Chevrolet Sonic Repair Manual: Brake Rotor Thickness Measurement

Warning:

Refer to Brake Dust Warning.

- If the inboard friction surface of the brake rotor is not accessible, reposition and support the caliper with the brake pads. Refer to Front Disc Brake Pads Replacement.

- Clean the friction surfaces of the brake rotor with denatured alcohol, or an equivalent approved brake cleaner.

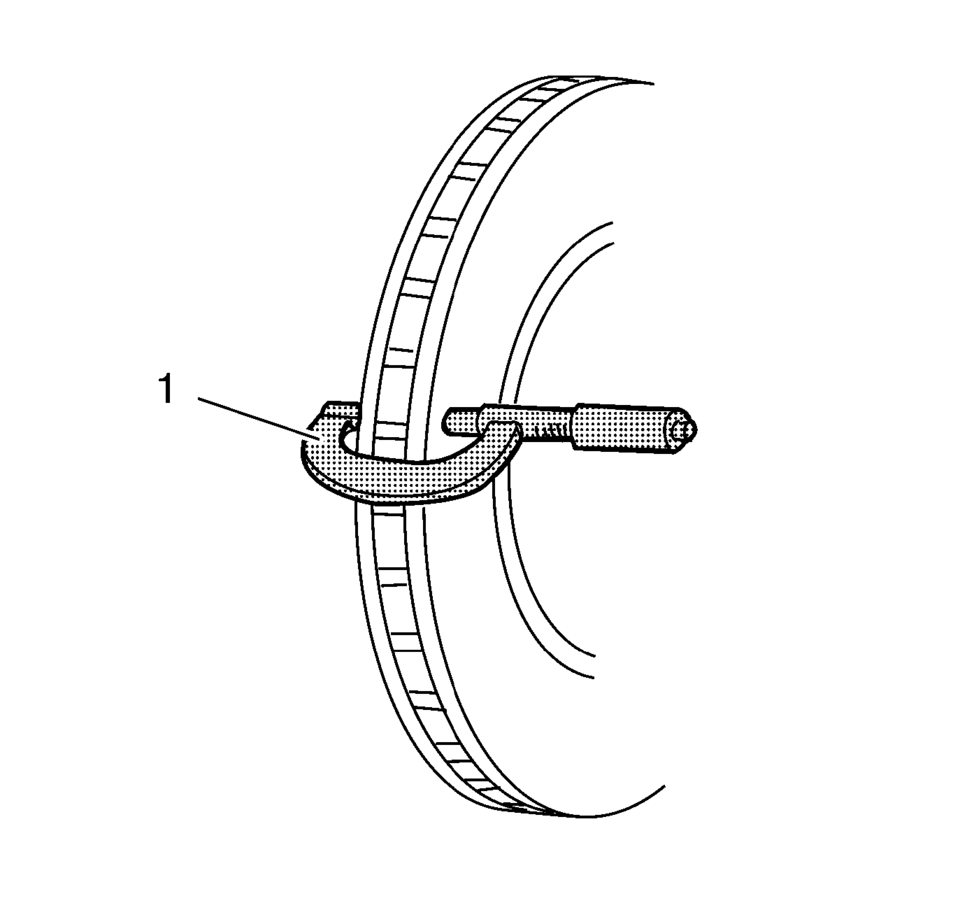

- Using a micrometer (1) calibrated in thousandths-of-a-millimeter, or ten-thousandths-of-an-inch,

measure and record the thickness of the brake rotor at four or more points,

evenly spaced around the brake rotor.

Make sure that the measurements are only taken within the friction surfaces and that the micrometer is positioned the same distance from the outer edge of the brake rotor, about 13 mm (1/2 in), for each measurement.

- Compare the lowest thickness measurement recorded to the specifications. Refer to Disc Brake Component Specifications.

- If the lowest thickness measurement of the brake rotor is above the minimum allowable thickness after refinishing specification, the brake rotor may be able to be refinished, depending upon surface and wear conditions which may be present.

- If the lowest thickness measurement of the brake rotor is at or below the discard thickness specification, the brake rotor requires replacement.

Brake Rotor Surface and Wear Inspection

Brake Rotor Surface and Wear Inspection

Warning: Refer to Brake Dust Warning.

If the inboard friction surface of the brake rotor is not accessible, reposition

and support the caliper with the brake pads. Refer to Front Disc Bra ...

Brake Rotor Thickness Variation Measurement

Brake Rotor Thickness Variation Measurement

Warning: Refer to Brake Dust Warning.

Note: Any disc brake rotor that exhibits thickness variation exceeding

the maximum acceptable level must be refinished or replaced. Thickness variati ...

Other materials:

Rear Compartment Lid Hinge Torque Rod Replacement

Rear Compartment Lid Hinge Torque Rod Replacement

Callout

Component Name

Warning: Refer to Hood Hold-Open Device Warning.

Preliminary Procedure

Open and support the rear compartment lid.

Special Tools

BO-125 ...

Gears Cleaning and Inspection (Gen 1)

Gears

Warning: Wear safety glasses to avoid injury when using compressed

air or any cleaning solvent. Bodily injury may occur if fumes are inhaled

or if skin is exposed to chemicals.

Clean the following gears in a suitable solvent and

air dry all the p ...

Transmission Control Replacement

Removal Procedure

Remove the floor console. Refer to

Front Floor Console Replacement.

Lift both cable adjustment retainers (1), one for

each cable, to release the shift lever and selector lever cable.

.1

Pull the shift lever and selector lever cable ret ...

0.0078