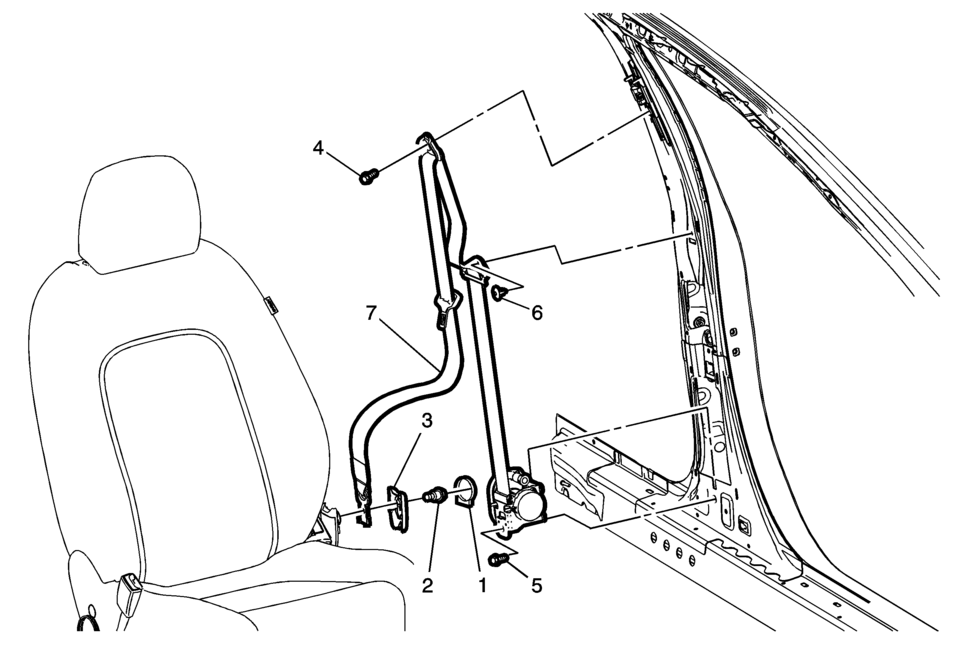

Chevrolet Sonic Repair Manual: Driver or Passenger Seat Shoulder Belt Replacement (with A69)

|

Callout |

Component Name |

|---|---|

|

Warning: Refer to SIR Warning. Warning: Refer to SIR Inflator Module Handling and Storage Warning. Warning: Refer to SIR Seatbelt Pretensioner Handling Warning. Warning: In order to prevent accidental deployment and the risk of personal injury, do not dispose of an undeployed inflatable restraint seat belt pretensioner as normal shop waste. Undeployed seat belt pretensioners contain substances that could cause severe illness or personal injury if their sealed containers are damaged during disposal. Use the following deployment procedures to safely dispose of an undeployed seat belt pretensioner. Failure to observe the following disposal methods may be a violation of federal, state, or local laws.

|

|

|

1 |

Driver or Passenger Seat Belt Tensioner Cover |

|

2 |

Driver or Passenger Seat Belt Tensioner Cover Fastener Caution: Refer to Fastener Caution.

7.5?€‰Y (66?€‰lb?€‰in) |

|

3 |

Driver or Passenger Seat Belt Tensioner Cover |

|

4 |

Driver or Passenger Seat Shoulder Belt Fastener Tighten

45?€‰Y (33?€‰lb?€‰ft) |

|

5 |

Driver or Passenger Shoulder Belt Retractor Fastener Tighten

45?€‰Y (33?€‰lb?€‰ft) Note: When the seat belt retractor is replaced with a new one, there is no thread in the nut welded to the retractor. This is normal as the bolt will make the thread in the welded nut when the bolt is tightened. |

|

6 |

Driver or Passenger Seat Belt Push On Retainer Procedure

Use a flat-bladed tool to remove locking pin in retainer. |

|

7 |

Driver or Passenger Seat Shoulder Belt Retractor Assembly Procedure

|

Driver or Passenger Seat Removal and Installation

Driver or Passenger Seat Removal and Installation

Driver or Passenger Seat Removal and Installation

Callout

Component Name

Warning: Refer to SIR Warning.

Preliminary Pr ...

Driver or Passenger Seat Shoulder Belt Replacement (without A69)

Driver or Passenger Seat Shoulder Belt Replacement (without A69)

Driver or Passenger Seat Shoulder Belt Replacement

Callout

Component Name

Warning: Refer to SIR Warning.

Warning: ...

Other materials:

California Fuel Requirements

If the vehicle is certified to meet California Emissions Standards, it is designed

to operate on fuels that meet California specifications. See the underhood emission

control label. If this fuel is not available in states adopting California Emissions

Standards, the vehicle will operate satisf ...

Front Side Door Outer Panel Replacement

Removal Procedure

Note: According to different corrosion warranties, only the regional

mandatory joining methods are allowed.

Disable the SIR System. Refer to SIR Disabling and Enabling.

Disconnect the negative battery cable. Refer to Battery Negative Cable

Disconn ...

Front Bumper Lower Impact Bar Replacement

Front Bumper Lower Impact Bar Replacement

Callout

Component Name

Preliminary Procedure

Remove the front bumper fascia. Refer to Front Bumper Fascia Replacement.

1

Front Bumper Lower Impact Bar Br ...

0.007