Chevrolet Sonic Repair Manual: Crankshaft Balancer Replacement

Special Tools

- EN-470–B Angular Torque Wrench

- EN-49979 Crankshaft Shock Mount Retainer

For equivalent regional tools, refer to Special Tools.

- Removal Procedure

-

- Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

- Remove front wheelhouse liner extension right side. Refer to Front Wheelhouse Liner Inner Front Extension Replacement.

- Remove the drive belt. Refer to Drive Belt Replacement.

- Place collecting basin underneath.

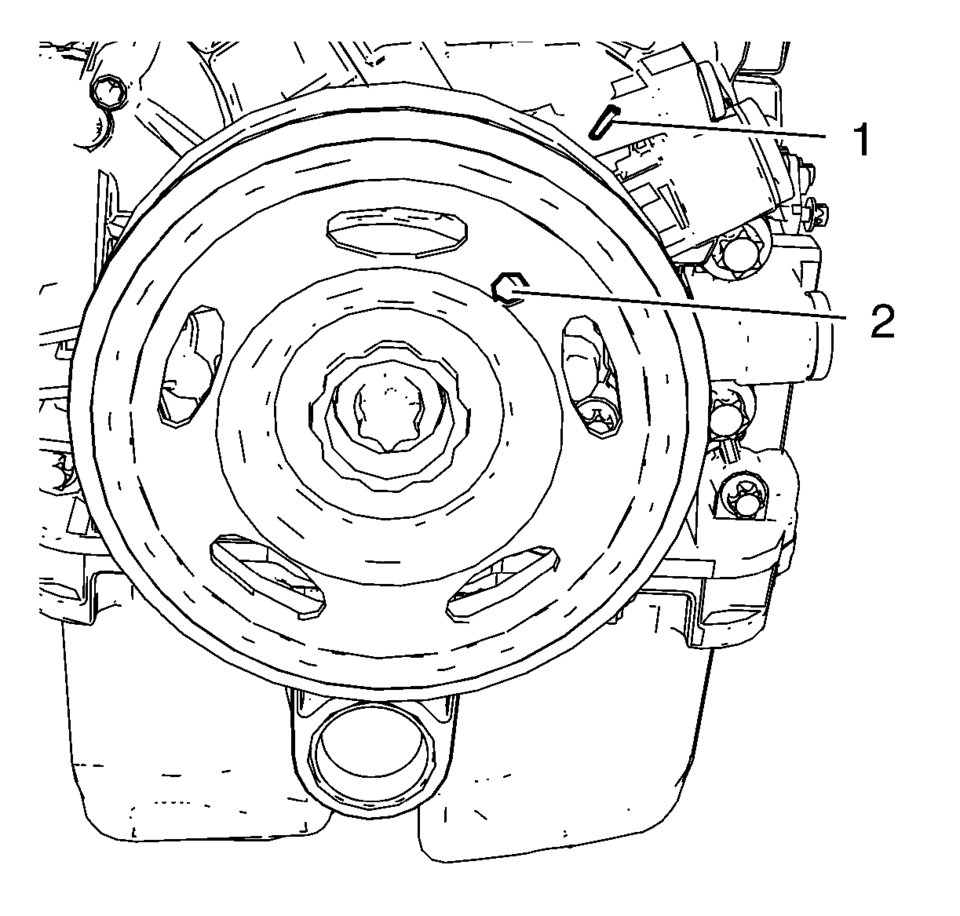

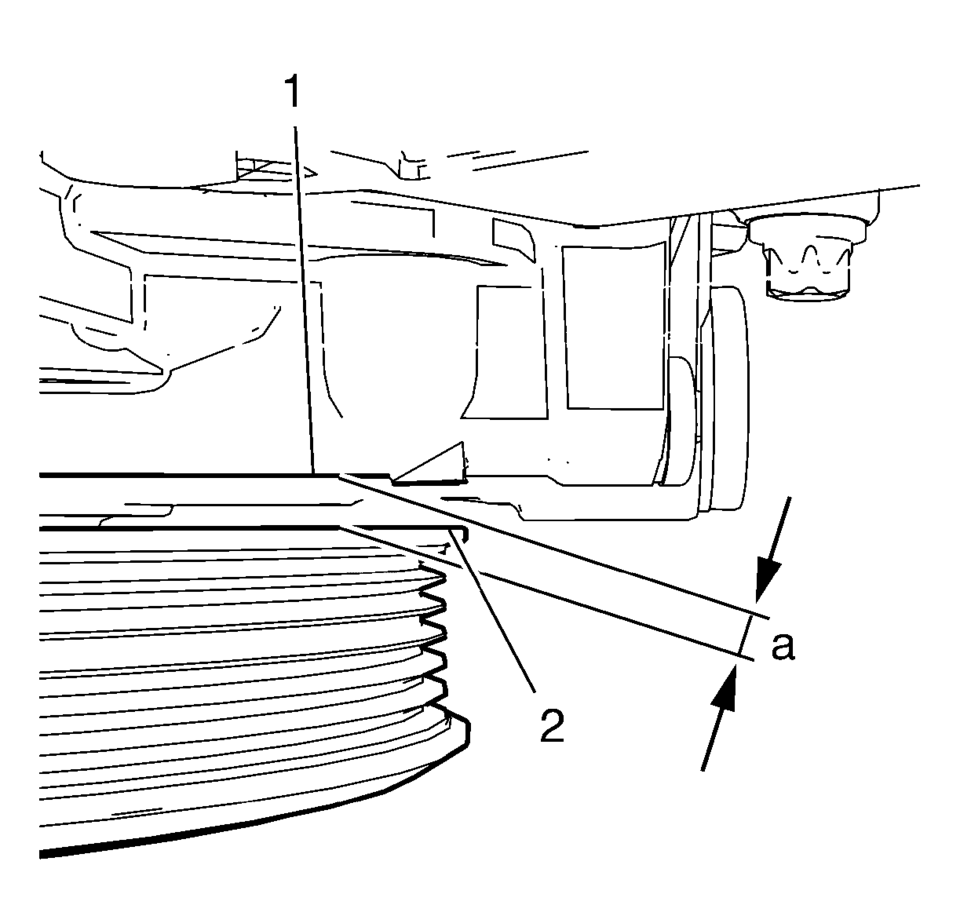

- Rotate the engine clockwise until the bore (2) in the crankshaft balancer aligns with the mark (1) on the engine front cover.

