Chevrolet Sonic Repair Manual: Turbocharger Installation

Special Tool

EN-49942 Holding Wrench

For equivalent regional tools, refer to Special Tools.

- Clean the sealing surfaces.

- Replace the connect fittings on the turbocharger coolant feed pipe and the turbocharger coolant return pipe. Refer to Turbocharger Disassemble and Turbocharger Assemble.

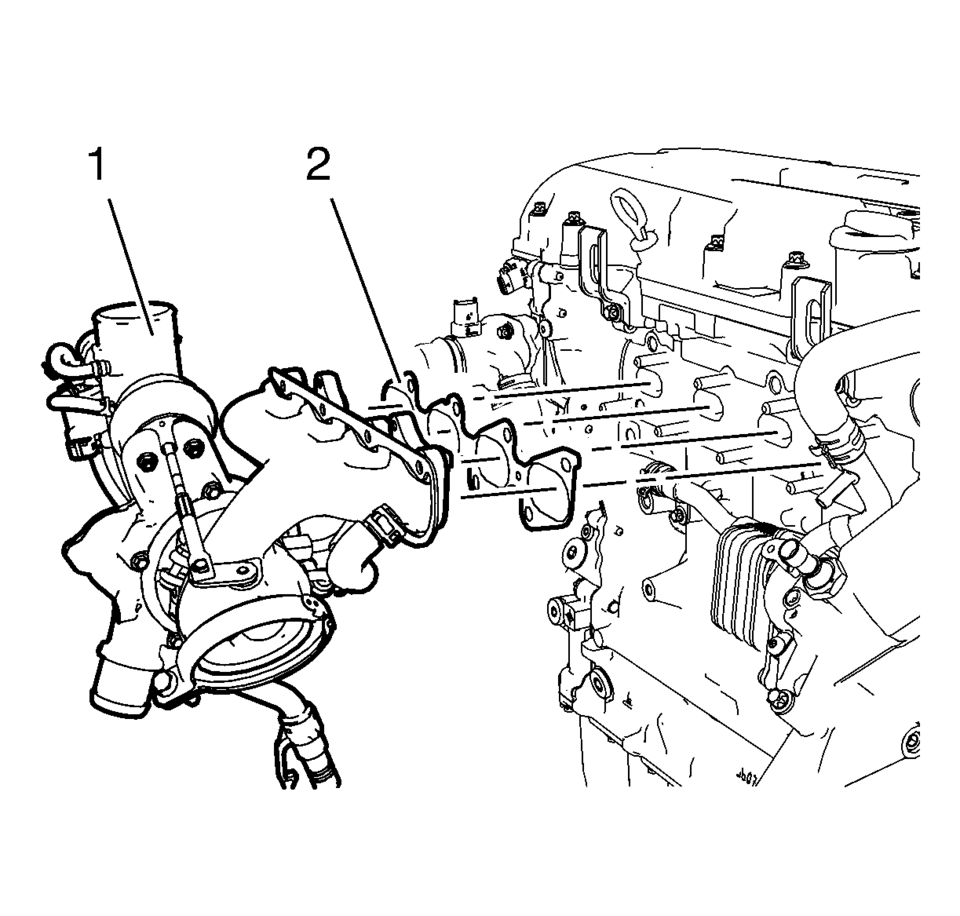

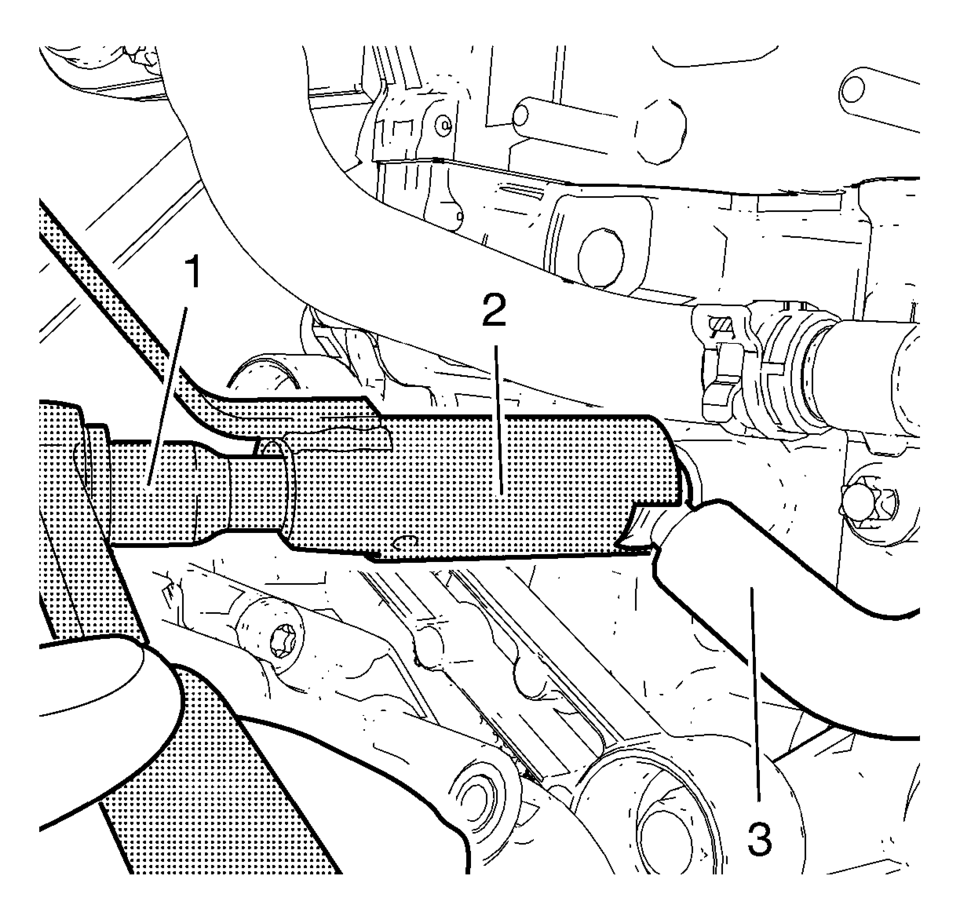

- Install the turbocharger assembly (1) and a NEW turbocharger gasket (2).

- Connect the turbocharger oil return pipe to the engine while installing the turbocharger.

