Chevrolet Sonic Repair Manual: 3-5-Reverse and 4-5-6 Clutch Housing Assemble (6T30/40/45/50 - Gen 2)

| Table 1: | 4?? Clutch Piston Installation |

| Table 2: | 4?? Clutch Fluid Dam Installation |

| Table 3: | 3? Reverse Clutch Plates Installation |

| Table 4: | Reluctor Wheel and Piston Installation |

| Table 5: | 4?? Clutch Plates Installation |

| Table 6: | Turbine Shaft Installation |

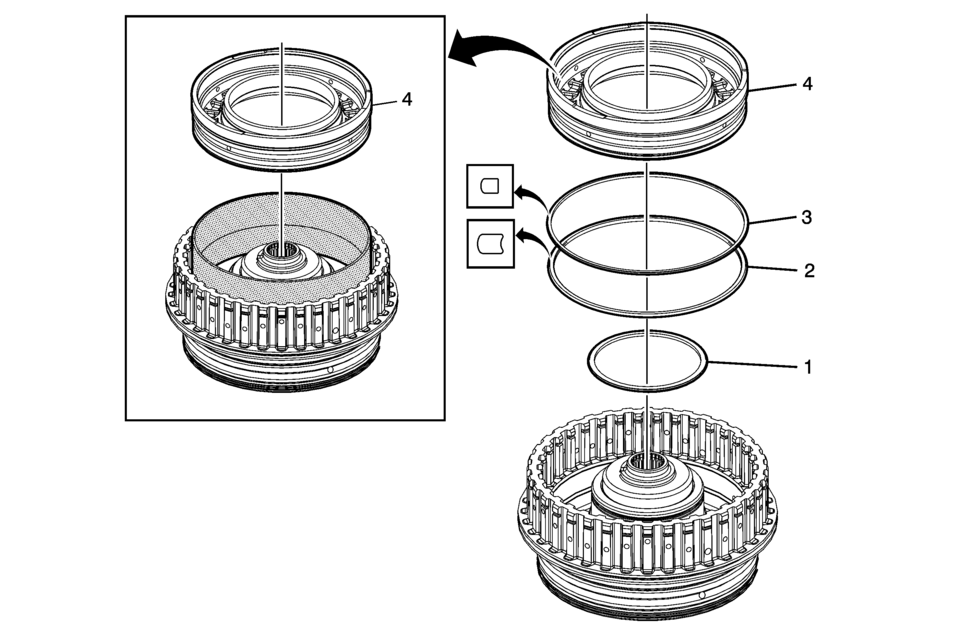

- 4?? Clutch Piston Installation

4?? Clutch Piston Installation Callout

Component Name

1

4?? Clutch Piston Inner Seal

2

4?? Clutch Piston Outer Seal (Large) (Rounded)

3

4?? Clutch Piston Outer Seal (Dark Blue) (Stepped)

4

4?? Clutch Piston

Special ToolsNote:

- DT-47805 seal protector prevents the piston seal lip from damage during installation. Apply a thin coat of ATF to the I.D. of DT-47805 seal protector to ease the installation of the piston.

- DT-47951-2 spring compressor can be used as a pusher if necessary.

- DT-47805 Seal Protector

- DT-47951-2 Spring Compressor

For equivalent regional tools, refer to Special Tools.