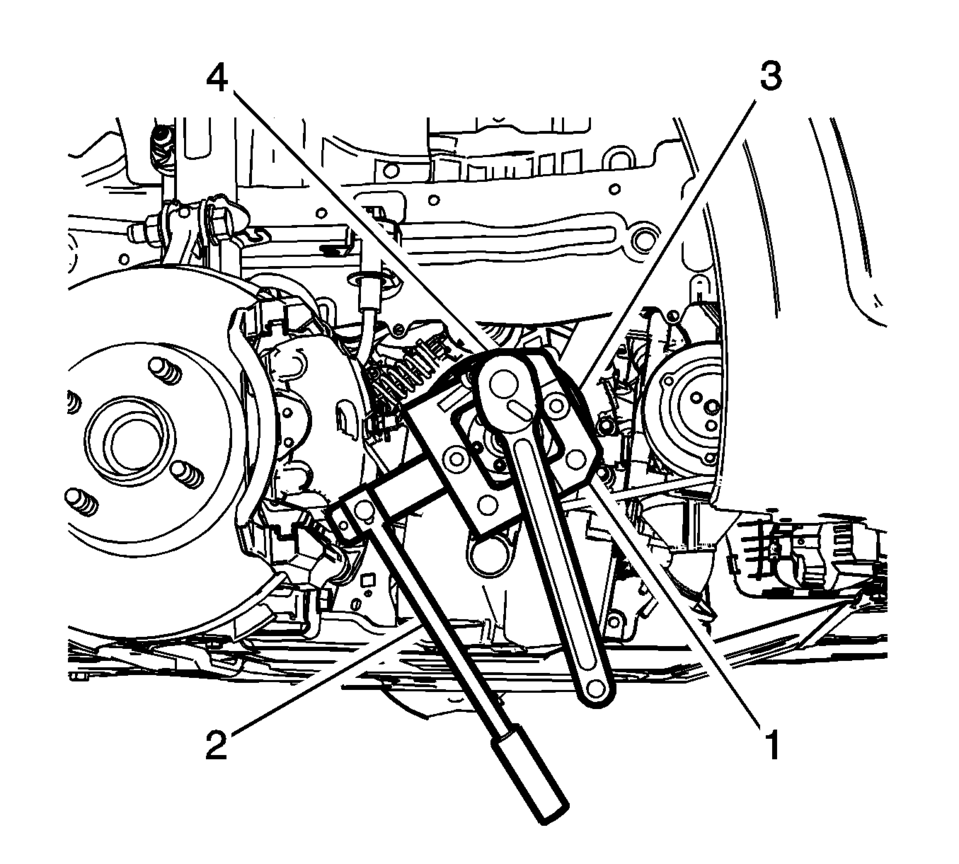

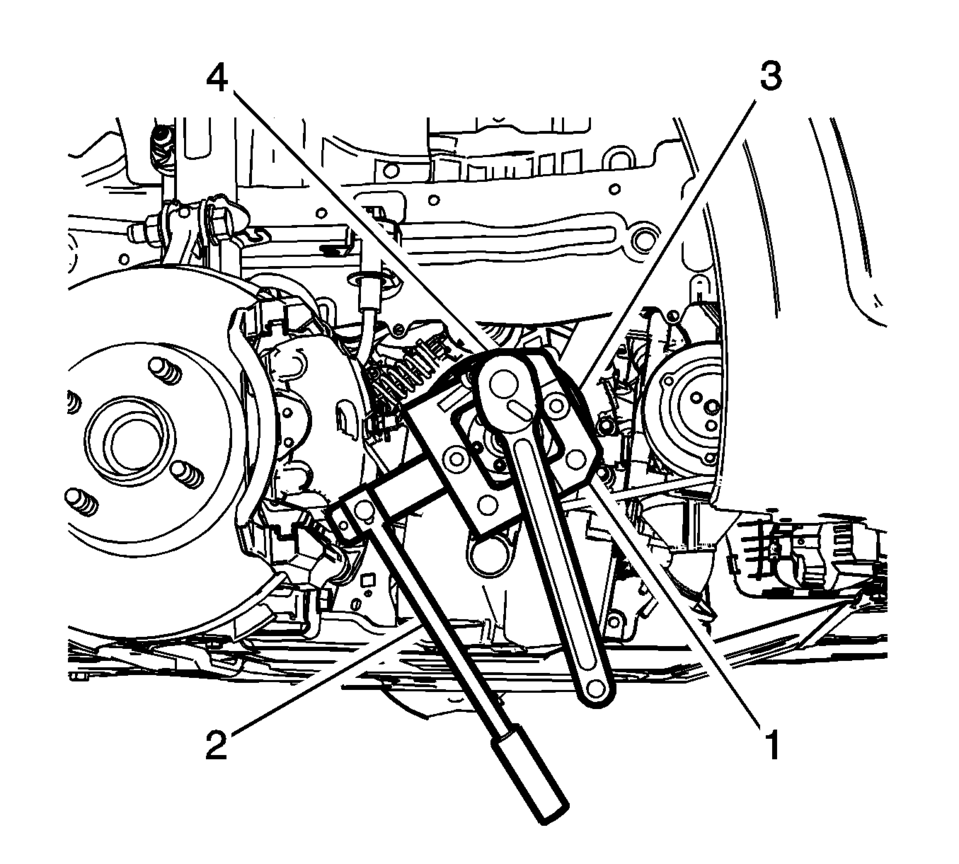

- Install EN-49979 crankshaft shock mount retainer (1) to suitable tool (2).

- Loosen the crankshaft balancer bolt (4) while holding the crankshaft balancer (3).

