Chevrolet Sonic Repair Manual: Differential Case Assemble

Special Tools

- J-810721 Axle Shaft Seal Remover Support Base

- R-0407011 Bearing Race Remover

- R-0407012 Differential Carrier Cone Bearing Cap Driver

- R-0007761 Universal Handle for Pullers and Installers

- S-9407194 Speed Sensor Impeller Ring Installer

- S-9407195 Pinion Gear Case Bearing Installer

- S-9707500 Seal Installer

For equivalent regional tools, refer to Special Tools.

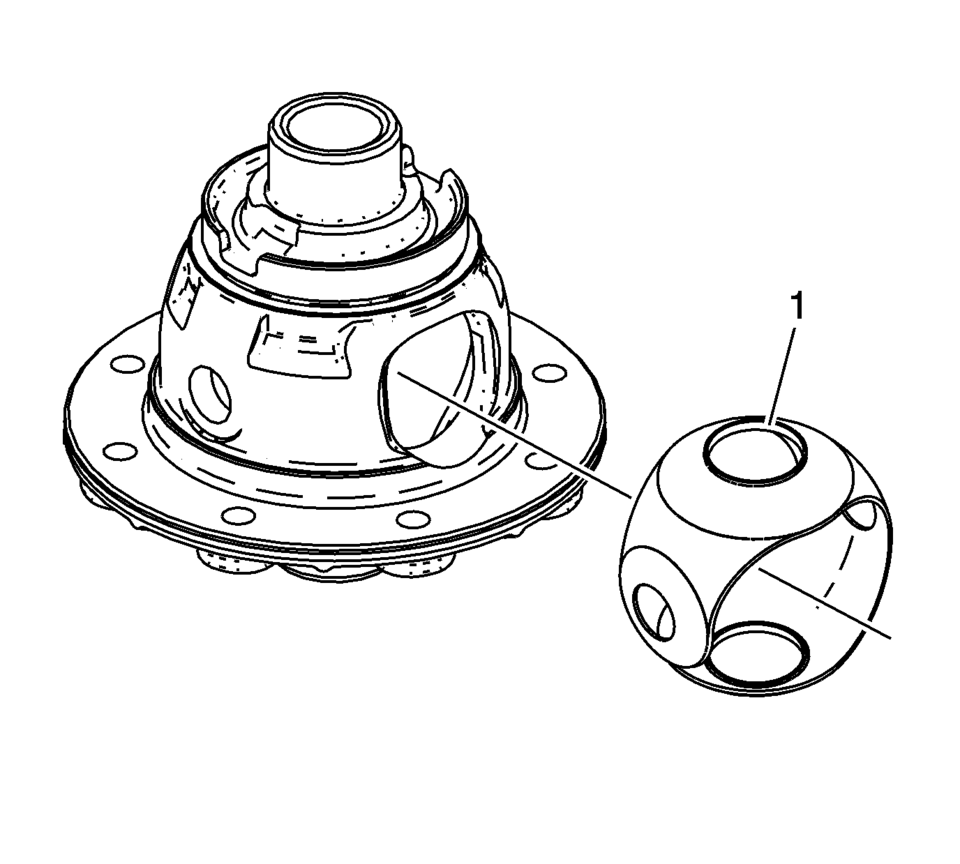

- Install the front differential pinion and side gear thrust washer. It must be possible to insert the collar (1) of the thrust washer into the guide for the pinion gears in the housing.