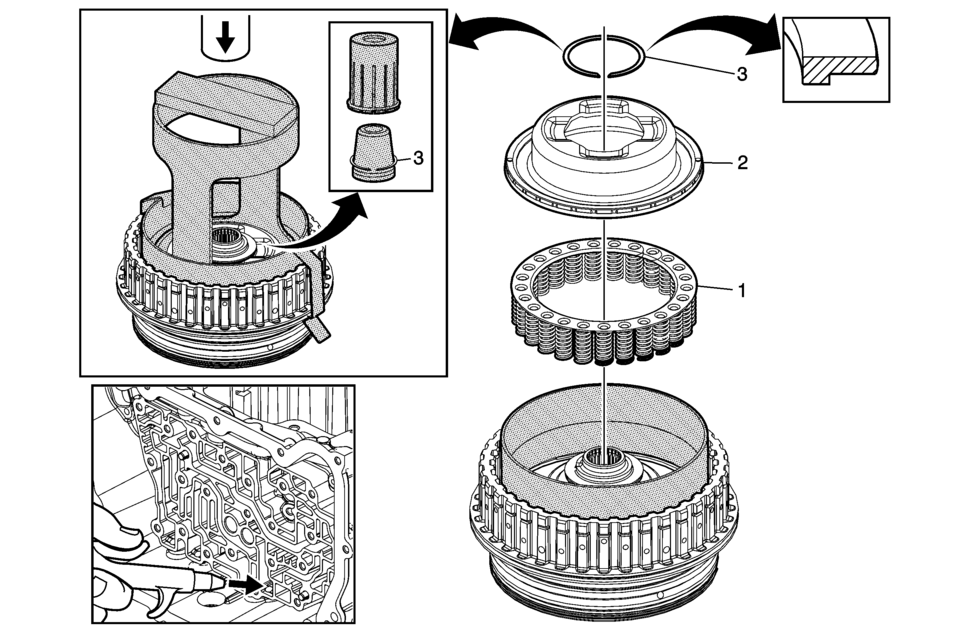

- 4?? Clutch Fluid Dam Installation

4?? Clutch Fluid Dam Installation Callout

Component Name

1

4?? Clutch Piston Return Spring Assembly

2

4?? Clutch Piston Fluid Dam Assembly

Special ToolsNote:

The seal protector prevents the dam seal lip from damage during installation. Apply a thin coat of ATF to the I.D. of the seal protector to ease the installation of the dam.

- DT-47951-1 Seal Protector for 6T40/45 applications

- DT-50117 Seal Protector for 6T50 applications

For equivalent regional tools, refer to Special Tools.

3

4?? Clutch Dam Retaining Ring

ProcedureCaution:

Regulate the air pressure to 276 kPa (40 psi) maximum. High pressure could cause the piston to over travel and damage the piston seals.

- Leave the seal protector on the clutch housing while installing the retaining ring. Install the dam retainer clips DT 50117-1 seal protector to hold the seal protector in place.

- Use DT 46620-2 retaining clips and DT 50573 ring guide to install a NEW 4-5-6 clutch dam retaining ring. Assemble the ring ??leg facing down, DT 50573 and DT 46620 and insert as an assembly onto the clutch hub to install the ring.

- Place the housing assembly onto the input shaft support inside the case. Apply shop air to the clutch fluid feed hole in the case to verify proper piston operation.

- DT-47951-2 Spring Compressor

- DT 46620 Seal Installer

- DT 50117-1 Seal Protector

- DT 50117-2 Seal Protector Retaining Clips

- DT 50573 Retaining Ring Installer

For equivalent regional tools, refer to Special Tools.