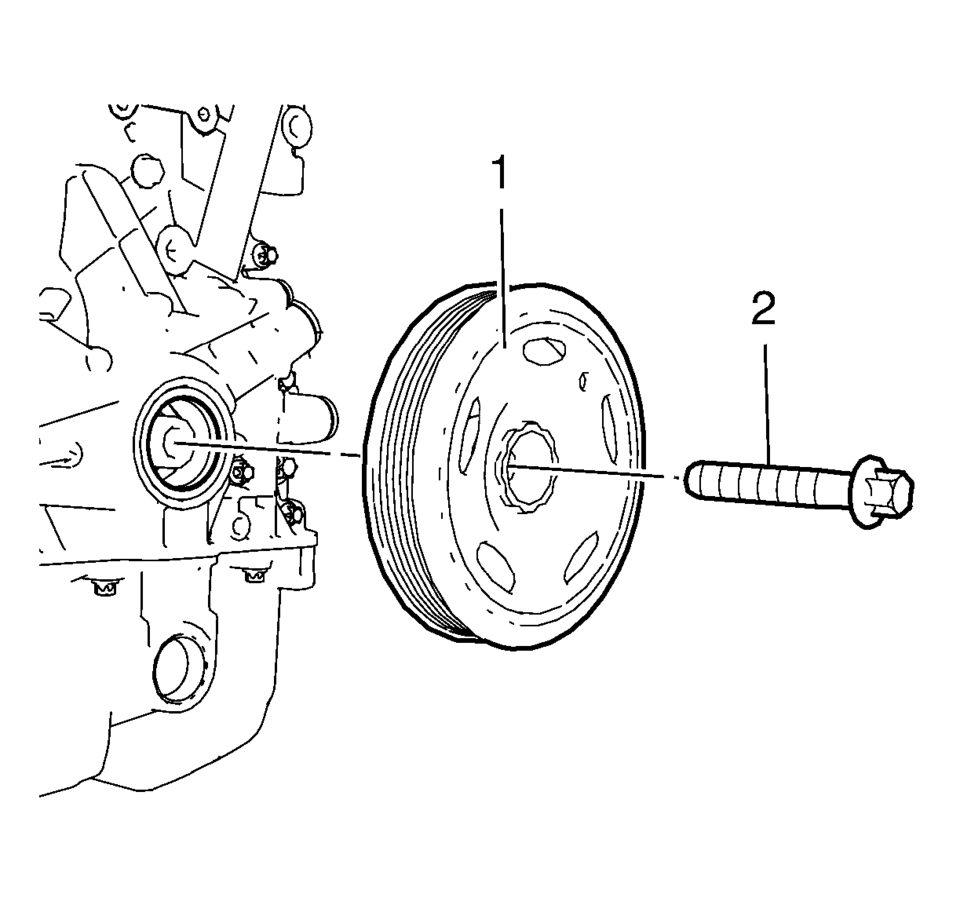

- Remove and DISCARD the crankshaft balancer bolt (2).

- Remove the crankshaft balancer (1).

Note:

The crankshaft balancer can be incorrectly installed 180° from the required position. Be sure to note the location of the alignment hole on the crankshaft balancer prior to removing the crankshaft balancer from the engine.

- Installation Procedure

-

- Install the crankshaft balancer carefully by pressing into position.

- Measure the distance (a) between the crankshaft balancer (2) and the

mark on the engine front cover (1). The distance (a) should be 5.5 mm (0.21654 in)

.

- Install a NEW crankshaft balancer bolt.

- Tighten the crankshaft balancer bolt (4) to 150 N•m (111 lb ft) while holding the crankshaft balancer (3) with EN-49979 crankshaft shock mount retainer (1) and suitable tool (2). Use EN-470-B wrench .

- Tighten the crankshaft balancer bolt to an additional 60°

.

- Install the drive belt. Refer to Drive Belt Replacement.

- Install the front wheelhouse liner extension right side. Refer to Front Wheelhouse Liner Inner Front Extension Replacement.

- Lower the vehicle.

- Check and correct engine oil level.

