Chevrolet Sonic Repair Manual: Air Conditioning System Seal Replacement

- Removal Procedure

-

- Disassemble the A/C refrigerant components. Refer to the appropriate repair procedure.

- Cap or tape the A/C refrigerant components.

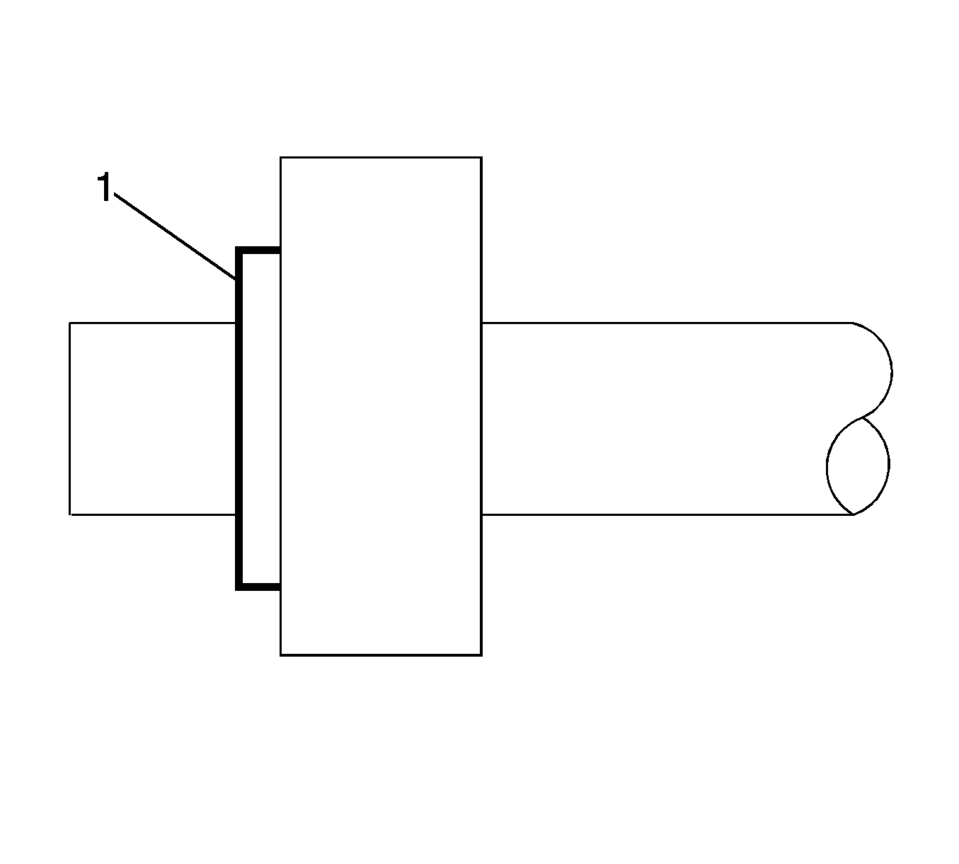

- Remove the sealing washer (1) from the A/C refrigerant component.

- Inspect the seal washer for signs of damage to help determine the root cause of the failure.

- Inspect the A/C refrigerant components for damage or burrs. Repair if necessary.

- DISCARD the sealing washer.

Note:

Cap or tape the open A/C refrigerant components immediately to prevent system contamination.

Note:

DO NOT reuse sealing washer.

- Installation Procedure

-

- Inspect the new sealing washer for any signs of cracks, cuts, or damage.

Do not use a damaged sealing washer.

- Remove the cap or tape from the A/C refrigerant components.

- Using a lint-free clean, dry cloth, clean the sealing surfaces of the A/C refrigerant components.

