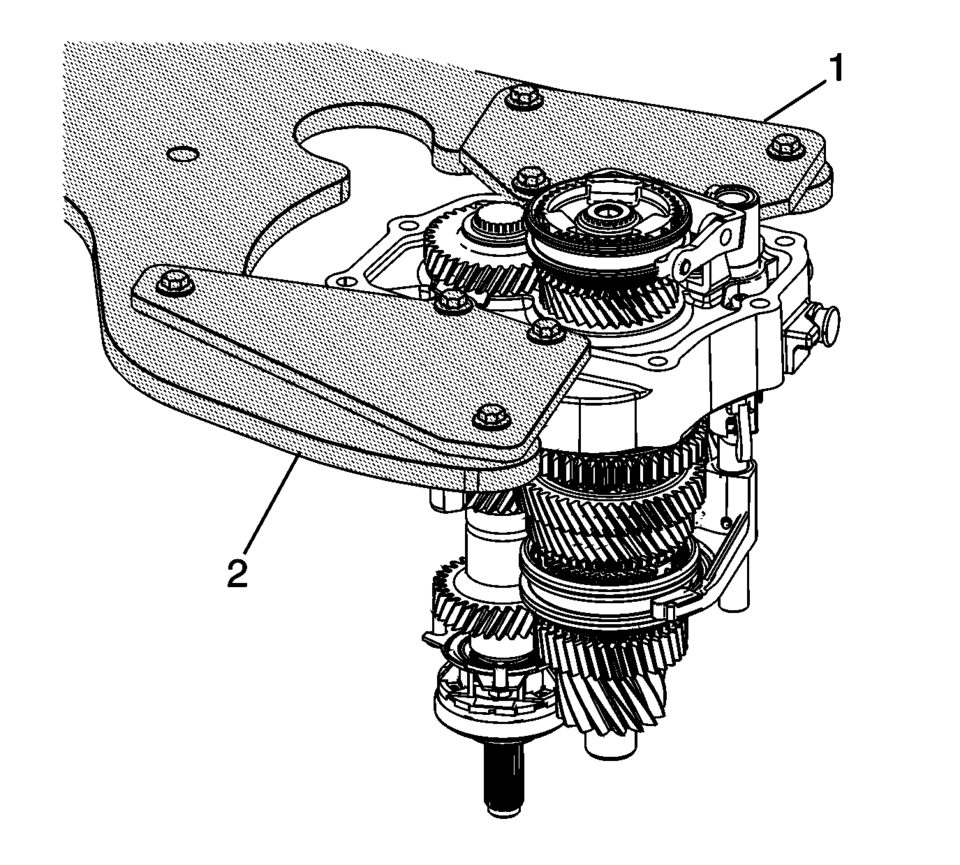

Chevrolet Sonic Repair Manual: Transmission Case Assemble (Gen 2)

Special Tools

- 3-9506289 Universal Adapter

- J-840733 Driver

- R-0007758 Holding Fixture

- R-0007761 Universal Handle

- R-0007770 Holding Fixture Adapter Plates

- T-9804669 Seal Installer

- T-0307000 Extractor and Driver Fixture

For equivalent regional tools, refer to Special Tools.