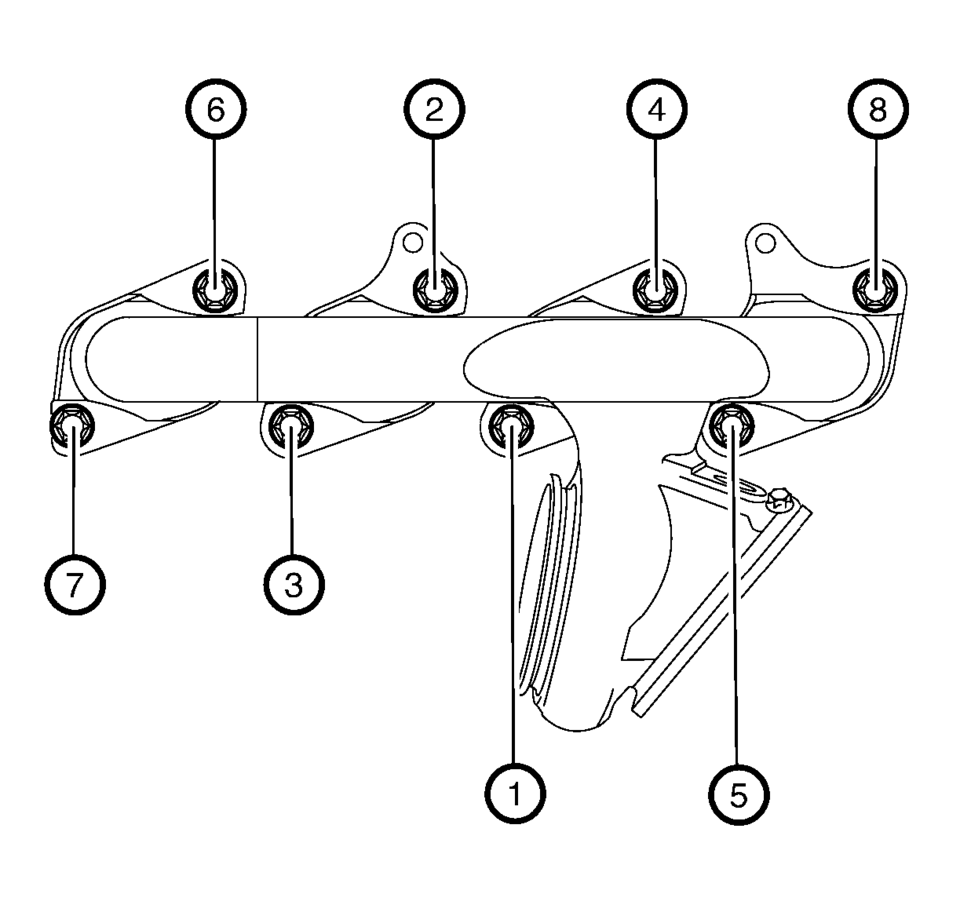

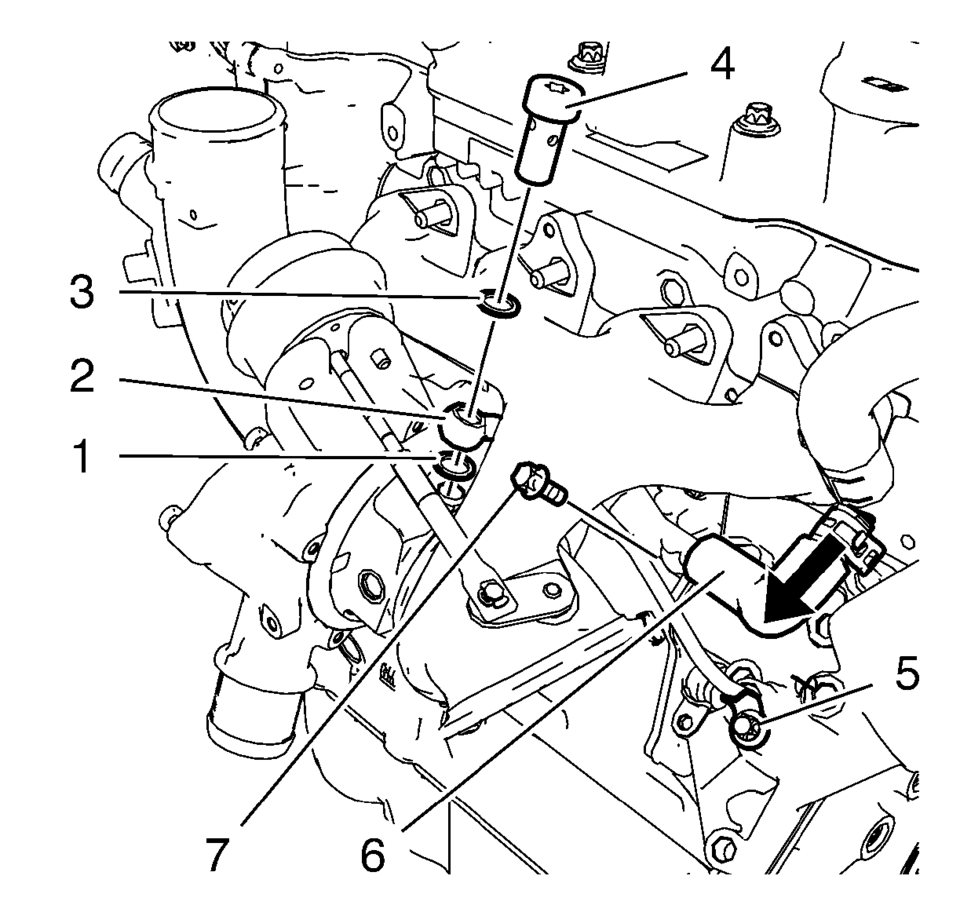

- Install the turbocharger coolant feed pipe hollow screw along with 2 NEW seal rings (1) and (2).

