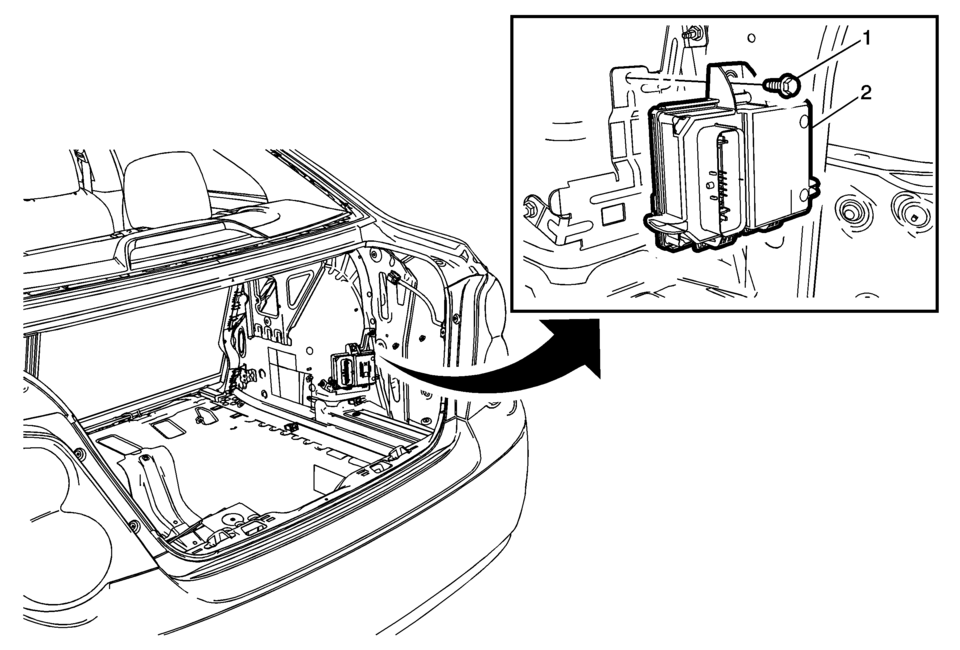

Chevrolet Sonic Repair Manual: Fuel Pump Flow Control Module Replacement

|

Callout |

Component Name |

|---|---|

Preliminary Procedures

|

|

|

1 |

Fuel Pump Control Module Fastener Caution: Refer to Fastener Caution.

10 Y (89 lb in) |

|

2 |

Fuel Pump Control Module Caution:

|

Fuel Pressure Relief

Fuel Pressure Relief

Special Tools

EN-34730-91 Pressure Tester

For equivalent regional tools, refer to Special Tools.

Warning: Gasoline or gasoline vapors are highly flammable. A fire

could occur if an ig ...

Fuel System Cleaning

Fuel System Cleaning

Note: If the fuel filter is plugged, the fuel tank should be inspected

internally and cleaned if necessary.

Drain the fuel tank. Refer to

Fuel Tank Draining.

Remove the f ...

Other materials:

Vehicle Load Limits

It is very important to know how much weight the vehicle can carry. This weight

is called the vehicle capacity weight and includes the weight of all occupants,

cargo, and all nonfactory-installed options. Two labels on the vehicle show how

much weight it may properly carry: the Tire and Loadin ...

Driver or Passenger Seat Head Restraint Guide Replacement

Driver or Passenger Seat Head Restraint Guide Replacement

Callout

Component Name

Preliminary Procedure

Remove the seat head restraint. Refer to Driver or Passenger Seat Head

Restraint Replacement.

1

...

Drive Range, Fifth Gear (Gen 1)

As vehicle speed increases, the transmission control module (TCM) processes input

signals from the automatic transmission input and output speed sensors, the throttle

position sensor and other vehicle sensors to determine the precise moment to command

ON the normally-high 35R pressure control ...

0.0047