Chevrolet Sonic Repair Manual: Tire Pressure Indicator Sensor Replacement

- Removal Procedure

-

- Raise the vehicle on a suitable support. Refer to Lifting and Jacking the Vehicle.

- Remove the tire/wheel assembly from the vehicle. Refer to Tire and Wheel Removal and Installation.

- Dismount the tire from the rim. Refer to Tire Dismounting and Mounting.

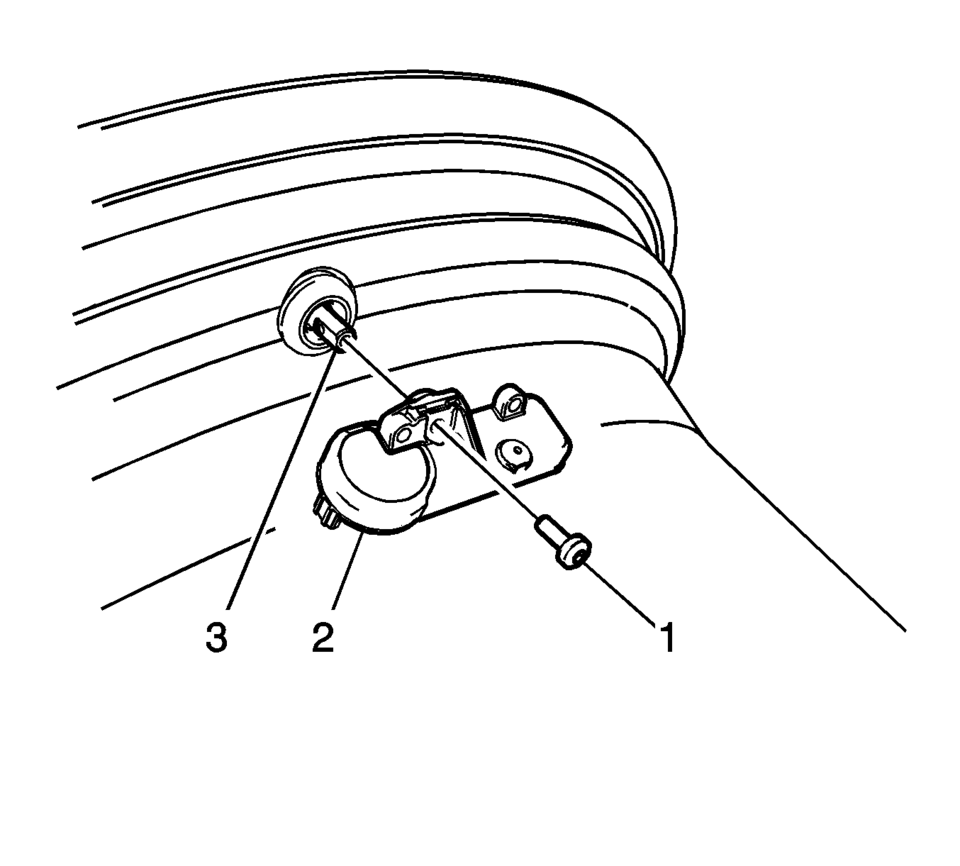

- Remove the TORX screw (1) from the tire pressure sensor (2) and pull it straight off the tire pressure valve stem (3).

- Remove the tire pressure valve stem by pulling it through the rim.

Note:

When servicing the tire pressure sensor always use a new Schrader® tire pressure monitoring (TPM) sensor and a new TORX screw during installation.

Caution:

Do not scratch or damage the clear coating on aluminum wheels with the tire changing equipment. Scratching the clear coating could cause the aluminum wheel to corrode and the clear coating to peel from the wheel.

