Chevrolet Sonic Repair Manual: Piston, Connecting Rod, and Bearing Installation

Special Tools

EN-470-B Angular Torque Wrench

For equivalent regional tools, refer to Special Tools.

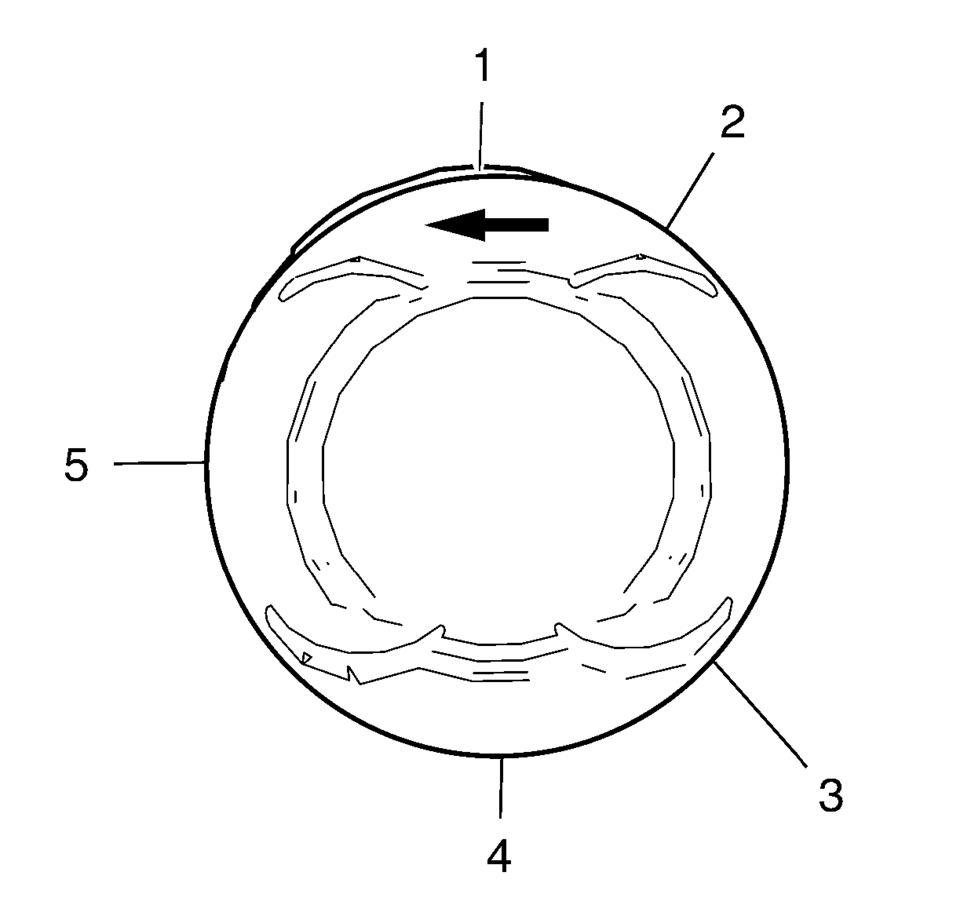

- Adjust the piston ring joints as follows:

- Upper compression ring (1).

- Lower compression ring (4).

- Oil rings (2) or (3).

- Oil ring spacer (5).

