Chevrolet Sonic Repair Manual: Engine Front Cover and Oil Pump Cleaning and Inspection

- Engine Front Cover Cleaning Procedure

-

- Clean the engine front cover sealing surface.

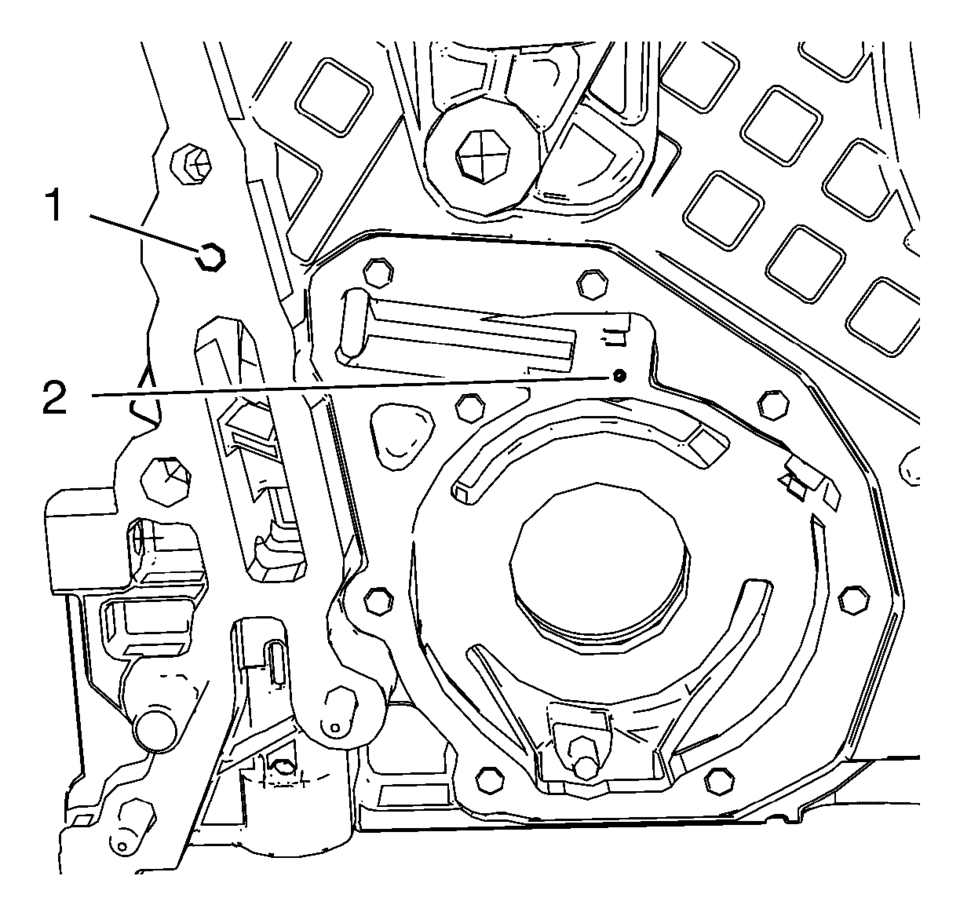

- Clean the shown oil gallery with solvent and compressed air. Blow compressed air from bore (2) to bore (1).

Warning:

Wear safety glasses when using compressed air in order to prevent eye injury.

Caution:

To ensure proper engine lubrication, clean clogged or contaminated oil galleries in an approved solvent and with compressed air. Failure to clean oil galleries may cause engine damage.

- Engine Front Cover Visual Inspection

-

Inspect the engine front cover for cracks, scratches and damage.

