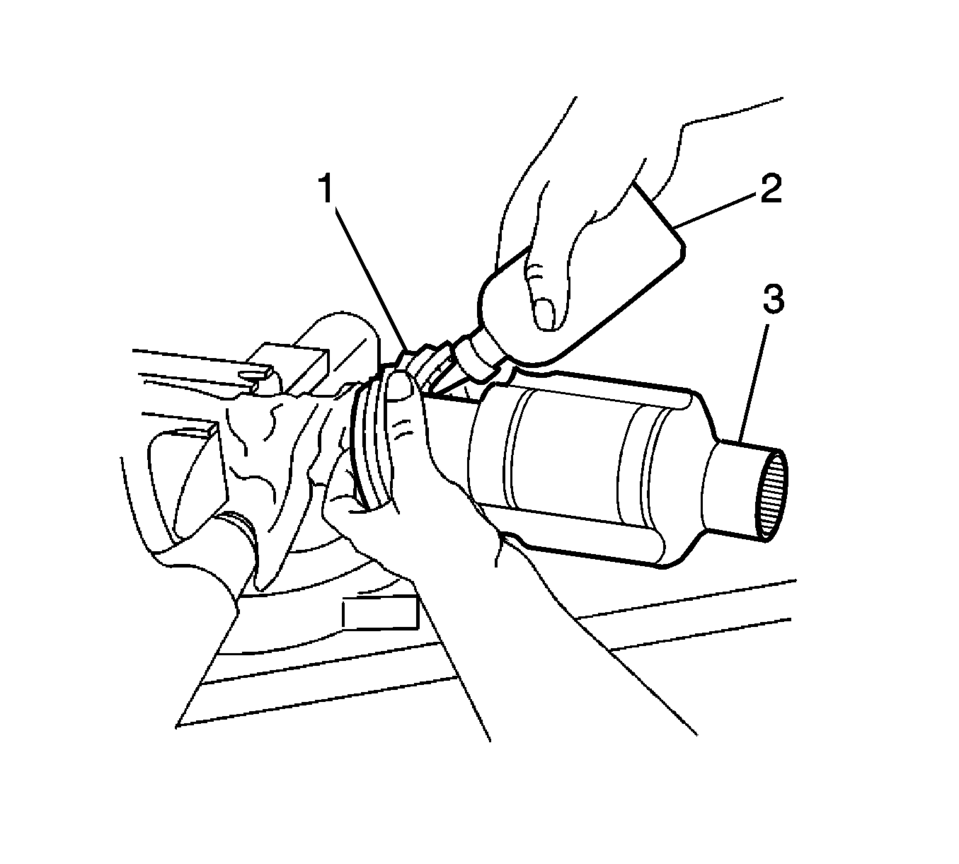

- Install the tripot housing (1) on the wheel drive shaft (3).

- Install the wheel drive shaft boot (3) on the tripot housing (1).

- Place approximately half of the lubricant (2) in the boot (1) and the remaining half in the tripot housing (3).

- Using the DT-35910 drive axle boot clamp pliers (3), a ratchet

wrench (4) and a breaker bar (5), close the boot clamp (1) until the gap (6) measures

1.9 mm (0.07 in)

.

- Remove any of the excess lubricant from the tripot housing and wheel drive shaft.

- Move the tripot joint housing in a circular motion to distribute the lubricant in the tripot housing.

- Remove the wheel drive shaft from the vise.

- Install the wheel drive shaft in the vehicle. Refer to Front Wheel Drive Shaft Replacement.

Note:

Ensure that the boot clamp is properly positioned around the entire circumference of the boot.

Front Wheel Drive Intermediate Shaft Replacement

Front Wheel Drive Intermediate Shaft Replacement

Front Wheel Drive Intermediate Shaft Replacement

Callout

Component Name

Preliminary Procedure

Raise and support the vehicle. Refer ...

Front Wheel Drive Shaft Outer Joint and Boot Replacement

Front Wheel Drive Shaft Outer Joint and Boot Replacement

Special Tools

DT-35910 Drive Axle Boot Clamp Pliers

For equivalent regional tools, refer to Special Tools

Disassemble Procedure

Remove the wheel drive shaft from the vehicle. Refer ...

Other materials:

Front Bumper Fascia Air Deflector Replacement

Front Bumper Fascia Air Deflector Replacement

Callout

Component Name

Preliminary Procedure

Remove the front bumper fascia opening lower cover. Refer to Front Bumper

Fascia Opening Lower Cover Replacement.

...

Windshield Wiper Motor Replacement

Windshield Wiper Motor Replacement

Callout

Component Name

Preliminary Procedure

Remove the wiper system module. Refer to Windshield Wiper System Module

Replacement

1

Windshield Wiper Motor Brack ...

Water Inlet Replacement (LUW)

Removal Procedure

Drain the engine coolant system. Refer to Cooling System Draining and

Filling.

Disconnect the engine coolant temperature sensor connector (1).

Remove the radiator outlet hose connector clip (2) and the radiator

outlet hose ...

0.0069