Chevrolet Sonic Repair Manual: Oil Pan Installation

Special Tools

EN-49980 Guidance Pins

For equivalent regional tools, refer to Special Tools.

- Clean the sealing surfaces from old sealing material, dirt, oil and grease.

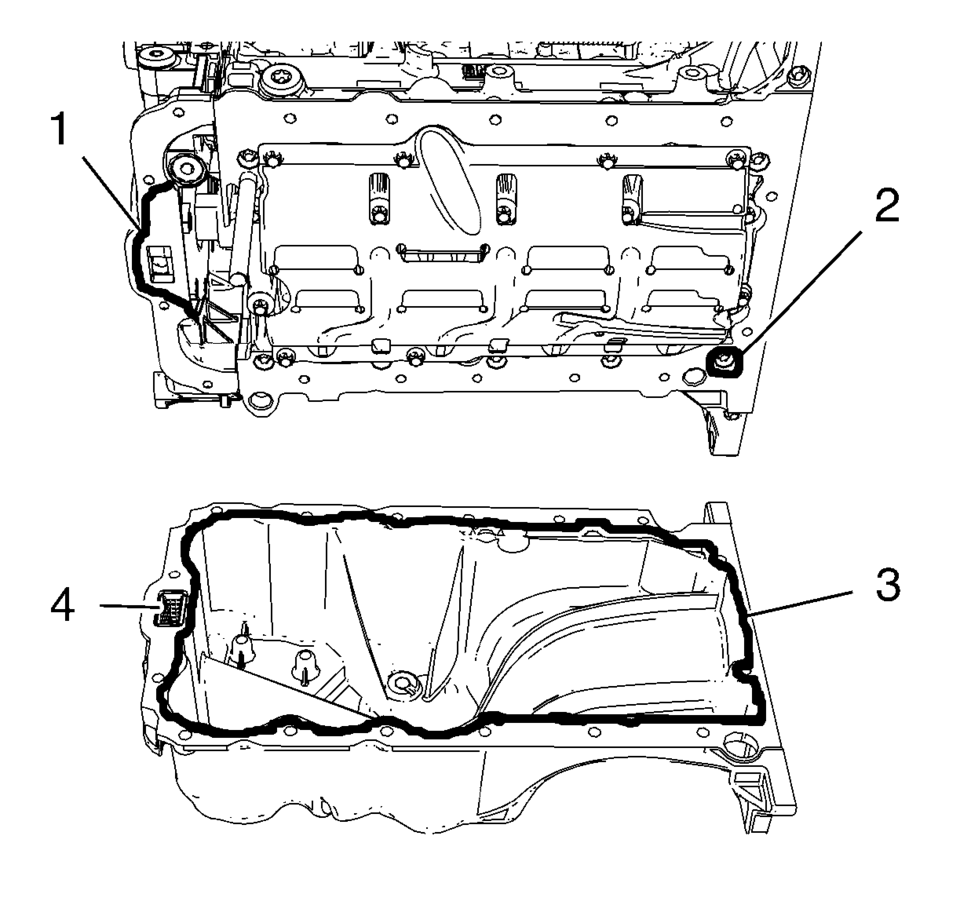

- Apply sealing compound to the oil pan. Refer to Adhesives, Fluids, Lubricants, and Sealers.

- Apply sealing compound to the groove of the engine front cover (1). Refer to Adhesives, Fluids, Lubricants, and Sealers.

- Apply sealing compound around the screw bore (2) of the crankshaft bearing cap tie plate.

