Chevrolet Sonic Repair Manual: Main Shaft Assemble (Gen 1)

Special Tools

3-0207944 Main Shaft Tapered Bearing Insert Tool

For equivalent regional tools, refer to Special Tools.

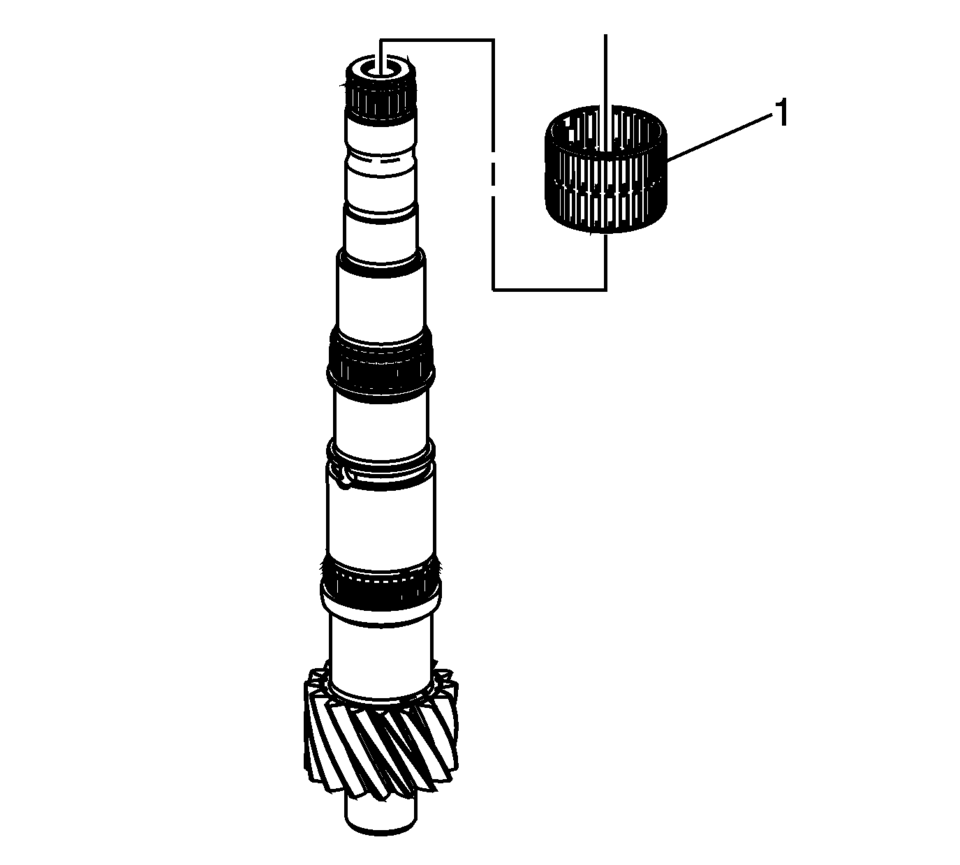

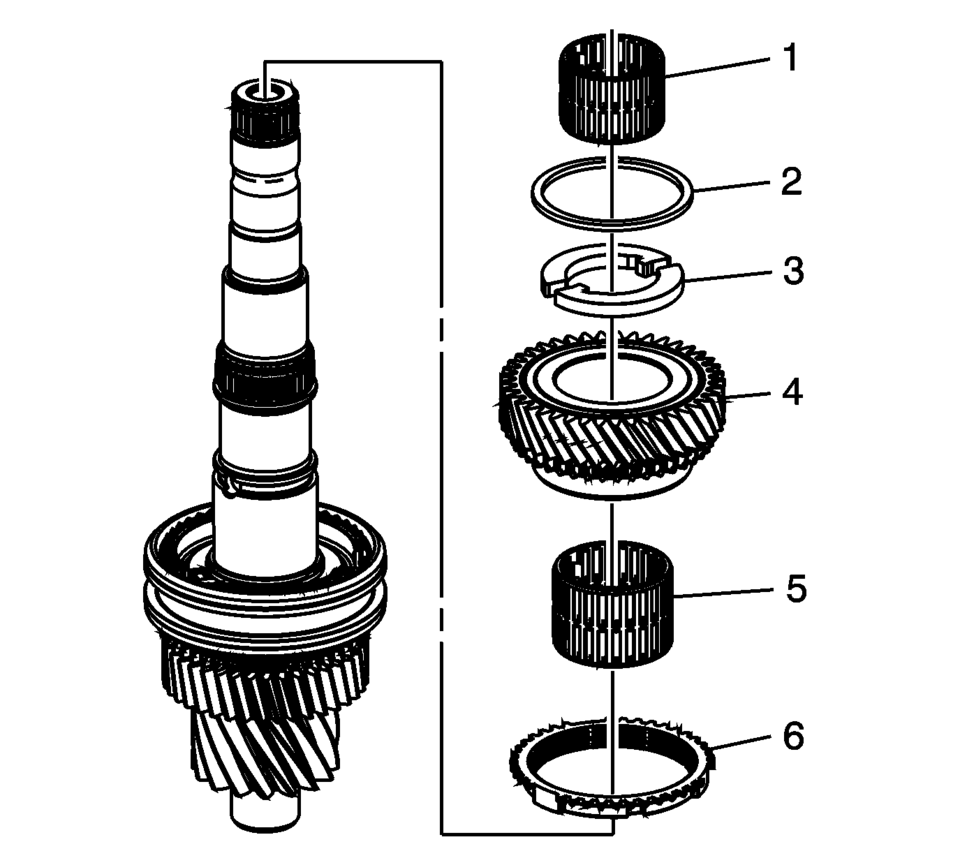

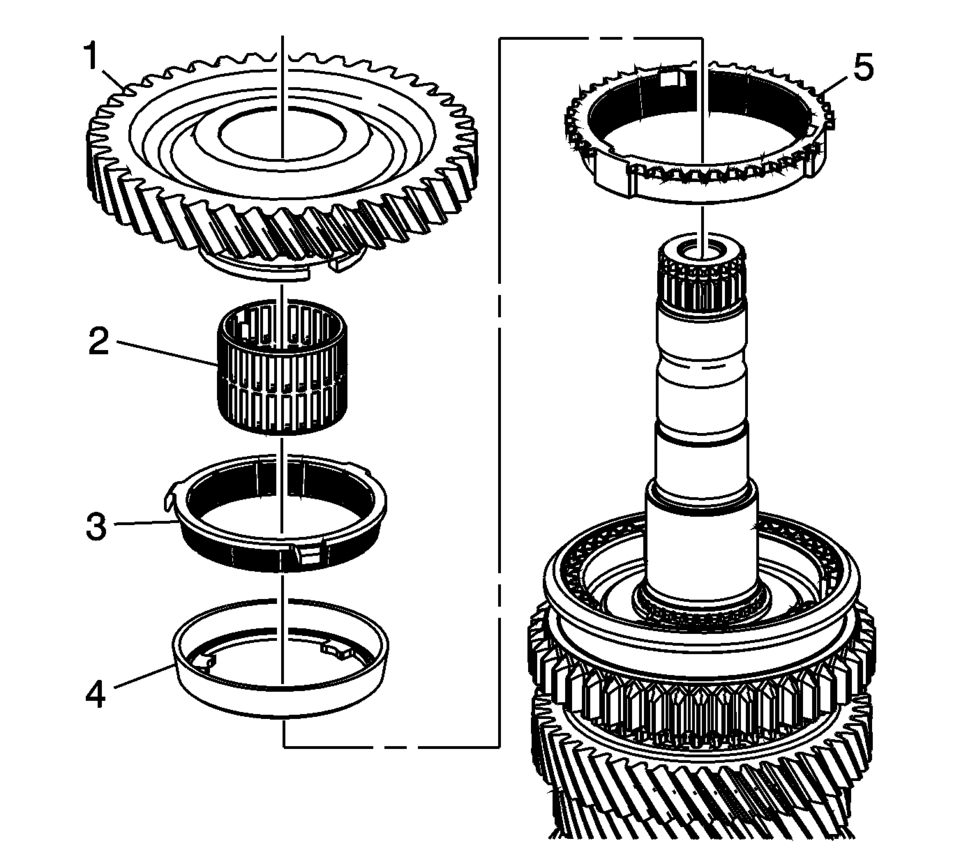

- Install the 4th gear bearing assembly (1).