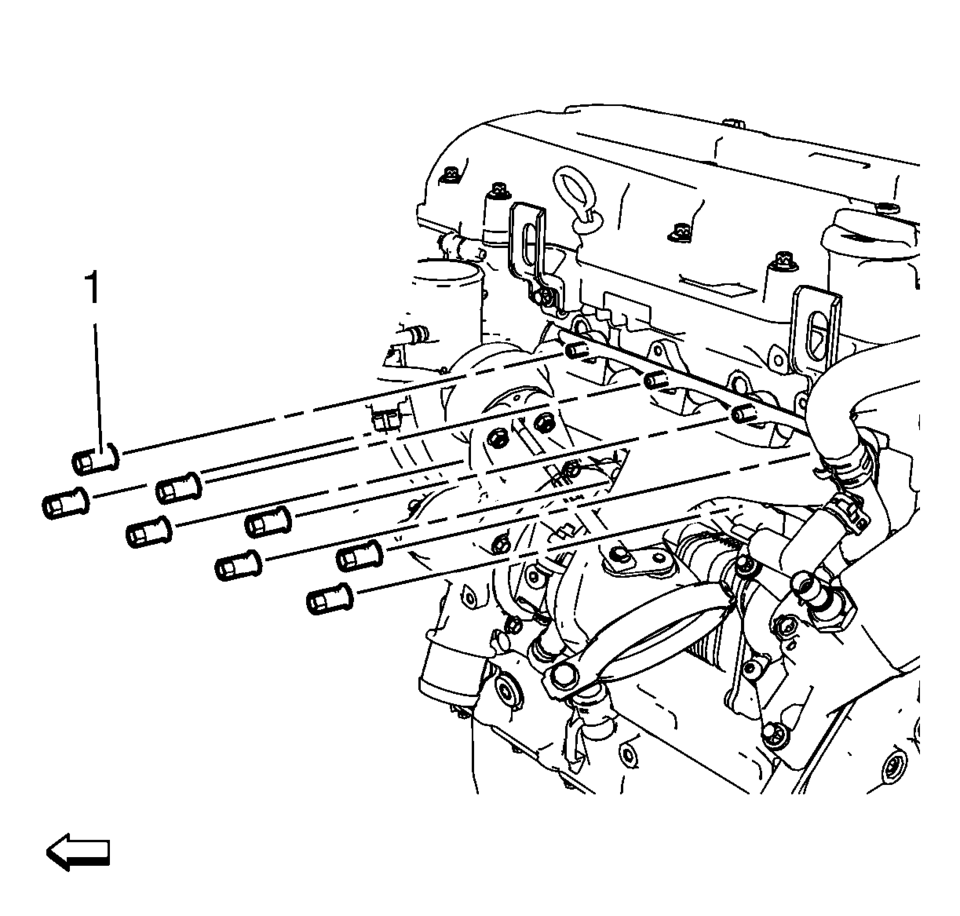

- Install the 8 NEW turbocharger nuts (1).

- Tighten the 8 turbocharger nuts in a sequence as shown to 8 Y (71 lb in)

.

- Repeat the tightening procedure to ensure a proper fastening of the turbocharger nuts.

- Connect the turbocharger coolant return hose (6) to the oil cooler coolant

inlet pipe and install the turbocharger coolant return pipe bolt (7) to the

oil cooler. Tighten the turbocharger coolant return pipe bolt to 8 Y (71 lb in)

.