Note:

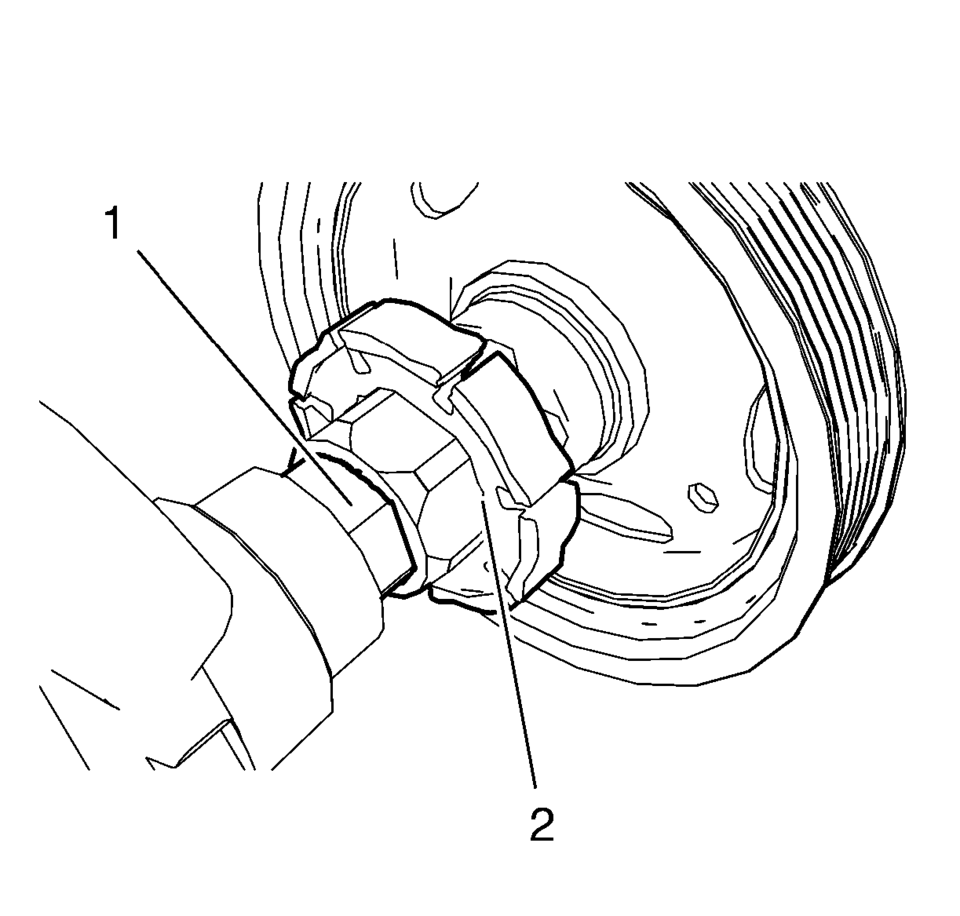

The crankshaft balancer flange must fit to the hexagon of the oil pump rotor (2) and to the two-flats of the crankshaft (1). The TDC markings on crankshaft balancer and engine front cover must match.

Note:

Never re-use the crankshaft balancer bolt.

Caution:

Refer to Fastener Caution.

Caution:

Refer to Torque-to-Yield Fastener Caution.

Crankshaft Balancer Removal

Crankshaft Balancer Removal

Special Tools

EN-652 Flywheel Holder

For equivalent regional tools, refer to Special Tools.

Install the EN-652 holder (1). Lock the flywheel (2) or the automatic

transmis ...

Crankshaft Position System Variation Learn

Crankshaft Position System Variation Learn

Note: The crankshaft position sensor system variation learn procedure

is required when the following service procedures have been performed, regardless

of whether DTC P0315 is set:

...

Other materials:

Radio Rear Side Door Speaker Replacement

Radio Rear Side Door Speaker Replacement

Callout

Component Name

Preliminary Procedure

Remove the rear side door trim. Refer to Rear

Side Door Trim Replacement.

1

Radio Rear Side Door Speaker Bol ...

Seat Belt System Description and Operation

Restraint System

Note: If the vehicle has been in a collision, refer to Repairs

and Inspections Required After a Collision.

The vehicle has front and rear seat belts that are the primary means of occupant

restraint. Seat belts help to keep the occupants inside the passenger ...

Passenger Compartment Air Filter Replacement (LHD)

Passenger Compartment Air Filter Replacement

Callout

Component Name

Preliminary Procedure

Remove IP compartment. Refer to Instrument Panel Lower Compartment Replacement.

1

Passenger Compartment A ...

0.0063