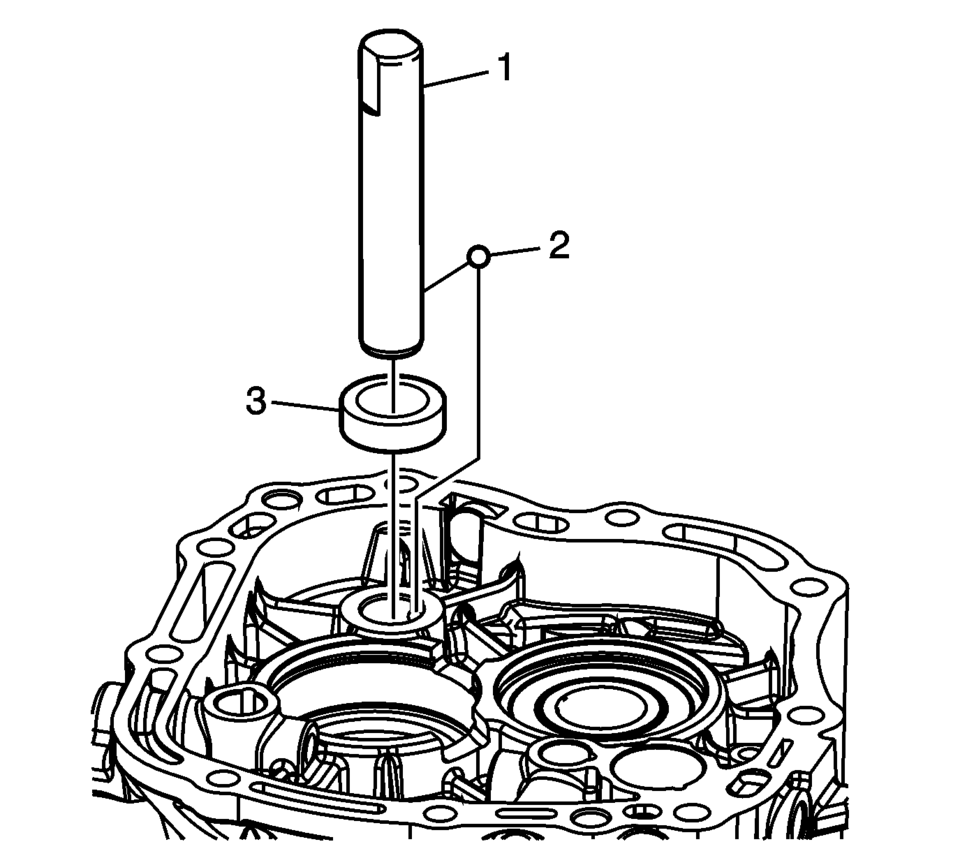

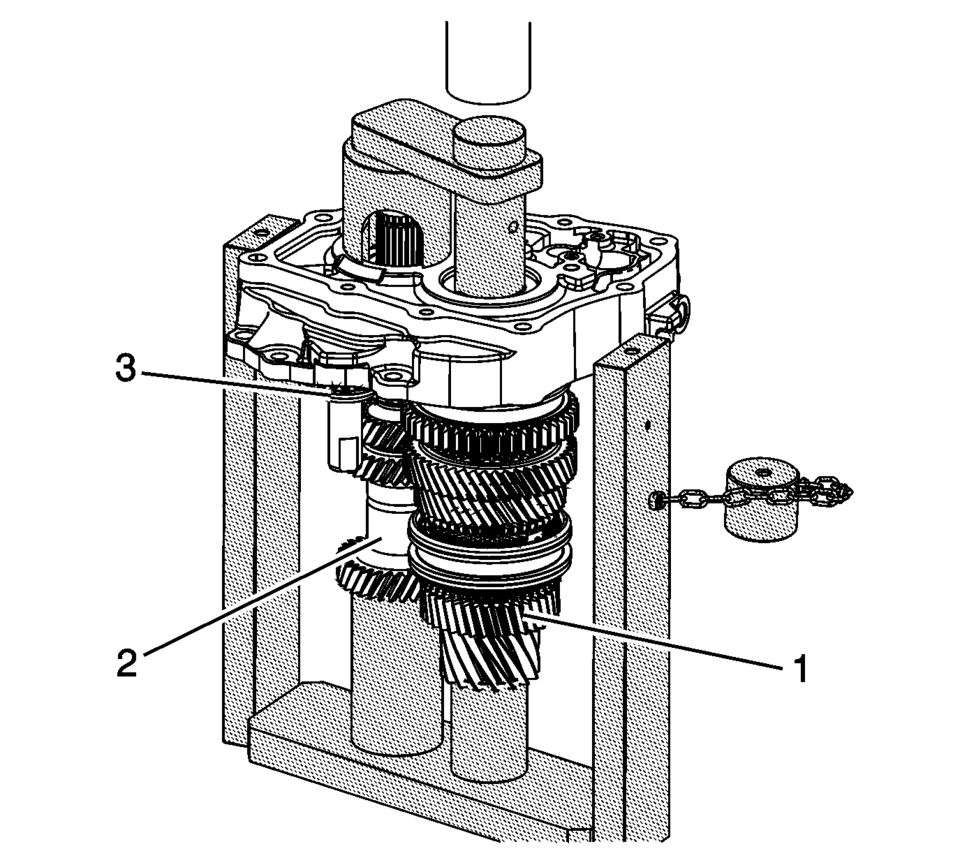

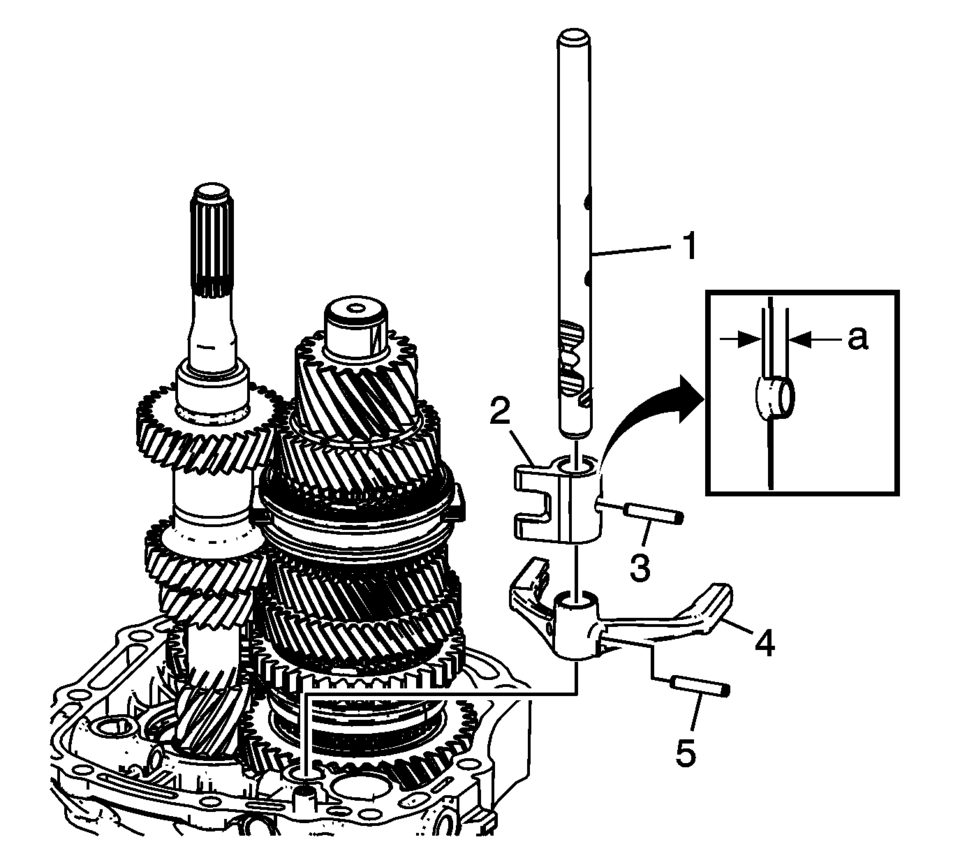

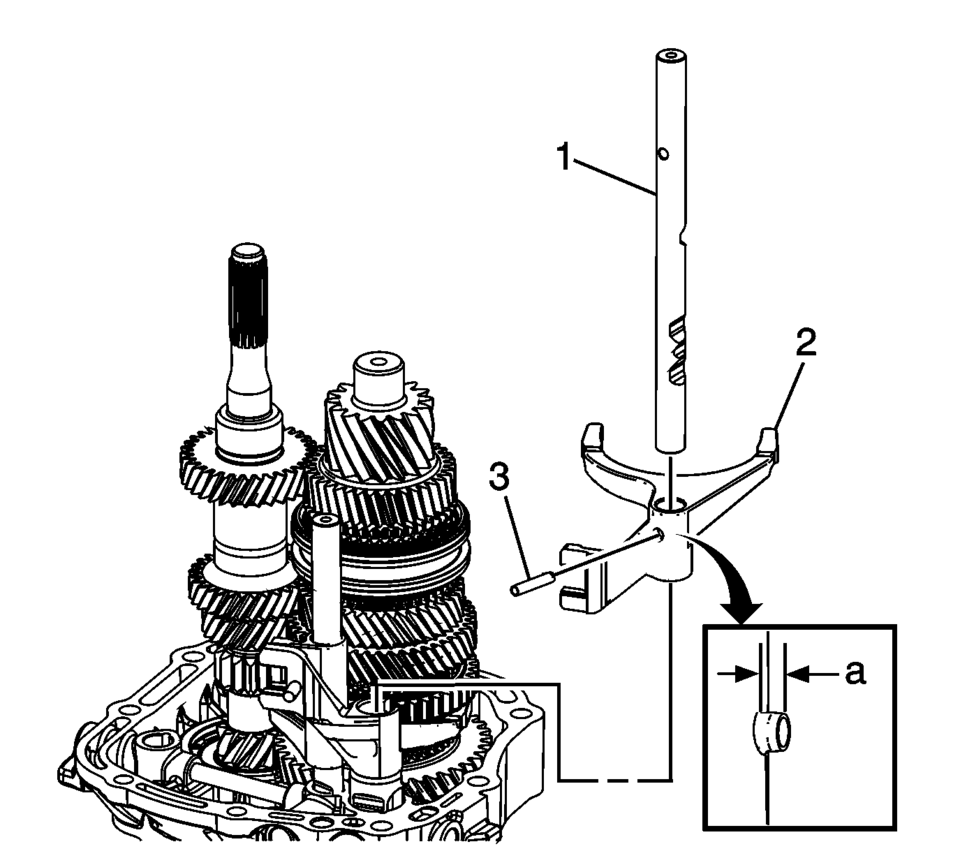

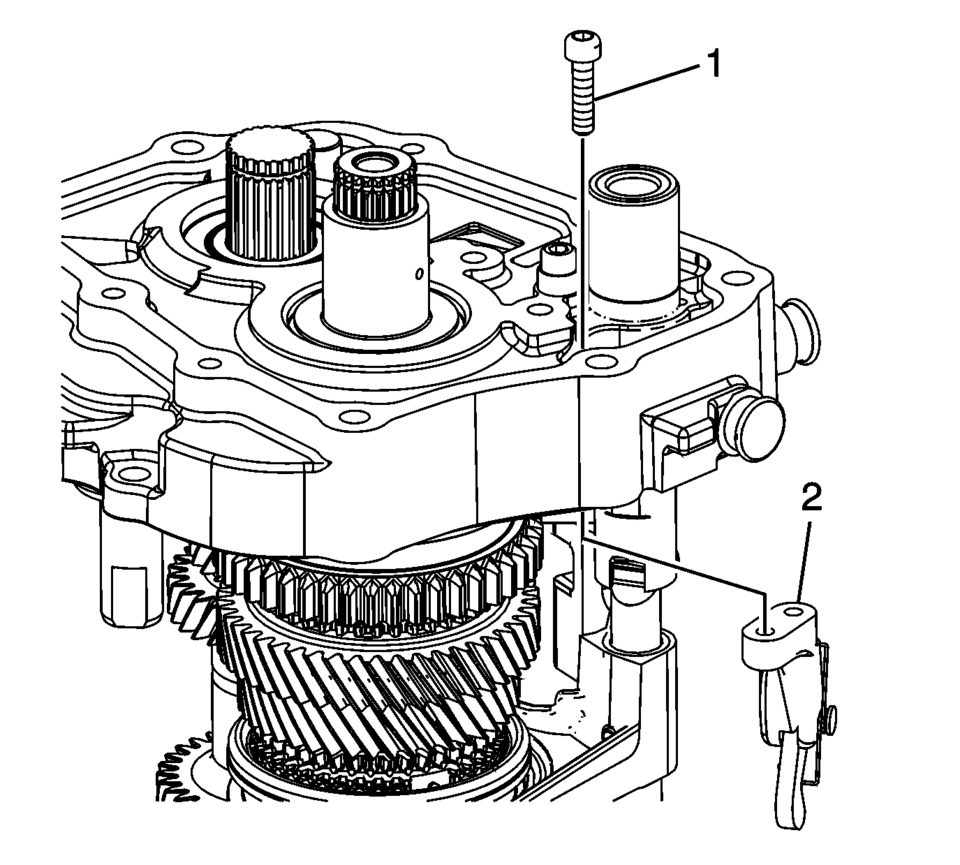

- Install the reverse helical gear washer (3) onto the reverse idler gear shaft.

- Install the reverse idler gear shaft retaining ball (2).