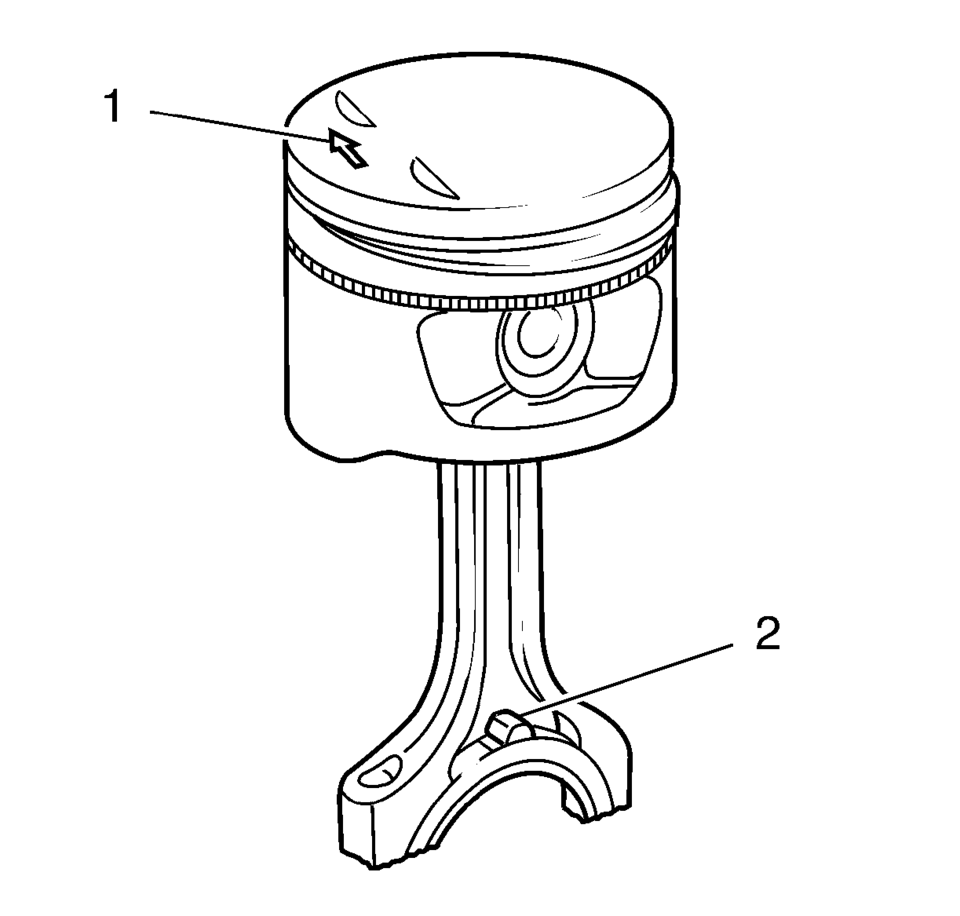

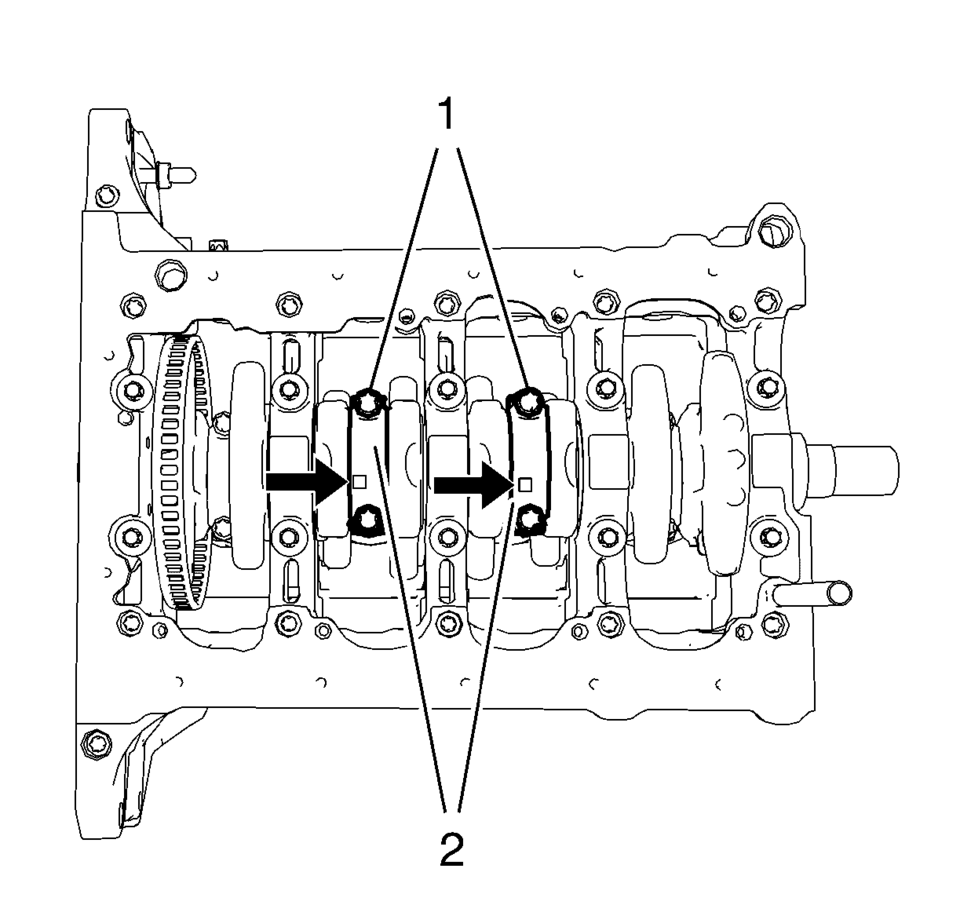

- The arrow (1) on the piston head must point to the timing side.

