Chevrolet Sonic Repair Manual: Synchronizers Cleaning and Inspection

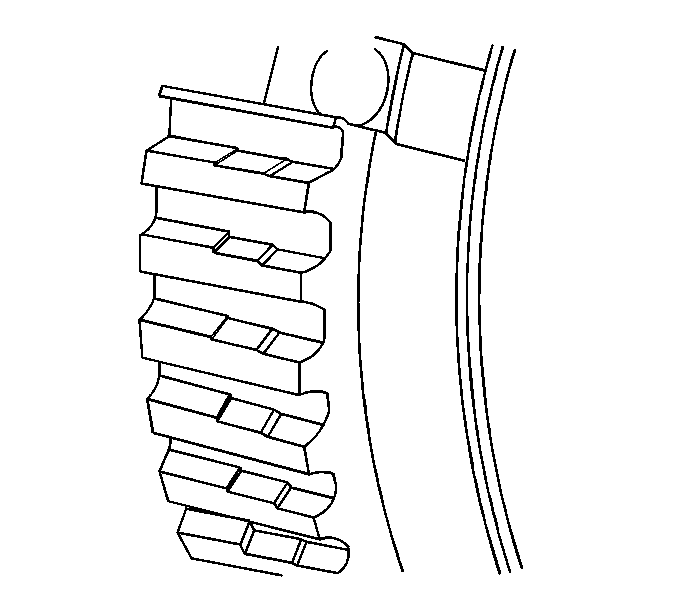

- Clean all the synchronizer parts in a suitable cleaning solvent and air dry all the parts.

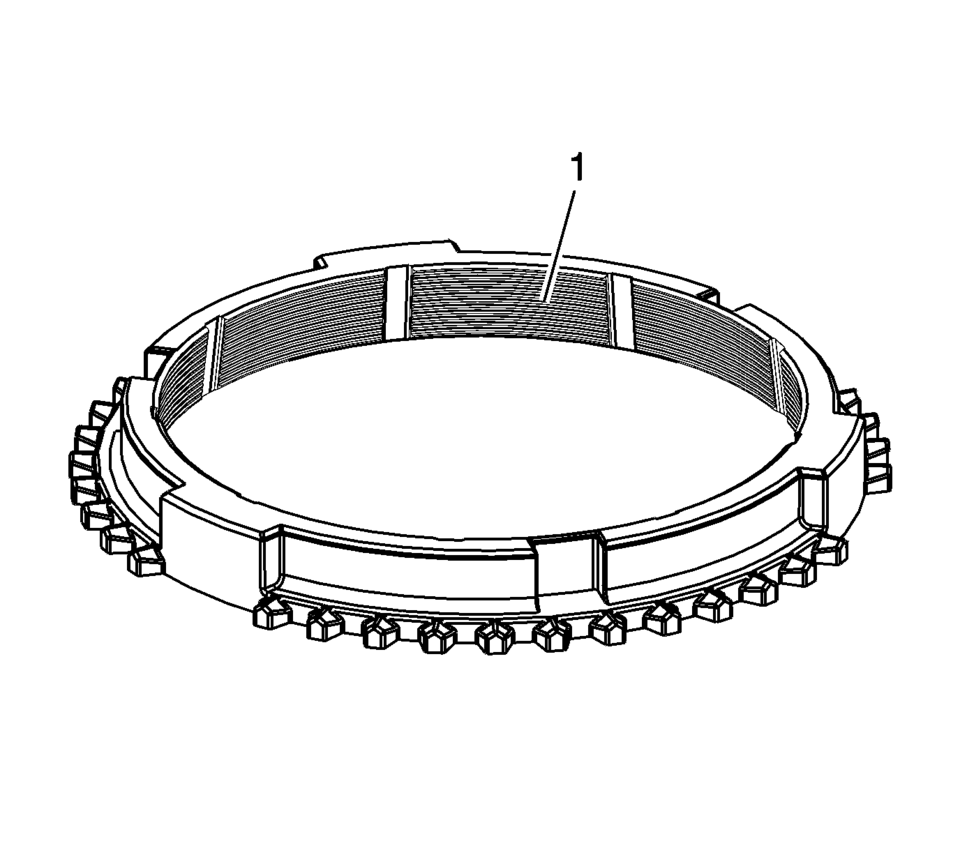

- Inspect the 1st/2nd gear, 3rd/4th gear, and 5th gear synchronizer hubs for a force fit on the main shaft.