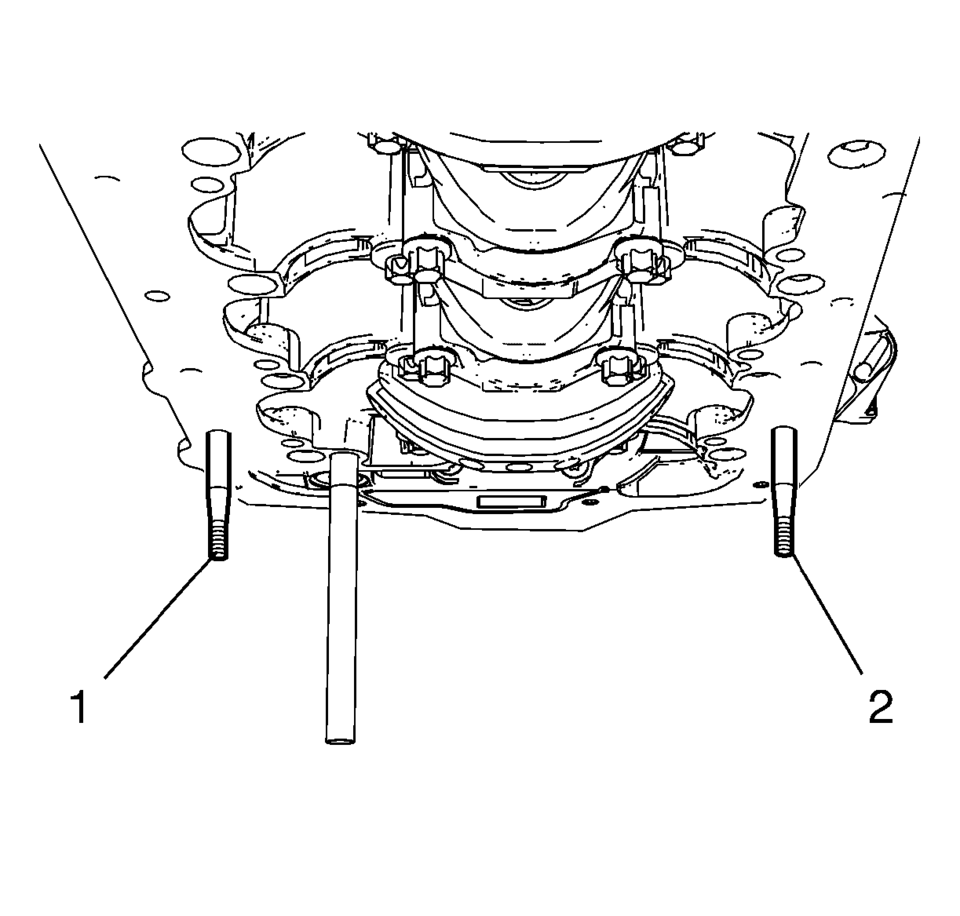

- Install the 2 EN-49980 pins (1) and (2) to the shown oil pan screw bores.

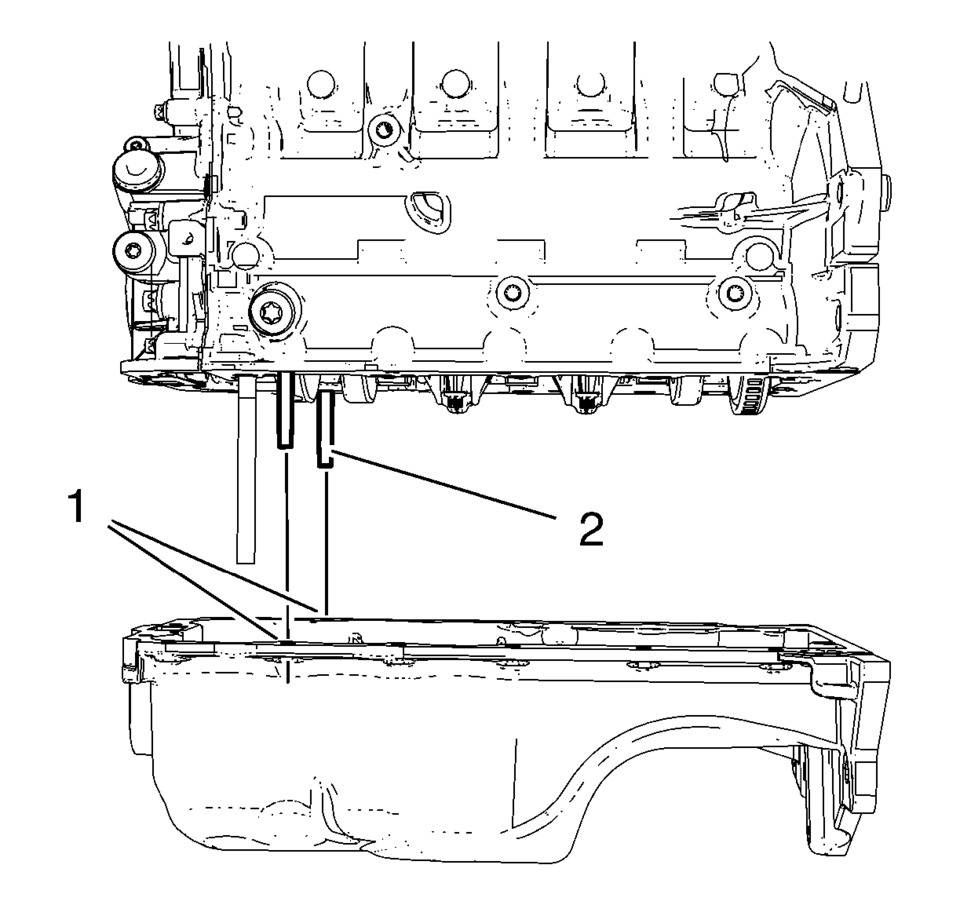

- Carefully install the oil pan. Guide the oil pan with EN-49980 pins (2) and the equivalent screw bores (1).

- Hold the oil pan with 4 oil pan bolts.

- Remove EN-49980 pins.

- Install the remaining 12 oil pan bolts and hand tighten.

