Chevrolet Sonic Repair Manual: Engine Block Cleaning and Inspection

Special Tools

EN-8087 Cylinder Gauge

For equivalent regional tools, refer to Special Tools.

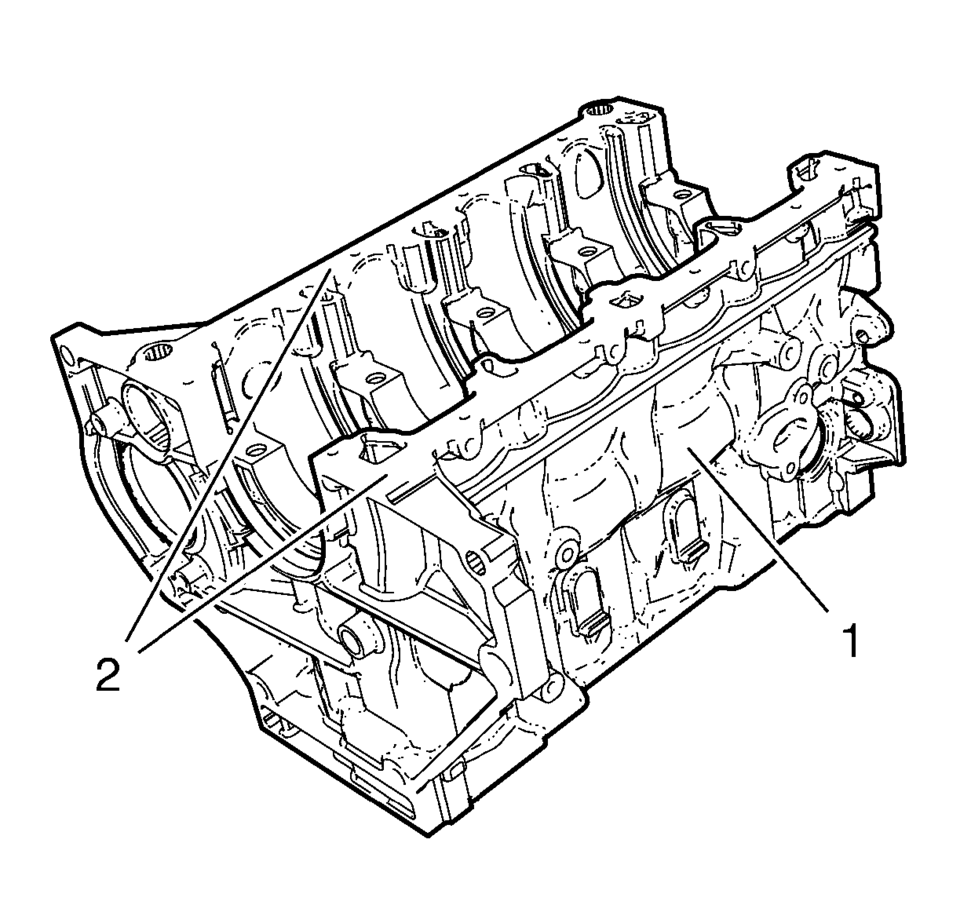

- Clean the sealing material from the gasket mating surfaces (2).

- Clean the engine block (1) and lower crankcase in a cleaning tank with solvent appropriate for aluminum. Refer to Adhesives, Fluids, Lubricants, and Sealers for the recommended solvent.

- Flush the engine block with clean water or steam.

- Clean the oil passages.

- Clean the blind holes.

- Spray the cylinder bores and the machined surfaces with engine oil.

- Inspect the threaded holes. Clean the threaded holes with a rifle brush. If necessary, drill out the holes and install thread inserts. Refer to Thread Inserts.

