Chevrolet Sonic Repair Manual: Wheel Stud Replacement

Special Tools

CH 43631 Ball Joint Separator

For equivalent regional tools, refer to Special Tools.

- Removal Procedure

-

- Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

- Remove the tire and wheel assembly. Refer to Tire and Wheel Removal and Installation.

- Without disconnecting the hydraulic brake flex hose, remove and support the brake caliper and bracket as an assembly. Refer to Front Brake Rotor Replacement.

- Remove the front wheel hub. Refer to Front Wheel Bearing and Hub Replacement.

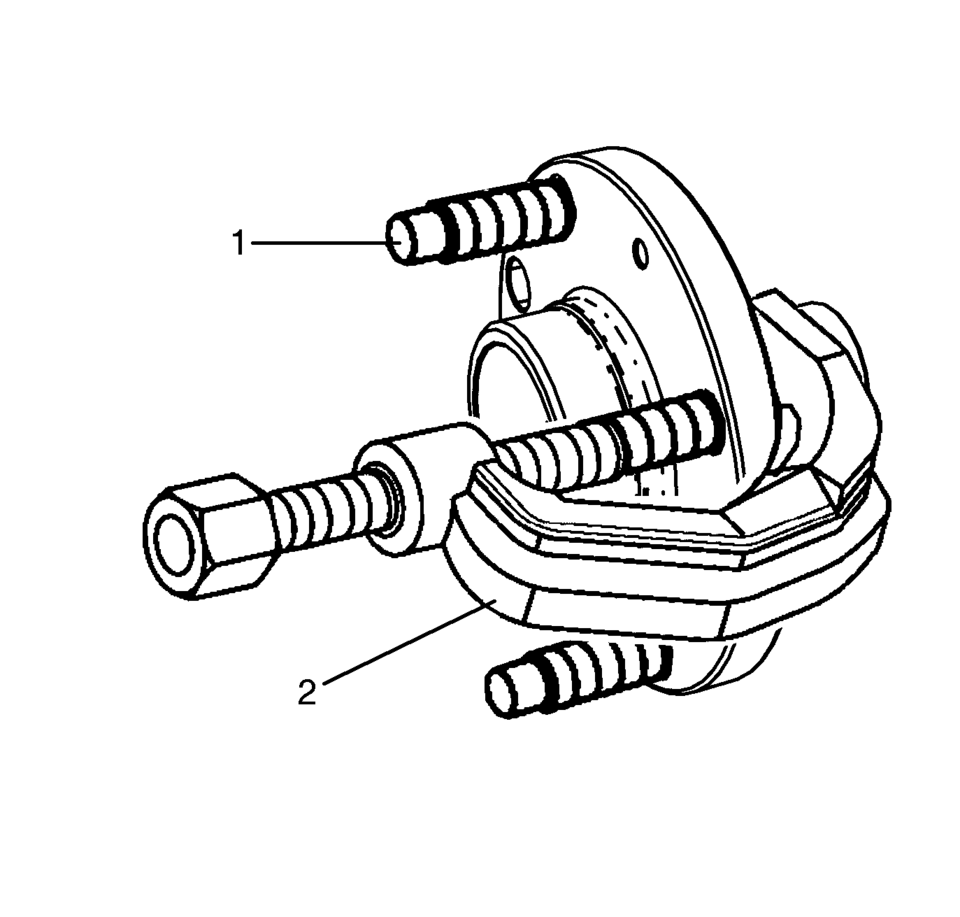

- Using the CH 43631 separator (2), remove the wheel stud (1) from the wheel bearing and hub.