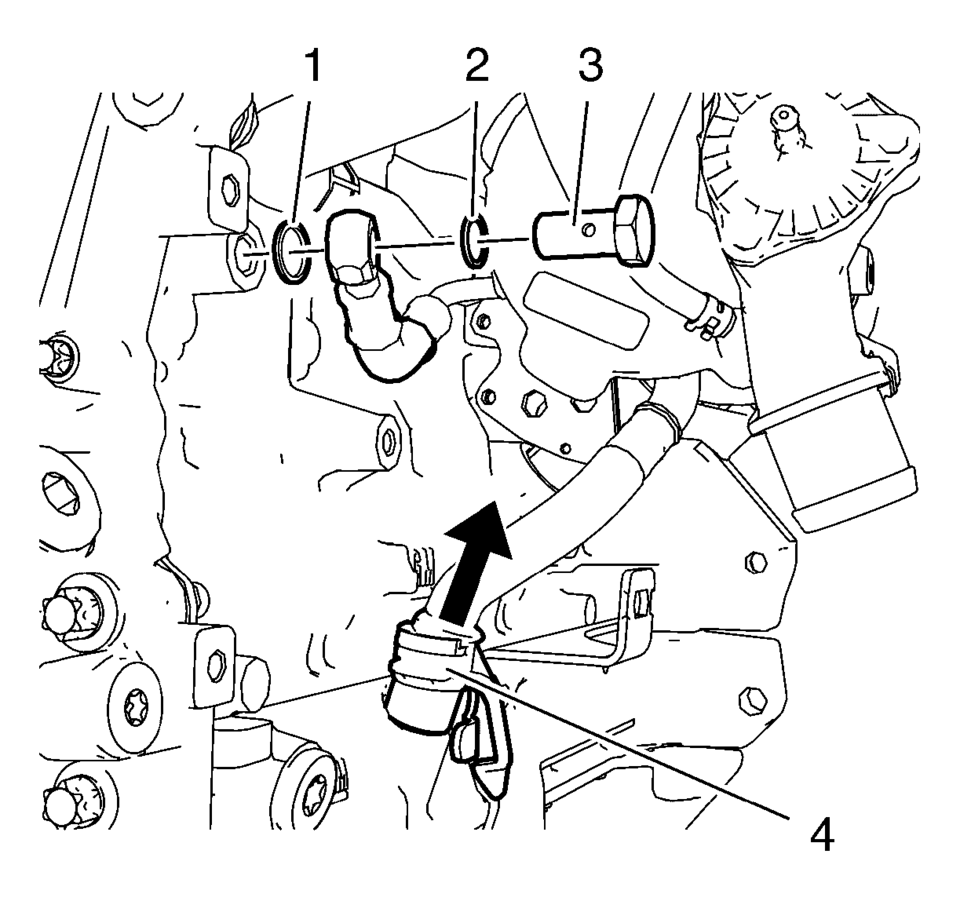

- Install the turbocharger oil feed pipe (2) along with a NEW rubber seal ring.

- Install the turbocharger oil feed pipe hollow screw (4) in compound with 2 NEW seal rings (1) and (3).

- Install the turbocharger oil feed pipe bolt (5) to the oil cooler and tighten

to 10 Y (89 lb in)

.

- Tighten the turbocharger oil feed pipe hollow screw to 30 Y (22 lb ft)

.