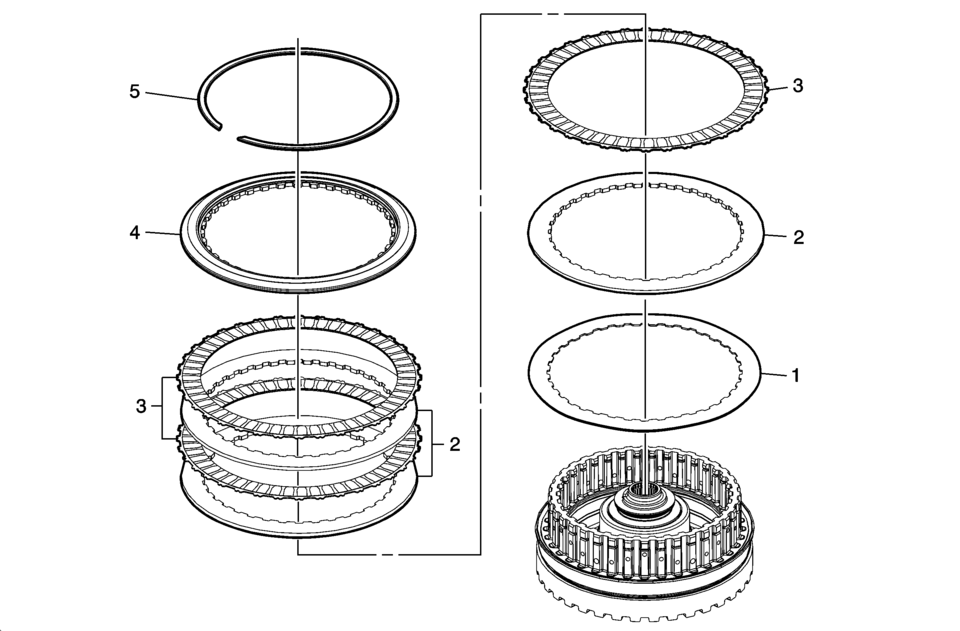

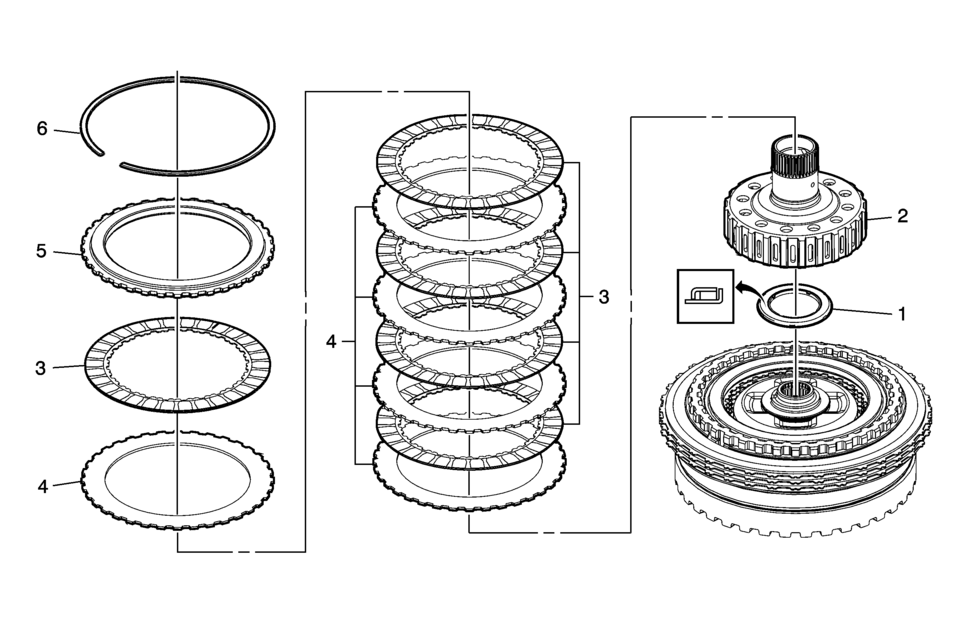

- 3? Reverse Clutch Plates Installation

3? Reverse Clutch Plates Installation Callout

Component Name

1

3? Reverse Clutch Apply Plate (Waved)

2

3? Reverse Clutch Plate (Qty: 3)

3

3? Reverse Clutch Plate Assembly (Qty: 3)

4

3? Reverse Clutch Backing Plate

5

3? Reverse Clutch Backing Plate Ring Retainer Ring

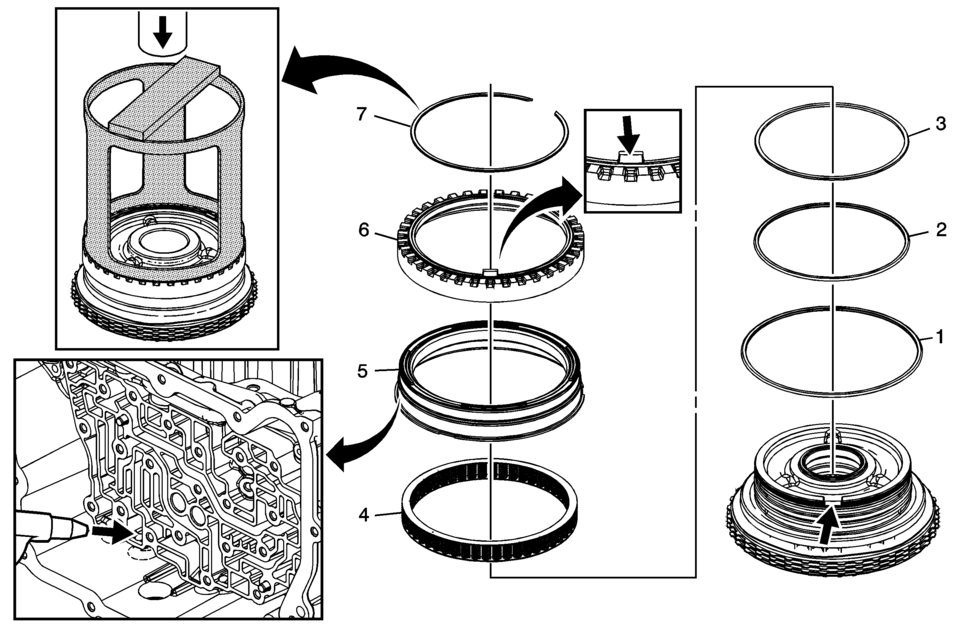

- Reluctor Wheel and Piston Installation

Reluctor Wheel and Piston Installation Callout

Component Name

1

3? Reverse Clutch Piston Dam Seal (Black)

2

3? Reverse Clutch Piston Inner Seal

3

3? Reverse Clutch Piston Inner (Reluctor) Seal (Orange)

4

3? Reverse Clutch Piston Return Spring Assembly

5

3? Reverse Clutch Piston

6

Input Shaft Speed Sensor Reluctor Wheel

7

Input Shaft Speed Sensor Reluctor Ring Retainer Ring

Caution:

Compress the reluctor wheel just enough to clear the retainer. Over compressing the reluctor wheel will break the alignment tab and the clutch housing.

Caution:

Regulate the air pressure to 276 kPa (40 psi) maximum. High pressure could cause the piston to over travel and damage the piston seals.