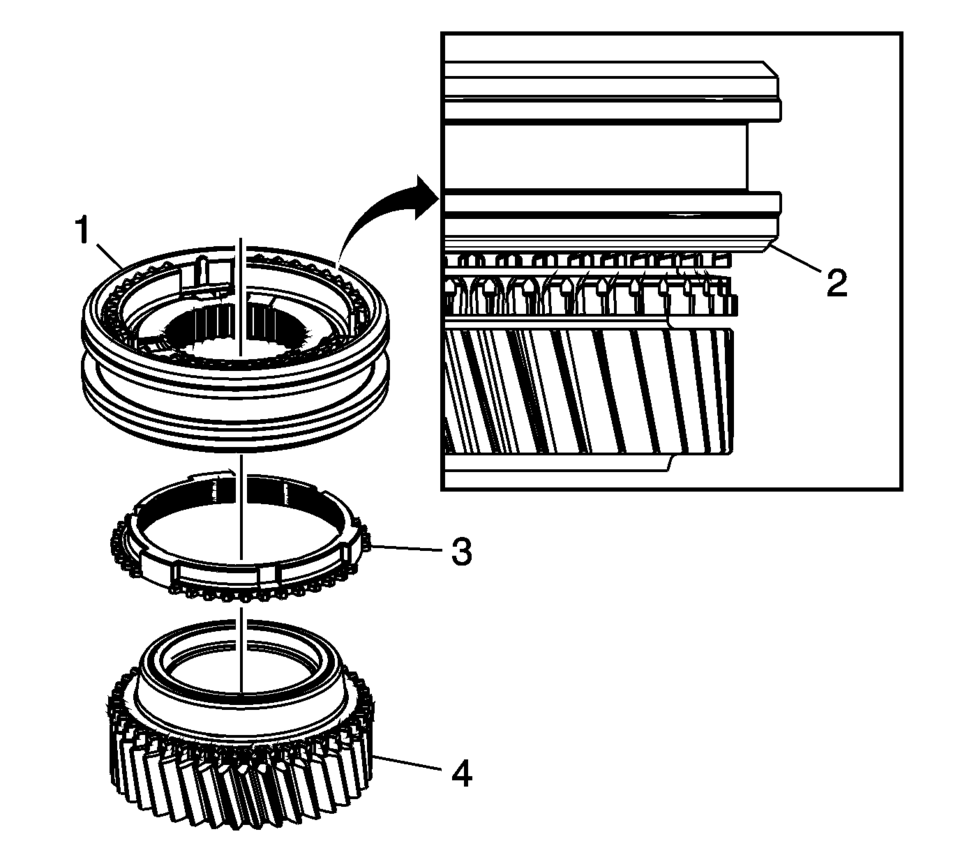

- Assemble the following components:

Note:

The 3rd gear blocking ring lugs must be aligned with the 3rd/4th gear synchronizer assembly grooves.

Note:

The groove on the 3rd/4th gear synchronizer assembly (2) should point toward the 4th gear assembly.

- 3rd/4th gear synchronizer assembly (1)

- 3rd gear blocking ring (3)

- 4th gear assembly (4)

- 3rd gear blocking ring (6)

- 3rd gear bearing assembly (5)