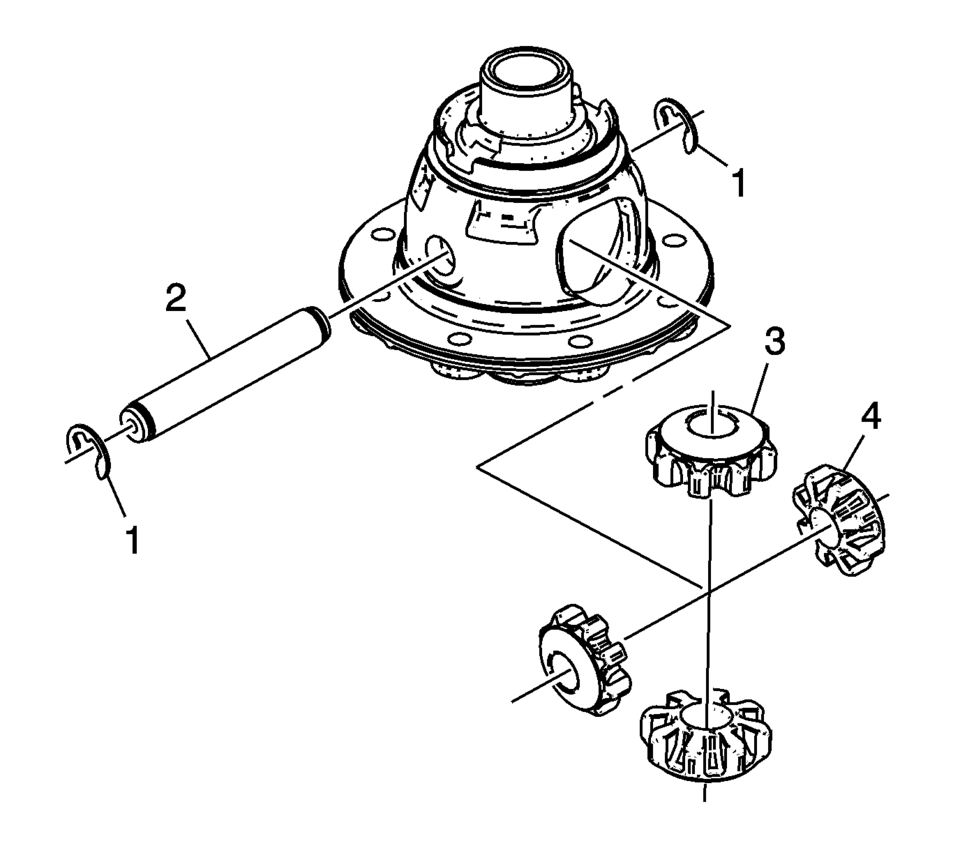

- Install the front differential pinion gears (3) and side gears (4).

- Install the front differential pinion gear shaft (2) and the pinion gear shaft retaining washers (1).

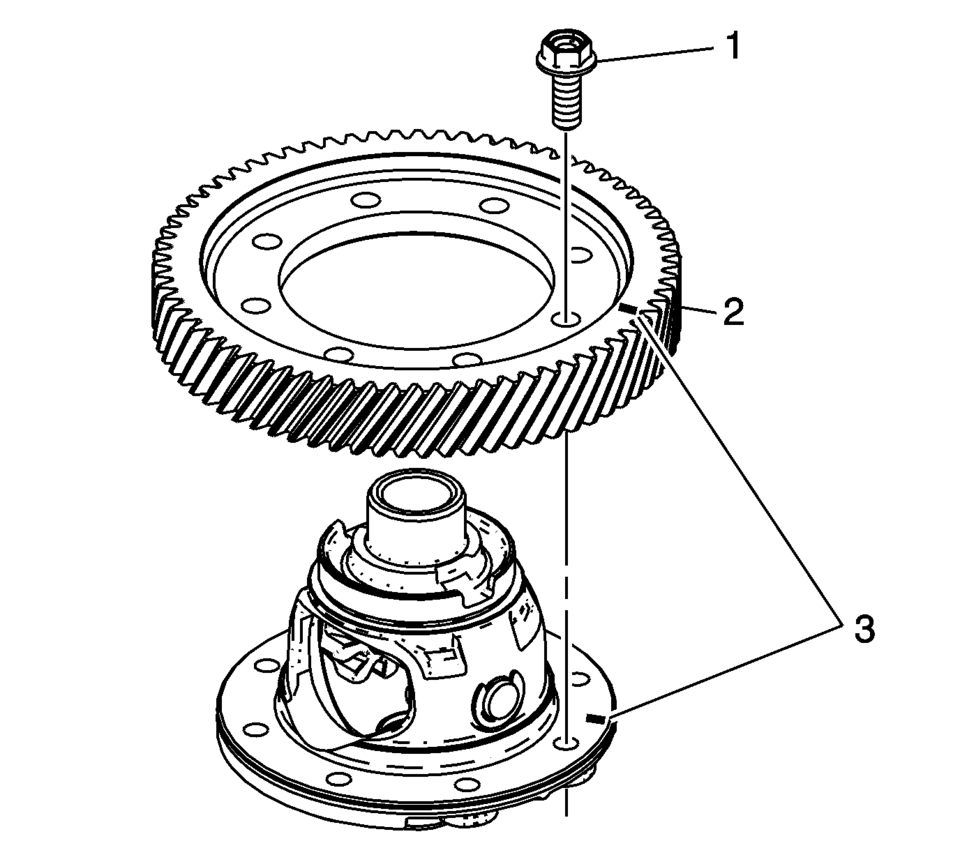

- If both components are reused align the assembly marks (3).