- Replace synchronizer hubs that do not require a force fit.

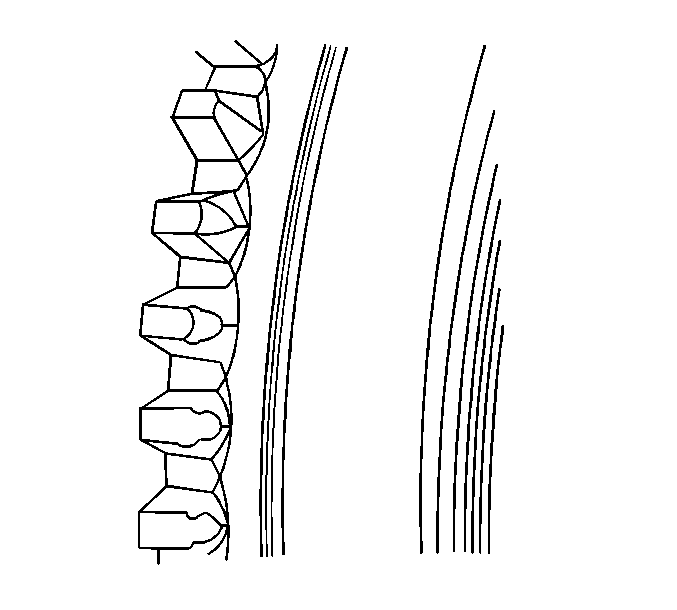

- Inspect the synchronizer hubs for wear on the external splines. A stepped effect on the teeth, due to wear, may cause shift concerns.

- Replace a worn hub.

- Correct the cause, such as, but not limited to the following conditions:

Note:

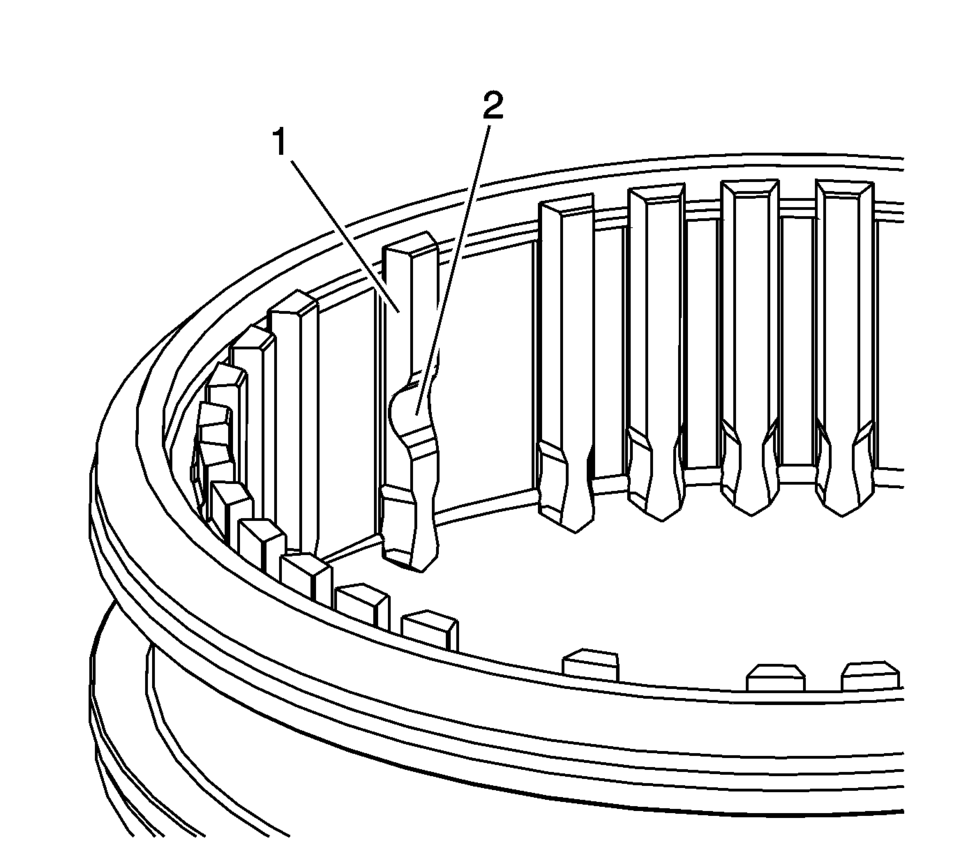

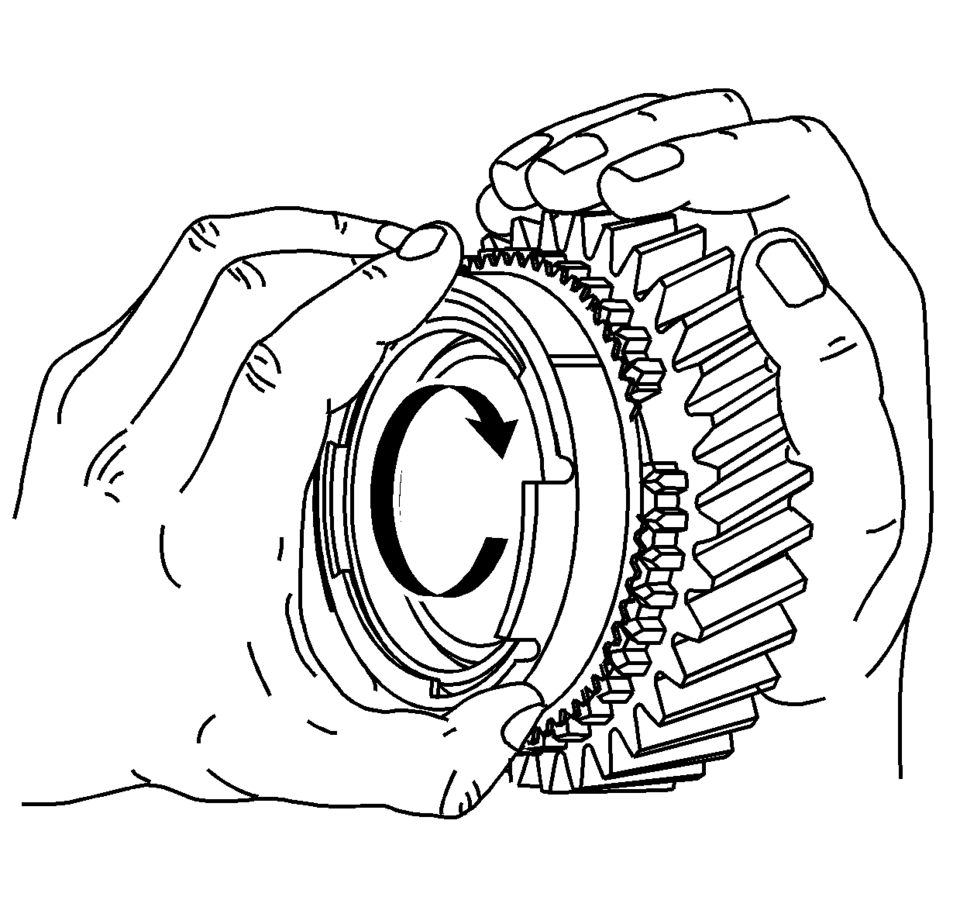

When servicing the synchronizers, retain them in the order that they are removed. Mark the parts to ensure the correct position for inspection and assembly.