- Oil Pump Visual Inspection and Measurement

-

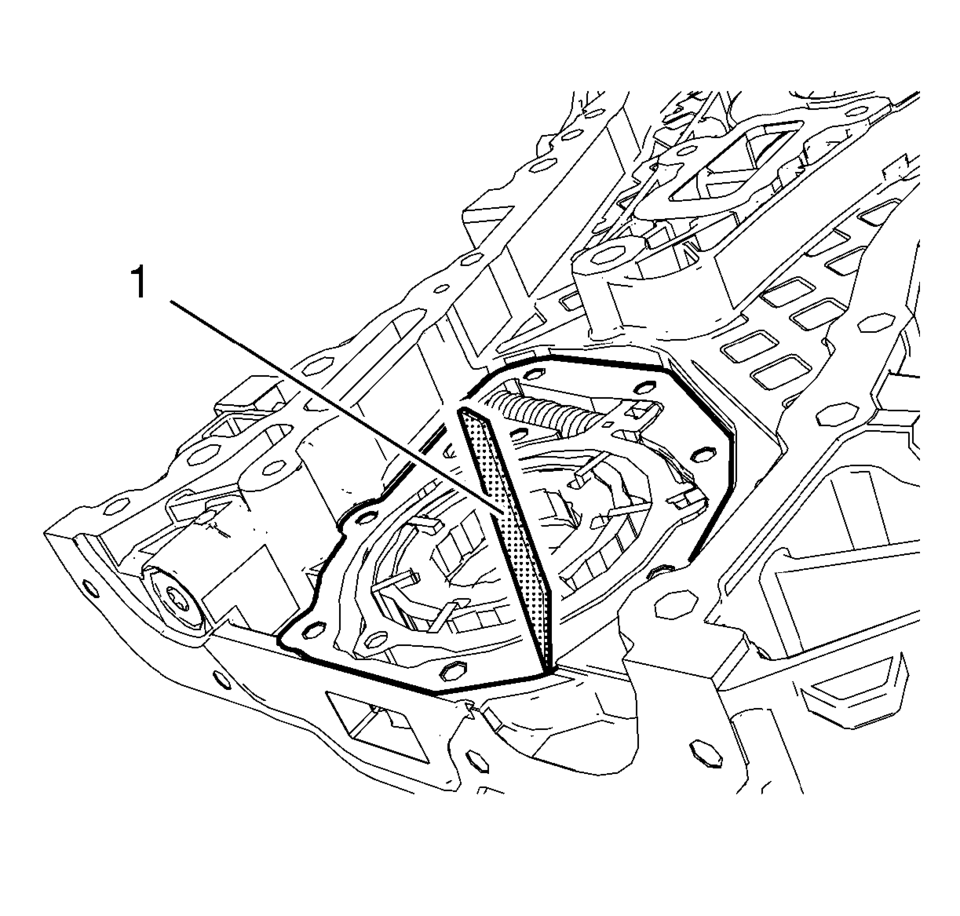

- Inspect the oil pump cover and the engine front cover for flatness.

- Inspect the oil pump vanes, the oil pump vane rotor, the oil pump vane rings and the oil pump slide for localized flatting.

- Inspect the oil pump slide pivot pin for firm seat.

- Measure the oil pump axial clearances. Use a straight edge (1) and a feeler gauge.

- The maximal axial clearance between engine front cover and oil pump vane rotor should be 0.1 mm (0.004 in).

- The maximal axial clearance between engine front cover and oil pump vane should be 0.09 mm (0.0035 in).

- The maximal axial clearance between engine front cover and oil pump vane ring should be 0.4 mm (0.016 in).

- The maximal axial clearance between engine front cover and oil pump slide should be 0.08 mm (0.0031 in).

- The maximal axial clearance between engine front cover and oil pump slide seal should be 0.09 mm (0.0035 in).

