Chevrolet Sonic Repair Manual: Shock Absorber Disposal

Warning:

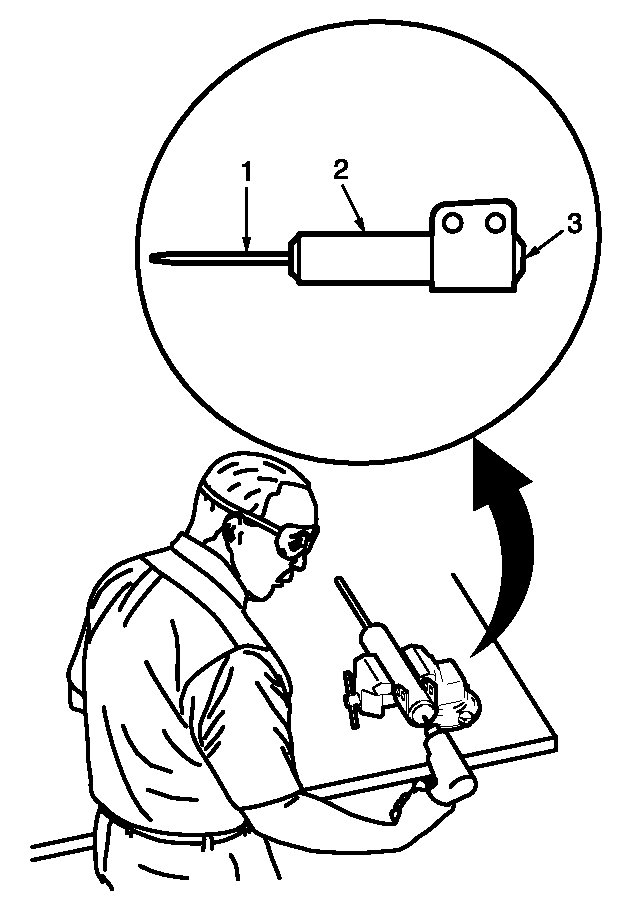

Use the proper eye protection when drilling to prevent metal chips from causing physical injury.

- Clamp the strut in a vise horizontally with the rod (1) completely extended.

- Drill a hole in the strut at the center of the end cap (3) using a 5 mm (3/16 in) drill bit. Gas or a gas/oil mixture will exhaust when the drill bit penetrates the strut. Use shop towels in order to contain the escaping oil.

- Remove the strut from the vise.

- Hold the strut over a drain pan vertically with the hole down.

- Move the rod (1) in and out of the tube (2) to completely drain the oil from the strut.

Strut, Strut Component, or Spring Replacement

Strut, Strut Component, or Spring Replacement

Disassembly Procedure

Remove the strut assembly from the vehicle. Refer to Strut Assembly

Removal and Installation.

Note: The spring is compressed when the strut move ...

Shock Absorber Replacement

Shock Absorber Replacement

Shock Absorber Replacement

Callout

Component Name

Preliminary Procedure

Raise and support the vehicle. Refer to Lifting and Jacking ...

Other materials:

Home Page (Radio with Touchscreen)

Touchscreen Buttons

Touchscreen buttons show on the screen when available. When a function is

unavailable, the button may gray out. When a function is selected, the button

may highlight.

Home Page Features

audiopicturemovietelephoneelsmartphonelinksettings03/06/2012

...

Crankshaft Position System Variation Learn

Note: The crankshaft position sensor system variation learn procedure

is required when the following service procedures have been performed, regardless

of whether DTC P0315 is set:

Engine replacement

Engine control module (ECM) replacement

Crankshaft damper replacement

...

Crankshaft and Bearing Installation

Special Tools

EN-45059 Torque Angle Sensor Kit

For equivalent regional tools, refer to Special Tools

Note: Inspect the installation position.

Install the crankshaft bearing clips, oil bearing clips.

Install the crankshaft.

Note: Inspect the installation position.

...

0.0043