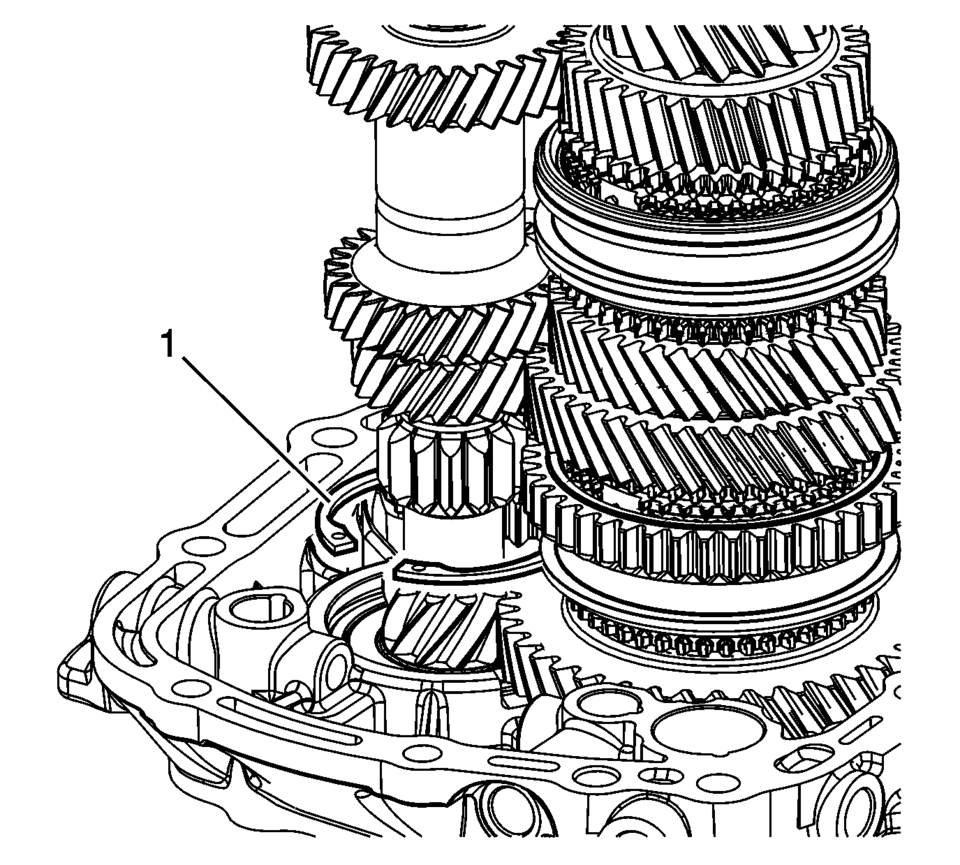

- Install the reverse idler gear shaft (1).

