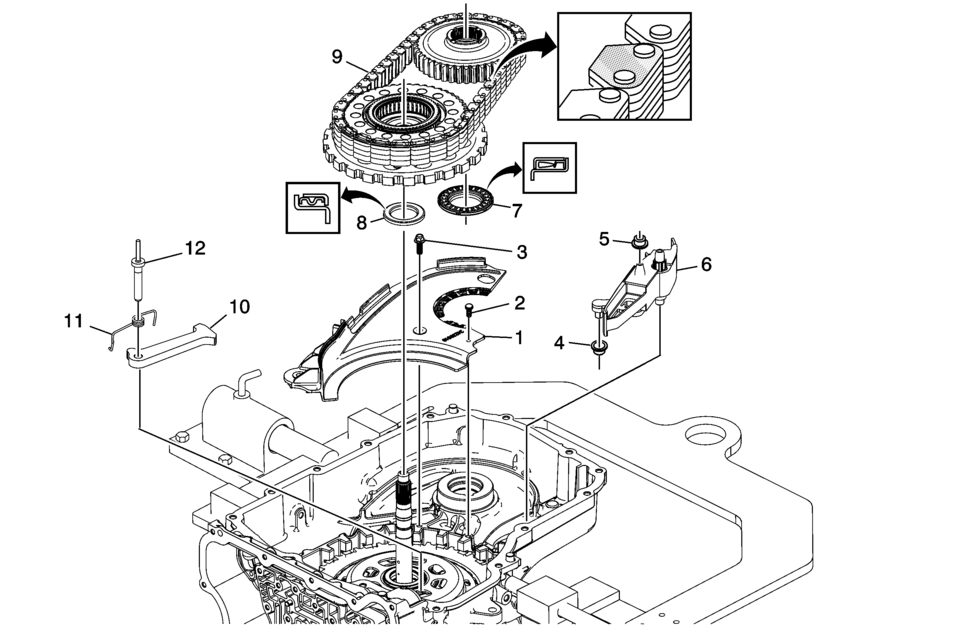

Chevrolet Sonic Repair Manual: Drive and Driven Sprocket, Drive Link, and Park Pawl Installation (6T30)

|

Callout |

Component Name |

|---|---|

|

1 |

Front Differential Carrier Baffle |

|

2 |

Baffle Retainer |

|

3 |

Front Differential Carrier Baffle Bolt M6 x 16 (Qty: 2) Caution: Refer to Fastener Caution.

12 Y (106 lb in) |

|

4 |

Drive Link Lube Scoop Seal |

|

5 |

Drive Link Lube Fluid Seal |

|

6 |

Drive Link Lube Scoop |

|

7 |

Driven Sprocket Bearing Assembly |

|

8 |

Drive Sprocket Bearing Assembly |

|

9 |

Driven Sprocket Assembly, Drive Sprocket Assembly and Drive Link Note:

|

|

10 |

Park Pawl |

|

11 |

Park Pawl Spring |

|

12 |

Park Pawl Shaft Note: Check to ensure that the park pawl operates freely and is not binding. |

Drive Sprocket, Driven Sprocket, and Drive Link Cleaning and Inspection

Drive Sprocket, Driven Sprocket, and Drive Link Cleaning and Inspection

Drive Sprocket, Driven Sprocket, and Drive Link Cleaning and Inspection

Callout

Component Name

1

Drive Sprocket Thrust W ...

Drive and Driven Sprocket, Drive Link, and Park Pawl Installation (6T40/45/50)

Drive and Driven Sprocket, Drive Link, and Park Pawl Installation (6T40/45/50)

Drive and Driven Sprocket, Drive Link, and Park Pawl Installation

Callout

Component Name

1

Front Differential Carrier Ba ...

Other materials:

Personalization Menu (Radio with Touchscreen)

Settings can be made with the ignition ON and the vehicle not moving.

Use the audio system controls to access the personalization menus for customizing

vehicle features.

The following are all possible personalization features. Depending on the vehicle,

some may not be available.

(Home): Pres ...

Front Wheel Drive Shaft Seal Replacement - Case Side

Front Wheel Drive Shaft Seal Replacement - Case Side

Callout

Component Name

1

Front Wheel Drive Shaft Oil Seal

Special Tools

DT-23129 Universal Seal Remover

DT-47790 Seal Installer

GE-6125-1B Slide Hamme ...

Catalytic Converter Heat Shield Replacement (LUV)

Catalytic Converter Heat Shield Replacement

Callout

Component Name

Warning: Refer to Exhaust Service Warning.

1

Catalytic Converter Heat Shield Fasteners (Qty: 4)

Caution: Refer ...

0.006