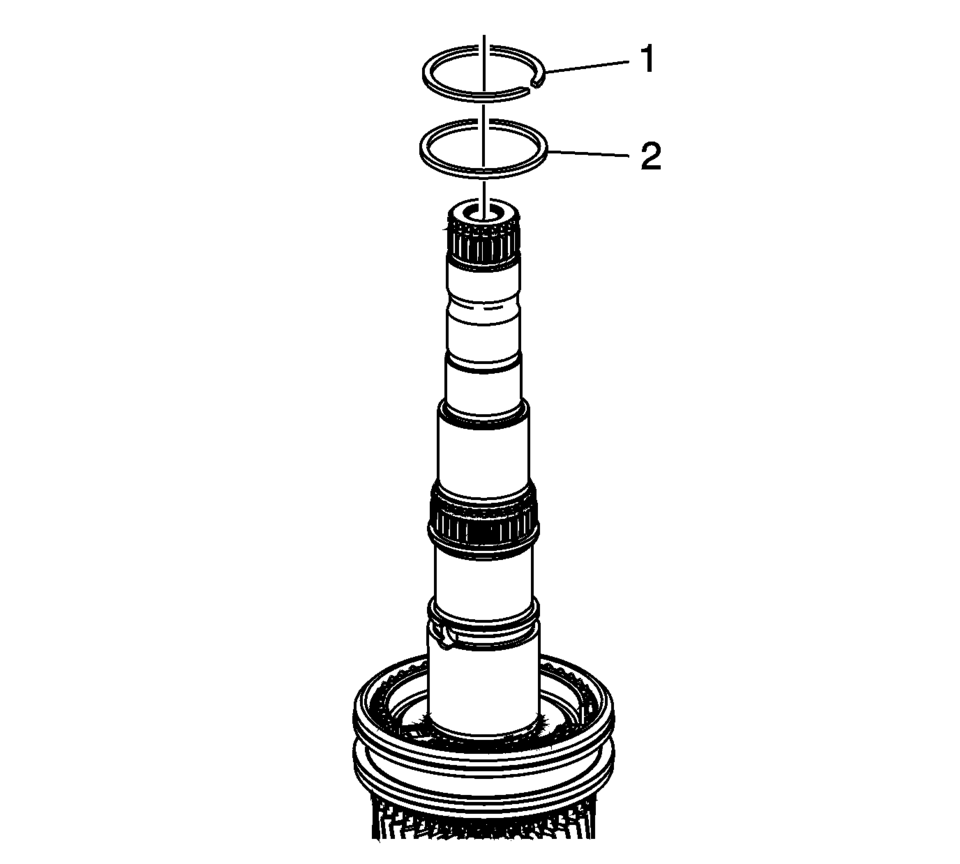

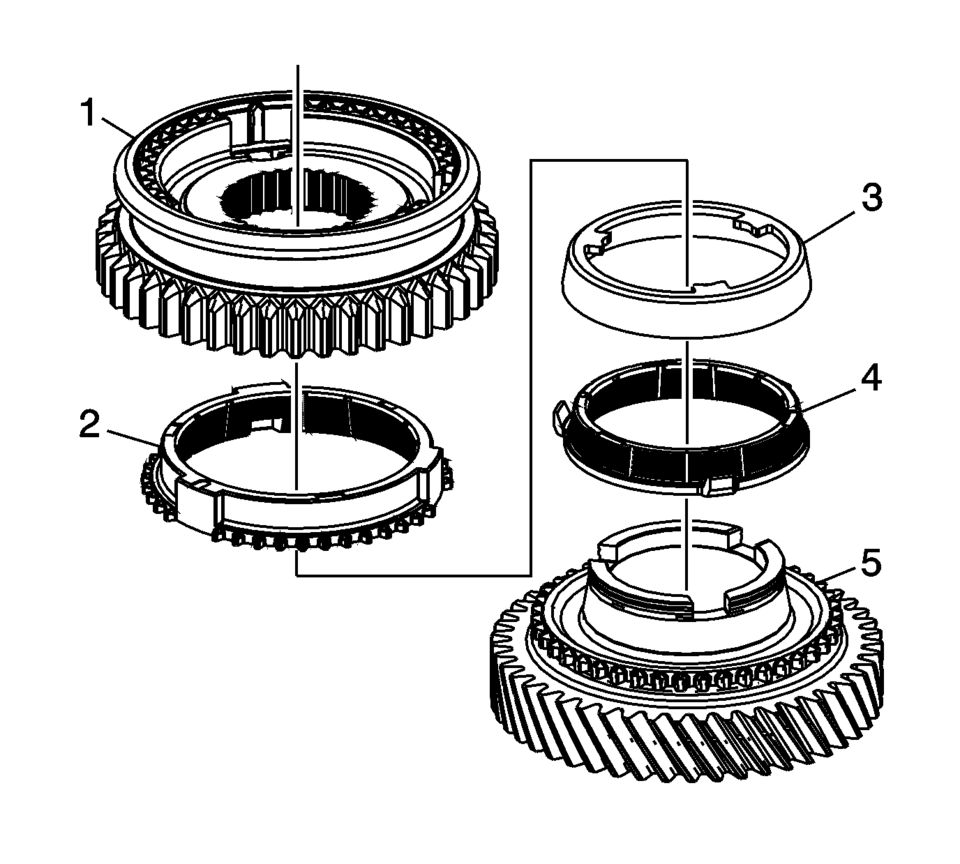

- 3rd gear assembly (4)

- 3rd gear thrust washer (3)

- 3rd gear thrust washer retaining ring (2)

- 2nd gear bearing assembly (1)

Note:

The lugs on the blocking rings must be aligned with the 2nd gear assembly and the 1st/2nd gear synchronizer assembly.