- Install the front differential ring gear (2).

- Install the front differential ring gear bolts (1). Tighten to 90 N•m

(66.4 lb ft)

.

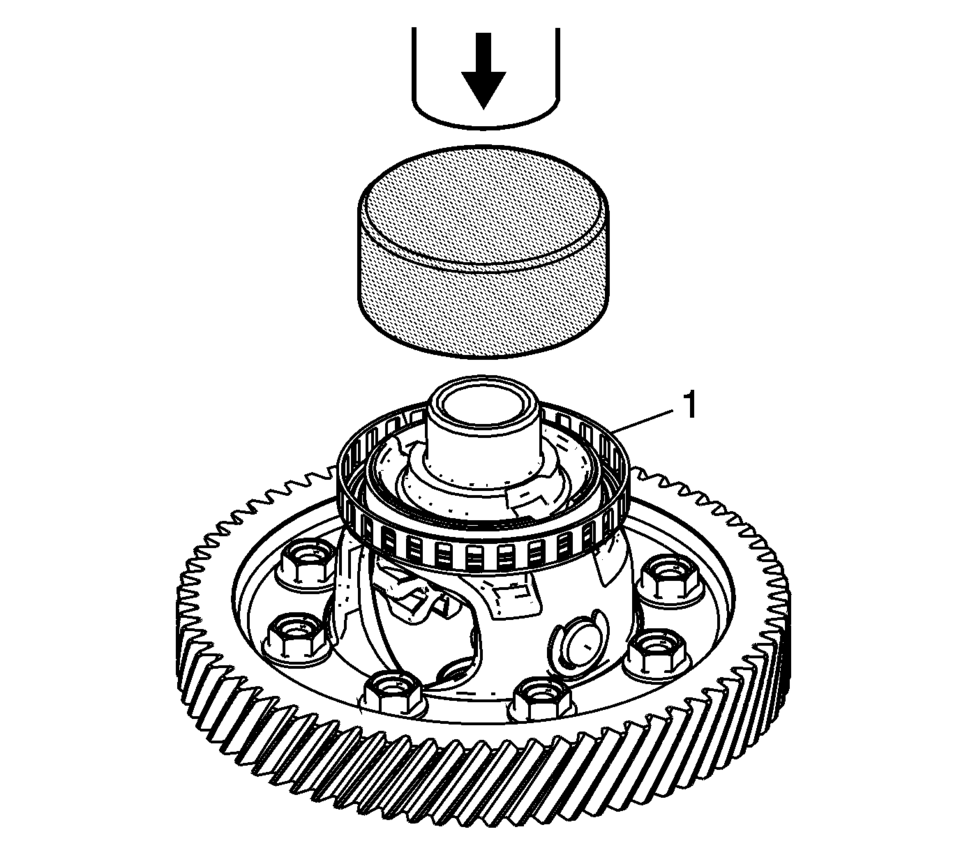

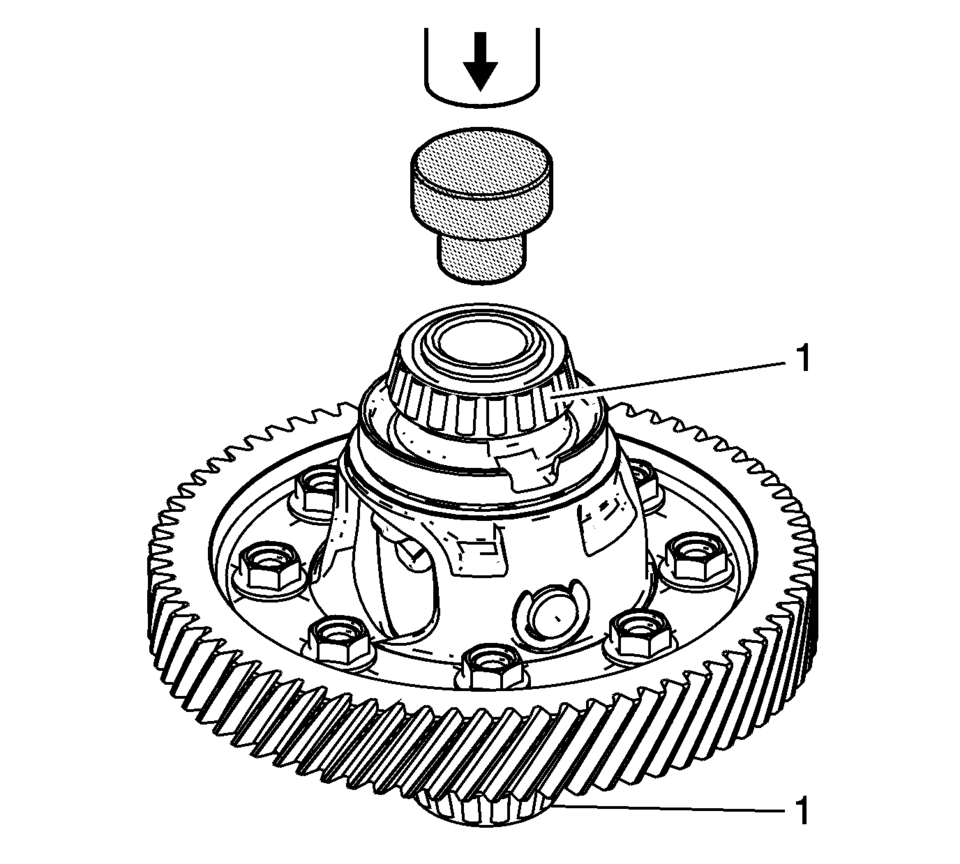

- Install the ring front wheel speed sensor reluctor wheel (1) using the S-9407194 installer and a hydraulic press.