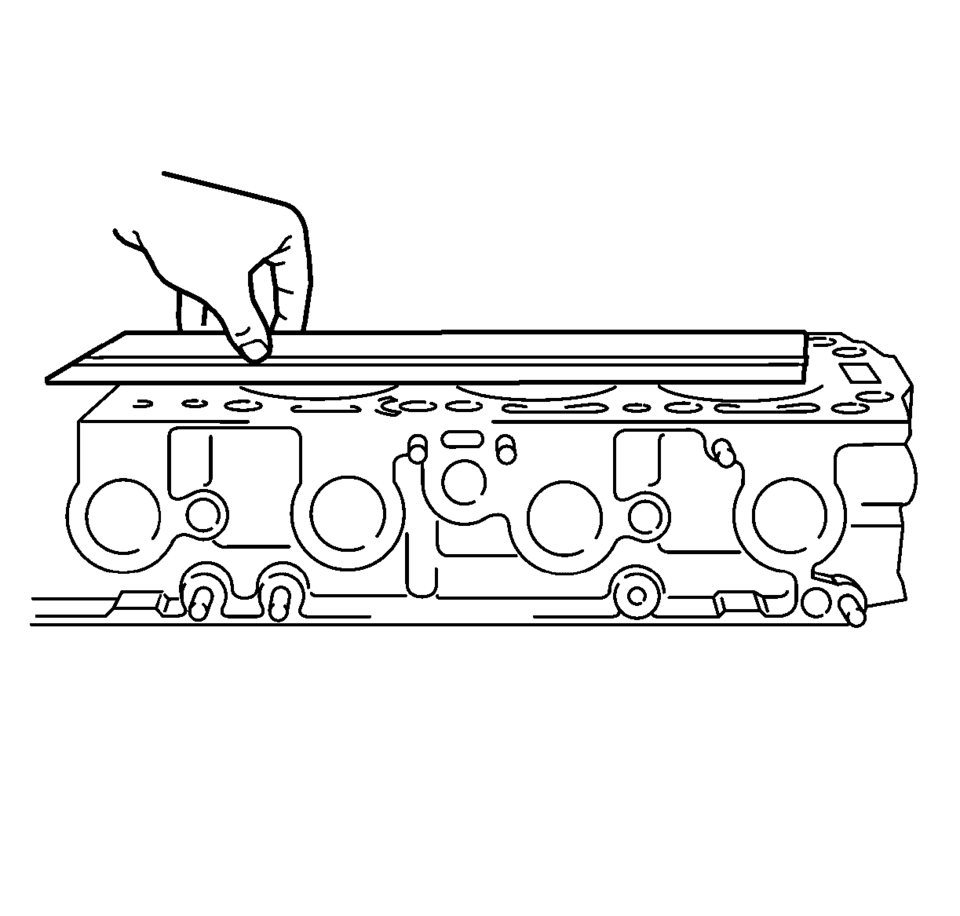

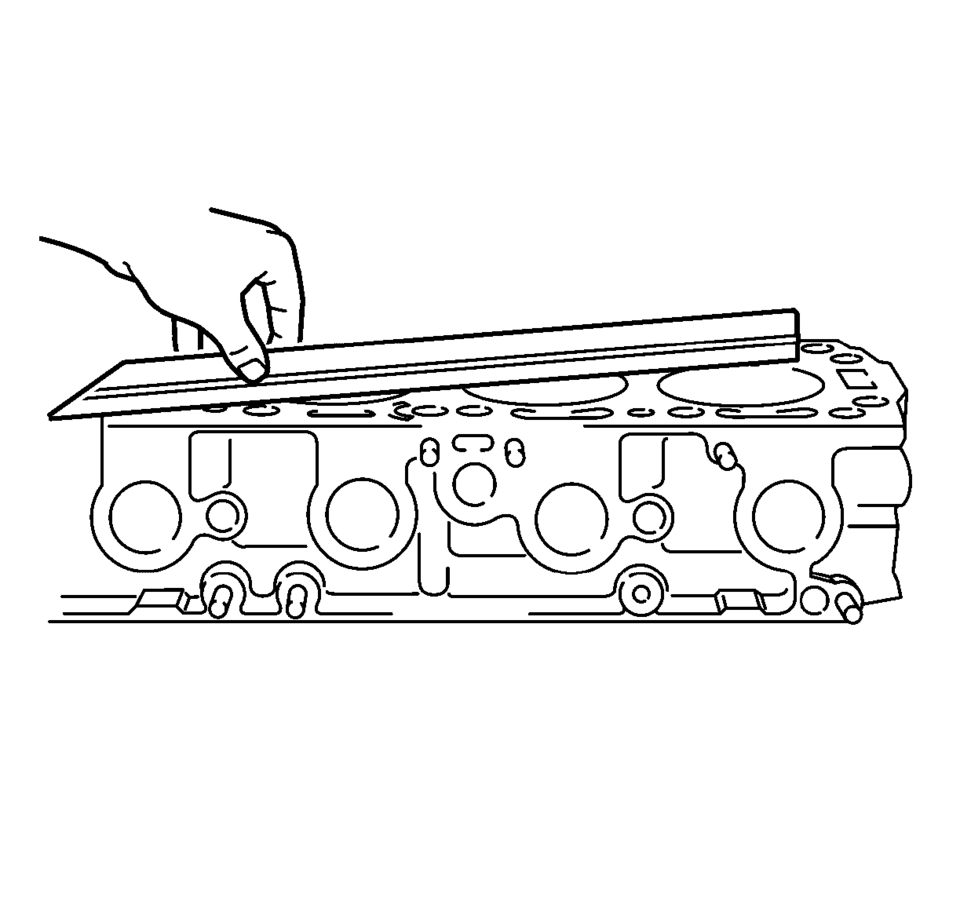

- Inspect the engine block for sag in length and width on the sealing surfaces.

- Inspect the engine block for distortion along the diagonals.

If the deck surface is out of specification, replace the block. Do not machine the block.