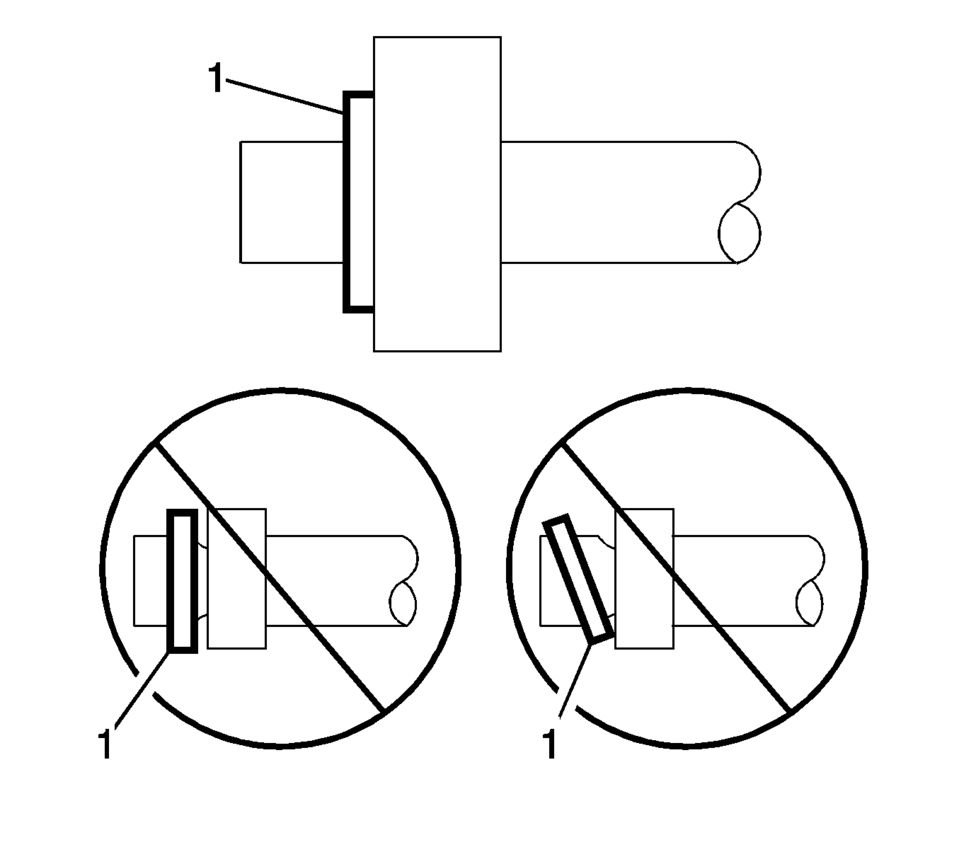

- Carefully install the NEW sealing washer (1) onto the A/C refrigerant

component.

The sealing washer (1) must completely bottom against the surface of the fitting.

- Assemble the remaining A/C refrigerant components. Refer to the appropriate repair procedure.

Note:

Flat washer type seals do not require lubrication.

Note:

After tightening the A/C components, there should be a slight sealing gap of approximately 1.2 mm (3/64 in) between the A/C line and the A/C component.

- Inspect the new sealing washer for any signs of cracks, cuts, or damage.

Air Conditioning Refrigerant Service Valve Core Replacement

Air Conditioning Refrigerant Service Valve Core Replacement

Special Tools

GE-39400-A Halogen Leak Detector

GE-46246 Valve Core Removal Tool

For equivalent regional tools, refer to Special Tools.

Removal Procedure

Recover the refrigerant ...

Air Inlet Assembly Replacement

Air Inlet Assembly Replacement

Air Inlet Assembly Replacement

Callout

Component Name

Preliminary Procedures

Remove the Heater and Air Conditioning Evaporator and ...

Other materials:

Rear Side Door Window Regulator Motor Replacement

Rear Side Door Window Regulator Motor Replacement

Callout

Component Name

Warning: Refer to Glass and Sheet Metal Handling Warning.

Preliminary Procedure

Remove the rear side door window regulator. Refer to Rear ...

Front Bumper Impact Bar Lower Bracket Replacement

Front Bumper Impact Bar Lower Bracket Replacement

Callout

Component Name

Preliminary Procedure

Remove the front bumper opening cover. Refer to Front Bumper Fascia Opening

Lower Cover Replacement.

1

...

Torque Converter Housing with Fluid Pump Assembly Installation (6T40/45/50 Non

Hybrid)

Torque Converter Housing with Fluid Pump Assembly Installation

Callout

Component Name

1

Fluid Pump Seal Assembly

2

Torque Converter Housing Gasket

3

Torque Converte ...

0.0057