- The markings on the connecting rods (2) must point to the transmission side.

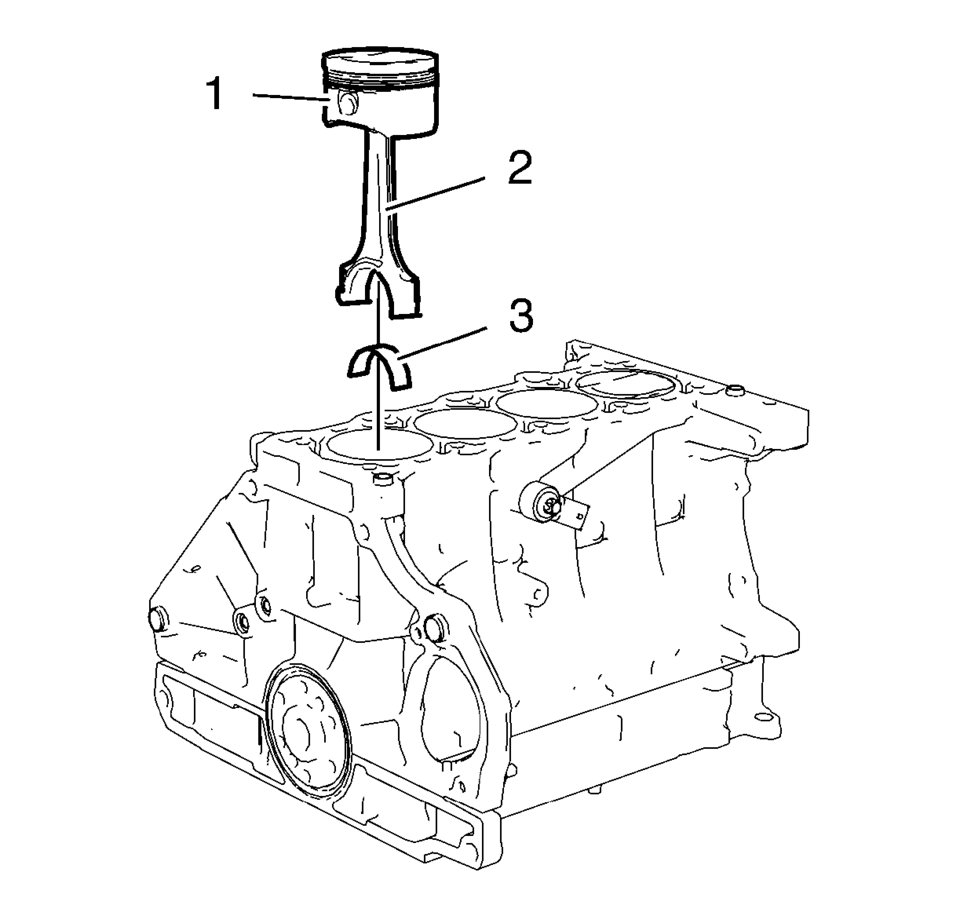

- Install a piston ring compressor to compress the piston rings.

- Install the pistons (1) in along with connecting rods (2) and upper connecting rod bearings (3) to the engine block and to the crankshaft.

