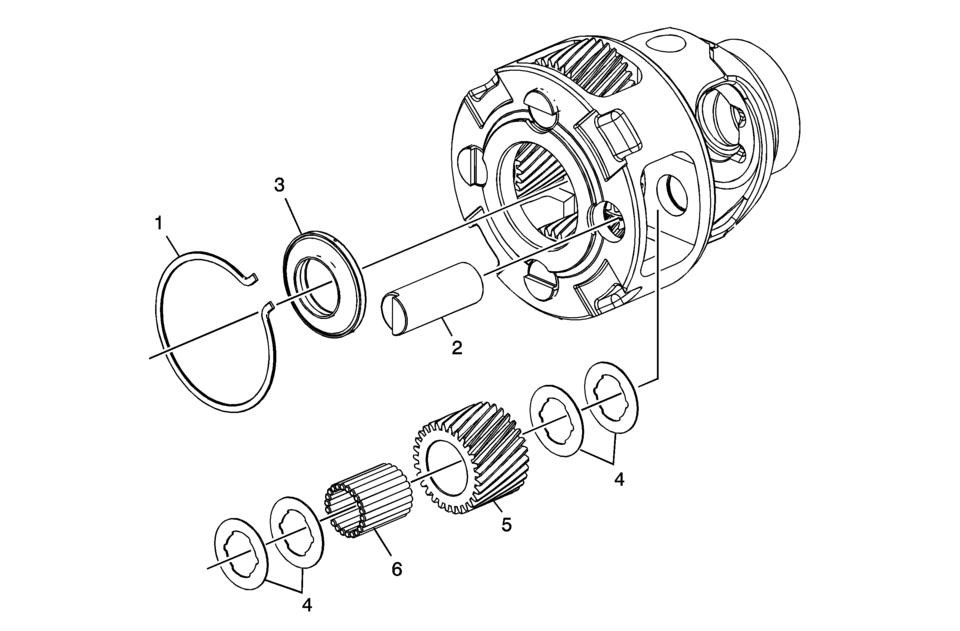

Chevrolet Sonic Repair Manual: Front Differential Carrier Cleaning and Inspection

|

Callout |

Component Name |

|---|---|

|

Caution: After cleaning the transmission components, allow to air dry. Do not use cloth or paper towels in order to dry any transmission components. Lint from the towels can cause component failure. Caution: Do not reuse cleaning solvents. Previously used solvents may deposit sediment which may damage the component. Caution: Keep thrust washers with the gear it was matched to. The thrust washers are selective sizes and it is difficult to identify the proper washer thickness. Improper assembly can cause premature failure of the differential assembly.

|

|

|

1 |

Front Differential Pinion Gear Shaft Retainer |

|

2 |

Front Differential Pinion Gear Pin |

|

3 |

Sun Gear to Differential Housing Bearing Assembly |

|

4 |

Front Differential Pinion Gear Washer |

|

5 |

Front Differential Pinion Gear |

|

6 |

Front Differential Planetary Pinion Gear Bearing Roller |

Differential Carrier Removal (6T40/45/50)

Differential Carrier Removal (6T40/45/50)

Differential Carrier Removal

Callout

Component Name

1

Front Differential Carrier Bearing Assembly

2

...

Front Differential Carrier Installation (6T30)

Front Differential Carrier Installation (6T30)

Front Differential Carrier Installation

Callout

Component Name

1

Final Drive Sun Gear

2

Diff ...

Other materials:

Front Side Door Window Regulator Handle Replacement

Front Side Door Window Regulator Handle Replacement

Callout

Component Name

1

Front Side Door Window Regulator Handle Clip

Procedure

Use the appropriate tool, remove the clip from handle.

2

...

Wheel Drive Shaft Inner Joint Inspection

Inspection Procedure

Remove the front wheel drive shaft inner joint and boot. Refer to Front

Wheel Drive Shaft Replacement.

Remove the wheel drive shaft tripod bushing (1) from the tripod housing (3).

Remove the wheel drive shaft tripod housi ...

Drive Range, First Gear Engine Braking (Gen 1)

When the gear selector lever is moved to the Drive (D) range from the Neutral

(N) position, the transmission will provide engine braking. In this operating range,

the normally-low 1234 pressure control solenoid 5 is commanded ON and, in the engine

braking mode, the following changes occur with ...

0.0046