Procedure

Place the housing assembly onto the input shaft support inside the case. Apply shop air to the clutch fluid feed hole in the case to verify proper piston operation.

Special Tools

DT-47694 Piston Spring Compressor

For equivalent regional tools, refer to Special Tools.

- 4?? Clutch Plates Installation

4?? Clutch Plates Installation Callout

Component Name

1

Reaction Carrier Hub Thrust Bearing Assembly

2

Reaction Carrier Hub Assembly

3

4?? Clutch Plate Assembly (Qty: 5)

4

4?? Clutch Plate (Qty: 5)

5

4?? Clutch Backing Plate

6

4?? Clutch Backing Plate Retaining Ring

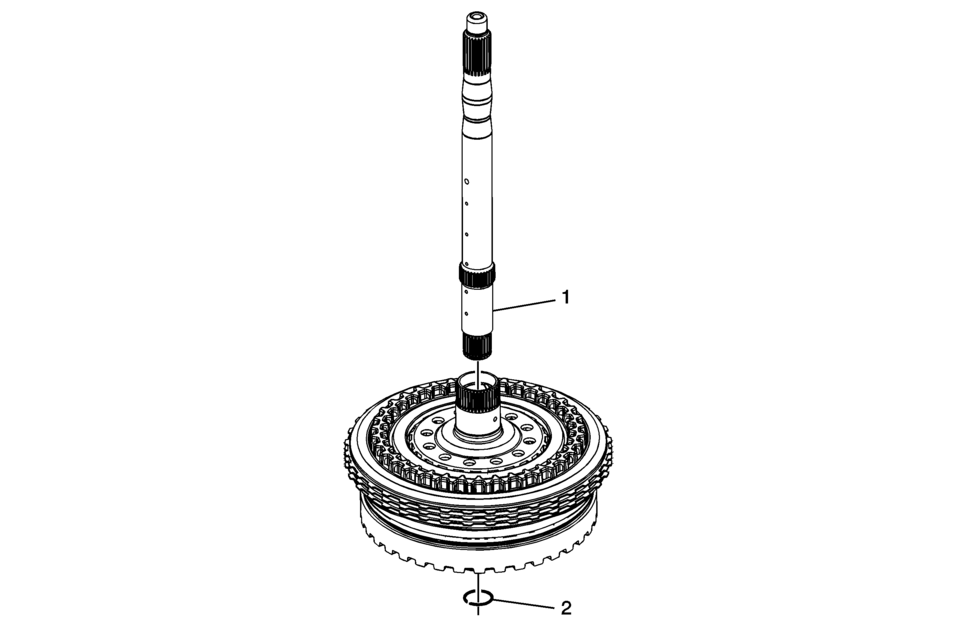

- Turbine Shaft Installation

Turbine Shaft Installation Callout

Component Name

1

Turbine Shaft

2

Turbine Shaft Retainer Ring

Note:

Do not re-use the turbine shaft retainer ring.

Special Tools

GE 5586-A Snap Ring Pliers or equivalent

For equivalent regional tools, refer to Special Tools.

3-5-Reverse and 4-5-6 Clutch Fluid Seal Ring Replacement (Gen 2)

3-5-Reverse and 4-5-6 Clutch Fluid Seal Ring Replacement (Gen 2)

3-5-Reverse and 4-5-6 Clutch Fluid Seal Ring Replacement

Callout

Component Name

Special Tools

DT-46620 Seal Installer

For e ...

3-5-Reverse and 4-5-6 Clutch Housing Disassemble (6T30/40/45/50 - Gen 2)

3-5-Reverse and 4-5-6 Clutch Housing Disassemble (6T30/40/45/50 - Gen 2)

Table 1:

Turbine Shaft, Reluctor Wheel and Piston Removal

Table 2:

4?? Clutch Plate Removal

Table 3:

4?? Clutch Piston Removal

Table 4:

Reluctor Wheel ...

Other materials:

Airbag Steering Wheel Module Replacement

Removal Procedure

Warning: Refer to SIR Inflator Module Handling and Storage

Warning.

Warning: Refer to SIR Warning.

Disable the SIR system. Refer to SIR Disabling and Enabling.

Rotate the steering wheel 180?€‰degrees.

Using a bl ...

Generator Replacement (LUV)

Removal Procedure

Disconnect the negative battery cable. Refer to Battery Negative Cable

Disconnection and Connection.

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle.

Remove the drive belt. Refer to Drive Belt Replacement.

Remove the drive bel ...

Transmission Replacement (With 1.6L or 1.8L Engine)

Removal Procedure

Remove the battery tray. Refer to Battery Tray Replacement.

Without draining the coolant or removing the hoses, remove and position

aside the radiator surge tank. Refer to Radiator Surge Tank Replacement.

Remove the transmission range selector lever cabl ...

0.0082