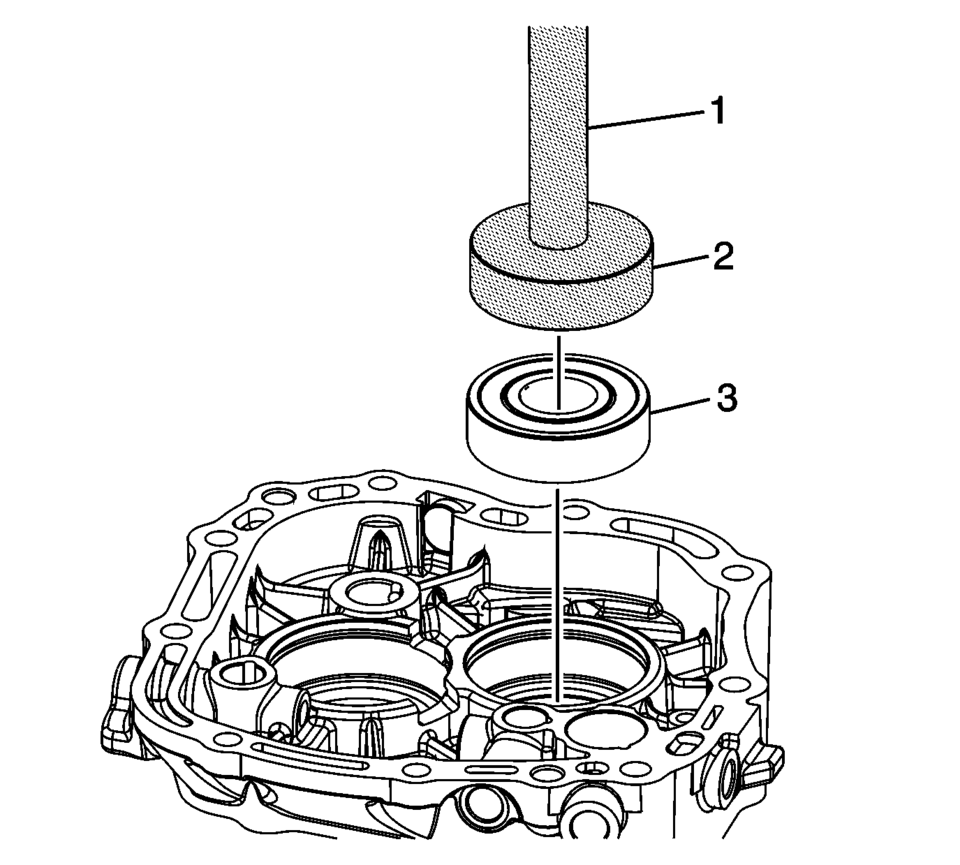

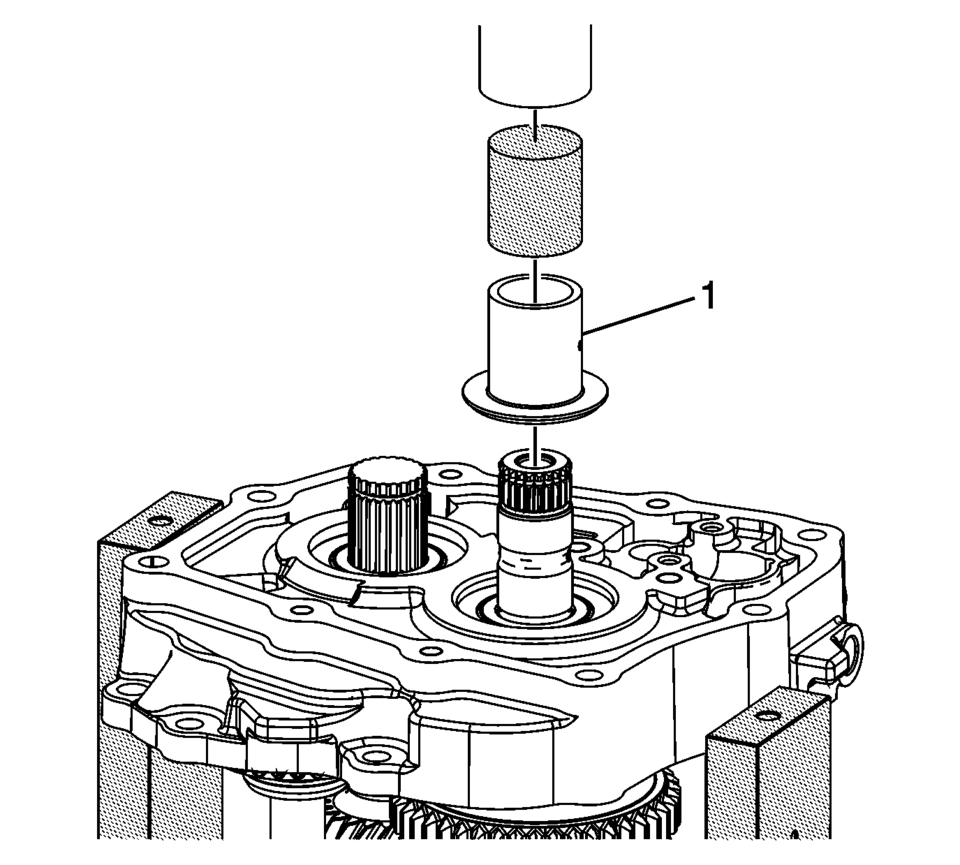

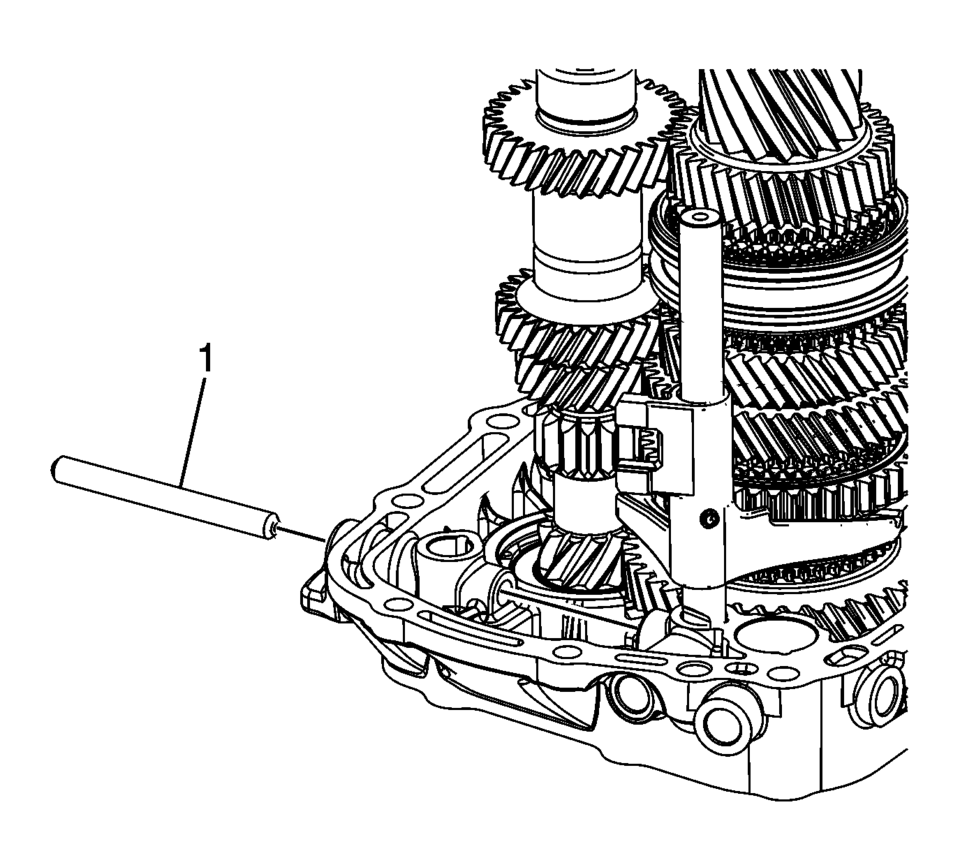

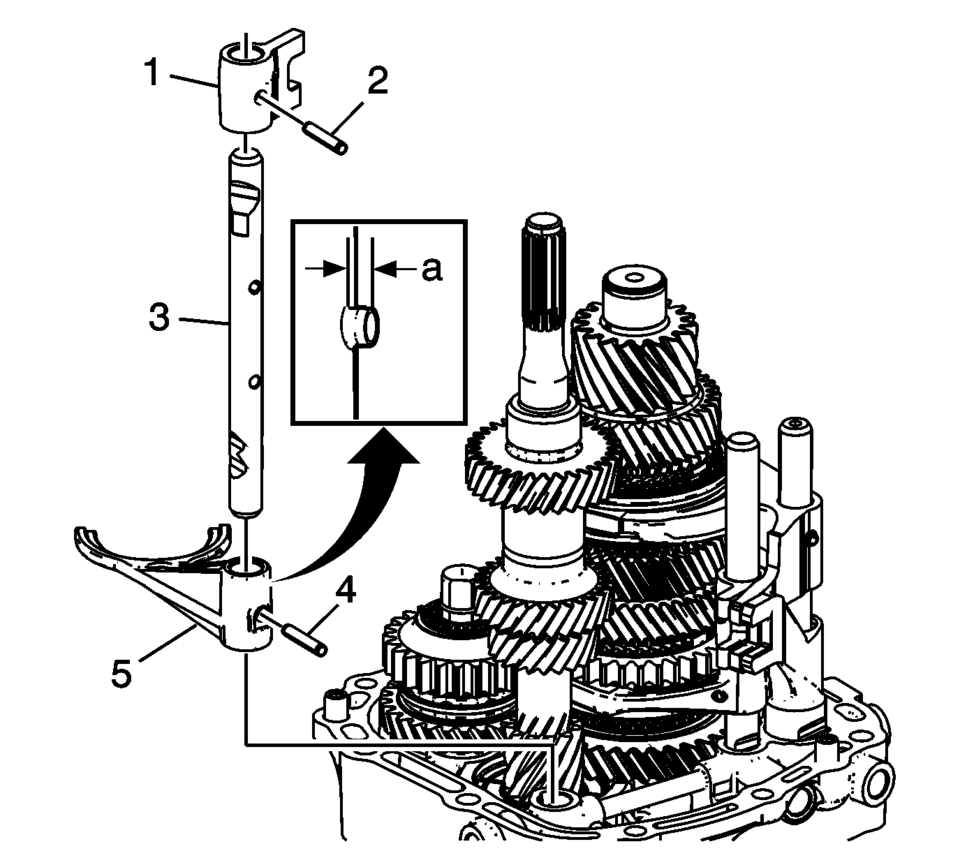

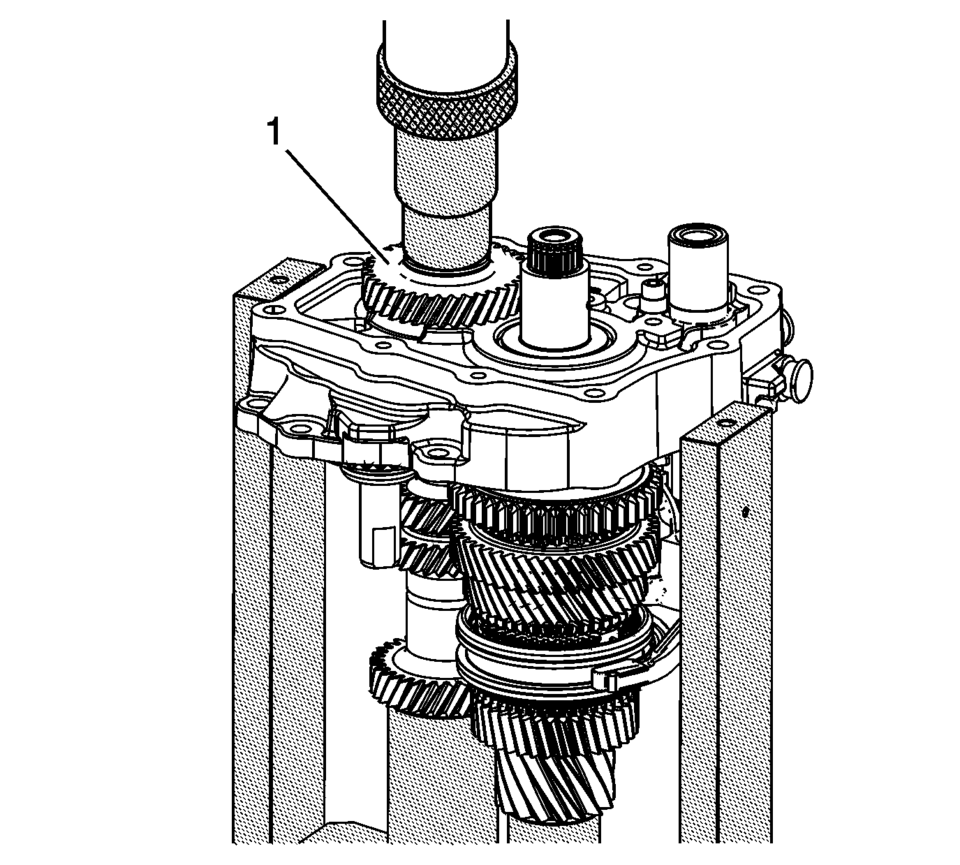

