Chevrolet Sonic Repair Manual: Master Cylinder Bench Bleeding

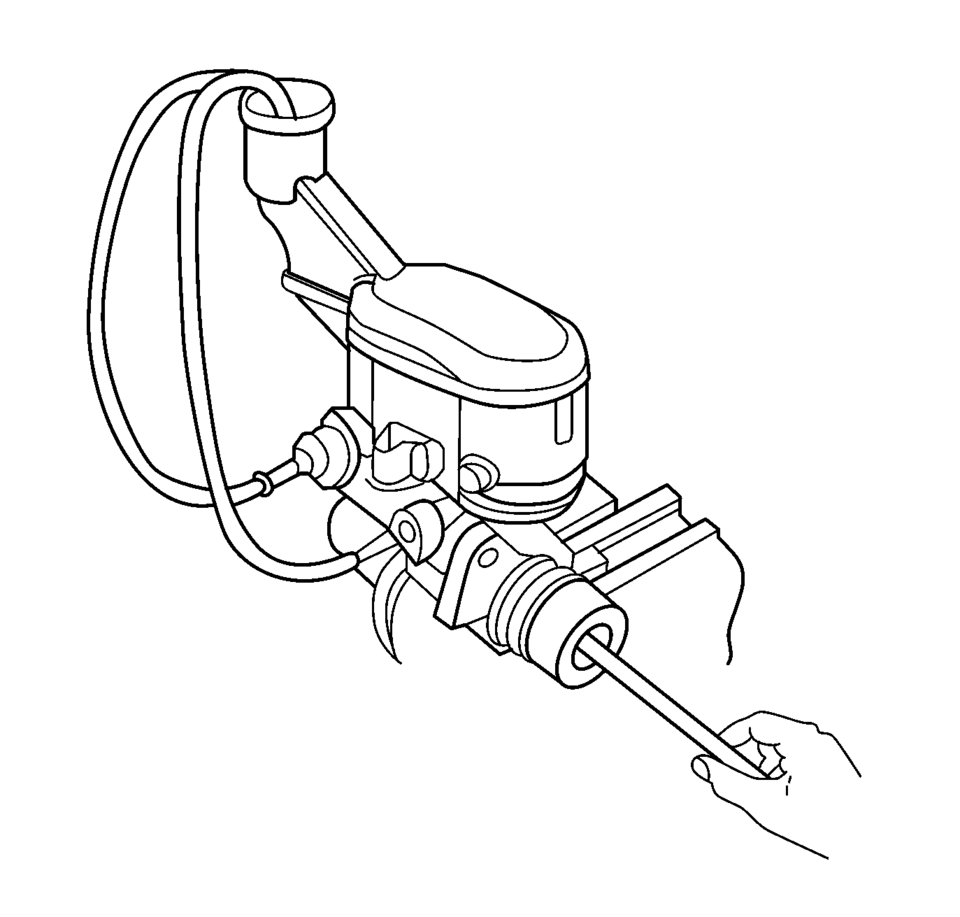

- Secure the mounting flange of the brake master cylinder in a bench vice so that the rear of the primary piston is accessible.

- Remove the master cylinder reservoir cap and diaphragm.

- Install suitable fittings to the master cylinder ports that match the type of flare seat required and also provide for hose attachment.

- Install transparent hoses to the fittings installed to the master cylinder ports, then route the hoses into the master cylinder reservoir.

- Fill the master cylinder reservoir to the maximum fill level with brake fluid from a clean, sealed brake fluid container. Refer to Master Cylinder Reservoir Filling.

- Ensure that the ends of the transparent hoses running into the master cylinder reservoir are fully submerged in the brake fluid.

- Using a smooth, round-ended tool, depress and release the primary piston

as far as it will travel, a depth of about 25 mm (1 in), several times. Observe

the flow of fluid coming from the ports.

As air is bled from the primary and secondary pistons, the effort required to depress the primary piston will increase and the amount of travel will decrease.

- Continue to depress and release the primary piston until fluid flows freely from the ports with no evidence of air bubbles.

- Remove the transparent hoses from the master cylinder reservoir.

- Install the master cylinder reservoir cap and diaphragm.

- Remove the fittings with the transparent hoses from the master cylinder ports. Wrap the master cylinder with a clean shop cloth to prevent brake fluid spills.

- Remove the master cylinder from the vice.

Warning:

Refer to Brake Fluid Irritant Warning.

Caution:

Refer to Brake Fluid Effects on Paint and Electrical Components Caution.

Brake Warning System Description and Operation

Brake Warning System Description and Operation

Brake Warning Indicator

Brake Warning Block Diagram

B80Park

Brake

SwitchB20Brake

Fluid Level

SwitchK9Body

Control

ModuleP16Inst ...

Master Cylinder Replacement

Master Cylinder Replacement

Removal Procedure

Warning: Refer to Brake Fluid Irritant Warning.

Caution: Refer to Brake Fluid Effects on Paint and Electrical

Components Caution.

Place the ignit ...

Other materials:

Air Inlet Grille Panel Replacement

Air Inlet Grille Panel Replacement

Callout

Component Name

Preliminary Procedure

Remove both wiper arm assemblies. Refer to Windshield Wiper Arm

Replacement.

Remove both outer hood rear seals. Refer to Hood Rear Seal Repla ...

SIR Service Precautions

General Service Instructions

Warning: When performing service on or near the SIR components

or the SIR wiring, the SIR system must be disabled. Refer to SIR Disabling

and Enabling . Failure to observe the correct procedure could cause deployment

of the SIR components, person ...

Engine Front Cover and Oil Pump Cleaning and Inspection

Engine Front Cover Cleaning Procedure

Clean the engine front cover sealing surface.

Warning: Wear safety glasses when using compressed air in

order to prevent eye injury.

Caution: To ensure proper engine lubrication, clean clogged

or contaminated oil g ...

0.006