- Install the front differential bearing assemblies (1) using the S-9407195 installer and a hydraulic press.

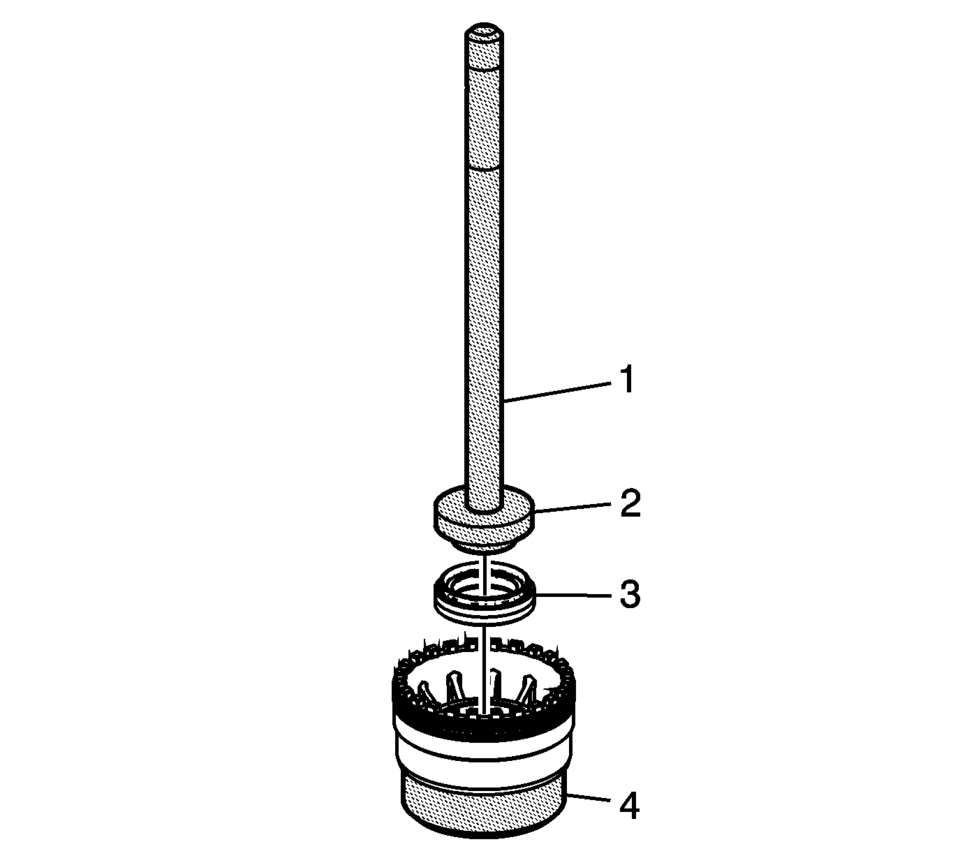

- Install the front wheel drive shaft oil seal (3) using the R-0007761 handle (1), S-9707500 seal installer (2), and the J-810721 support base (4).