- Installation Procedure

-

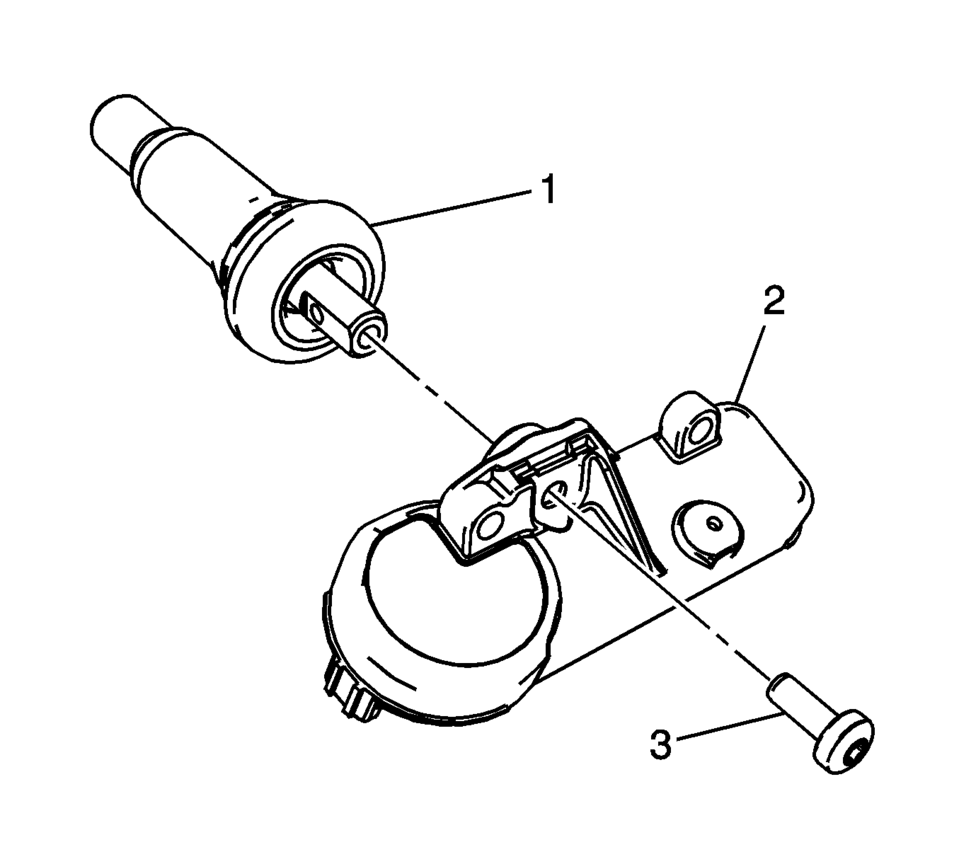

- Ensure the flat of the valve, lines up with the flats of the snap in the enclosure.

- TPM valves and TORX screws are single use items.

- Assemble the tire pressure sensor (2) to the valve stem and install

the new TORX screw (3), tighten to 1.3 Y (11.5 lb in)

.

- Apply tire soap to the rubber portion of the valve stem (1).