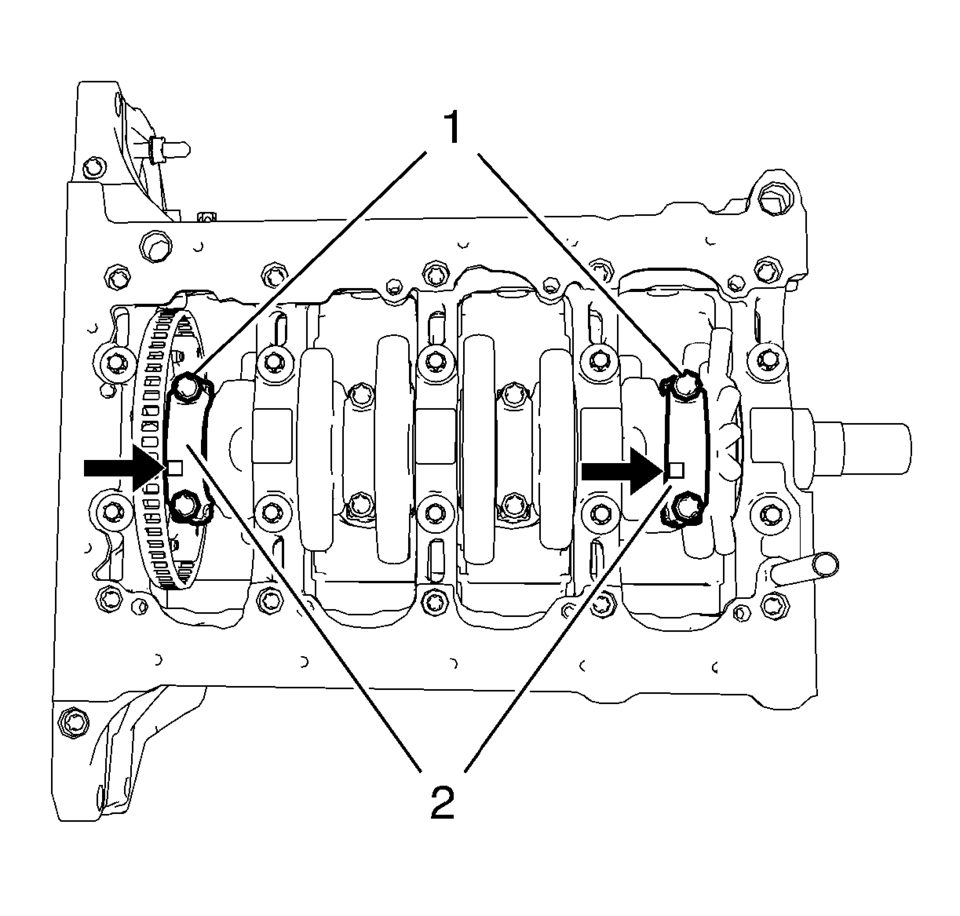

- Install the 2 connecting rod bearings and the 2 connecting rod bearing caps (2) of cylinder 1 and 4.

- Install the 4 NEW connecting rod bearing cap bolts (1) and tighten in the following sequence:

- Tighten the connecting rod bearing cap bolts to 25 Y (18 lb ft)

.

- Tighten the connecting rod bearing cap bolts an additional 45 degrees. Use EN-470 B wrench.

- Rotate the crankshaft 180 degrees.

- Install the 2 connecting rod bearings and the 2 connecting rod bearing caps (2) of cylinder 3 and 2.

- Install the 4 NEW connecting rod bearing cap bolts (1) and tighten in the following sequence:

- Tighten the connecting rod bearing cap bolts to 25 Y (18 lb ft)

.

- Tighten the connecting rod bearing cap bolts an additional 45 degrees. Use EN-470–B wrench.

Note:

The flarings (arrows) on the connecting rod bearing caps must point to the transmission side. The connecting rod bearing caps must be installed in their original position.

Caution:

Refer to Fastener Caution.

Caution:

Refer to Torque-to-Yield Fastener Caution.

Note:

Do not reuse the old bolts.

Note:

The flarings (arrows) on the connecting rod bearing caps must point to the transmission side. The connecting rod bearing caps must be installed in their original position.

Note:

Do not reuse the old bolts.

Piston, Connecting Rod, and Bearing Cleaning and Inspection

Piston, Connecting Rod, and Bearing Cleaning and Inspection

Special Tools

EN-470-B Angular Torque Wrench

For equivalent regional tools, refer to Special Tools.

Visual Inspection And Cleaning Procedure

Connecting Rod

Warning: Wear safety gla ...

Piston, Connecting Rod, and Bearing Removal

Piston, Connecting Rod, and Bearing Removal

Install the crankshaft balancer bolt.

Set the pistons 1 and 4 to TDC in direction of engine rotation.

Note: Note cylinder sequence.

Mark the connecting rod with the ...

Other materials:

Distracted Driving

Distraction comes in many forms and can take your focus from the task of driving.

Exercise good judgment and do not let other activities divert your attention away

from the road. Many local governments have enacted laws regarding driver distraction.

Become familiar with the local laws in your ...

Pretensioner Handling and Scrapping

Scrapping Procedure

During the course of a vehicles useful life, certain situations may arise

which will necessitate the disposal of a live (undeployed) pretensioner. The

following information covers the proper procedures for the disposing of a live

(undeployed) pretensioner. Deplo ...

Front End Upper Tie Bar Replacement

Front End Upper Tie Bar Replacement

Callout

Component Name

Preliminary Procedures

Disable the SIR system. Refer to SIR Disabling and Enabling.

Remove the front fascia. Refer to Front Bumper Fascia Replacement.

Rem ...

0.0072