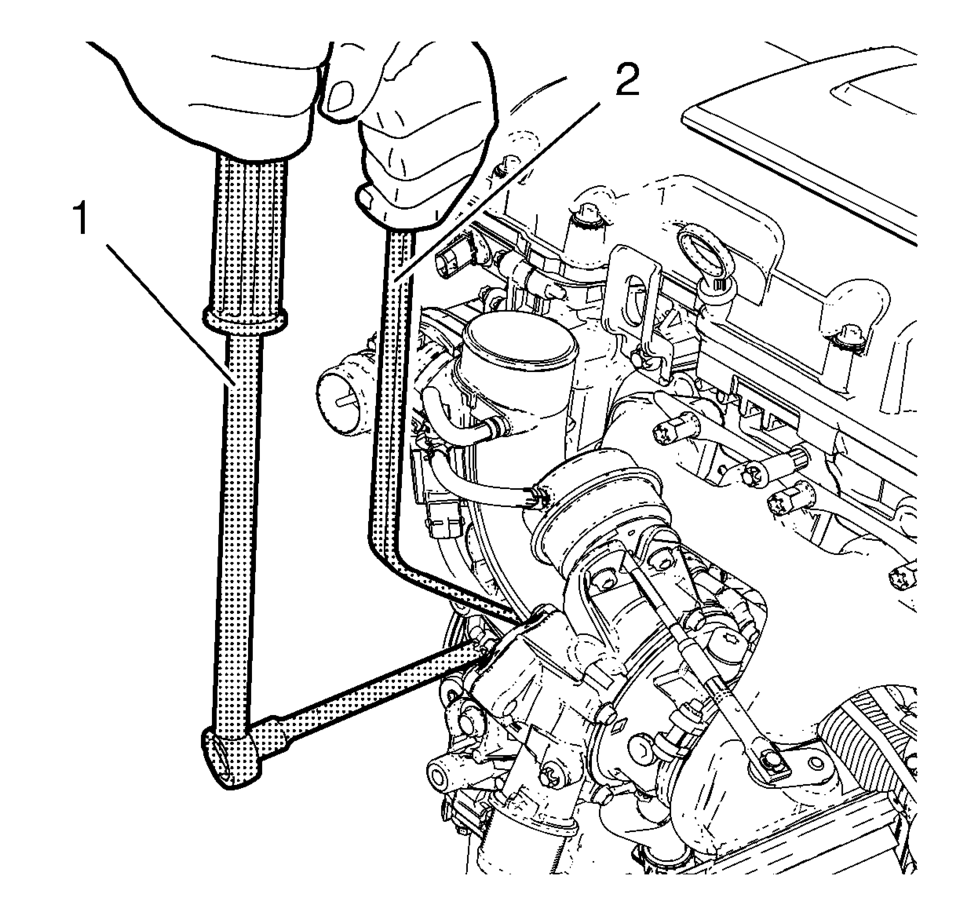

- Install the EN-49942 holding wrench (2) to the turbocharger coolant feed pipe. Guide a ratchet wrench (1) along with an extension through EN-49942 holding wrench to the turbocharger coolant feed pipe hollow screw.

- Tighten the turbocharger coolant feed pipe hollow screw with ratchet wrench

and extension (1) to 30 Y (22 lb ft)

.

Note:

Mind the turbocharger oil return pipe.

Caution:

Refer to Fastener Caution.

Caution:

Refer to Torque-to-Yield Fastener Caution.

Note:

The EN-49942 holding wrench (2) should be installed to turbocharger coolant feed pipe as shown. The holding wrench should be installed to avoid twisting of the turbocharger coolant feed pipe during the fastening procedure.

Note:

EN-49942 holding wrench (2) should be installed to turbocharger coolant feed pipe as shown. The holding wrench should be installed to avoid twist of the turbocharger coolant feed pipe while the fastening procedure.

Turbocharger Disassemble

Turbocharger Disassemble

Special Tool

EN-49940 Remover Quick Connector

For equivalent regional tools, refer to Special Tools.

Remove the 2 turbocharger oil return pipe bolts (2).

Remove the turbo ...

Turbocharger Oil Feed Pipe Replacement

Turbocharger Oil Feed Pipe Replacement

Removal Procedure

Open the hood.

Disconnect battery negative cable. Refer to Battery Negative Cable Disconnection

and Connection.

Remove the exhaust manifold heat shield. Refer ...

Other materials:

If the Off Indicator Is Lit for an Adult-Size Occupant

If a person of adult size is sitting in the front outboard passenger seat, but

the off indicator is lit, it could be because that person is not sitting properly

in the seat. Use the following steps to allow the system to detect that person and

enable the front outboard passenger frontal airb ...

Front Side Door Trim Replacement

Front Side Door Trim Replacement

Callout

Component Name

Preliminary Procedure

Remove the front side door upper front trim panel. Refer to Front Side

Door Upper Front Trim Panel Replacement.

1

Fr ...

Battery Charging

Special Tools

EL 50313 Battery Tester

For equivalent regional tools, refer to Special Tools.

Diagnostic Aids

For best results, use an automatic taper-rate battery charger with a

voltage capability of 16 V.

The charging area should be well ventilated.

Do not charge a bat ...

0.0058