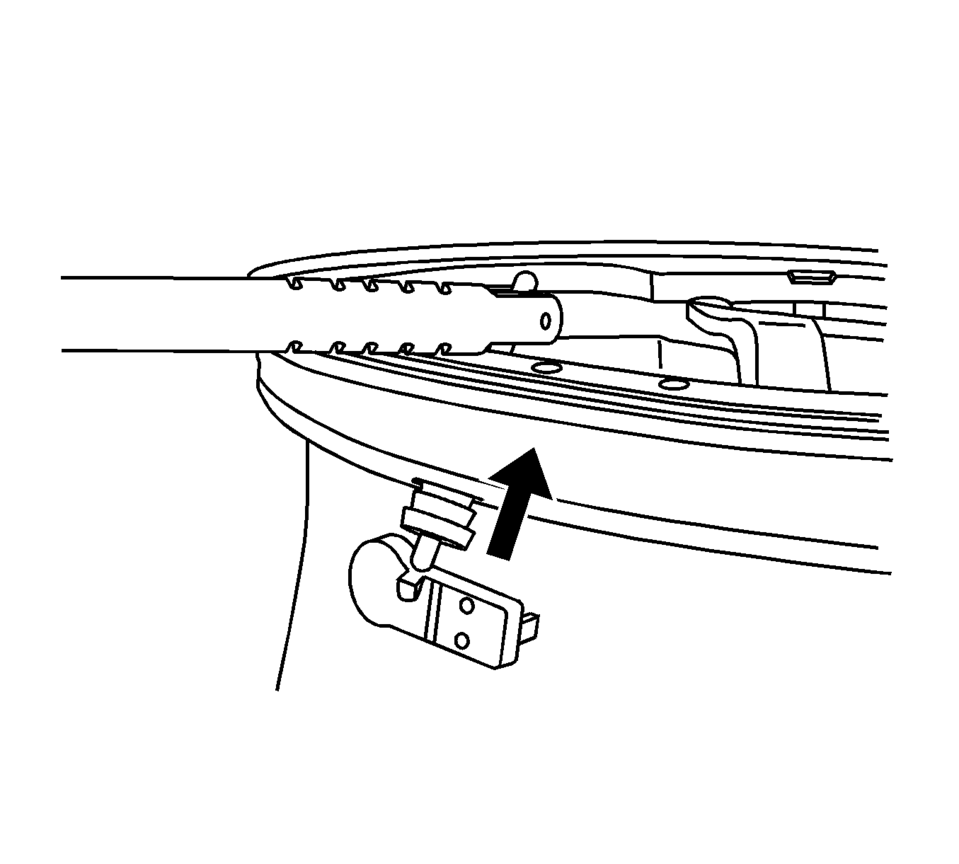

- Using a tire valve stem mounting tool, pull the valve stem through in a direction parallel to the valve hole on the rim.

- Mount the tire to the rim. Refer to Tire Dismounting and Mounting.

- Install the tire/wheel assembly on the vehicle. Refer to Tire and Wheel Removal and Installation.

- Lower the vehicle.

- Learn the tire pressure sensors. Refer to Tire Pressure Indicator Sensor Learn.

Caution:

Refer to Fastener Caution.

Note:

Note:

Use an approved tire mounting lubricant. DO NOT use silicon or corrosive base compounds to lubricate the tire bead and the wheel rim. A corrosive type compound can cause tire or rim deterioration.

Note:

Snap Fit TPM sensors are shipped in the OFF mode. The sensor will exit its OFF state when the tire is inflated.

Tire Pressure Indicator Sensor Learn

Tire Pressure Indicator Sensor Learn

Special Tools

EL-46079 Tire Pressure Monitor Diagnostic Tool

EL-50448 Tire Pressure Monitor Sensor Activation Tool

For equivalent regional tools, refer to Special Tools.

Learn Mode Descr ...

Tire Pressure Monitor Description and Operation

Tire Pressure Monitor Description and Operation

Tire Pressure Monitoring Block Diagram

...

Other materials:

Remote Vehicle Start

If equipped, this feature allows the engine to be started from outside the vehicle.

(Remote Vehicle Start): This button

will be on the RKE transmitter if the vehicle has remote start.

The climate control system will use the previous settings during a remote start.

The rear defog may come on d ...

Side Window Defogger Outlet Grille Replacement

Side Window Defogger Outlet Grille Replacement

Callout

Component Name

1

Side Window Defroster Outlet Grille (Qty:?€‰2)

Procedure

Use a flat bladed plastic trim tool to aid in the removal of the grille

ass ...

Intake Manifold Cleaning and Inspection

Clean the intake manifold mating surfaces.

Inspect the intake manifold (2) for damage.

Inspect the intake manifold for cracks near metallic inserts.

Inspect the crankcase ventilation passages in the intake manifold face for

blockage.

Warning: Wear safety glasses in or ...

0.0084