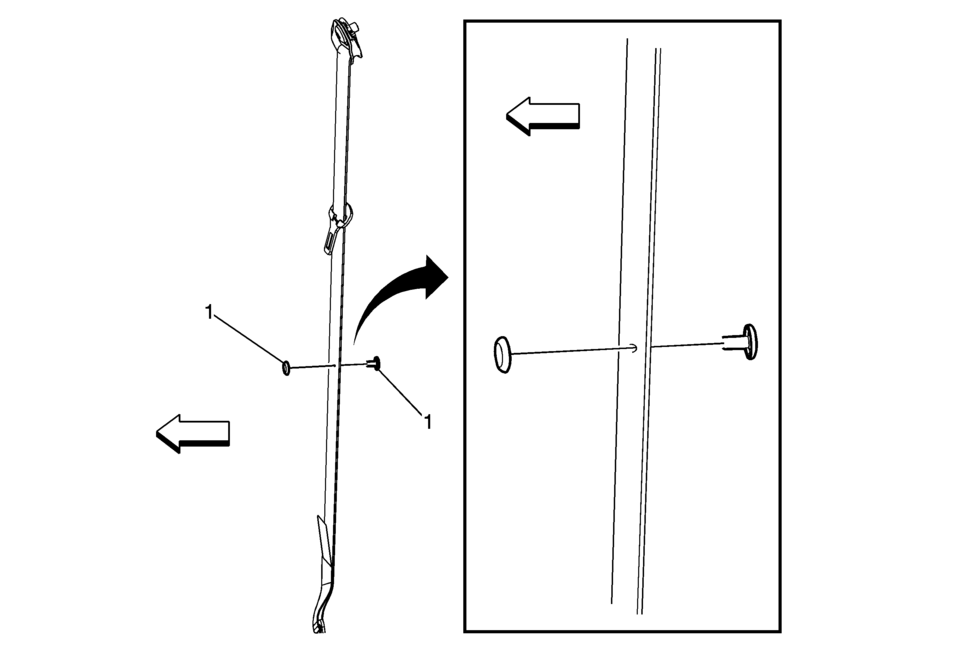

Chevrolet Sonic Repair Manual: Seat Belt Latch Stop Installation

|

Callout |

Component Name |

|---|---|

Preliminary Procedure

|

|

|

1 |

Seat Belt Stop Button Procedure

Tip: Ensure the male half of the stop button is facing forward in the vehicle in order to ensure the stop button will not snag customers clothing. |

SIR Seatbelt Pretensioner Handling Warning

SIR Seatbelt Pretensioner Handling Warning

Warning: When carrying an undeployed inflatable restraint seat belt

retractor pretensioner:

Do not carry the seat belt pretensioner by the seat belt webbing or

pigtail connector, if e ...

Seat Belt Service Precautions

Seat Belt Service Precautions

Note: If the vehicle has been in a collision, refer to Repairs

and Inspections Required After a Collision for additional information.

Do not bleach or dye the seat belt webbing. Us ...

Other materials:

Hazard Warning Flashers

(Hazard Warning Flasher): Press

and momentarily hold this button to make the front and rear turn signal lamps flash

on and off. This warns others that you are having trouble. Press and momentarily

hold again to turn the flashers off. ...

Rear End Panel Replacement

Removal Procedure

Warning: Refer to Approved Equipment for Collision Repair

Warning.

Warning: Refer to Glass and Sheet Metal Handling Warning.

Note: The rear end lower panel reinforcement extension is

made of Ultra High Strength Dual Phase St ...

Service Prior to Assembly

The importance of cleanliness during assembly cannot be overstated. Dirt or debris

will cause engine damage. An automobile engine is a combination of many machined,

honed, polished and lapped surfaces with minor tolerances. When any internal engine

parts are serviced, care and cleanliness are ...

0.0056