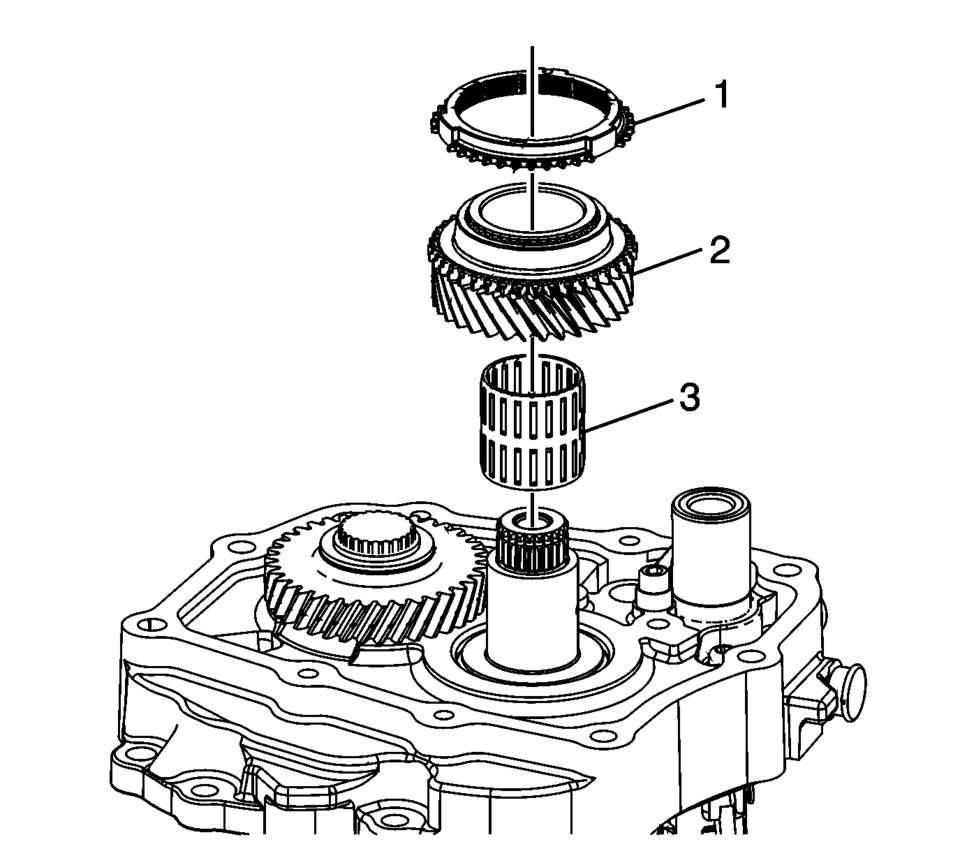

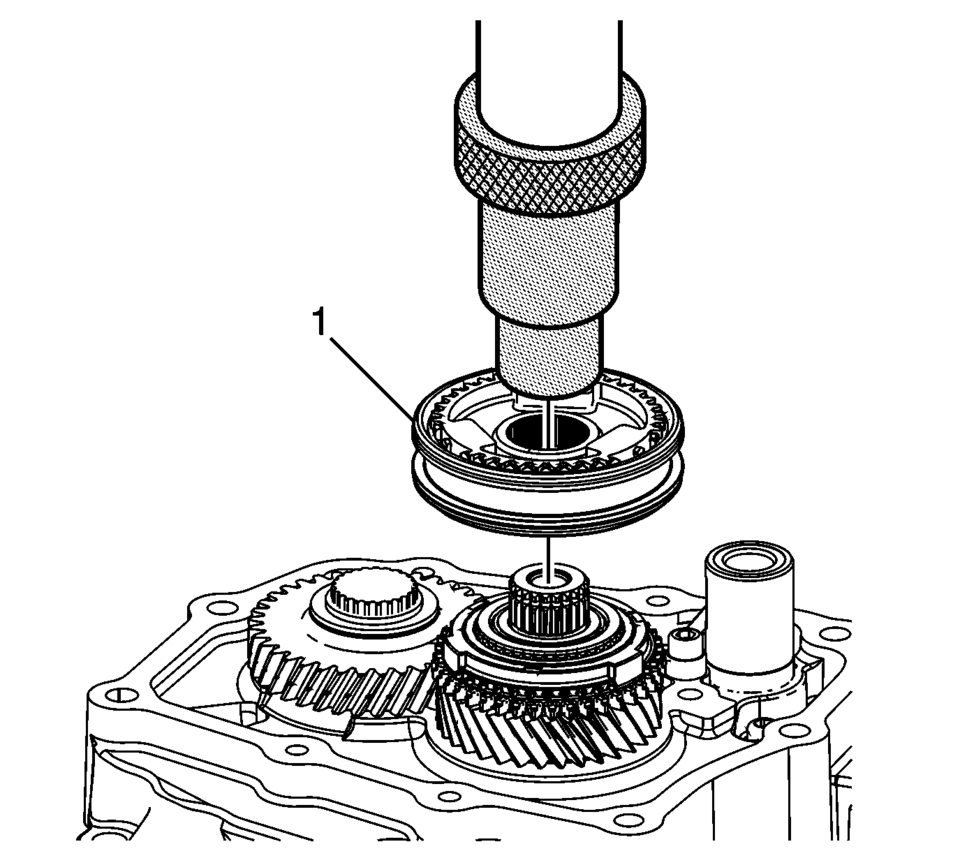

- Using T-9804669 seal installer (2) and R-0007761 handle (1), install the mainshaft bearing (3) into the case.