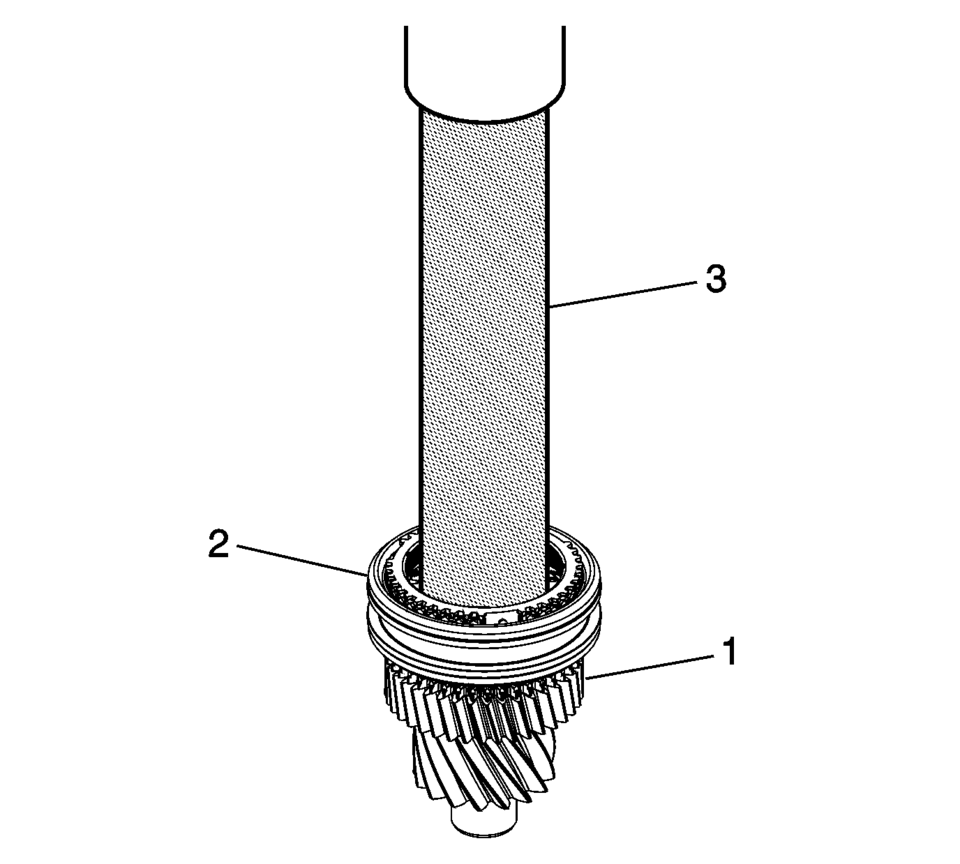

- 1st/2nd gear synchronizer assembly (1)

- 1st/2nd gear outer blocking ring (2)

- 1st/2nd gear intermediate cone ring (3)

- 1st/2nd gear inner blocking ring (4)

- 2nd gear assembly (5)