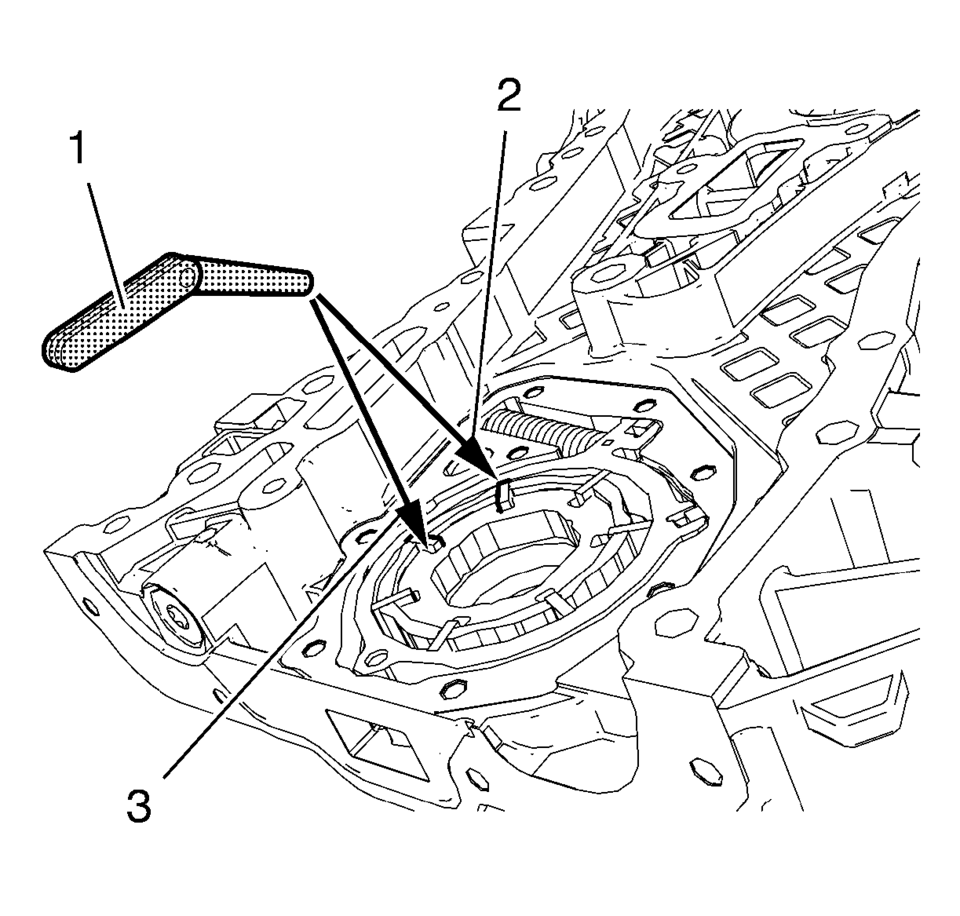

- Measure the oil pump radial clearance. Use a feeler gauge (1). Measure

the clearance between oil pump vane rotor and oil pump vane (3).

The maximal clearance should be 0.05 mm (0.002 in).

- Measure the clearance between oil pump vane and oil pump slide (2).

The maximal clearance should be 0.2 mm (0.008 in).

Note:

Oil pump components are installed.

Engine Front Cover and Oil Pump Assemble

Engine Front Cover and Oil Pump Assemble

Oil Pump Installation

Note: The oil pump slide spring and pin, as well as the slide

seal and slide seal spring can be ordered as single parts. All other

oil pump co ...

Engine Front Cover and Oil Pump Disassemble

Engine Front Cover and Oil Pump Disassemble

Engine Front Cover Disassemble

Remove the intake camshaft position sensor bolt (1).

Remove the intake camshaft position sensor (2) and the seal ring (3).

...

Other materials:

How to Identify Plastic Parts

saepvcsae

Plastic parts can be identified by the SAE code, which is usually found on the

rear of the part, and/or by the characteristics of the plastic. Knowing the type

of plastic aids in selecting the proper repair materials and in selecting the proper

repair procedure.

Look for the SAE ...

Inflatable Restraint Sensing and Diagnostic Module Programming and Setup

Special Tools

EL-49642 SPS Programming Support Tool

For equivalent regional tools, refer to Special Tools.

Note:

DO NOT program a control module unless directed to by a service procedure

or a service bulletin. If the ECU is not properly configured with the correct

calibration ...

Fluid Cooler Outlet Hose Replacement

Removal Procedure

Remove the front bumper fascia opening lower cover.

Refer to Front Bumper Fascia Opening Lower Cover

Replacement

Remove the front wheelhouse liner inner front extension.

Refer to Front Wheelhouse Liner Inner Front Extension

Replacement

...

0.0085