Chevrolet Sonic Repair Manual: Tire-to-Wheel Match-Mounting (Vectoring)

Note:

After remounting a tire to a wheel or after replacing a tire and/or a wheel, remeasure the tire and wheel assembly runout in order to verify that the amount of runout has been reduced and brought to within tolerances. Ensure that the tire and wheel assembly is properly balanced before reinstalling to the vehicle.

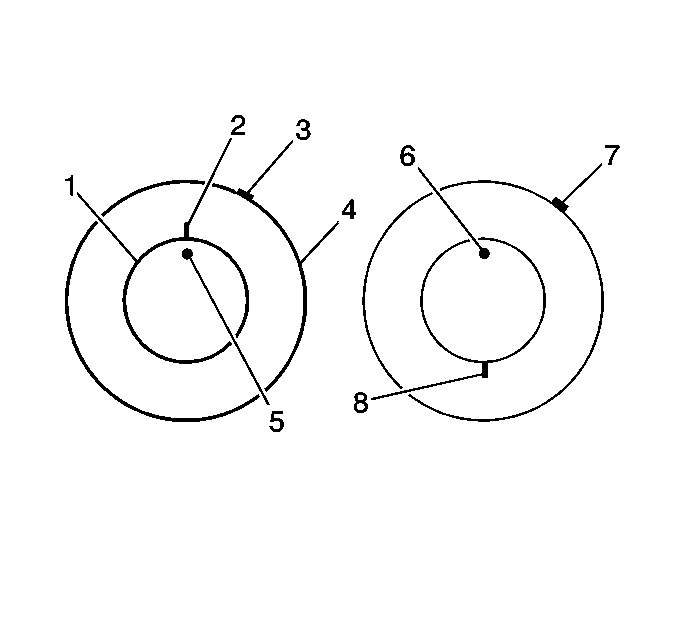

- Mark the location of the high spot (3) on the tire as determined during the off-vehicle tire and wheel assembly runout measurement.

- Place a reference mark (2) on the tire sidewall at the location of the valve stem (5).

- Always refer to the valve stem as the 12 o'clock position.

- Refer to the location of the high spot (3) by its clock position on the wheel, relative to the valve stem.

- Tire and Wheel Assembly Balancing - Off Vehicle

- Tire and Wheel Removal and Installation

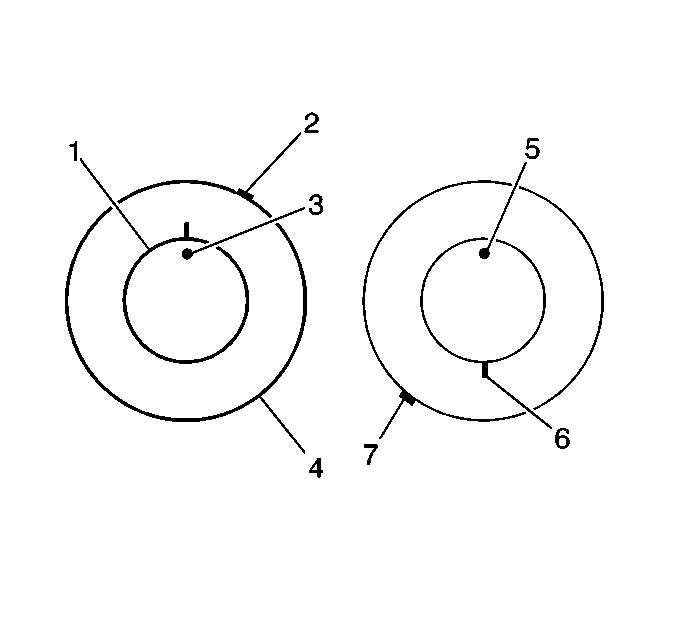

- If the clock location of the high spot (7) is now at or near a position 180 degrees from the original clock location of the high spot, the tire is the major contributor to the assembly runout concern.

- If the clock location of the high spot is now in-between the 2 extremes, then both the tire and the wheel are both contributing to the assembly runout concern. Rotate the tire an additional 90 degrees in both the clockwise and the counterclockwise directions to obtain the lowest amount of assembly runout.

Tire and Wheel Removal and Installation

Tire and Wheel Removal and Installation

Special Tools

CH-41013 Rotor Resurfacing Kit

CH-42450-A Wheel Hub Resurfacing Kit

For equivalent regional tools, refer to Special Tools.

Removal Procedure

Ra ...

Tires and Wheels Description and Operation

Tires and Wheels Description and Operation

There are two types of tire and wheel balancing: static and dynamic.

Static balance is the equal distribution of weight around the wheel. Assemblies

that are statically unbalanced cause a bouncing ...

Other materials:

Front Fog Lamp Cover Replacement (Without T3U)

Front Fog Lamp Cover Replacement

Callout

Component Name

Preliminary Procedure

Remove the front wheelhouse liner. Refer to Front Wheelhouse Liner Replacement.

1

Front Fog Lamp Front Cover

Proce ...

Instrument Panel Compartment Replacement

Instrument Panel Compartment Replacement

Callout

Component Name

Preliminary Procedure

Remove the right instrument panel upper trim panel. Refer to Instrument

Panel Upper Trim Panel Replacement - Right Side.

...

Engine Coolant Thermostat Replacement (LUV)

Removal Procedure

Drain the cooling system. Refer to Cooling System Draining and Filling.

Remove the air cleaner outlet duct. Refer to Air Cleaner Outlet Duct

Replacement.

Remove the engine coolant temperature sensor connector (1).

Disconnect the radi ...

0.0048