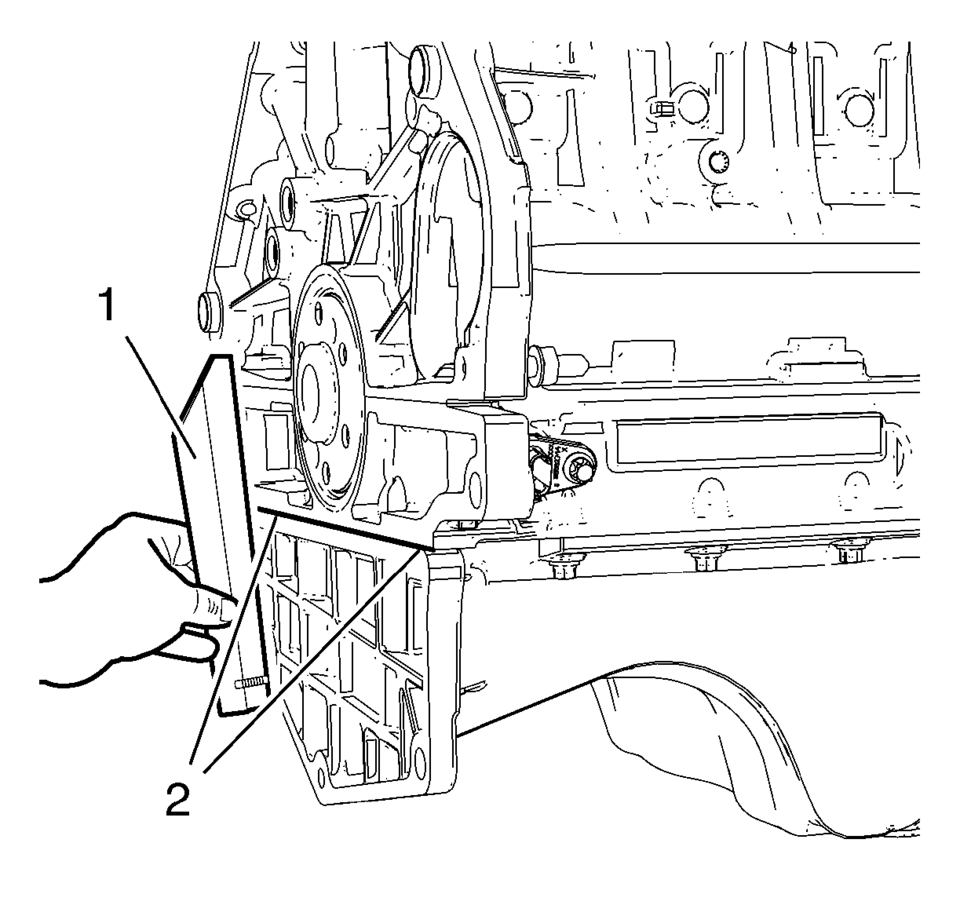

- Lay a straight edge (1) against the oil pan and engine block. Using a rubber mallet, adjust the transition in area (2) until there is no clearance between oil pan and the straight edge.

- Tighten the 16 oil pan bolts to 10 Y (89 lb in)

.

Note:

The sealing bead should be applied close to the inner edge of the oil pan. Take care that the oil suction gallery (4) will not get contaminated with sealing compound or dirt. The thickness of the sealing bead (3) should be 2 mm (0.0787 in).

Note:

The complete installation procedure of the oil pan should not take longer than 10 minutes.

Caution:

Use care when installing the oil pan to prevent disruption of the sealing bead. The sealing bead should remain consistent until the oil pan is mated with the engine. An inconsistent sealing bead can cause an insufficient seal and result in engine damage.

Caution:

Refer to Fastener Caution.

Oil Pan Cleaning and Inspection

Oil Pan Cleaning and Inspection

Warning: Wear safety glasses when using compressed air in order

to prevent eye injury.

Caution: To ensure proper engine lubrication, clean clogged or

contaminated oil ga ...

Oil Pan Removal

Oil Pan Removal

Remove the 16 oil pan bolts (1).

Caution: Pry the oil pan carefully in order to prevent damage

to the transaxle case or the oil pan sealing surfaces.

Place a ...

Other materials:

Horn Replacement

Horn Replacement

Callout

Component Name

Preliminary Procedure

Remove the front wheelhouse liner front. Refer to Front Wheelhouse Liner

Replacement.

1

Horn Nut

Caution: Refer to Fastener ...

Sun Load Temperature Sensor Replacement

Sun Load Temperature Sensor Replacement

Callout

Component Name

1

Sun Load Temperature Sensor Bezel

2

Sun Load Temperature Sensor

Procedure

Disconnect the electrical connector.

Twist ...

Air Cleaner Assembly Replacement

Air Cleaner Assembly Replacement

Callout

Component Name

1

Air Cleaner Outlet Duct Clamp.

Procedure

Loosen clamp and remove air cleaner outlet duct from air cleaner assembly.

2

Mass ...

0.0078