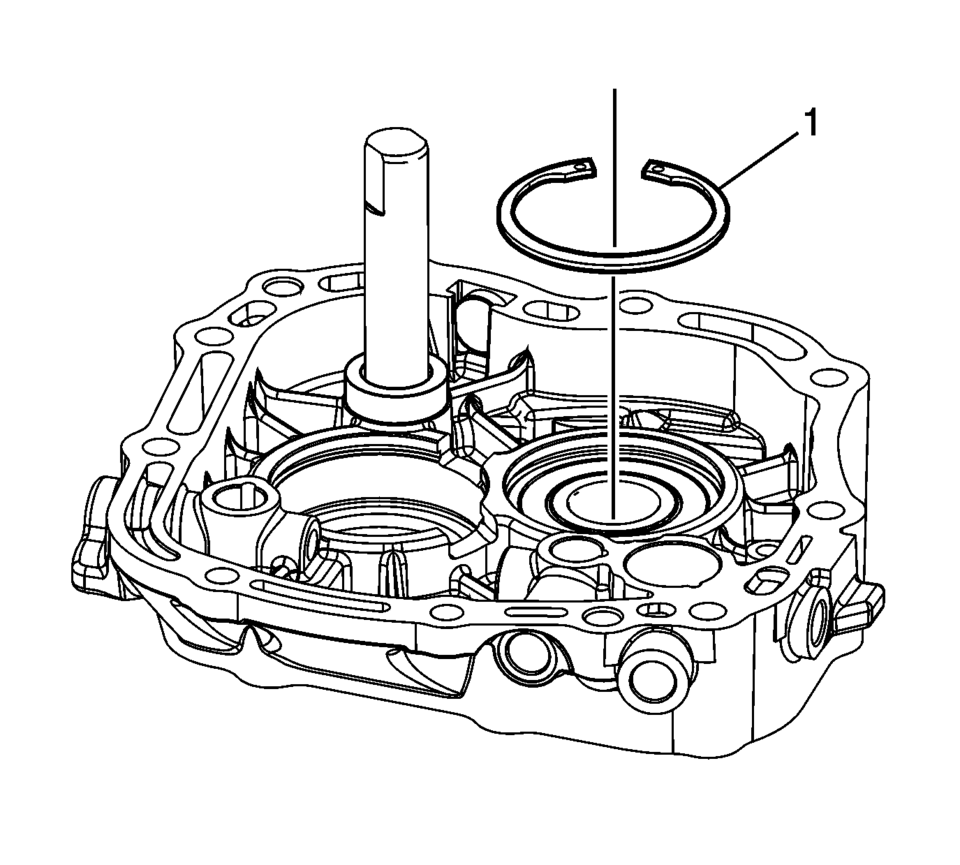

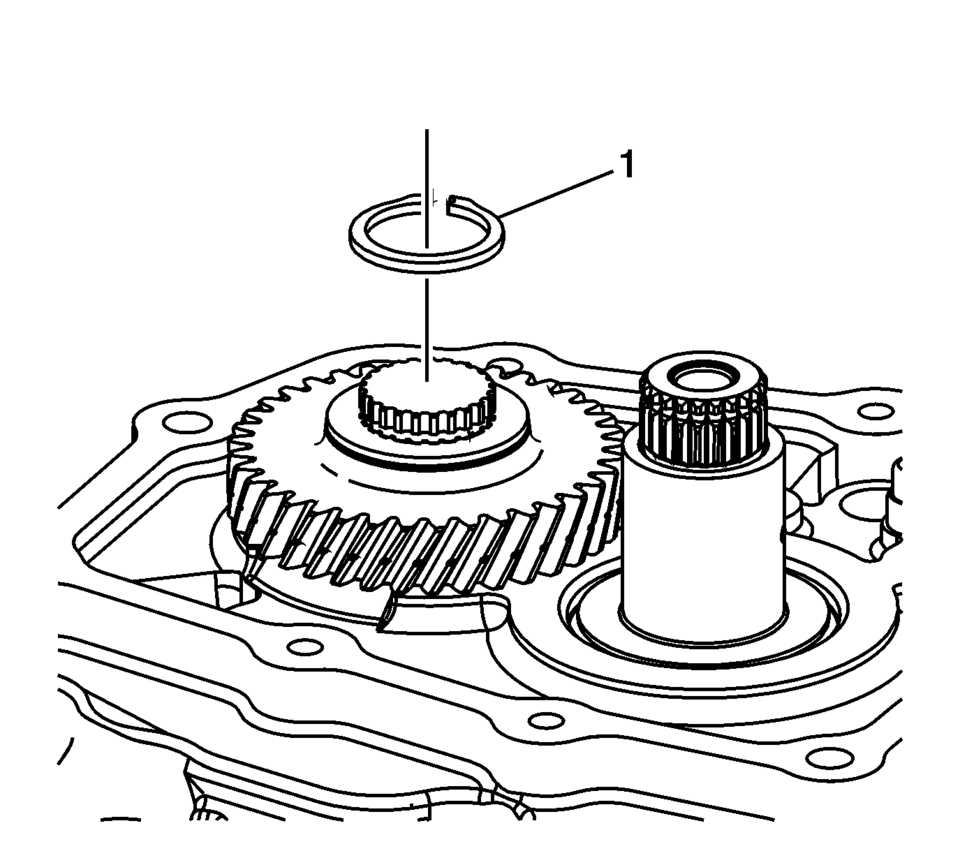

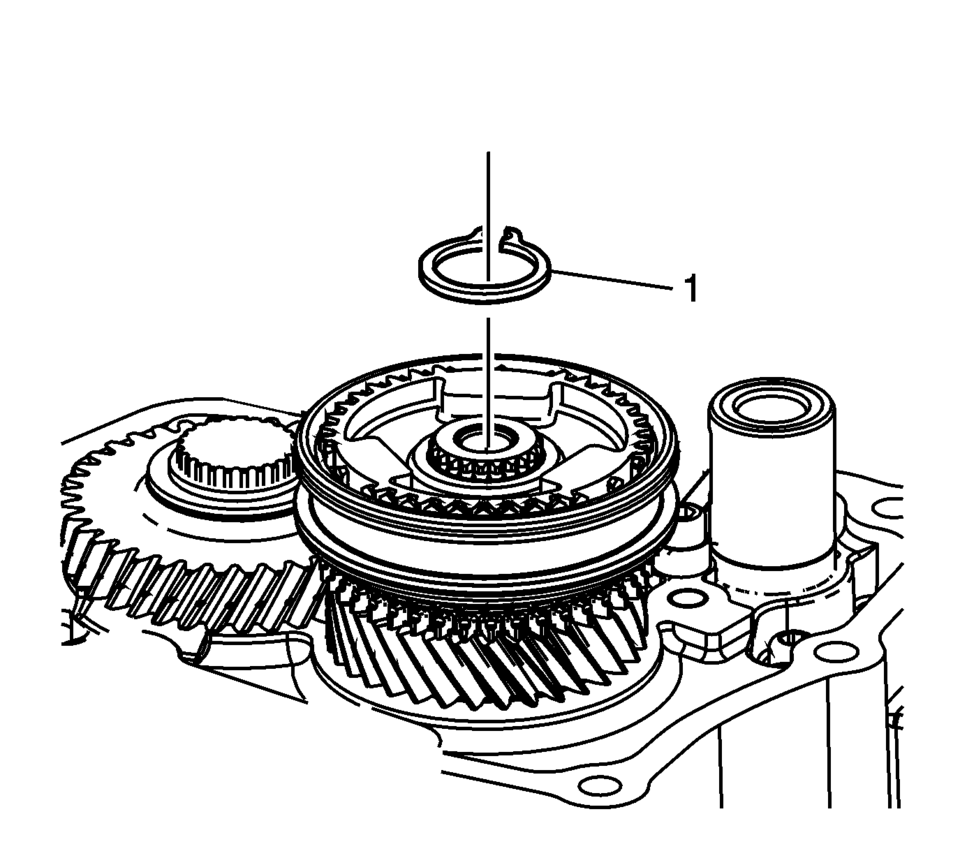

- Install the mainshaft bearing retaining ring (1).