- Installation Procedure

-

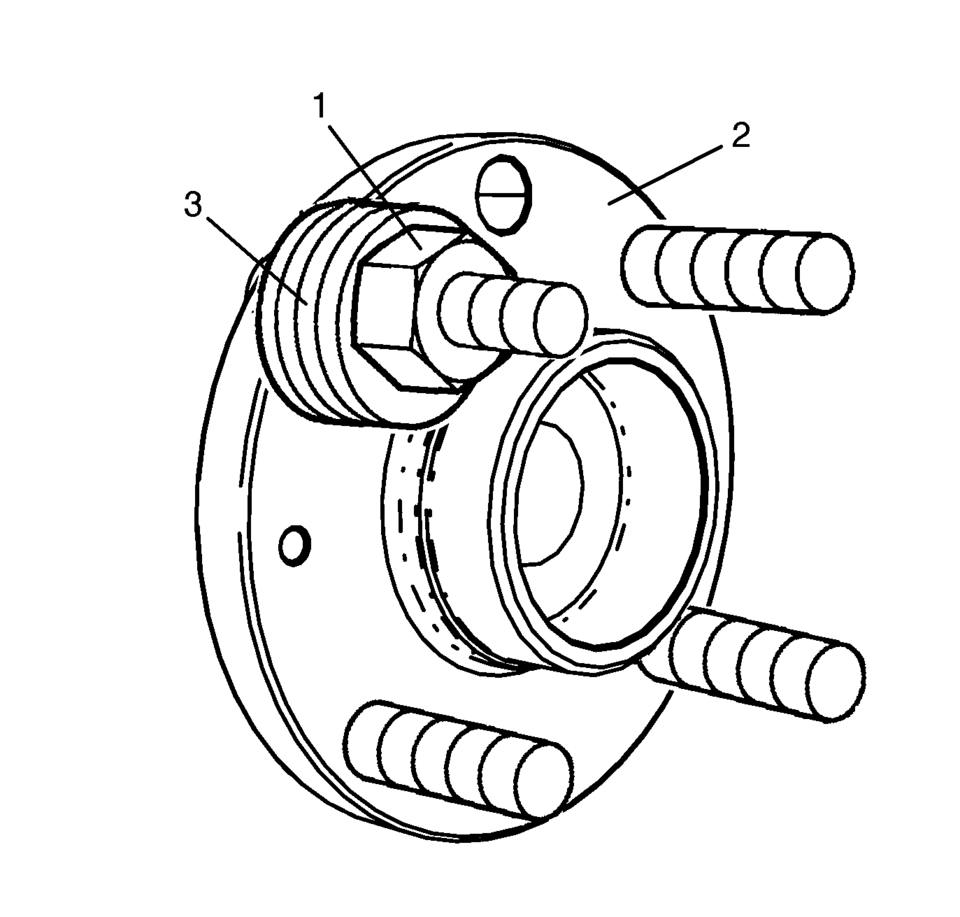

- Install a NEW wheel stud to the wheel hub flange (2).

- Position three washers (3) and an old lug nut (1) on the stud to be replaced.

- Position the pry bar to hold the wheel bearing flange while tightening the wheel lug nut.

- Tighten the old lug nut (1) until the wheel stud is firmly seated in the wheel hub flange.

- Remove the washers (3) and the old lug nut (1) and the pry bar.

- Install the front wheel hub. Refer to Front Wheel Bearing and Hub Replacement.

- Install the front brake rotor. Refer to Front Brake Rotor Replacement.

- Install the tire and wheel assembly. Refer to Tire and Wheel Removal and Installation.

- Lower the vehicle.

Wheel Replacement

Wheel Replacement

Replace any wheel that is bent, cracked, or badly rusted or corroded. If wheel

nuts keep coming loose, the wheel, wheel bolts, and wheel nuts should be replaced.

If the wheel leaks air, replace it ...

Electrical

Electrical

...

Other materials:

Liftgate Replacement

Liftgate Replacement

Callout

Component Name

Preliminary Procedures

Disconnect the electrical connectors.

Disconnect the liftgate struts. Refer to Liftgate Strut Replacement.

Remove the body lock pillar upper trim. Refe ...

Tire Terminology and Definitions

Air Pressure

The amount of air inside the tire pressing outward on each square inch

of the tire. Air pressure is expressed in kPa (kilopascal) or psi (pounds per

square inch).

Accessory Weight

The combined weight of optional accessories. Some examples of optional

access ...

Toe Description

Toe is a measurement of how much the front and/or rear wheels are turned in or

out from a straight-ahead position. When the wheels are turned in, toe is positive (+).

When the wheels are turned out, toe is negative (−). The actual amount of toe is

normally only a fraction ...

0.0047