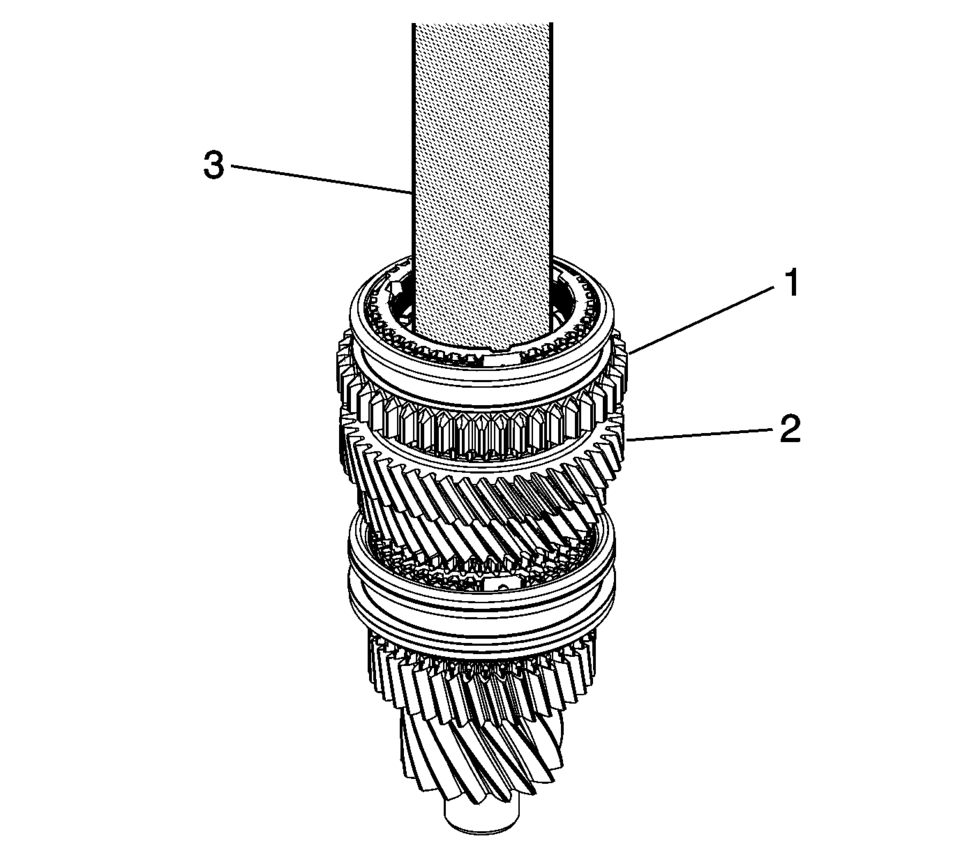

Note:

The lugs on the blocking rings must be aligned with the 1st/2nd gear synchronizer assembly grooves.

- 1st/2nd gear outer blocking ring (5)

- 1st/2nd gear intermediate cone ring (4)

- 1st/2nd gear inner blocking ring (3)

- 1st gear bearing assembly (2)

- 1st gear (1)

Input Shaft Disassemble

Input Shaft Disassemble

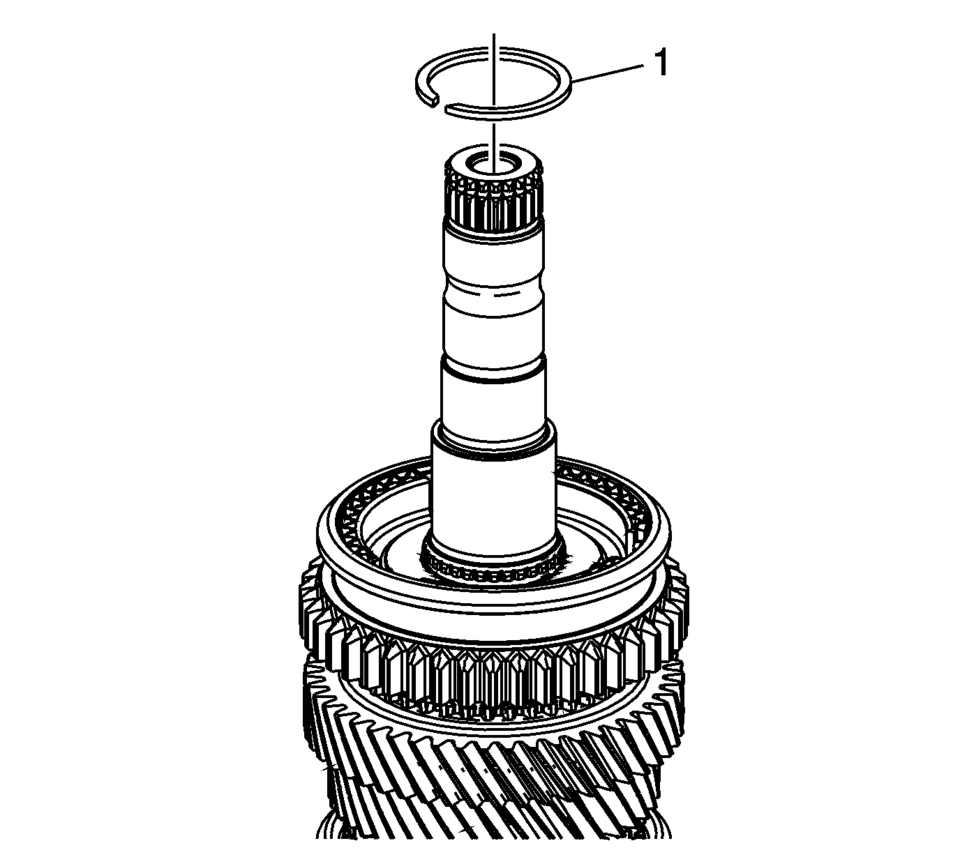

Note: The input shaft rear bearing retaining ring (2) remains

loose on the shaft.