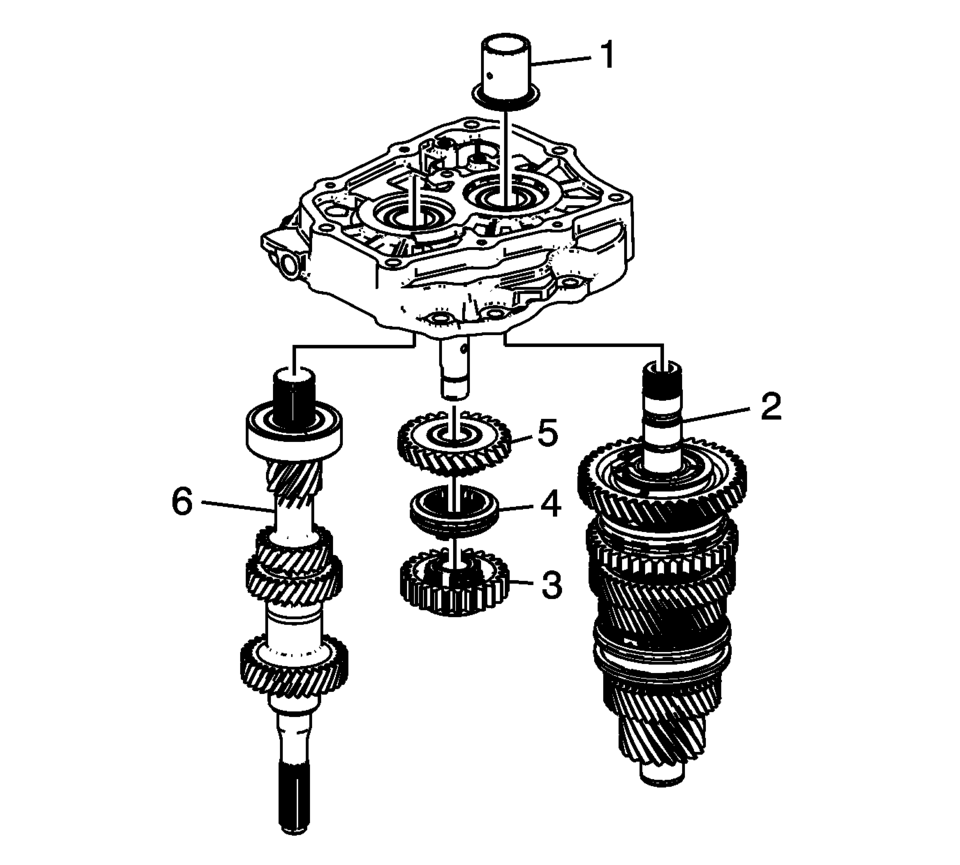

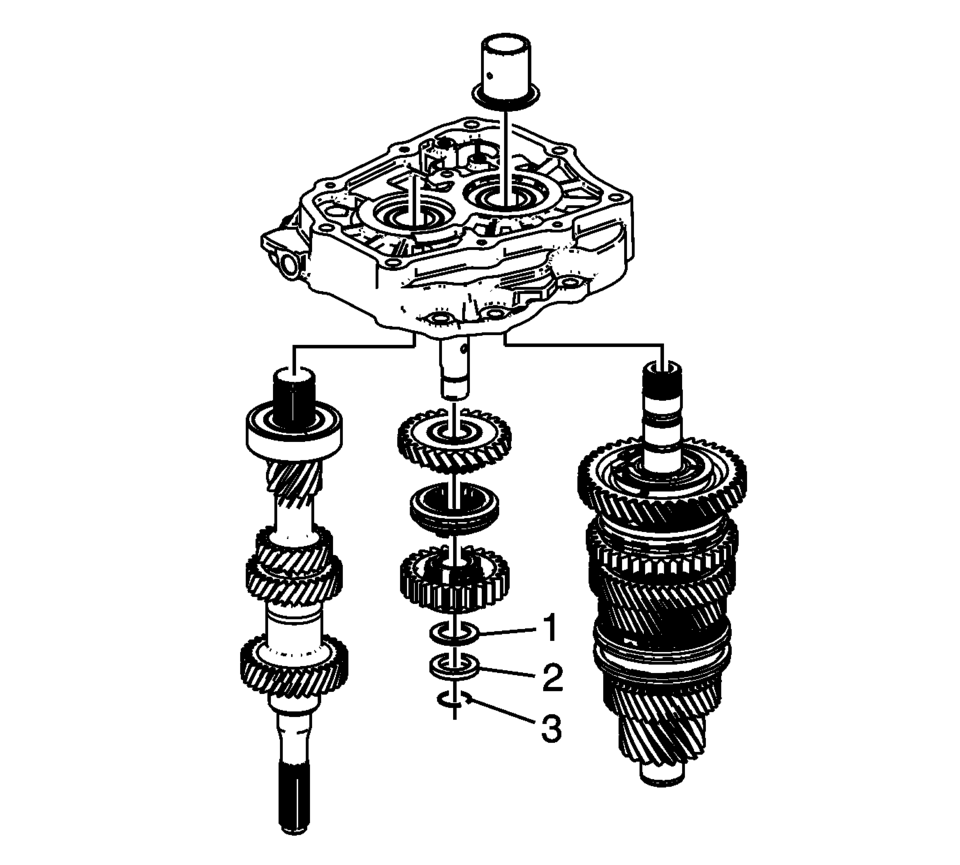

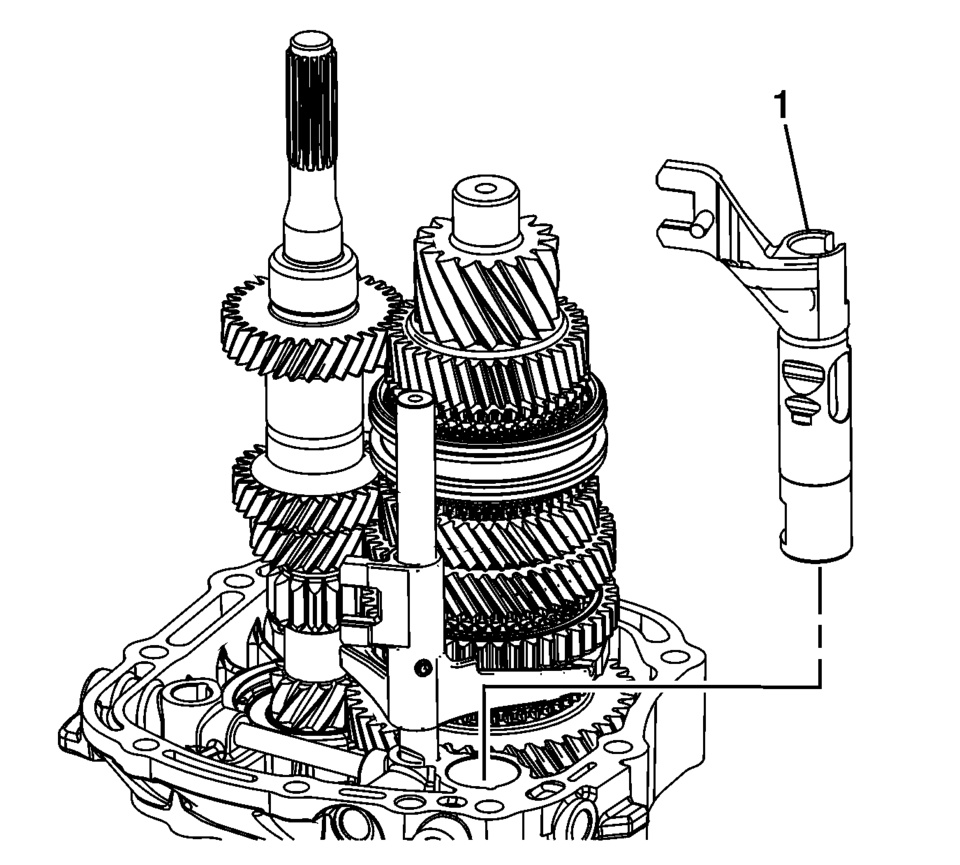

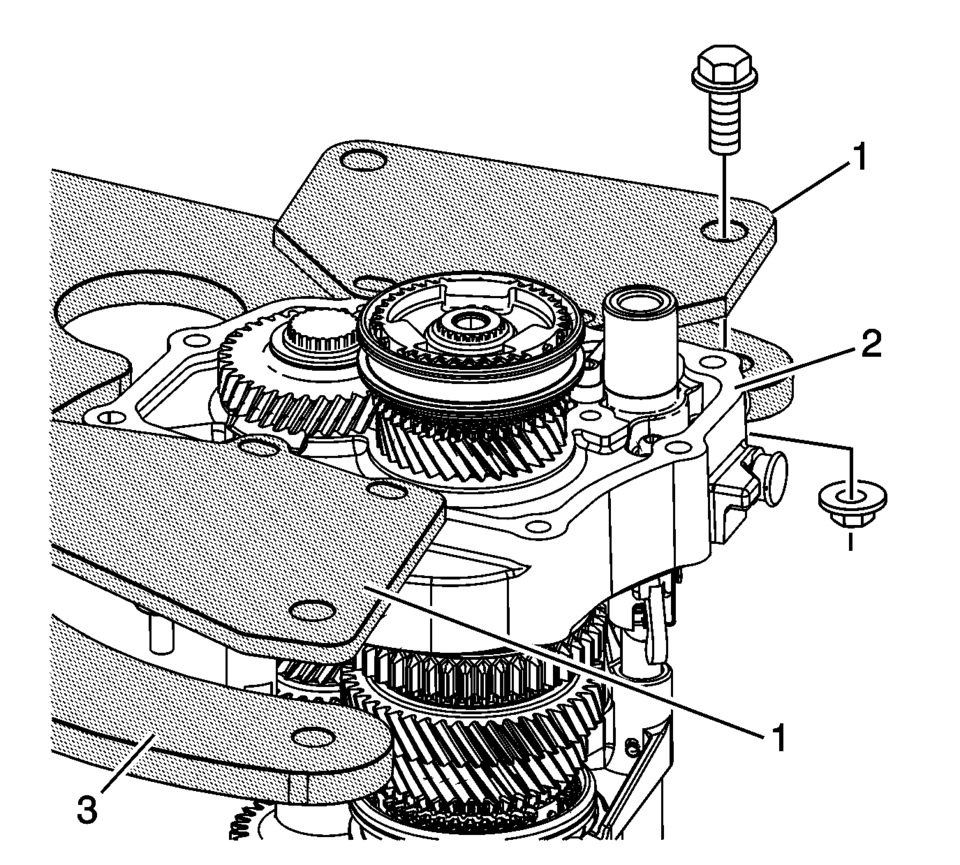

- Install the following components onto the T-0307000 driver fixture with top plate removed.

- Main shaft (2)

- Reverse helical gear (5)

- Reverse synchro assembly (4)

- Reverse spur gear (3)

- Input Shaft (6)

Note:

While pressing, pay attention to the input shaft bearing retaining ring, because it can be pressed into the first gear.

Note:

The reverse gear shaft snap ring (3) MUST be installed even if not originally equipped to prevent shifting issues caused by incorrect assembly or parts not in position.

.

.

.

.

.

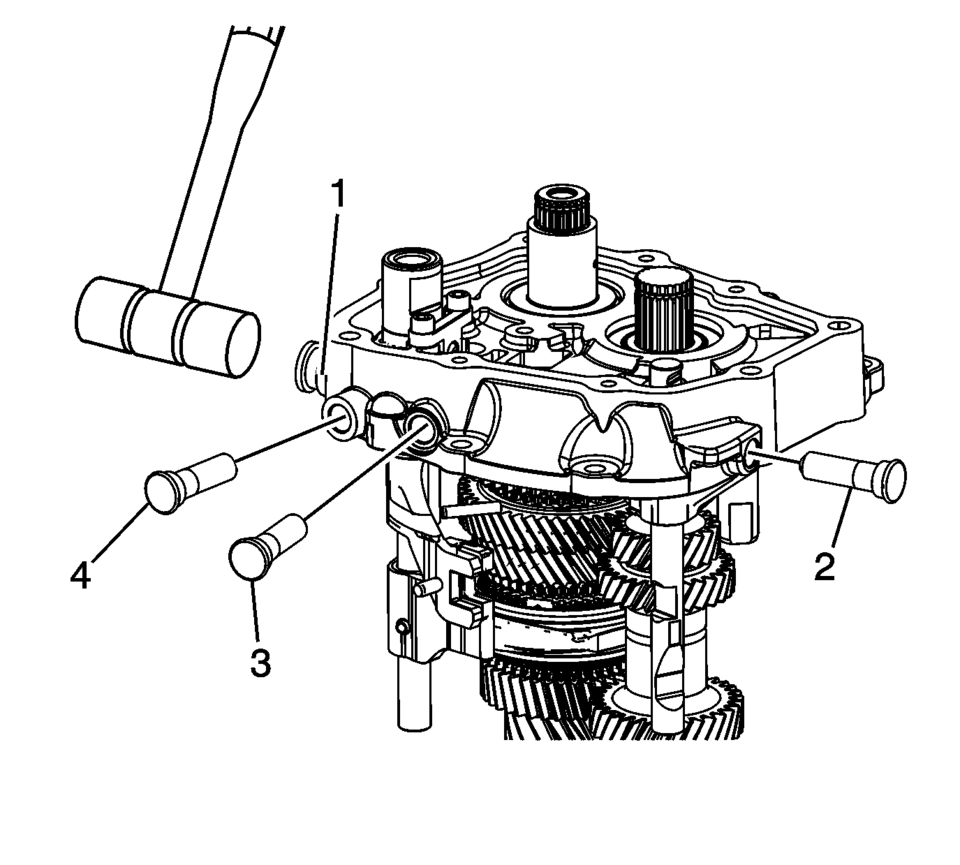

Note:

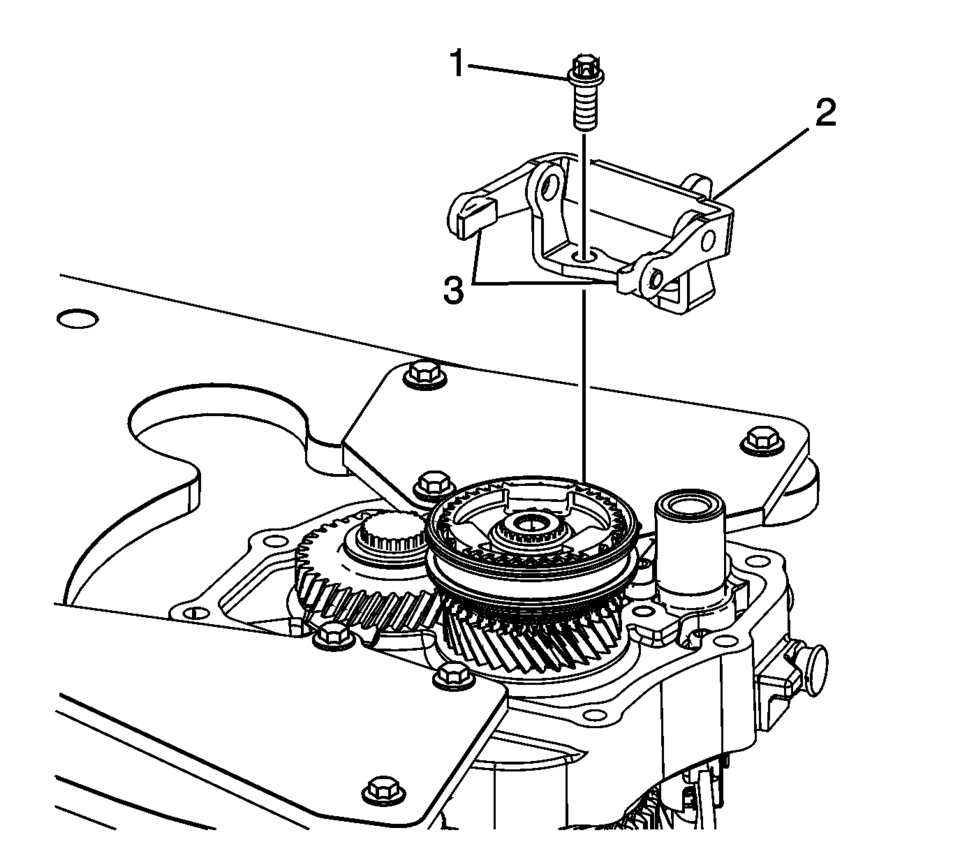

Engage the shift shafts into 2nd gear, 5th gear, and 3rd gear as indicated with arrows to install the interlock pin connector.

.

Note:

Move shift forks into neutral position.

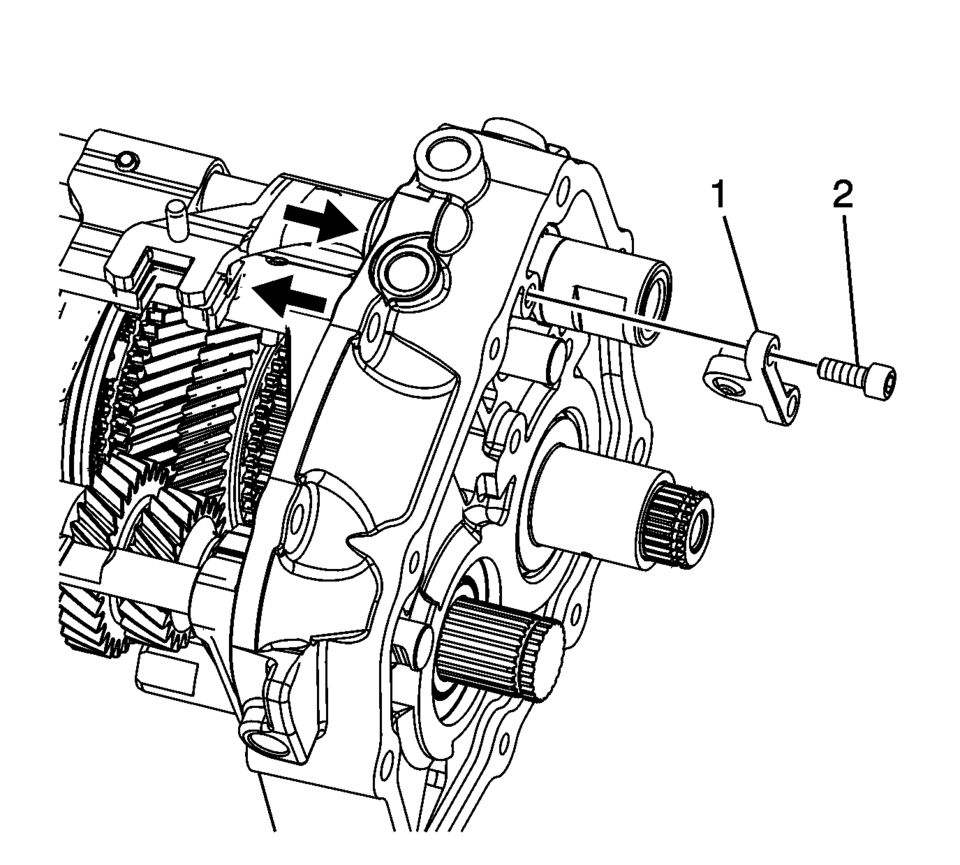

Caution:

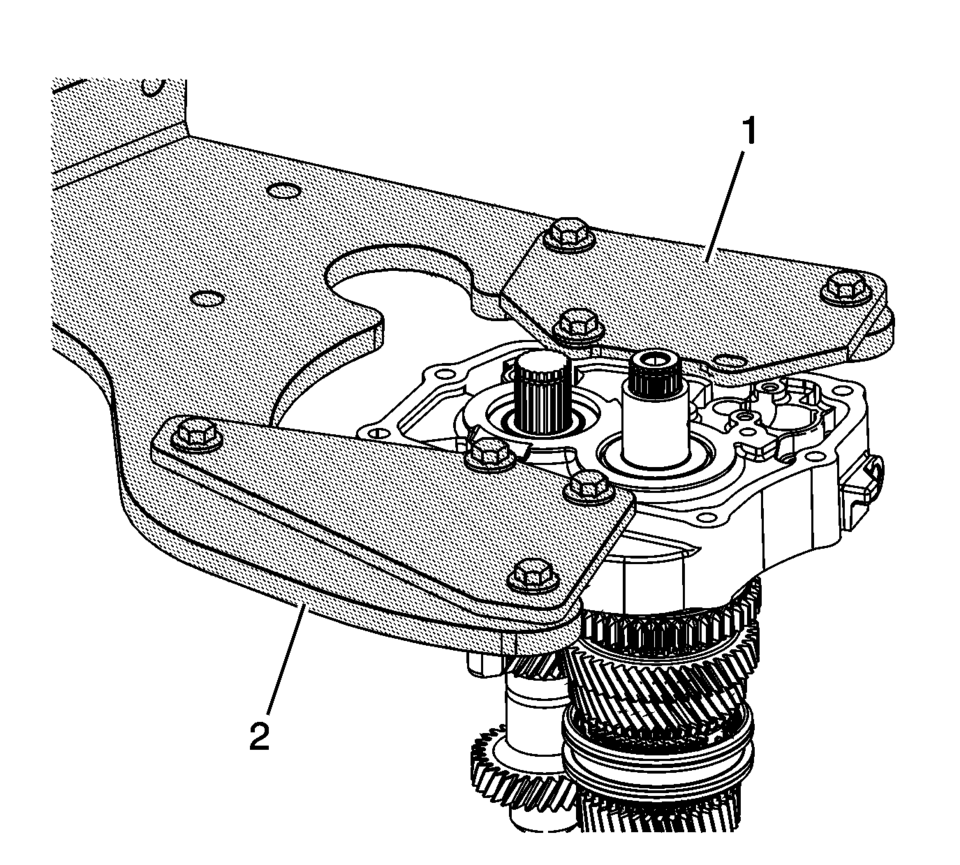

Refer to Fastener Caution.

.

.

Transmission Case Assemble (Gen 1)

Transmission Case Assemble (Gen 1)

Special Tools

3-9506289 Universal Adapter

J-840733 Driver

R-0007758 Holding Fixture

R-0007761 Universal Handle

R-0007770 Holding Fixture Adapter Plates

T-9804669 Seal Installer

T-0 ...

Transmission Case Disassemble (Gen 1)

Transmission Case Disassemble (Gen 1)

Special Tools

3-9506289 Universal Adapter

J-810700 Mainshaft Bearing Remover

J-810704 Center Bar Puller

M-680770 Universal Sliding Mallet

R-0007758 Holding Fixture

R-0007770 Holding F ...

Other materials:

Rear Side Door Window Outer Sealing Strip Replacement (Hatchback)

Rear Side Door Window Outer Sealing Strip Replacement

Callout

Component Name

1

Rear Side Door Window Outer Sealing Strip Screw

Caution: Refer to Fastener Caution.

Tighten

2?€‰Y (18?€‰lb?€‰i ...

Instrument Panel Accessory Bezel Package Installation

Installation Instructions Part Number

95205543

Kit Contents

Qty

Description

1

Molding Assembly - I/P Center Upper

1

Molding Assembly - I/P Center

1

Bezel Assembly - ...

Transmission Component and System Description

The mechanical components of the 6T30/40/45/50 are as follows:

A torque converter with an electronically controlled capacity clutch (ECCC)

Gear-type fluid pump assembly

1??? and low and reverse clutch housing assembly

4?? and 3? reverse clutch housing assembly

2? clutch assem ...

0.0276