- Engine related vibrations

- Driving at a low speed in a high gear

- Defective vibration damper or crankshaft

- Grated teeth

- Chipped off teeth

- Blunted teeth

Synchronizers Assemble

Synchronizers Assemble

1st/2nd Gear Synchronizer

iv

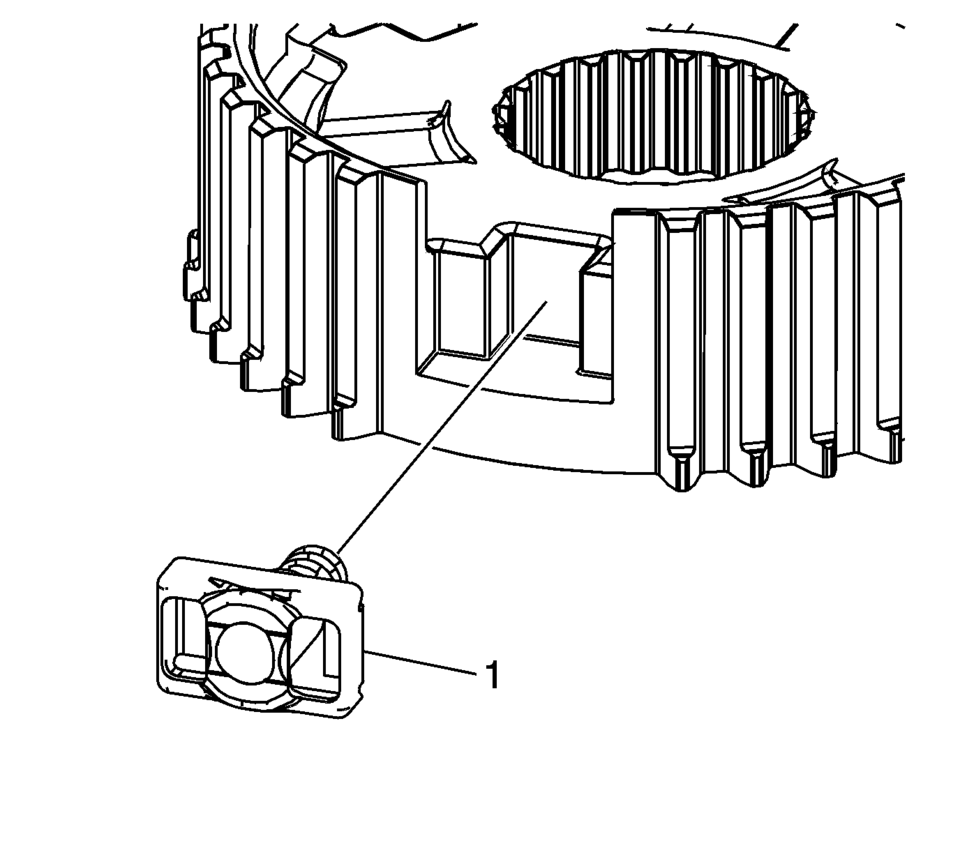

Note: When servicing the synchronizers, retain them in the

same order that they are removed. Keep the synchronizer components together

...

Synchronizers Disassemble

Synchronizers Disassemble

1st/2nd Gear Synchronizer

iv

Note: When servicing the synchronizers, retain them in the

same order that they are removed. Keep the synchronizer components together

...

Other materials:

Instrument Panel Fuse Block

The instrument panel fuse block is on the underside of the driver side instrument

panel.

The vehicle may not be equipped with all of the fuses, relays, and features shown.

...

Relay Replacement (Attached to Wire Harness)

Removal Procedure

Locate the relay. Refer to the Master Electrical Component List to locate

the relay in the vehicle.

Remove any fasteners which hold the relay in place.

Remove any connector position assurance (CPA) devices or secondary locks.

Note: Use care w ...

Heated Oxygen Sensor Replacement - Sensor 1

Heated Oxygen Sensor Replacement - Sensor 1

Callout

Component Name

Warning: In order to avoid being burned, do not service the

exhaust system while it is still hot. Service the system when it is

cool.

Prelimi ...

0.005