Remove the input shaft rear bearing assembly (1) using

a hydraulic press.

Rem ...

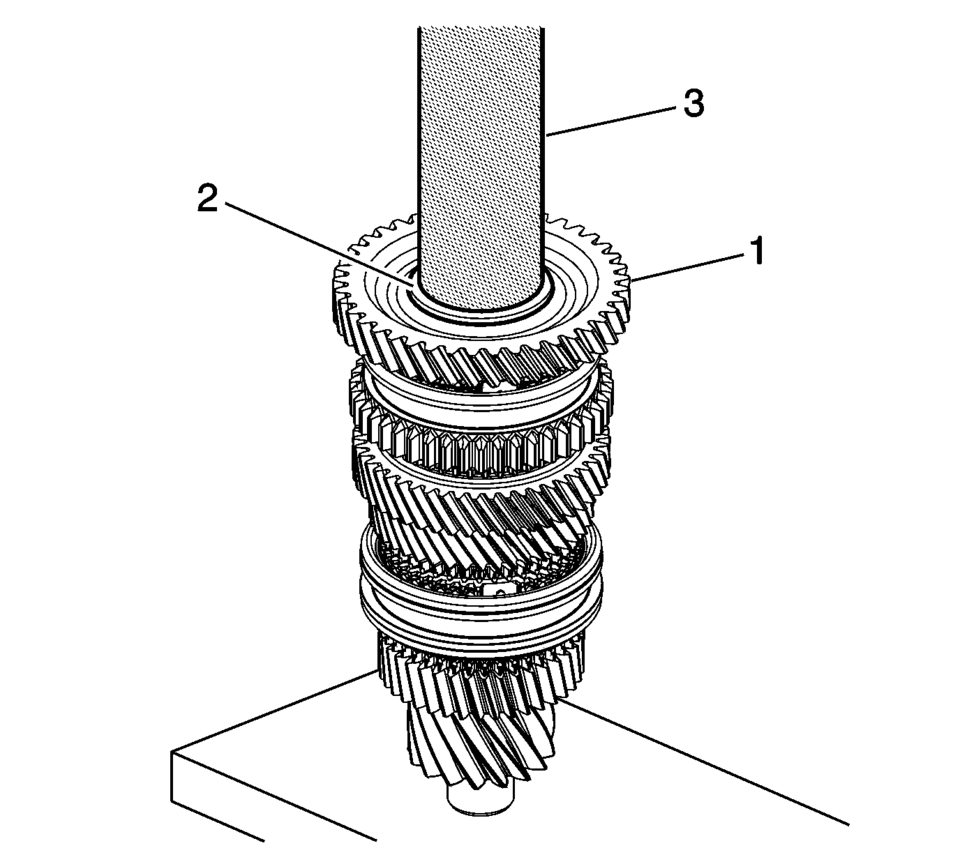

Main Shaft Assemble (Gen 2)

Main Shaft Assemble (Gen 2)

Special Tools

3-0207944 Main Shaft Tapered Bearing Insert Tool

For equivalent regional tools, refer to Special Tools.

Install the 4th gear bearing assembly (1).

in!i.l.i-if

...

Other materials:

How to Add Coolant to the Coolant Surge Tank

Caution

This vehicle has a specific coolant fill procedure. Failure to follow this

procedure could cause the engine to overheat and be severely damaged.

If no problem is found, check to see if coolant is visible in the coolant surge

tank. If coolant is visible but the coolant level is not at t ...

Outside Rearview Mirror Motor Replacement

Outside Rearview Mirror Motor Replacement

Callout

Component Name

1

Outside Rearview Mirror Glass

Procedure

Remove the outside rearview mirror glass. Refer to Outside Rearview Mirror

Glass Replacement.

...

Engine Oil Cooler Housing Replacement

Removal Procedure

Drain the engine coolant. Refer to Cooling System Draining and Filling.

Drain the engine oil. Refer to Engine Oil and Oil Filter Replacement.

Remove the exhaust manifold. Refer to Exhaust Manifold with Catalytic

Converter Replacement.

...

0.0075