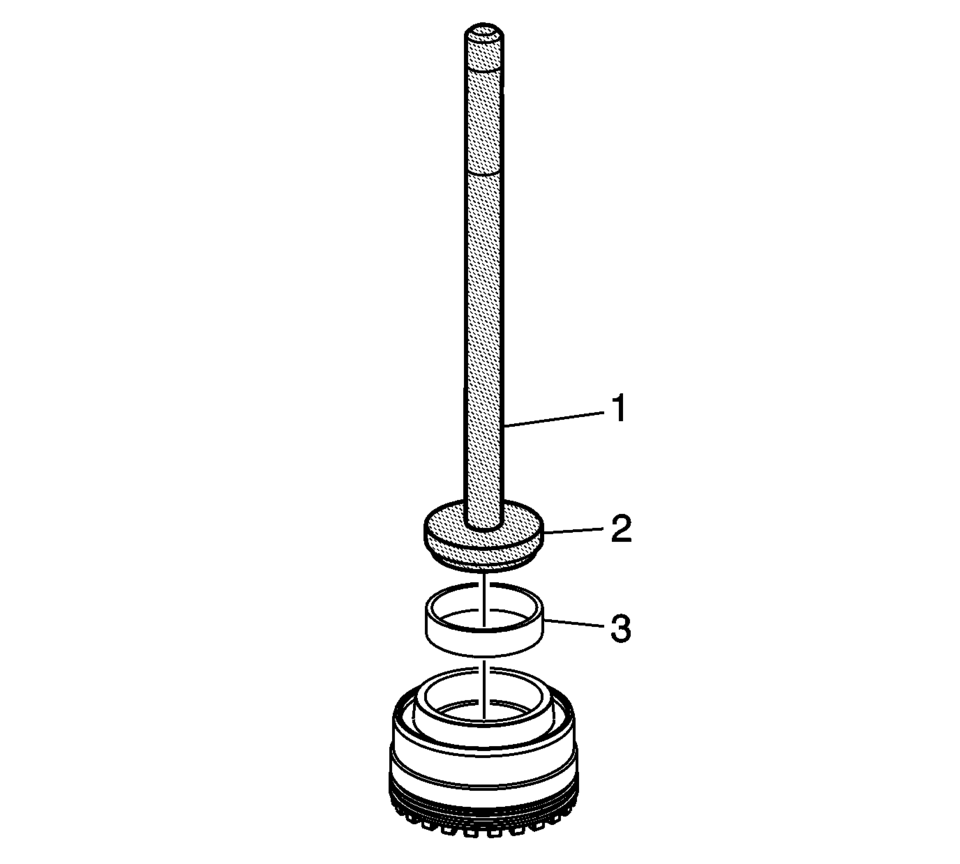

- Install the front differential bearing race (3) using the R-0007761 handle (1) and the R-0407012 driver (2).

Note:

Lubricate rotating parts on their bearing, running, seating, and pressure surfaces using transmission fluid.

Warning:

Refer to Safety Glasses Warning.

Differentials

Differentials

...

Differential Case Disassemble

Differential Case Disassemble

Special Tools

6-9607346 Sensor Ring Gear Puller

J-810704 Steering Column Center Bar Puller

J-810721 Axle Shaft Seal Remover Support Base

R-0006749 Support Base

R-0407011 Bearing Race Rem ...

Other materials:

Front Side Door Window Replacement

Front Side Door Window Replacement

Callout

Component Name

Warning: Refer to Glass and Sheet Metal Handling Warning.

Preliminary Procedures

Remove the front side door trim panel. Refer to Front Side Door

Tr ...

Steering Wheel Airbag Coil Replacement

Steering Wheel Airbag Coil Replacement

Callout

Component Name

Preliminary Procedures

Remove the steering wheel. Refer to Steering Wheel Replacement.

Remove the steering column upper trim cover. Refer to Steering Column

...

Tire Inflation Description

When you inflate the tires to the recommended inflation pressures, the factory-installed

wheels and tires are designed in order to handle loads to the tire's rated load

capacity. Incorrect tire pressures, or under-inflated tires, can cause the following

conditions:

Vehicle handling co ...

0.0061