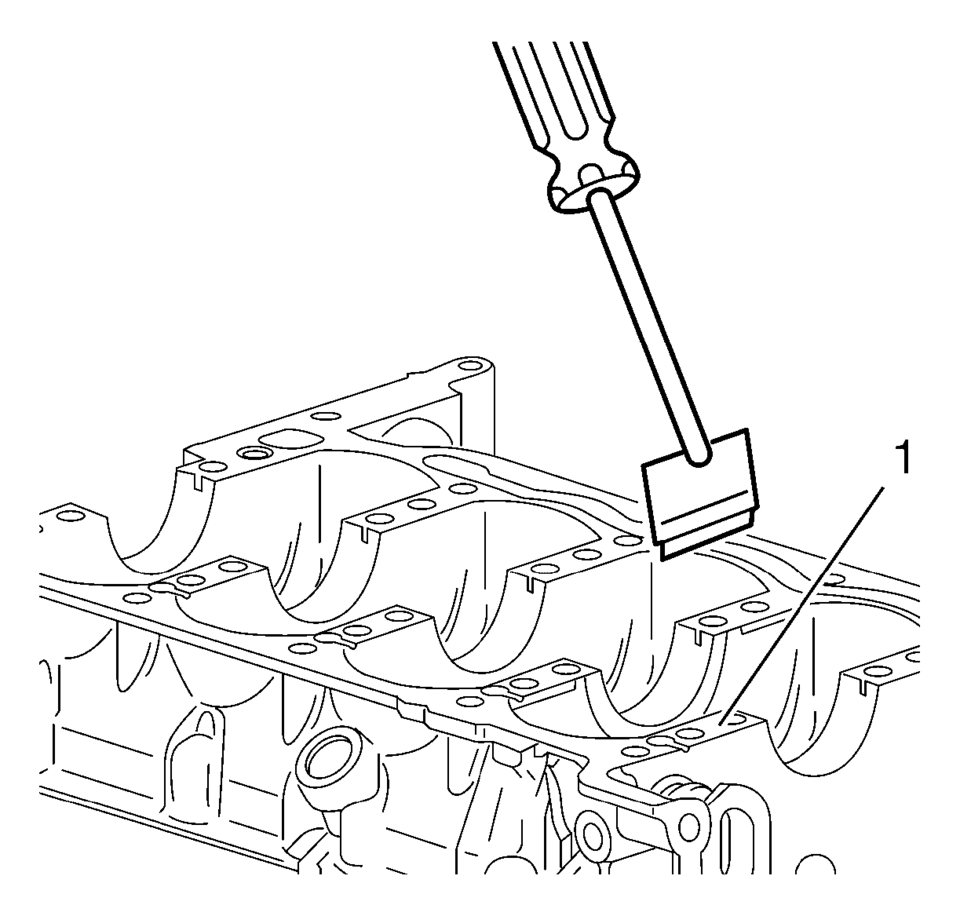

- Clean the sealing material from the gasket mating surfaces (1) on the lower crankcase oil pan side.

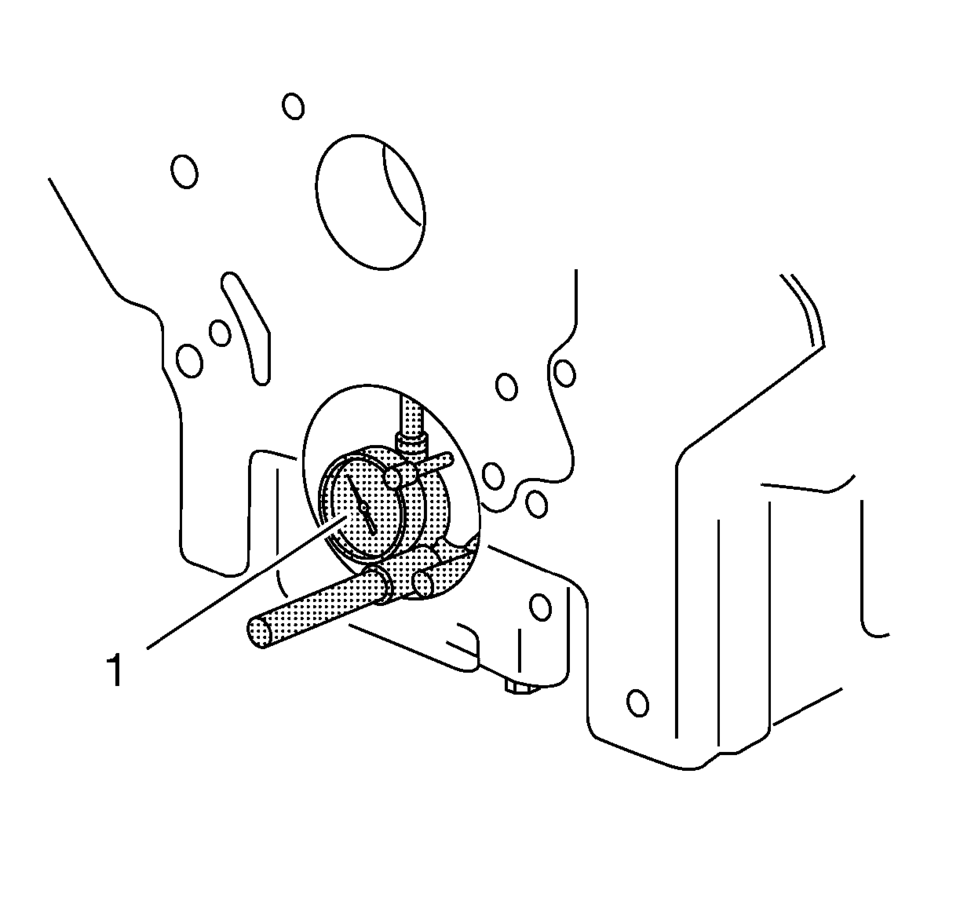

- Inspect the crankshaft main bearing bores. Use the EN-8087 gauge (1) to measure the bearing bore concentricity and alignment.

- Replace the engine block and bed plate if the crankshaft bearing bores are out of specification.

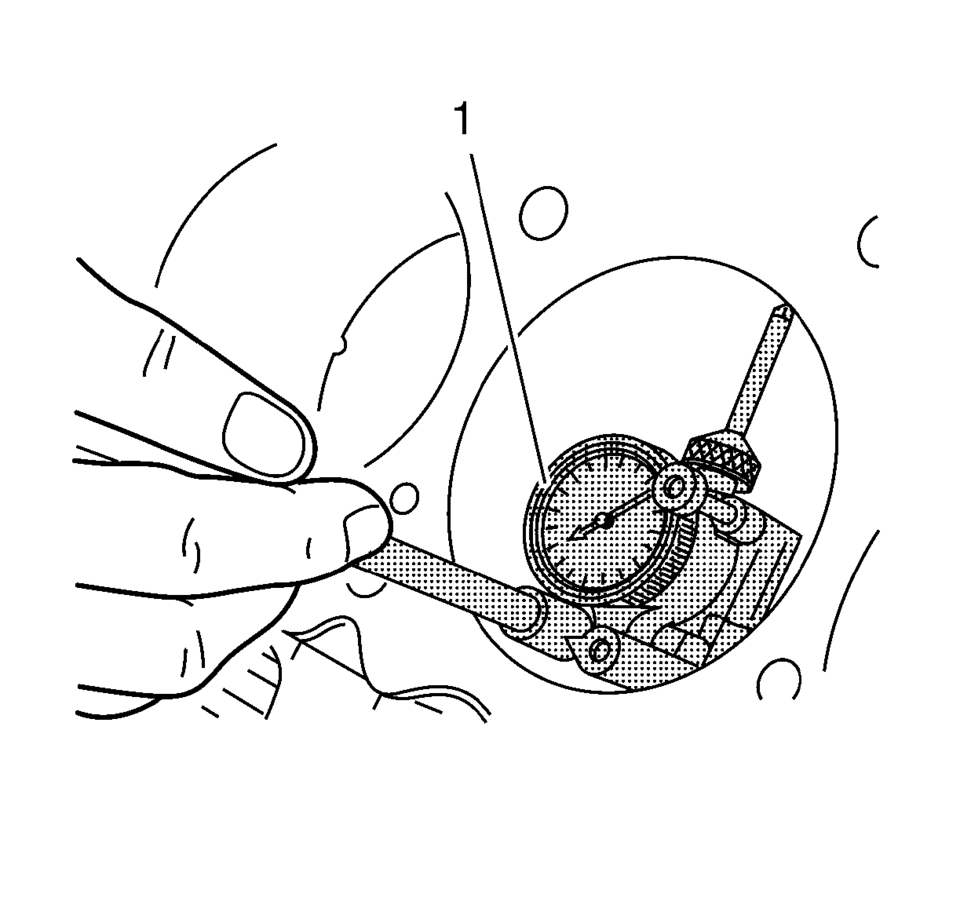

- Inspect the cylinder bores using the EN-8087 gauge (1). Inspect for the following items:

Note:

Do not attempt to machine the lower crankcase to engine block surfaces.

- Wear

- Taper

- Runout

- Ridging

Engine Block Disassemble

Engine Block Disassemble

Remove the cylinder head locating (1, 2).

Remove the oil pressure switch (1).

Remove the knock sensor bolt (2) and the knock sensor (1).

Clea ...

Cylinder Block

Cylinder Block

...

Other materials:

Air Vents

Use the air vents located in the center and on the side of the instrument panel

to direct the airflow. Move the slats on the center air vents to direct airflow.

Turn the knobs on the side air vents counterclockwise or clockwise to open or

close off the airflow.

Operation Tips

Clear away an ...

Outside Rearview Mirror Housing Replacement

Outside Rearview Mirror Housing Replacement

Callout

Component Name

Preliminary Procedures

Remove the outside rearview housing cover. Refer to Outside Rearview

Mirror Housing Rear Cover Replacement.

Remove the outside rear ...

Thrust Washer and Bearing Cleaning and Inspection

Warning: Wear safety glasses to avoid injury when using compressed

air or any cleaning solvent. Bodily injury may occur if fumes are inhaled

or if skin is exposed to chemicals.

Caution: Do not allow the bearings to spin. Turn them slowly by

hand. Spinning the beari ...

0.0067